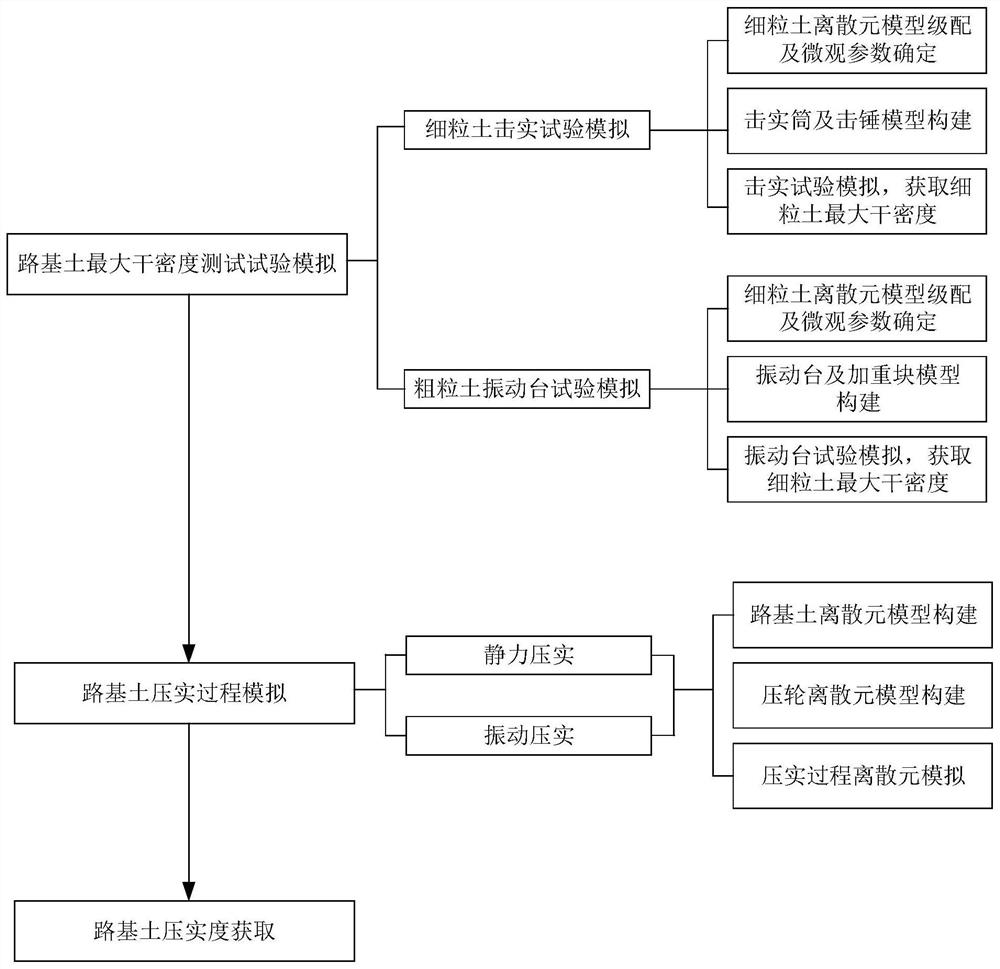

A method for obtaining the degree of compaction of subgrade soil under compaction

A technology of subgrade soil and compaction, which is applied in the preparation of test samples, the use of one-time impact force to test the strength of materials, and the use of stable tension/compression to test the strength of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

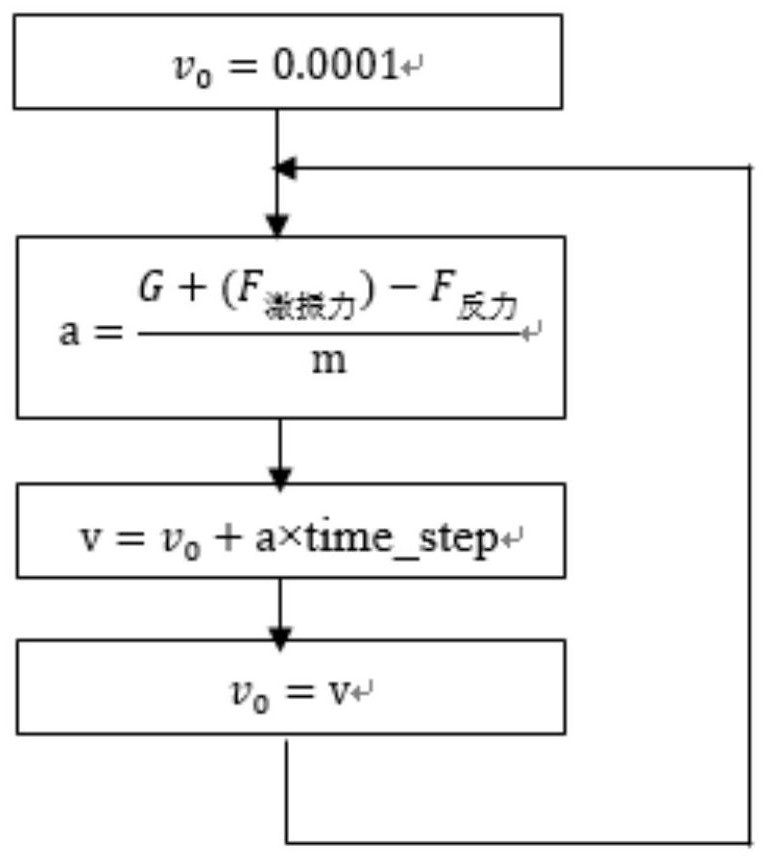

Method used

Image

Examples

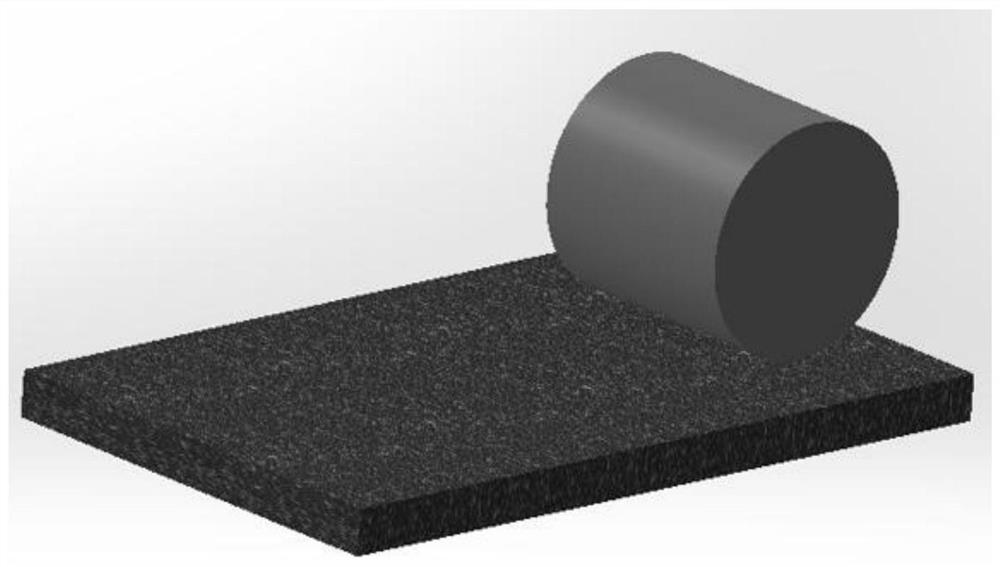

Embodiment 1

[0043] The subgrade soil of a certain road is coarse-grained sandy soil, the measured gradation is shown in Table 1, and the optimum moisture content is 10.5%. A discrete element subgrade soil model of 0.3m×2.5m×2.5m was established in PFC3D software. The model gradation and microscopic parameters are shown in Table 2 and Table 3. The initial porosity before compaction is 43%. The kn and ks values of each boundary wall of the subgrade soil model are consistent with the soil kn and ks values. The kn and ks values of the walls generated after the pressure roller model is imported are taken as 10 times the soil kn and ks values.

[0044] Table 1 Actual gradation of coarse-grained sand

[0045]

[0046] Table 2 Ball gradation in the discrete element model of coarse-grained sand

[0047] Particle size (mm) 15 22 28 / 25 44 Proportion(%) 1.4 21.7 45.6 29.0 2.3

[0048] Table 3 Microscopic parameters in the discrete element model of coarse-grained...

Embodiment 2

[0056] A subgrade soil is silty clay, the measured gradation is shown in Table 5, and the optimum moisture content is 13.5%. A discrete element subgrade soil model of 0.3m×2.5m×2.5m was established in PFC3D software. The model gradation and microscopic parameters are shown in Tables 6 and 7. The initial porosity before compaction is 48%. The kn and ks values of each boundary wall of the subgrade soil model are consistent with the soil kn and ks values. The kn and ks values of the walls generated after the pressure roller model is imported are taken as 10 times the soil kn and ks values.

[0057] Table 5 Actual gradation of silty clay

[0058] Particle size (mm) Below 0.075 0.075-0.25 0.25-0.5 0.5—1 1—2 2—5 Proportion(%) 56.6 13.9 12.7 7.7 7.2 1.9

[0059] Table 6 Ball gradation in the discrete element model of silty clay

[0060] Particle size (mm) 15 22 28 / 25 44 Proportion(%) 1.4 21.7 45.6 29.0 2.3

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com