Sound-proof door

A technology of sound insulation door and sound insulation block, applied in the direction of sound insulation door/window, door leaf, window/door frame, etc., can solve the problems of poor sealing and sound insulation effect of sound insulation door, easy rupture and damage of rubber sealing strip, unsatisfactory sound insulation effect, etc. , to achieve excellent sealing effect, better sealing and sound insulation effect, and the effect of promoting and using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

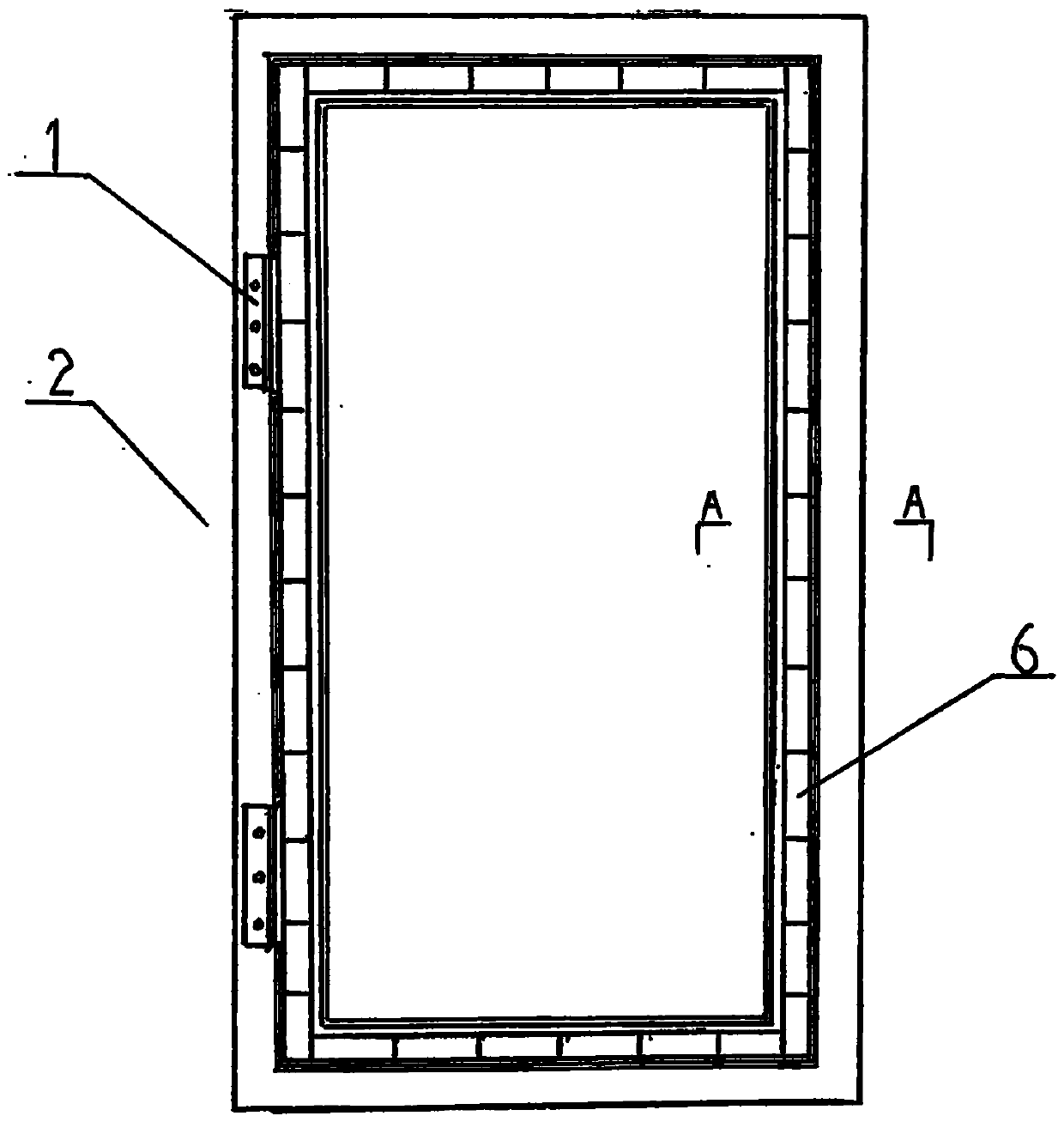

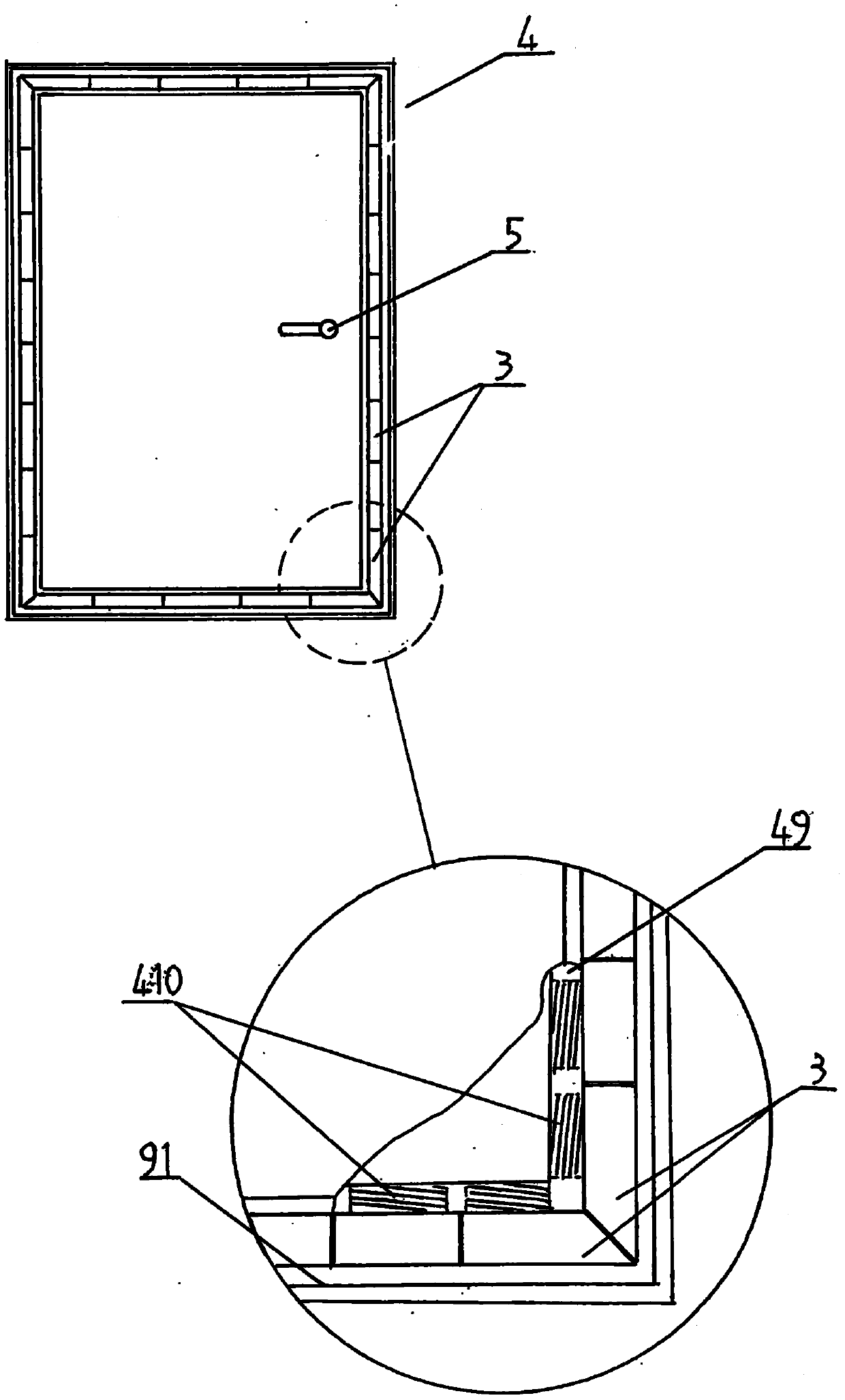

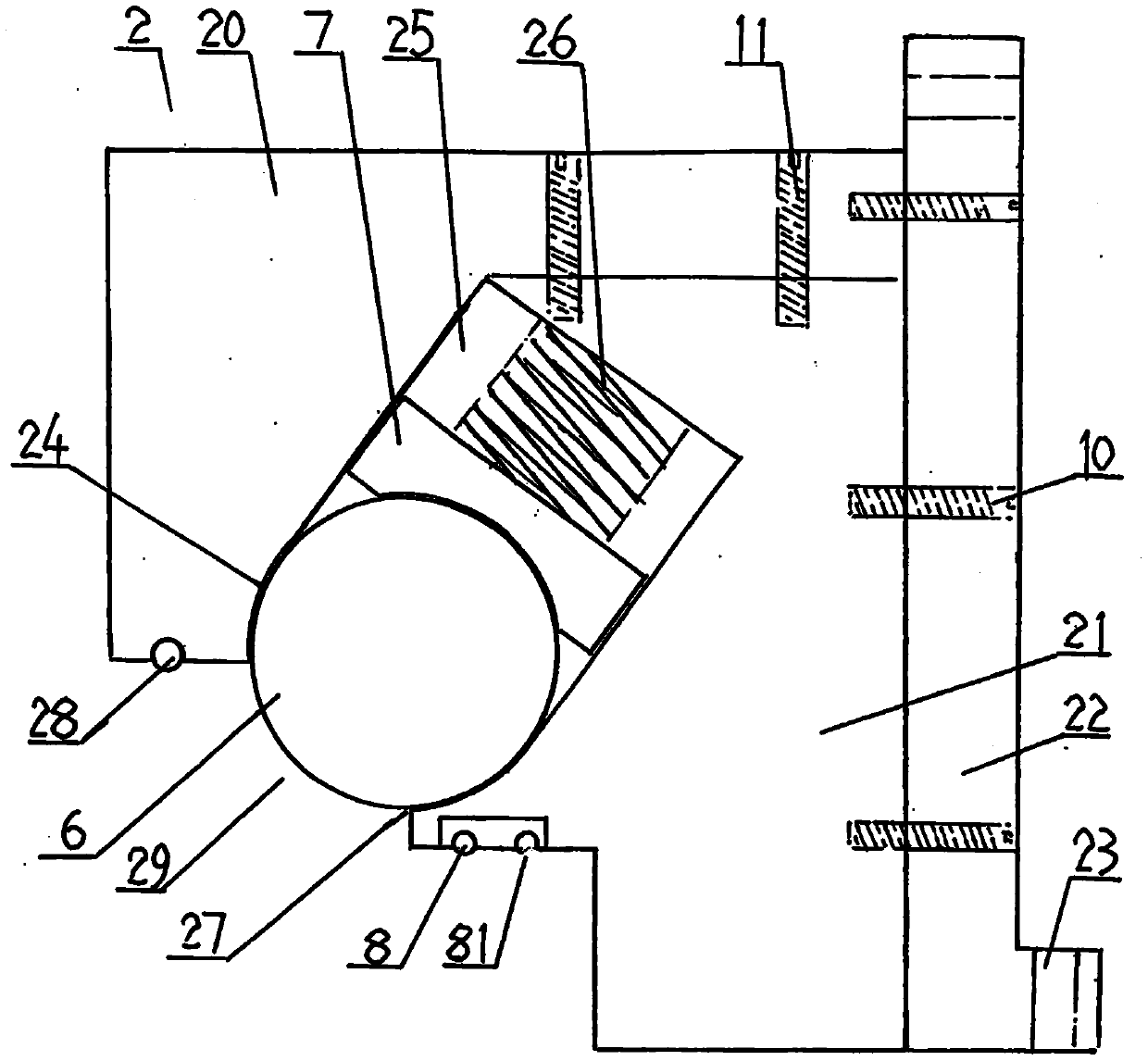

[0027] Such as Figure 1 to Figure 7 As shown, a soundproof door includes a hinge 1 and a door frame sealing strip 28, wherein:

[0028] Door frame 2: The door frame is composed of a main frame 21 , an inner frame 20 and an outer frame 22 . The main frame is located at the front side of the door frame, the inner frame is located at the inner side of the door frame, and the outer frame is located at the outer side of the main frame and the inner frame. The rear end of the main frame is integrated with the front end of the inner frame through several second bolts 11, and the inner side of the outer frame is connected with the outer side of the main frame and the inner frame through several first bolts 10. into one. The front end of the inner frame is arranged in the middle of the inner side of the main frame. The angle formed by the front end surface of the inner frame body and the inner surface of the main frame forms a door card slot 29 . Two ends of the outer frame body c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com