A method for extracting polysaccharides from Hericium erinaceus by internal boiling

A technology of Hericium erinaceus polysaccharides and Hericium erinaceus powder, applied in the field of polysaccharide extraction, achieving good application prospects, fast extraction speed, and high extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

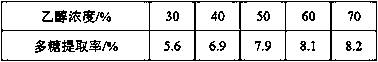

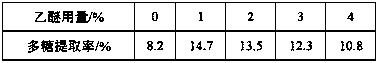

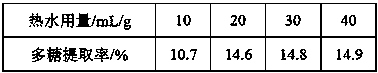

Method used

Image

Examples

Embodiment 1

[0045] 1) Dry and crush the fruiting bodies of Hericium erinaceus, pass through a 100-200 mesh sieve, and then add an ethanol solution with a mass concentration of 50wt% (containing 3wt% ether ), ultrasonic treatment at 5~10°C for 8 minutes to fully infiltrate Hericium erinaceus powder;

[0046] 2) Add hot water at 80°C in the amount of 20mL / g Hericium erinaceus powder to the liquid obtained in step 1), extract for 4 minutes, and then filter;

[0047] 3) Add 1 / 4 of the volume of absolute ethanol to the filtrate obtained in step 2), remove the supernatant after standing for 8 hours, and dry the obtained precipitate to obtain Hericium erinaceus polysaccharide, and the polysaccharide yield is 12.9%.

Embodiment 2

[0049] 1) Dry and crush the fruiting bodies of Hericium erinaceus, pass through a 100-200 mesh sieve, and then add an ethanol solution with a mass concentration of 70wt% (containing 2wt% ether ), ultrasonic treatment at 5~10°C for 5 minutes to fully infiltrate Hericium erinaceus powder;

[0050] 2) Add hot water at 90°C in the amount of 20mL / g Hericium erinaceus powder to the liquid obtained in step 1), extract for 4 minutes, and then filter;

[0051] 3) Add 1 / 2 of the volume of absolute ethanol to the filtrate obtained in step 2), remove the supernatant after standing for 6 hours, and dry the obtained precipitate to obtain Hericium erinaceus polysaccharide, and the polysaccharide yield is 13.7%.

Embodiment 3

[0053] 1) After drying and crushing the fruiting body of Hericium erinaceus, pass through a 100-200 mesh sieve, and then add an ethanol solution with a mass concentration of 60wt% (containing 1wt% ether ), ultrasonic treatment at 5~10°C for 6 minutes to fully infiltrate Hericium erinaceus powder;

[0054] 2) Add hot water at 80°C in the amount of 20mL / g Hericium erinaceus powder to the liquid obtained in step 1), extract for 5 minutes, and then filter;

[0055] 3) Add 1 / 2 of the volume of absolute ethanol to the filtrate obtained in step 2), remove the supernatant after standing for 7 hours, and dry the obtained precipitate to obtain Hericium erinaceus polysaccharide, and the polysaccharide yield is 15.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com