Printer color cycle correction method, device and equipment and storage medium

A calibration method and printer technology, applied in the direction of digital output to printing unit, instrument, electrical digital data processing, etc., can solve the problems of low color conversion accuracy and the inability of the printer to restore the color effect of the original image, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

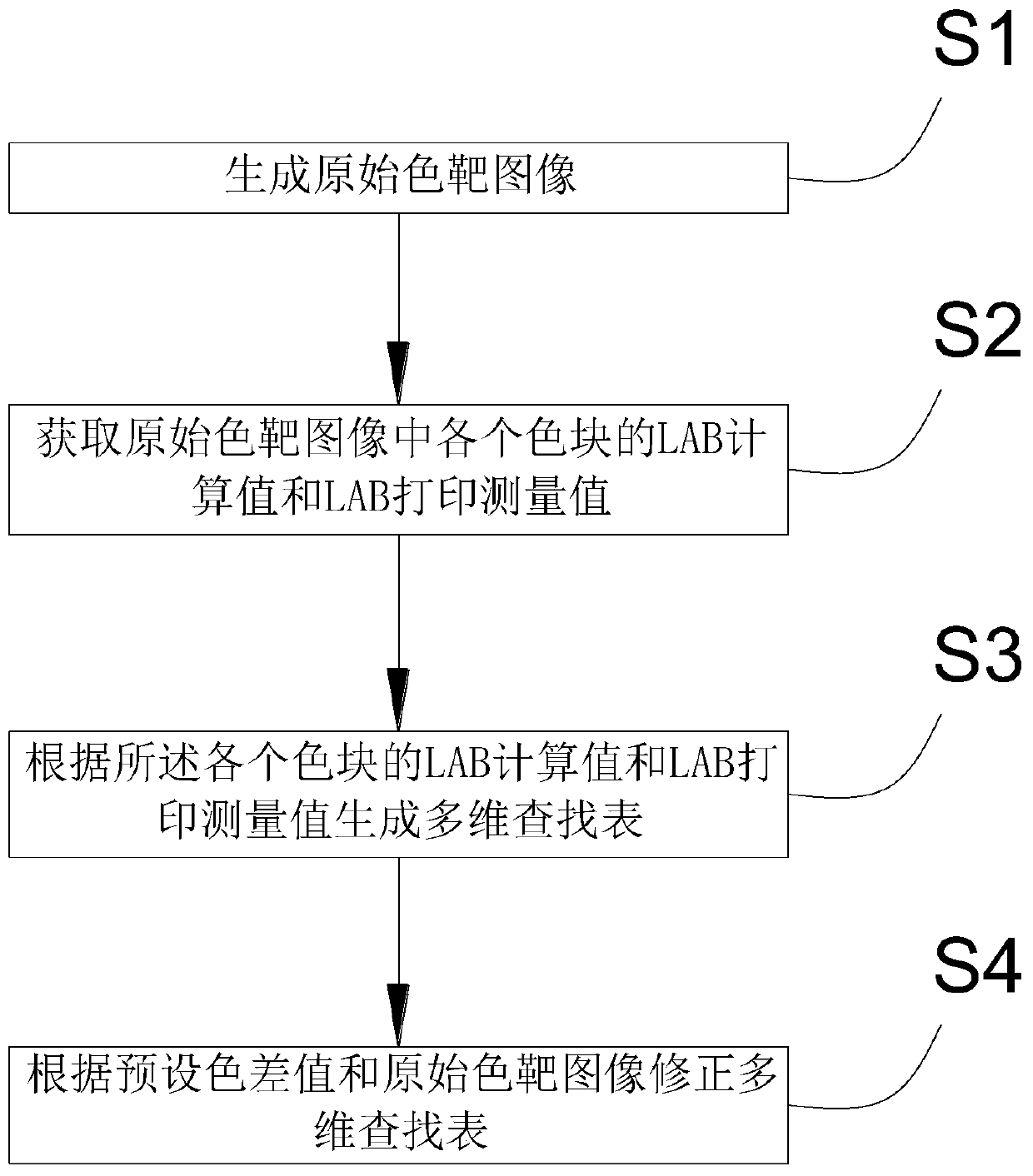

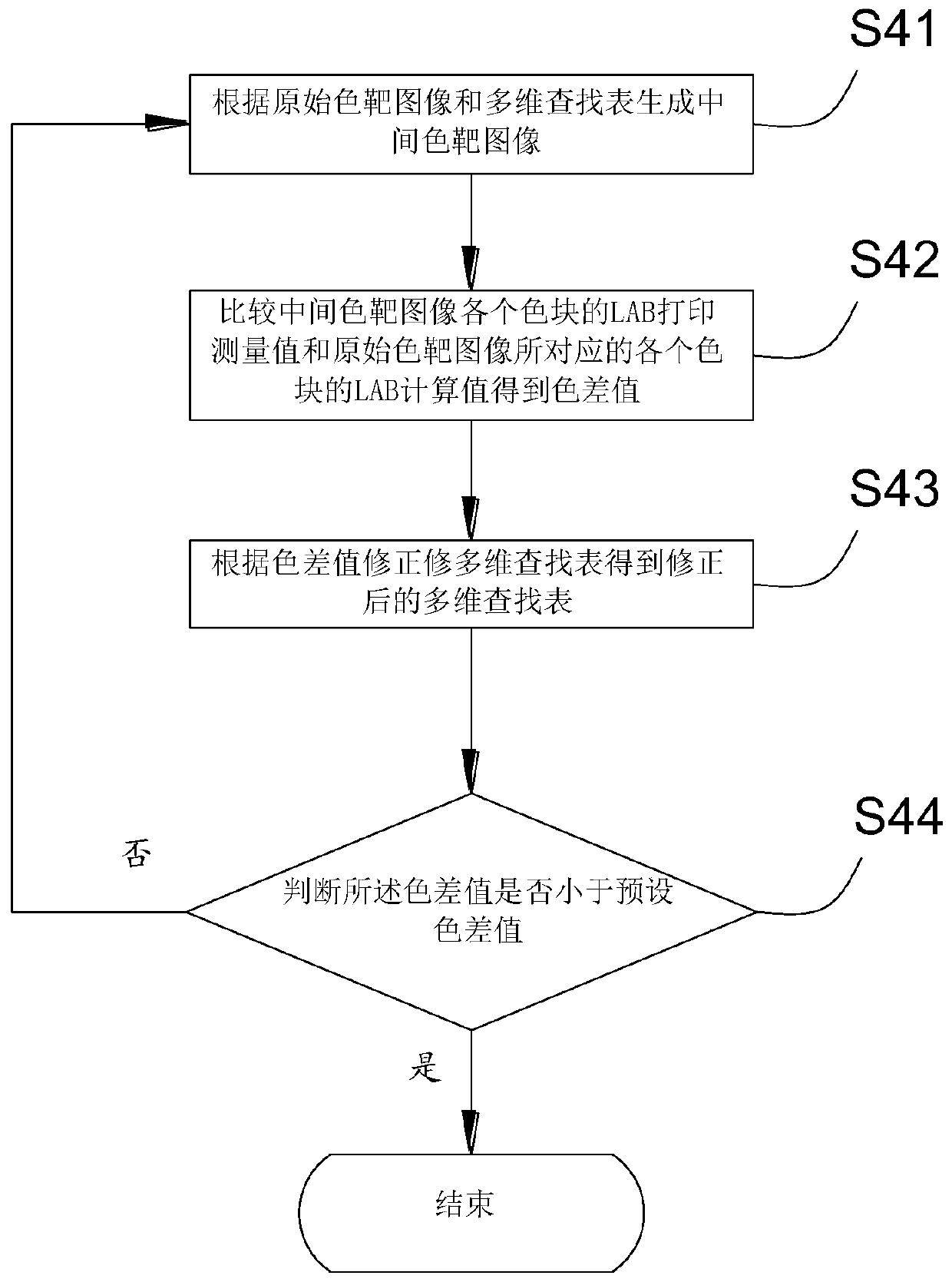

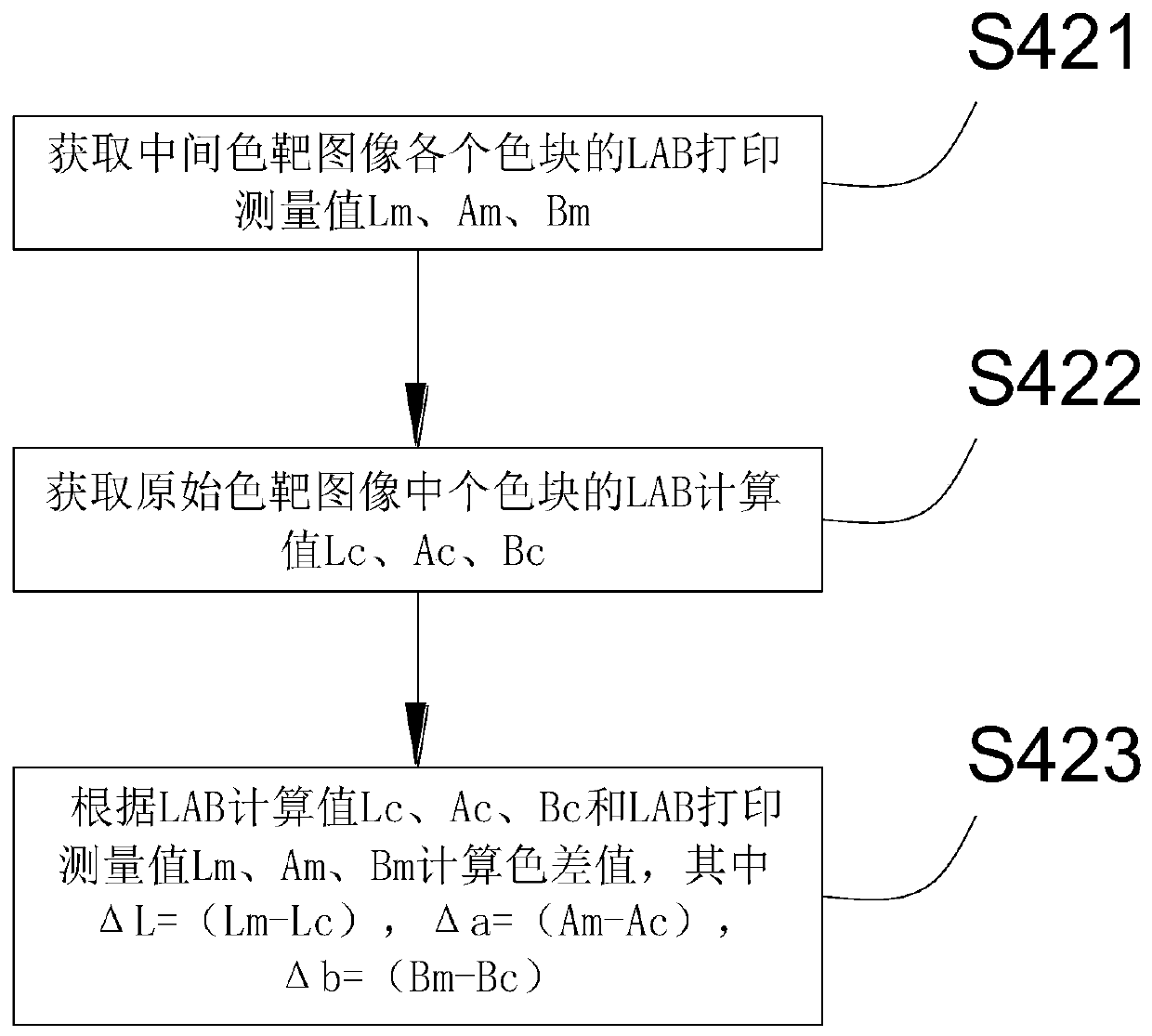

[0054] In this embodiment, a multi-dimensional lookup table from LAB to CMYK is established through the LAB calculated value of the color target image and the measured value of LAB printing. Color accuracy requirements between different devices. At the same time, the original color target image is processed and printed on the basis of the multidimensional lookup table, the color data of the printed image is compared with the color data of the original color target image to form a color difference value, and the multidimensional lookup table generated is repeatedly corrected by using the color difference value , until the color difference value meets the requirements. Since the actual printed color data is introduced into the correction process for cyclic correction, and the cycle is terminated when the color difference meets the requirements, the multi-dimensional lookup table after correction accurately reflects the corresponding relationship between the target color gamut an...

Embodiment 2

[0103] see Figure 5 , an embodiment of the present invention provides a printer color cycle correction device, the device includes:

[0104] An image generation module, the image generation module is used to generate the original color target image;

[0105] A numerical value acquisition module, the numerical value acquisition module is used to obtain the LAB calculation value and the LAB printing measurement value of each color block in the original color target image;

[0106] A multidimensional lookup table production module, the multidimensional lookup table generation module is used to generate a multidimensional lookup table according to the LAB calculation value and the LAB printing measurement value of each color block;

[0107] A multidimensional lookup table correction module, the multidimensional lookup table correction module is used to correct the multidimensional lookup table according to the preset color difference value and the original color target image.

Embodiment 3

[0109] Also, combine Figure 6 The described printer color cycle correction method according to the embodiment of the present invention can be implemented by a printer color cycle correction device. Figure 6 A schematic diagram of the hardware structure of the printer color cycle correction device provided by the embodiment of the present invention is shown.

[0110] The printer color cycle correction device may include a processor 401 and a memory 402 storing computer program instructions.

[0111] Specifically, the above-mentioned processor 401 may include a central processing unit (CPU), or an application specific integrated circuit (Application Specific Integrated Circuit, ASIC), or may be configured to implement one or more integrated circuits in the embodiments of the present invention.

[0112] Memory 402 may include mass storage for data or instructions. By way of example and not limitation, memory 402 may include a hard disk drive (Hard Disk Drive, HDD), a floppy d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com