Telescopic decelerator for mini tiller

A slow-moving device and micro-tiller technology, applied in the field of micro-tillers, can solve the problems that the four-wheel-drive micro-tiller cannot be used normally, the downforce pressure is unsuitable, and the operation and use are inconvenient, and achieves ingenious design, simple structure, and easy operation. Effort-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

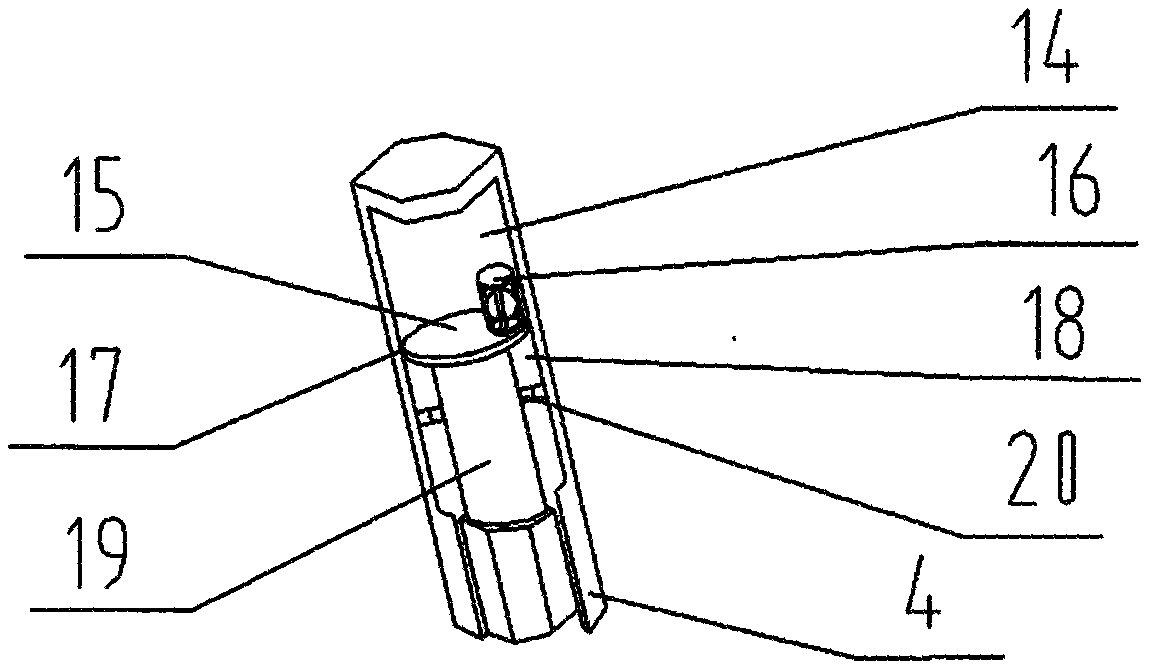

[0045] Such as Figure 4 , Figure 5 , Figure 6 As shown, the present embodiment is a two-axis double-knife drive four-wheel drive micro-cultivator comprising a telescopic and slow-moving device for the micro-cultivator, which includes: a handrail handle, a power assembly, a micro-cultivator bracket, front and rear transmission boxes and The utility model relates to a cultivating knife, a trailer plate, a limit component, and a telescopic slow-moving device for a tiller. Two fixing plates are welded and installed on the rear transmission box body, and round holes are drilled on the fixing plates. The said towable plate is drilled with round holes. The connecting plate a with a round hole is welded at one end of the casing of a telescopic and slow-moving device for a micro-cultivator, and the hexagonal shaft at the outlet of the other end of the casing of a telescopic and slow-moving device for a micro-tiller Connection plate b with round holes. The round hole of the conn...

Embodiment 2

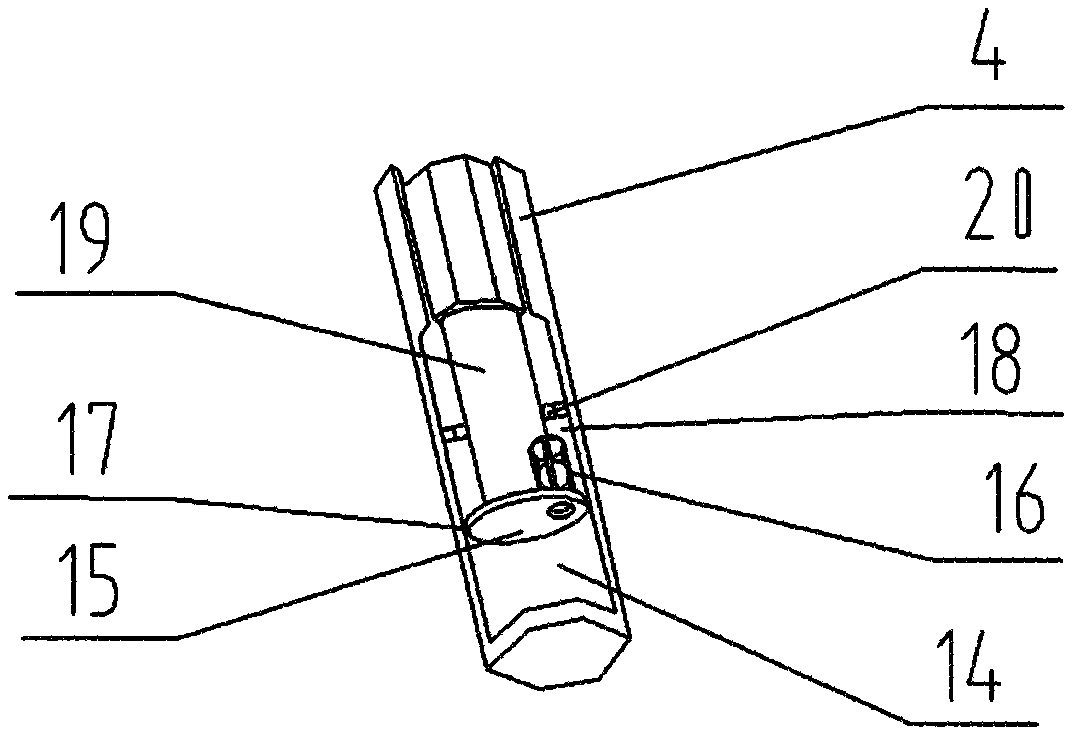

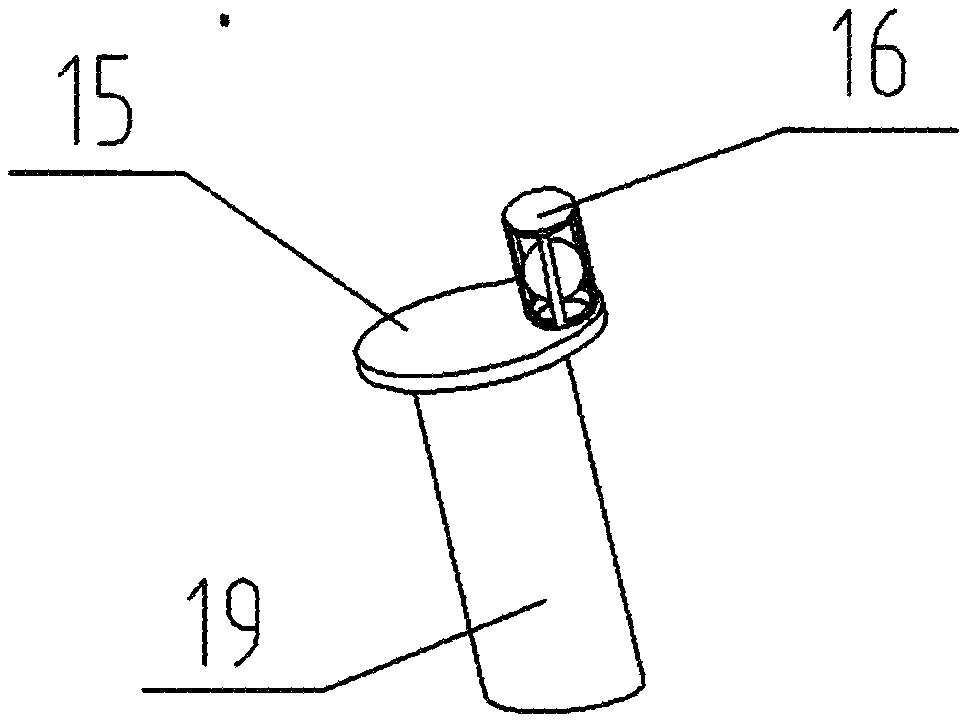

[0049] Such as Figure 7 , Figure 8 , Figure 9 As shown, the present embodiment is a front-drive four-wheel-drive micro-cultivator comprising a telescopic slow-moving device for a micro-cultivator, which includes: a handrail handle, a power assembly, a bracket, a front transmission case, a road wheel, a rear transmission case and a tiller. Knife, towing plate and limit parts with telescopic and slow-moving device for micro tillage machine. The limiting components include: a limiting rod, a limiting wheel, and a telescopic slow-moving device for a tiller. The limit rod is welded at one end of the housing, and the limit wheel is welded at one end of the hexagonal shaft of the telescopic slow-moving device of the tiller.

[0050] The rear transmission box is a transmission box with the input shaft of the rear transmission box as the center of a circle and can rotate freely locally.

[0051] The limiting part with the telescopic and slow-moving device of the tiller can be ex...

Embodiment 3

[0055] Such as Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the present embodiment is a front-drive four-wheel-drive micro-cultivator comprising a telescopic and slow-moving device for the micro-cultivator, which includes: handrail handle, power assembly, micro-cultivator bracket, front transmission box, road wheels, rear transmission Box, cultivator blade, trailer plate and limit parts with telescopic slow-moving device for micro tillage machine. The limiting components include: a limiting rod, a limiting wheel, and a telescopic slow-moving device for a tiller. The limit rod is welded at one end of the housing, and the limit wheel is welded at one end of the hexagonal shaft of the telescopic slow-moving device of the tiller.

[0056] The power input shaft of the rear transmission case is sleeved on the power output shaft of the road wheel, and the rear transmission case can partially rotate around its power input shaft.

[0057] The limiting part with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com