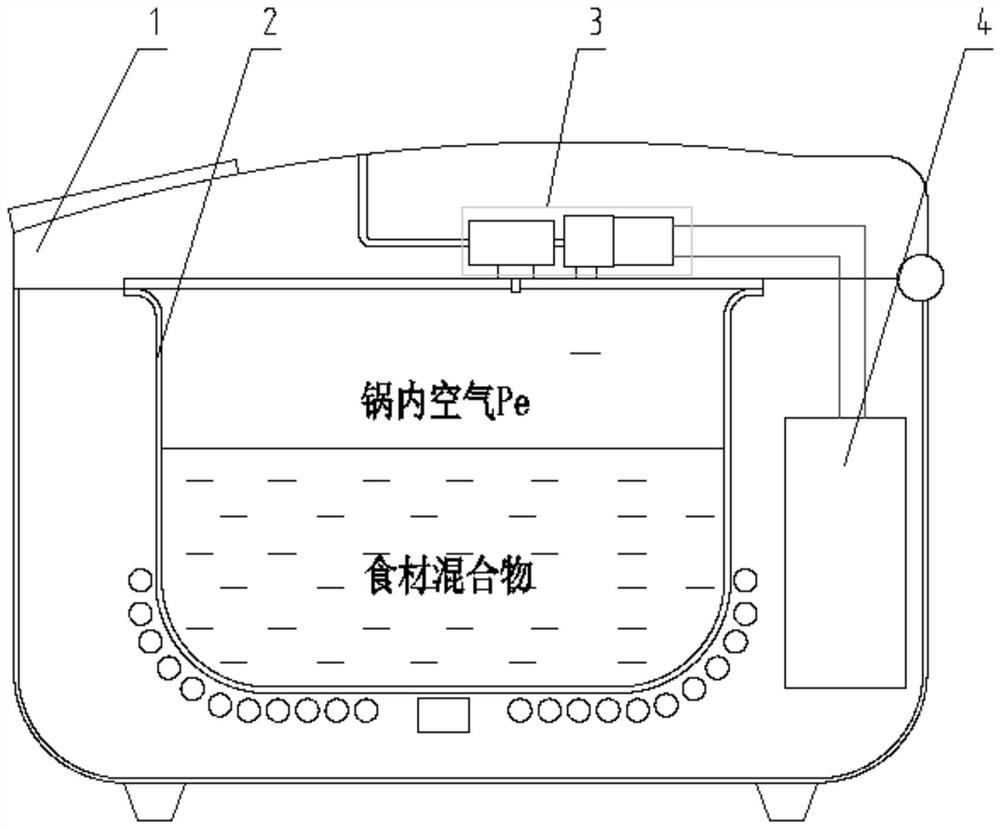

Pressure cooking appliance and its control method and device

A technology of cooking utensils and control methods, applied in pressure cookers, program control, cooking utensils, etc., can solve problems such as unevenness, rice grains absorb water when heated, and achieve the best boiling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

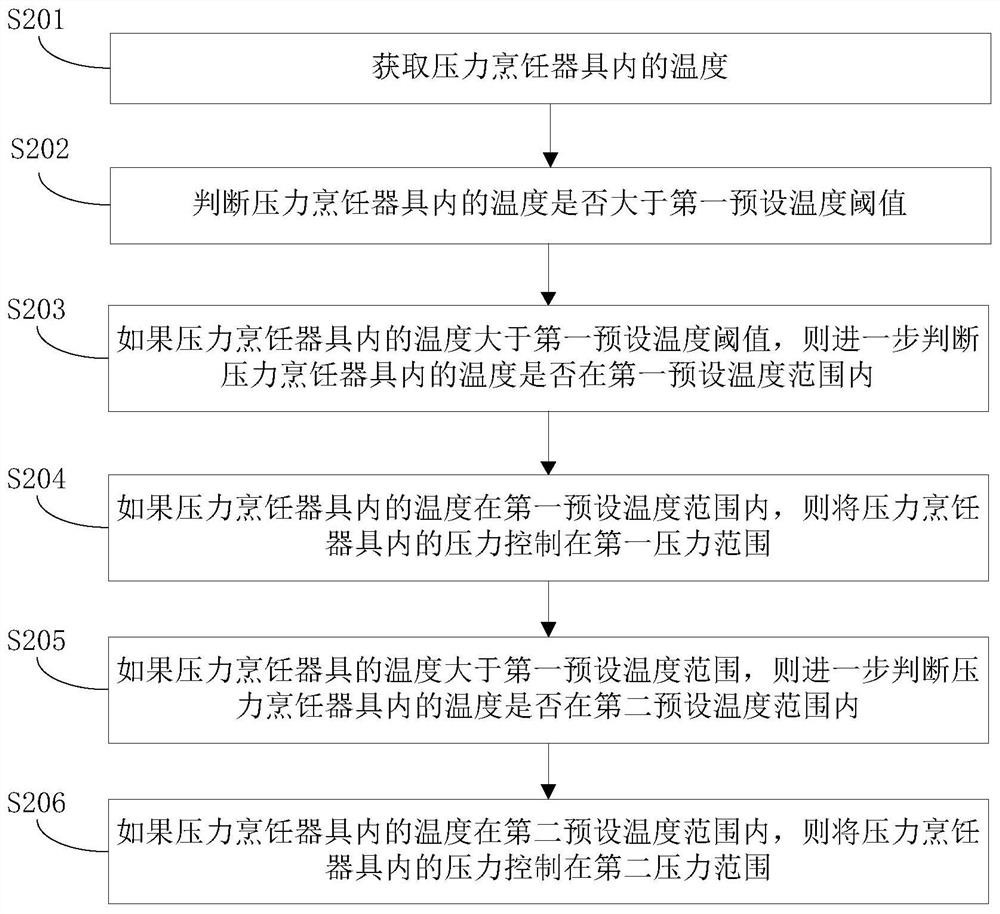

Method used

Image

Examples

example 1

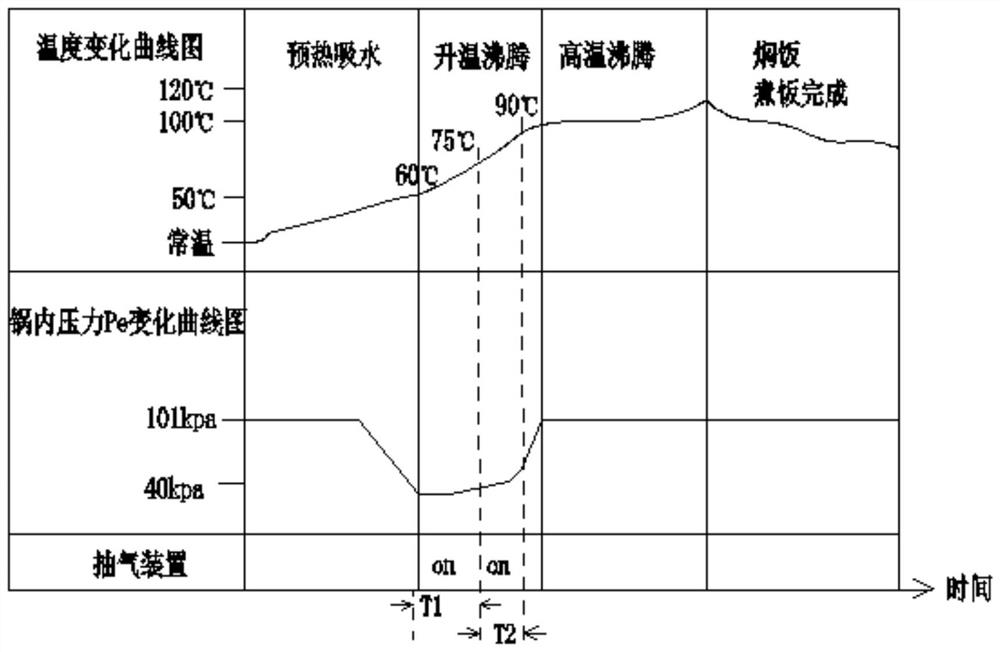

[0072] In the T1 stage, the pressure in the pot is controlled in the first pressure range of 10kPa-80kPa, and in the T2 stage, the pressure in the pot is controlled in the second pressure range of 30kPa-90kPa for experiments. The experimental results are shown in Table 1 below:

[0073] Table 1

[0074]

example 2

[0076] In order to better realize the negative pressure in the pot, reduce the cost of the air extraction device, and ensure the boiling effect, in this example, the pressure in the pot is controlled in the first pressure range of 20kPa-70kPa in the T1 stage, and the pot is controlled in the T2 stage. The internal pressure is controlled in the second pressure range of 40kPa-90kPa for experiments, and the experimental results are shown in Table 2 below:

[0077] Table 2

[0078]

example 3

[0080] In this example, the more common miniature vacuum pump can be used as the air extraction device, and the cost is relatively low. In order to make the boiling effect and the heating uniformity effect better, the pressure in the pot is controlled in the first pressure range of 40kPa-60kPa in the T1 stage. In the T2 stage, the pressure in the pot is controlled to the second pressure range of 50kPa-90kPa for experiments, and the experimental results are shown in Table 3 below:

[0081] table 3

[0082]

[0083] Example 4: It can be seen from Table 3 that if the parameters shown in Table 3 are designed, the boiling and heating effects are ideal. In order to further reduce the cost, low-end products can also achieve the reduction in boiling point caused by vacuuming. The heating performance is improved. In this example, the pressure in the pot is controlled in the first pressure range of 60kPa-80kPa in the T1 stage, and the experiment is carried out when the pressure in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com