Combined type floating roof tank sealing device

A technology of sealing device and floating roof tank, which is applied in the direction of packaging, transportation and packaging, containers, etc., to achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

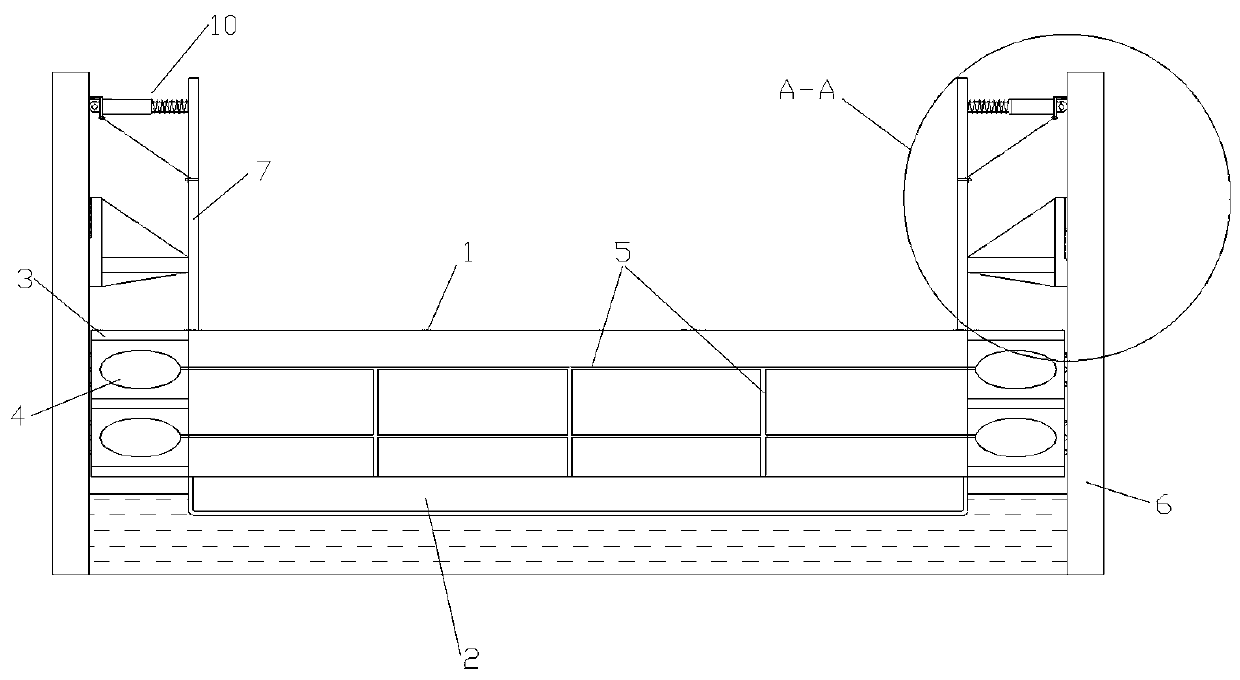

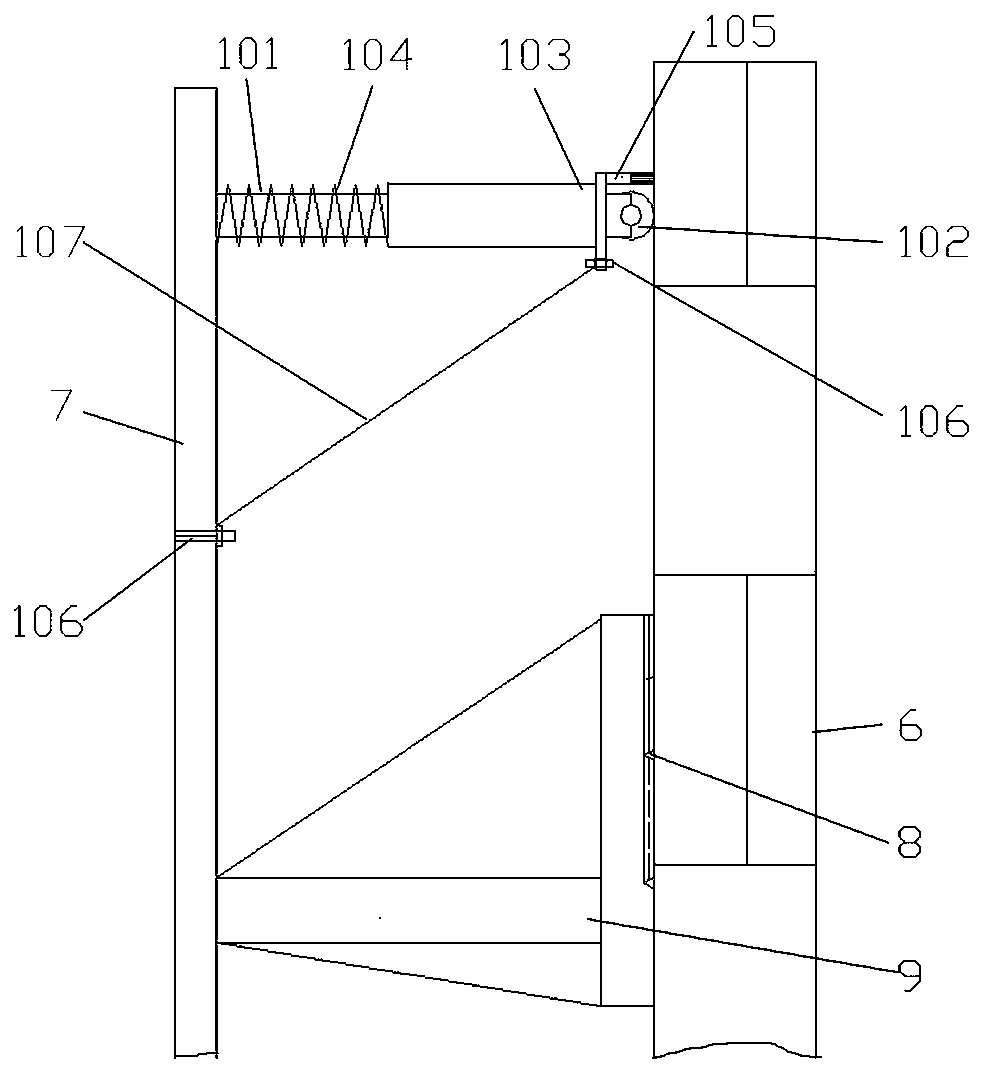

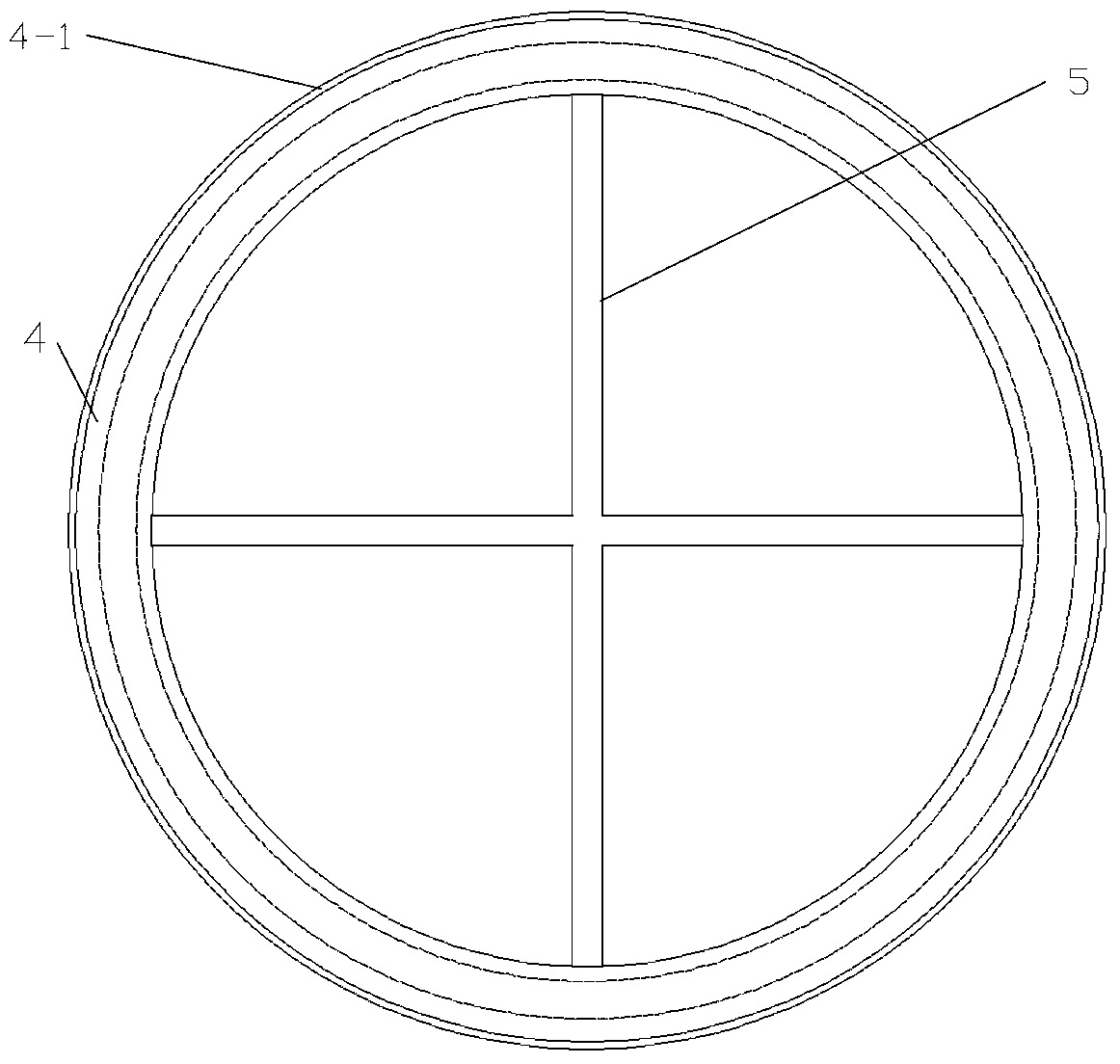

[0026] As shown in the figure: the embodiment of the present invention provides a combined floating roof tank sealing device, including a floating roof main body 1, the lower end surface of the floating roof main body 1 is provided with a nitrogen bag 2, and the floating roof main body 1 is a round cake structure, a primary sealing mechanism is provided on the side of the floating roof main body 1, the primary sealing mechanism includes multi-layer splints 3, and an annular airbag 4 is set between adjacent splints 3, and the annular airbag 4 passes through the pressure dividing pipe The mechanism 5 communicates with the nitrogen bag 2, and the inner side of the lower side wall of the nitrogen bag 2 is evenly arranged with a plurality of support platforms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com