Joint module of collaborative robot and collaborative robot

A technology of robot joints and joint modules, applied in the field of robots, can solve the problems of monotonous pick-up range, imperfect development, labor-intensive, etc., and achieve the effect of large pick-up range and the requirements of pick-up height and range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

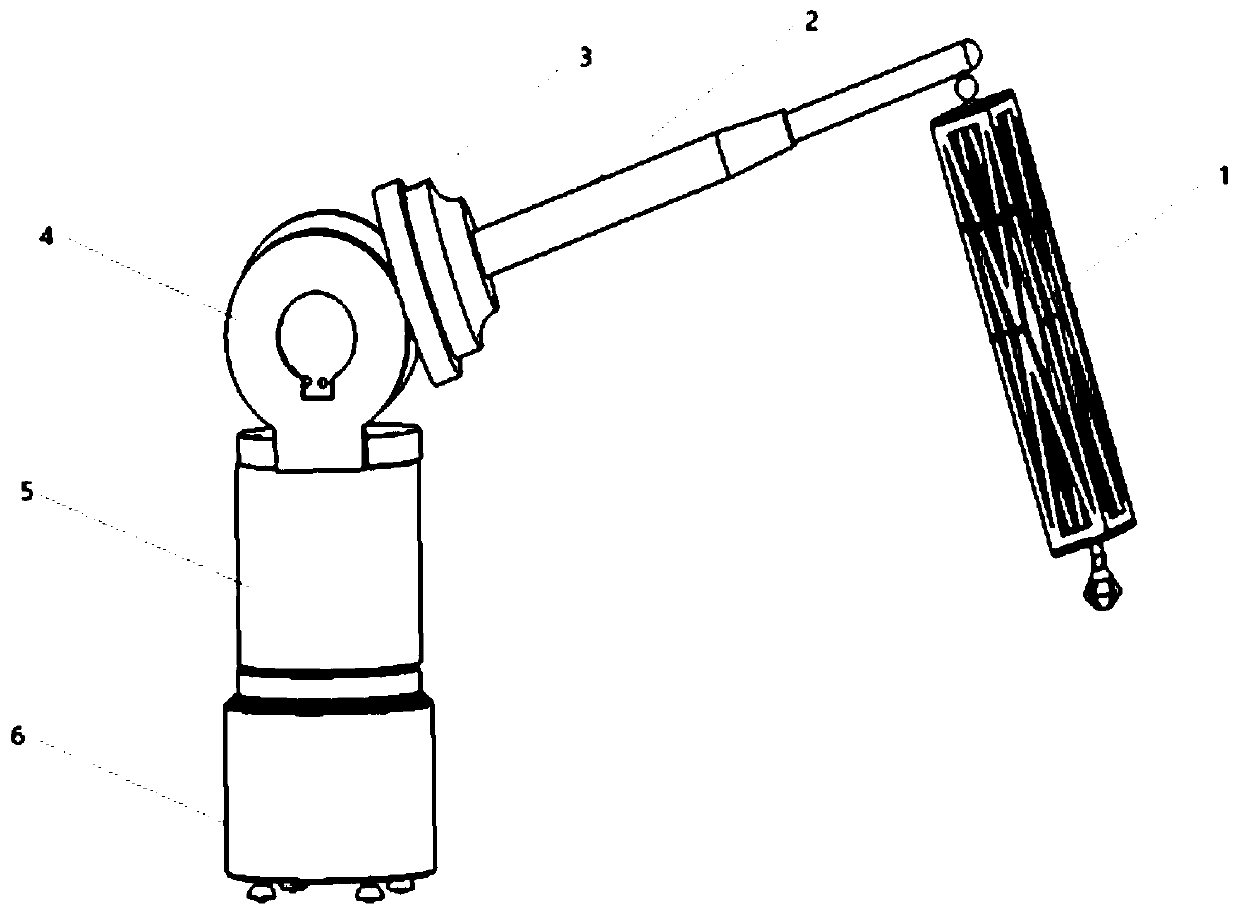

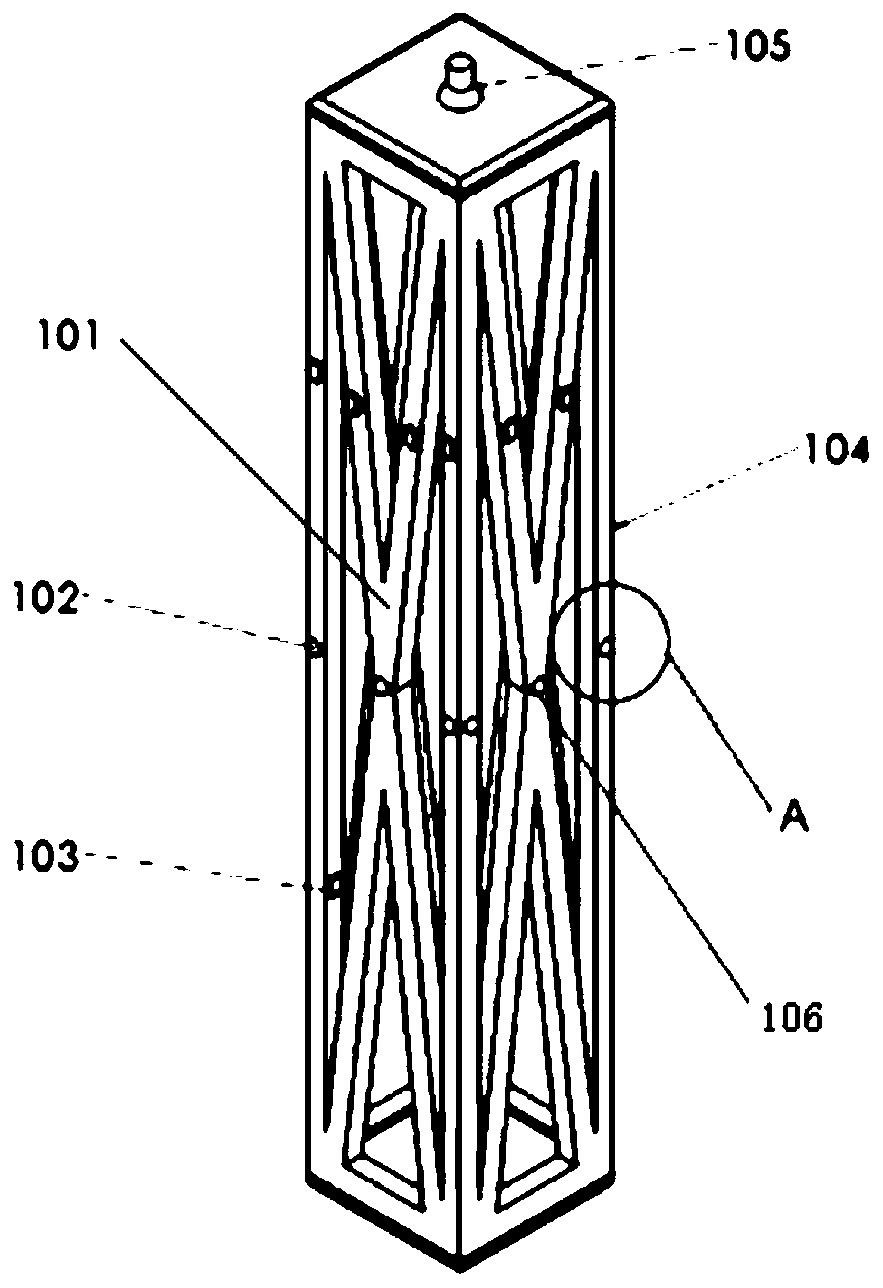

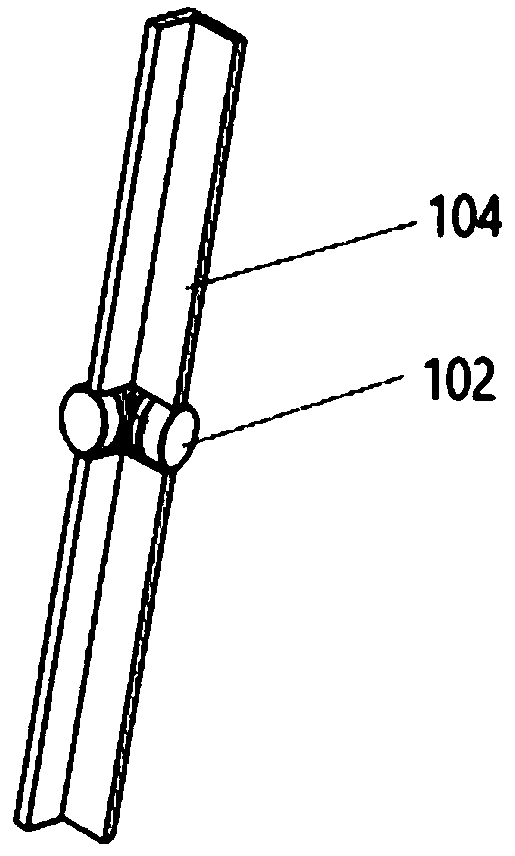

[0040] Attached below Figure 1-Figure 10 The present invention is described in detail, specifically, the structure is as follows:

[0041] This embodiment provides a collaborative robot joint module, including a mechanical arm 1, a telescopic joint module 2, a first rotation module 3, a right-angle joint module 4, a second rotation module 5 and a mobile support 6, the mechanical arm 1 is installed on one end of the telescopic joint module 2, and the other end of the telescopic joint module 2 is connected to the first rotation module 3; the first rotation module 3 is installed above the second rotation module 5 through the right-angle joint module 4, and the second rotation module The mobile support 6 is fixed at the bottom of the module 5; multi-directional rotation is realized through the first rotating module 3 and the second rotating module 5, and the purpose of picking up multi-directional garbage is achieved by cooperating with the deformable mechanical arm 1.

[0042] ...

Embodiment 2

[0053] This embodiment provides a collaborative robot, including the collaborative robot joint module described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com