Underground garage adopting pipeline corridors

A technology for underground garages and corridors, which is applied to underwater structures, buildings for parking cars, water conservancy projects, etc., can solve the problem of increasing the height of garages, and achieve the effect of improving fire protection level, saving volume, and saving overall volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

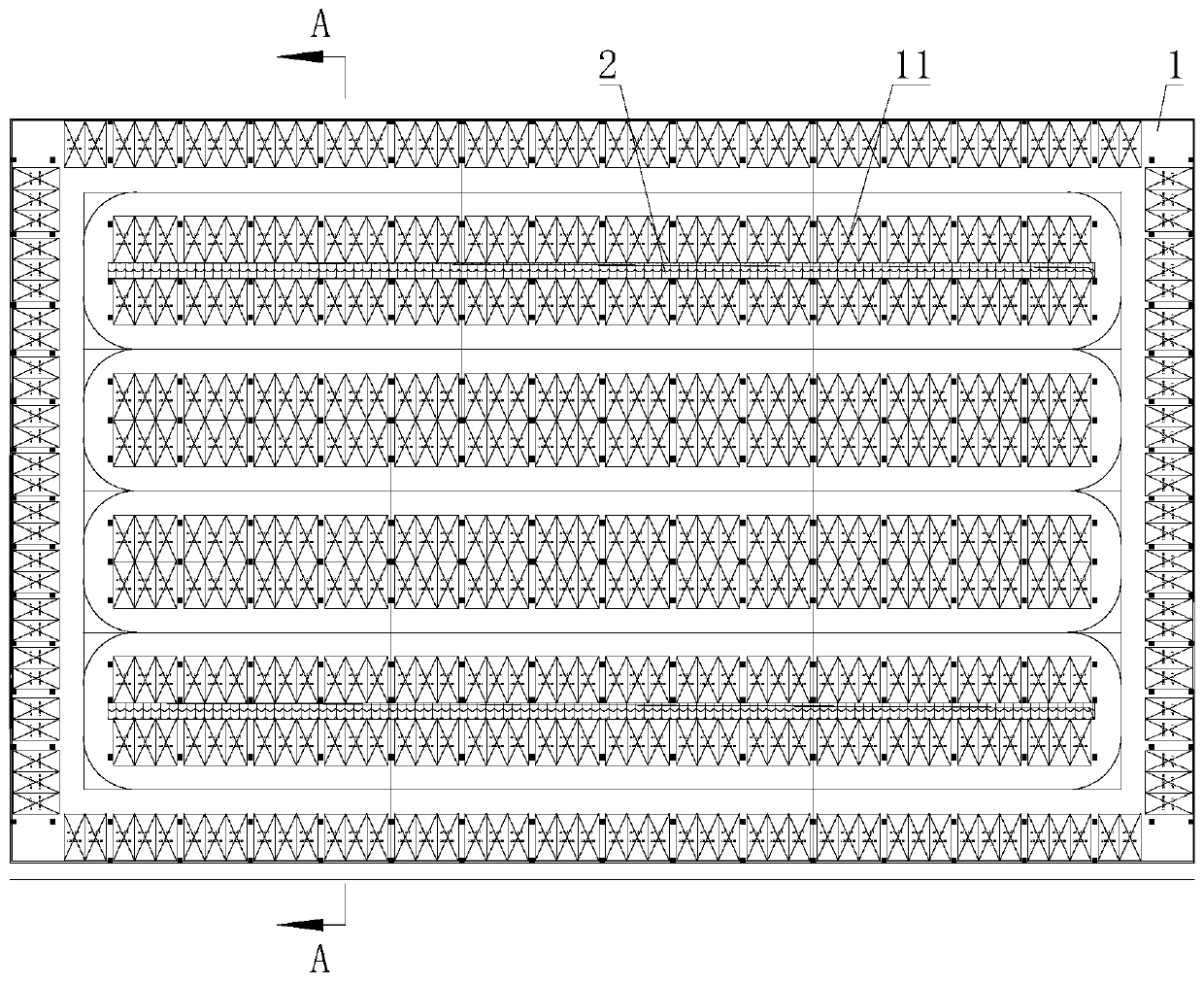

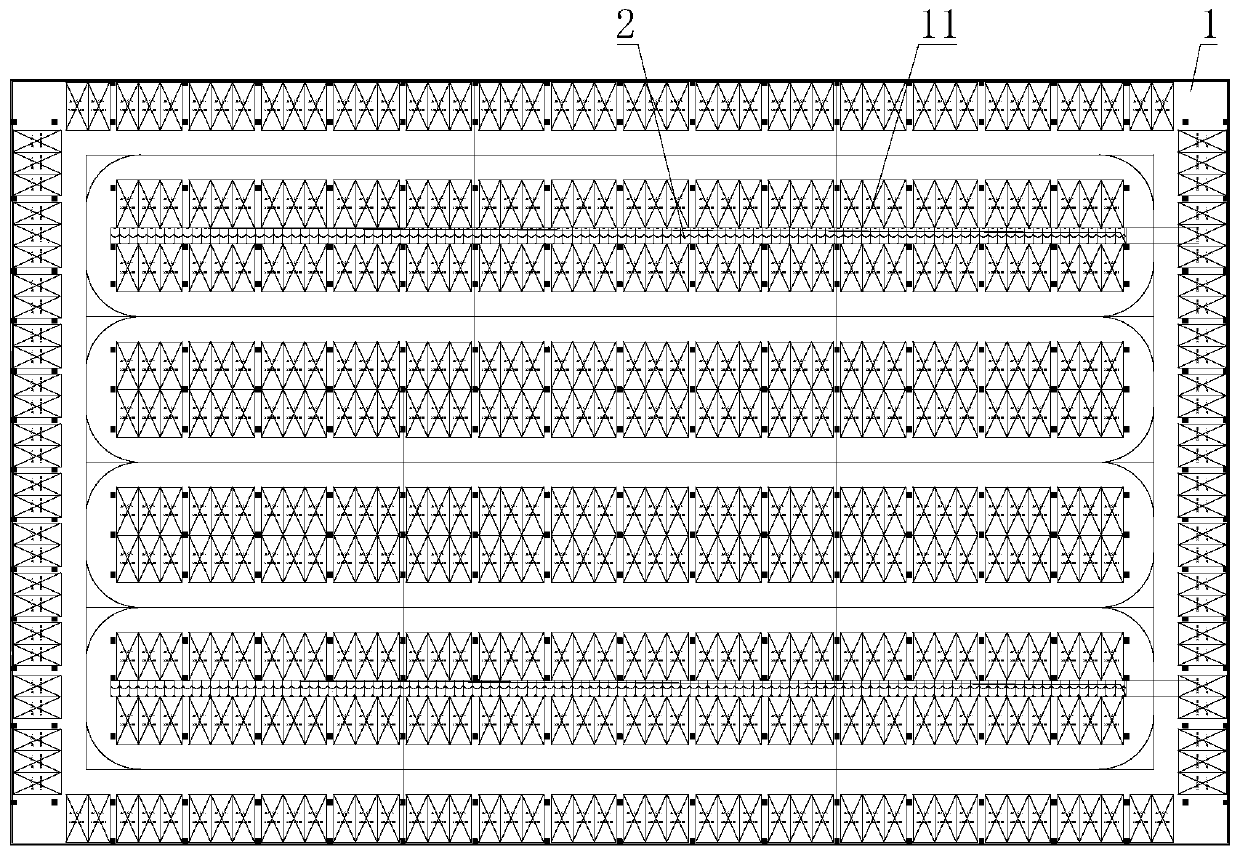

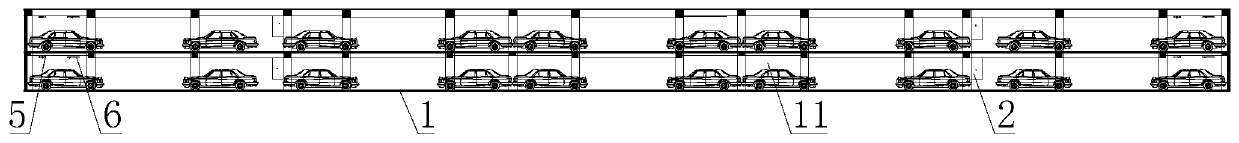

[0038] Such as Figure 1 to Figure 5 As shown, the underground garage of this embodiment includes several layers of garage main bodies 1, and the garage main body 1 is provided with several parking spaces 11 and several pipeline corridors 2, and several parking spaces 11 and several pipeline corridors 2 are mutually staggered in the horizontal direction.

[0039] The pipeline corridor 2 and the parking space 11 of the present invention are mutually staggered in the horizontal direction, then the pipeline corridor 2 will not occupy the upper space of the garage main body 1, and the height of the garage main body 1 can be correspondingly reduced, correspondingly saving the volume of the underground garage. The pipeline corridor 2 can be used to arrange pipelines and ventilation ducts. Therefore, when the pipeline corridor 2 is arranged next to the parking space 11, the height of the garage main body 1 can be designed to be shorter, saving the overall volume of the garage from the...

Embodiment 2

[0042] Such as Figure 1 to Figure 5 As shown, the underground garage of this embodiment includes several layers of garage main bodies 1, and the garage main body 1 is provided with several parking spaces 11 and several pipeline corridors 2, and several parking spaces 11 and several pipeline corridors 2 are mutually staggered in the horizontal direction.

[0043] The pipeline corridor 2 and the parking space 11 of the present invention are mutually staggered in the horizontal direction, then the pipeline corridor 2 will not occupy the upper space of the garage main body 1, and the height of the garage main body 1 can be correspondingly reduced, correspondingly saving the volume of the underground garage. The pipeline corridor 2 can be used to arrange pipelines and ventilation ducts. Therefore, when the pipeline corridor 2 is arranged next to the parking space 11, the height of the garage main body 1 can be designed to be shorter, saving the overall volume of the garage from the...

Embodiment 3

[0050] Such as Figure 1 to Figure 5 As shown, the underground garage of this embodiment includes several layers of garage main bodies 1, and the garage main body 1 is provided with several parking spaces 11 and several pipeline corridors 2, and several parking spaces 11 and several pipeline corridors 2 are mutually staggered in the horizontal direction.

[0051] The pipeline corridor 2 and the parking space 11 of the present invention are mutually staggered in the horizontal direction, then the pipeline corridor 2 will not occupy the upper space of the garage main body 1, and the height of the garage main body 1 can be correspondingly reduced, correspondingly saving the volume of the underground garage. The pipeline corridor 2 can be used to arrange pipelines and ventilation ducts. Therefore, when the pipeline corridor 2 is arranged next to the parking space 11, the height of the garage main body 1 can be designed to be shorter, saving the overall volume of the garage from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com