Conveying belt tear detecting method based on FPGA

A detection method and technology for conveyor belts, which are applied to conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as affecting the normal use of conveyor belts, unsatisfactory effects, and tedious installation. The effect of small size and low price of hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

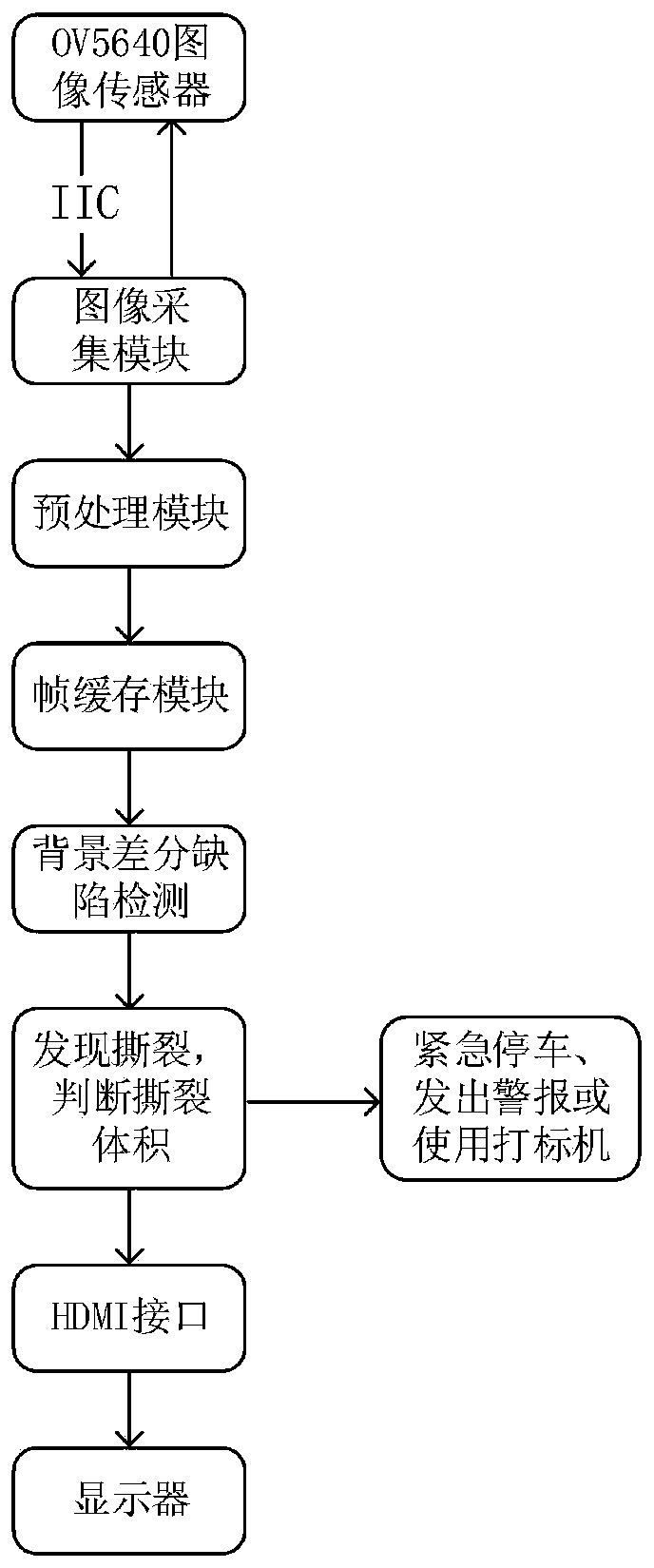

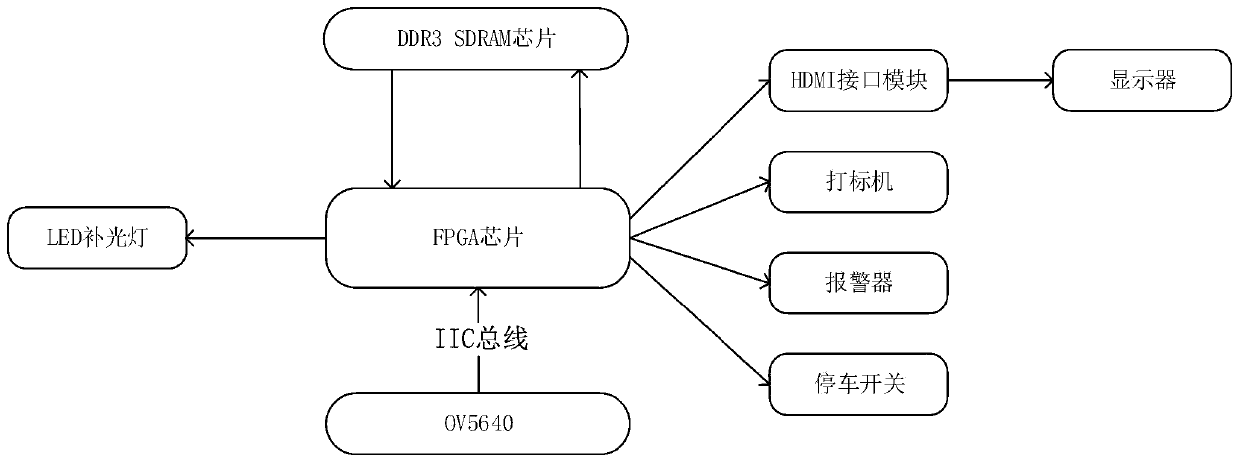

[0025] Such as figure 1 Shown, the process of the FPGA-based conveyor belt tear detection method is:

[0026] (1) Install OV5640 above the conveyor belt for long-term uninterrupted video recording of the conveyor belt, and then transmit it to the image acquisition module through the IIC bus;

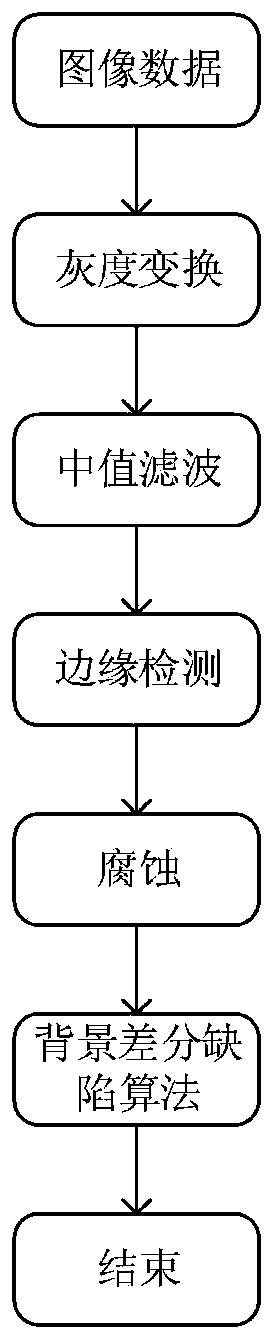

[0027] (2) Through the Verilog HDL hardware description language programming, the logic circuit of FPGA realizes the real-time preprocessing of the received image data;

[0028] (2a) Take pictures frame by frame from the recorded conveyor belt video;

[0029] (2b) For the acquired picture, use f(i,j)=0.2989R(i,j)+0.5870G(i,j)+0.1140B(i,j) for grayscale transformation, where f(i,j ) represents the gray value, R(i,j) represents the red component value, G(i,j) represents the green component value, B(i,j) represents the blue component value;

[0030] (2c) Use g(i,j)=median{f(i-k,j-l)}, (k,l)∈H to perform median filtering on the grayscale transformed image, where (i,j) represents the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com