Machining welding device

A welding device and mechanical processing technology, applied in the direction of welding accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

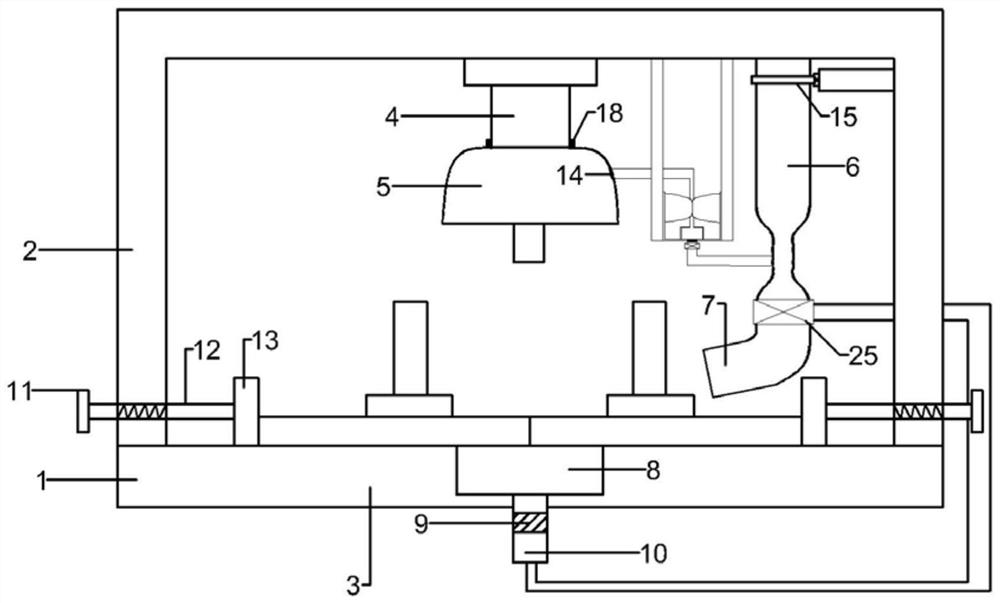

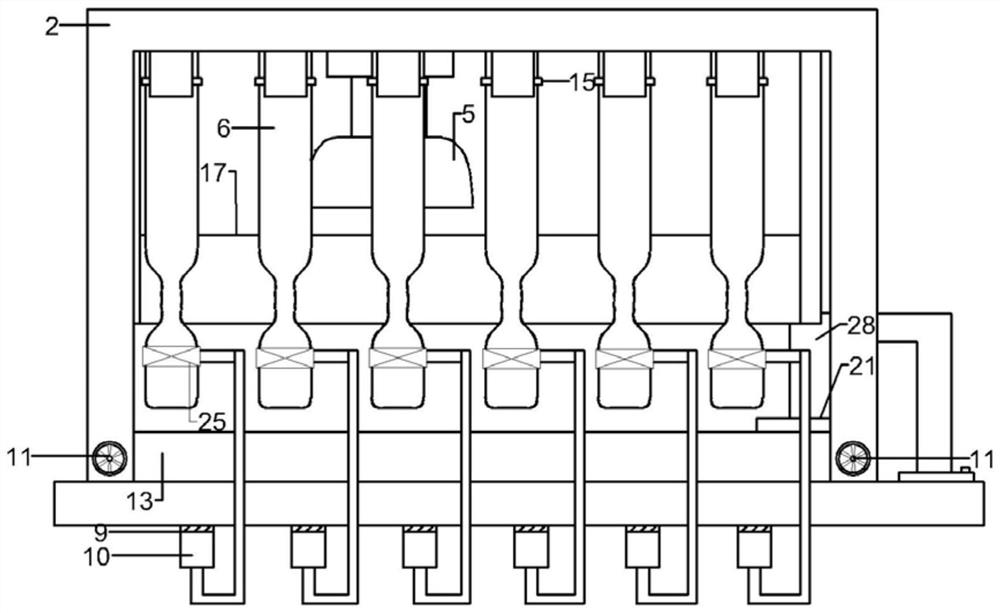

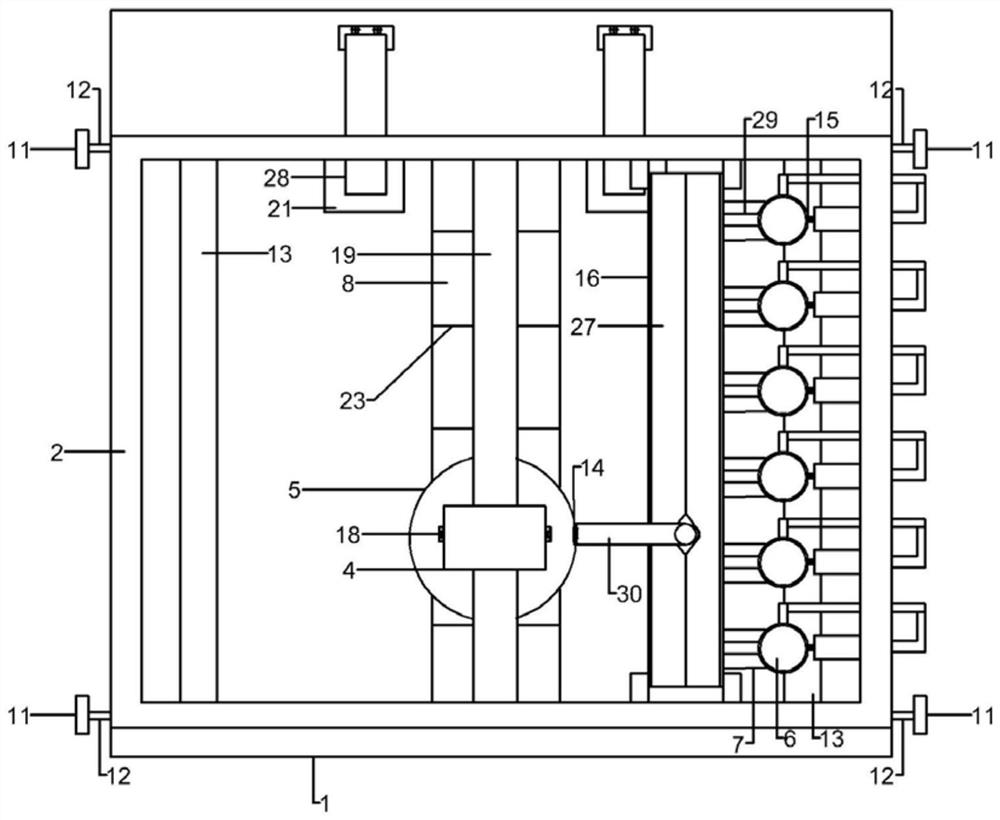

[0017] The following is further described in detail through specific implementation methods:

[0018] The reference signs in the drawings of the description include: 1 machine tool, 2 support, 3 base plate, 4 welding torch, 5 dust cover, 6 cooling pipe, 7 elbow, 8 cooling chamber, 9 piston, 10 air chamber, 11 turntable, 12 Screw, 13 splint, 14 air hole, 15 metal ring, 16 collection tank, 17 filter screen, 18 temperature sensor, 19 welding frame, 20 slide rail, 21 pressure plate, 22 plate, 23 partition, 24 one-way valve, 25 gas Control valve, 26 concave baffles, 27 colloids, 28 hydraulic cylinders, 29 exhaust pipes, 30 exhaust pipes.

[0019] Examples are attached Figure 1~4 Shown: a mechanical processing welding device, including a machine tool 1 and a bracket 2, the machine tool 1 and the bracket 2 are fixedly connected in a cuboid structure, the machine tool 1 is formed by splicing two bottom plates 3, and a cooling device is provided at the joint of the two bottom plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com