Raw material storage device for quantitative feeding

A technology for storage devices and raw materials, applied in mixers with rotating stirring devices, transportation and packaging, dissolution, etc., can solve problems such as inability to supply raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

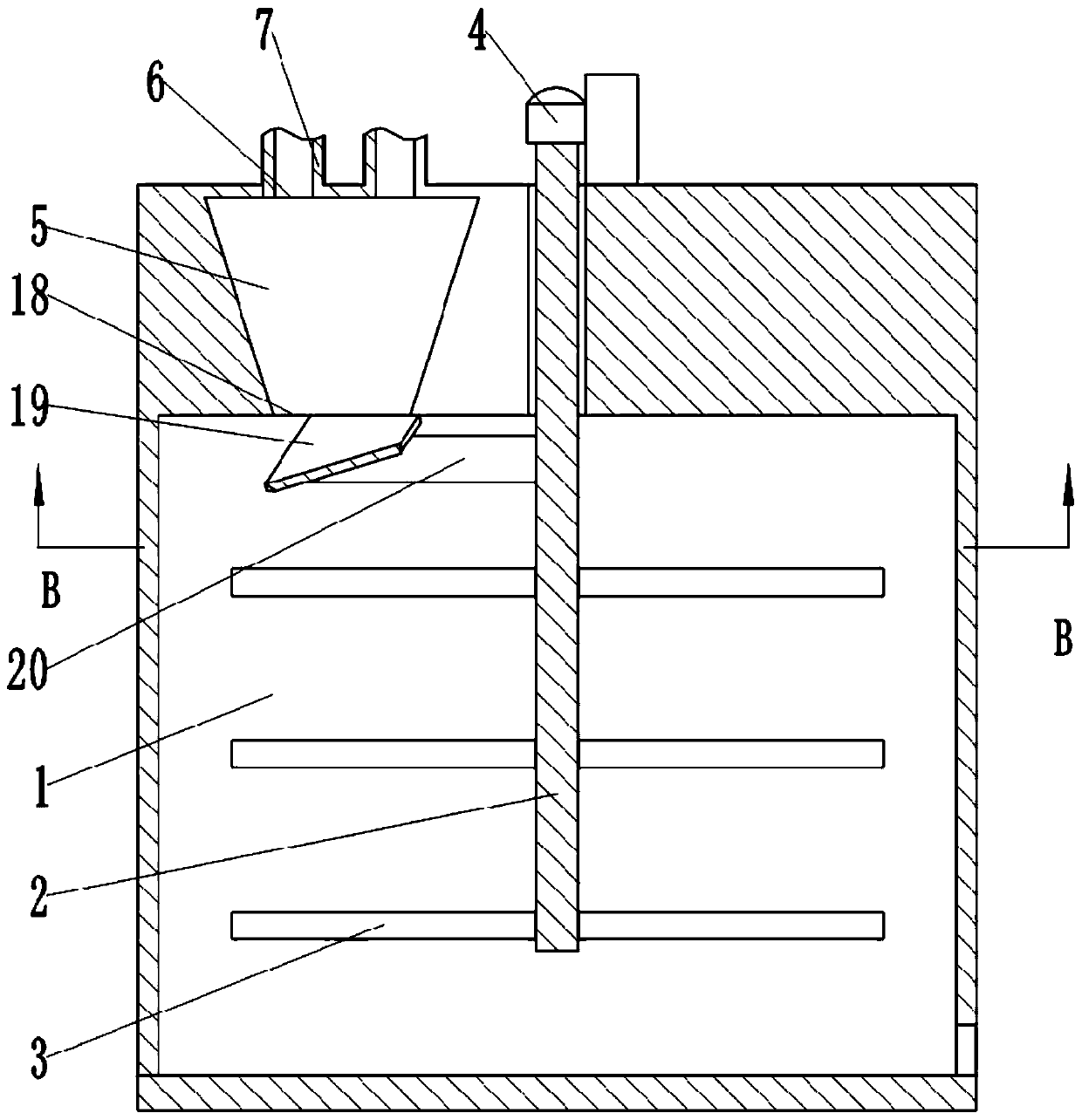

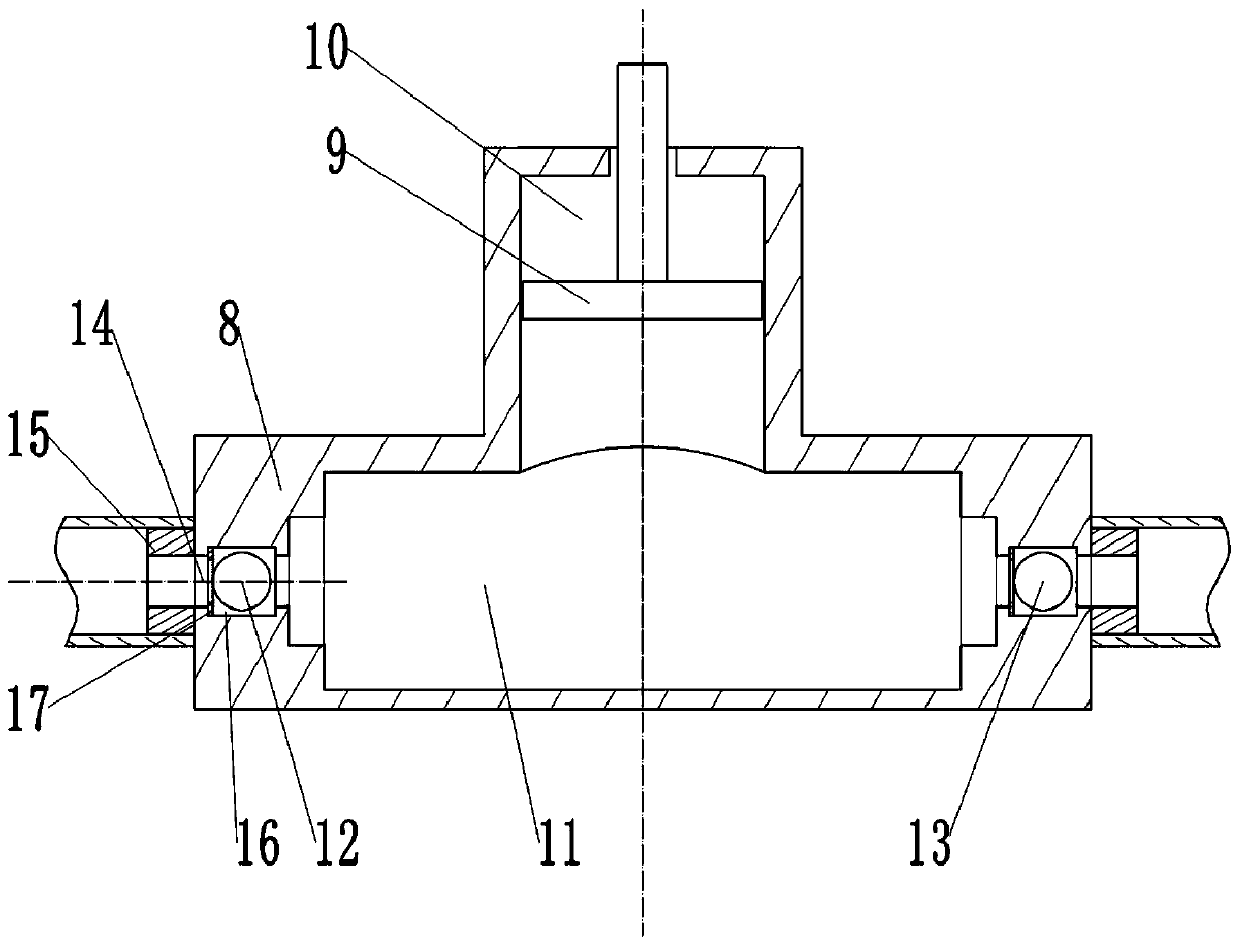

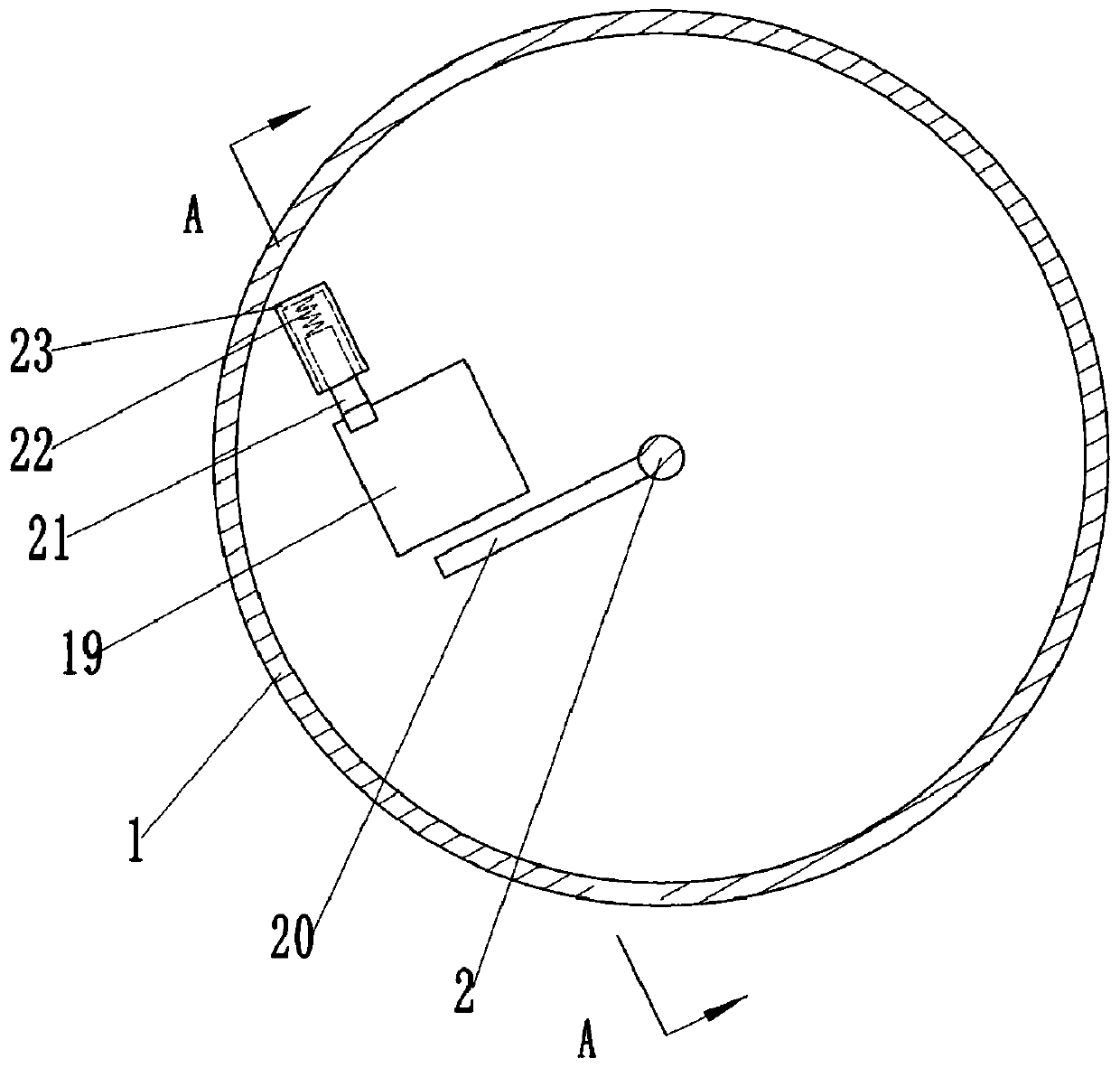

[0032] as attached figure 1 Shown: the raw material storage device for quantitative feeding, including a mixing tank 1 and a frame, the mixing tank 1 is fixed on the frame by bolts; Several stirring blades 3 are connected, three groups of stirring blades 3 are shown as an example in the figure. The mixing tank 1 is fixedly connected with a motor 4 by bolts, and a stepping motor 4 is selected here, and the output shaft of the motor 4 is fixedly clamped with the upper end of the stirring shaft 2 . The right side of the bottom of the mixing tank 1 is provided with a discharge port for discharge.

[0033] There is a pre-storage barrel 5 inside the mixing barrel 1. The longitudinal section of the pre-storage barrel 5 is a truncated cone shape with a large upper part and a smaller bottom. The upper end of the pre-storage barrel 5 is provided with a feeding port 6. Here, two feeding ports 6 are set as an example for illustration. , the two feed ports 6 are respectively connected wi...

Embodiment 2

[0042] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that a scraper 24 for cleaning the inner peripheral wall of the mixing tank 1 is fixedly clamped on the stirring shaft 2, and the end of the scraper 24 away from the stirring shaft 2 is connected to the mixing tank 1. The inner peripheral walls are arc-shaped, and here, there are two scrapers 24 , and the two scrapers 24 are symmetrical to the center of the stirring shaft 2 .

[0043] When using this solution for stirring, the stirring shaft 2 can drive the scraper 24 to rotate together, thereby scraping the raw materials adhered to the inner peripheral wall of the mixing barrel 1 into the stirring barrel 1, so that all the raw materials can be stirred evenly; at the same time, When unloading, the scraper 24 can also be driven to scrape off the raw materials adhered to the mixing tank 1, thereby realizing the purpose of thorough unloading, reducing material waste, and reducing the diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com