A kind of intelligent biomass waste degradation equipment

A biomass waste and intelligent technology, applied in the field of biomass waste treatment, can solve the problems of inability to destroy or change the internal structure of biomass, long fermentation cycle, low conversion utilization rate, etc., to avoid long fermentation treatment cycle, The feeding or discharging process is convenient, and the effect of convenient discharging and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

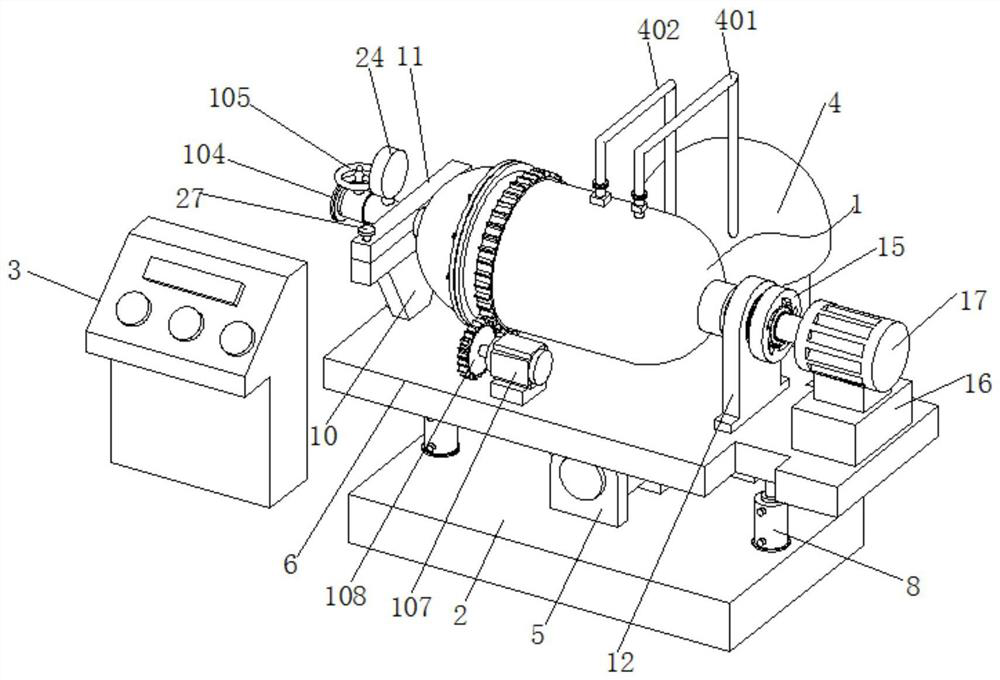

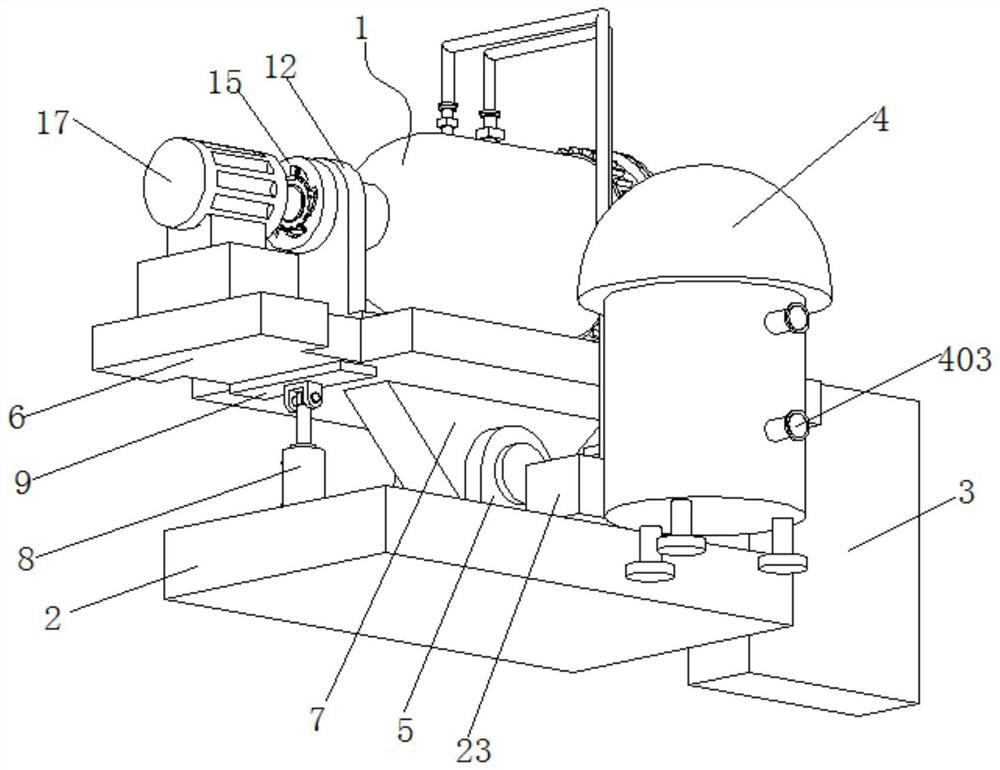

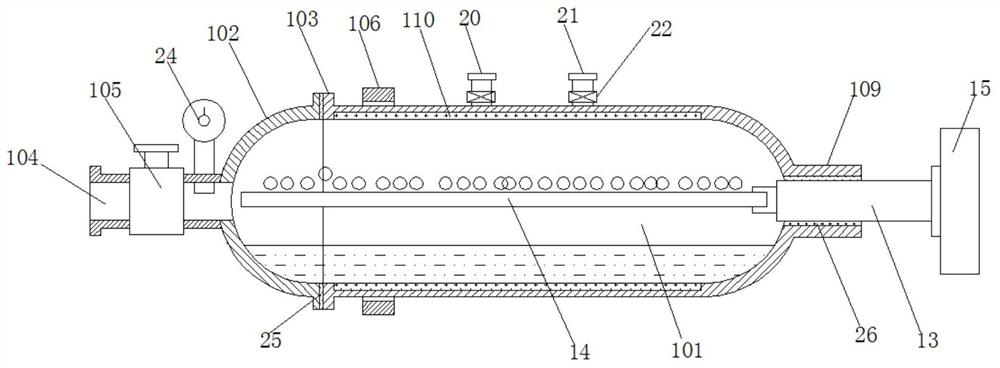

[0037] This embodiment 1 introduces a kind of intelligent biomass waste degradation equipment, refer to the attached figure 1 And attached figure 2 , its main structure includes a degradation tank 1, a base 2 and a control box 3, a rotating seat 5 is arranged at the center of the upper surface of the base 2, a loading plate 6 is arranged directly above the base 2, and the lower surface of the loading plate 6 A rotating member 7 connected to the rotating base 5 is provided, and telescopic devices 8 are fixed on the left and right ends of the rotating base 5. Specifically, the telescopic device 8 can be selected from one of an air cylinder or a hydraulic cylinder. The top of the device 8 is rotatably connected with a strip supporting plate 9, and the two strip supporting plates 9 abut against the left and right ends of the lower surface of the loading plate 6 respectively. The entire degradation tank body 1 can be tilted by the opposite extension or shortening of the two tele...

Embodiment 2

[0043] This embodiment 2 introduces the intelligent biomass waste degradation equipment improved on the basis of embodiment 1, refer to the attached figure 1 And attached figure 2 , its main structure includes a degradation tank 1, a base 2 and a control box 3, a rotating seat 5 is arranged at the center of the upper surface of the base 2, a loading plate 6 is arranged directly above the base 2, and the lower surface of the loading plate 6 A rotating member 7 connected to the rotating base 5 is provided, and telescopic devices 8 are fixed on the left and right ends of the rotating base 5. Specifically, the telescopic device 8 can be selected from one of an air cylinder or a hydraulic cylinder. The top of the device 8 is rotatably connected with a strip supporting plate 9, and the two strip supporting plates 9 abut against the left and right ends of the lower surface of the loading plate 6 respectively. The entire degradation tank body 1 can be tilted by the opposite extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com