Rotary lock and novel U-shaped support assembly thereof

A technology of rotating locks and components, applied in the field of U bracket components, which can solve the problems of large area involved in the stroke, easy to deform, short service life, etc., and achieve the effect of large contact area and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

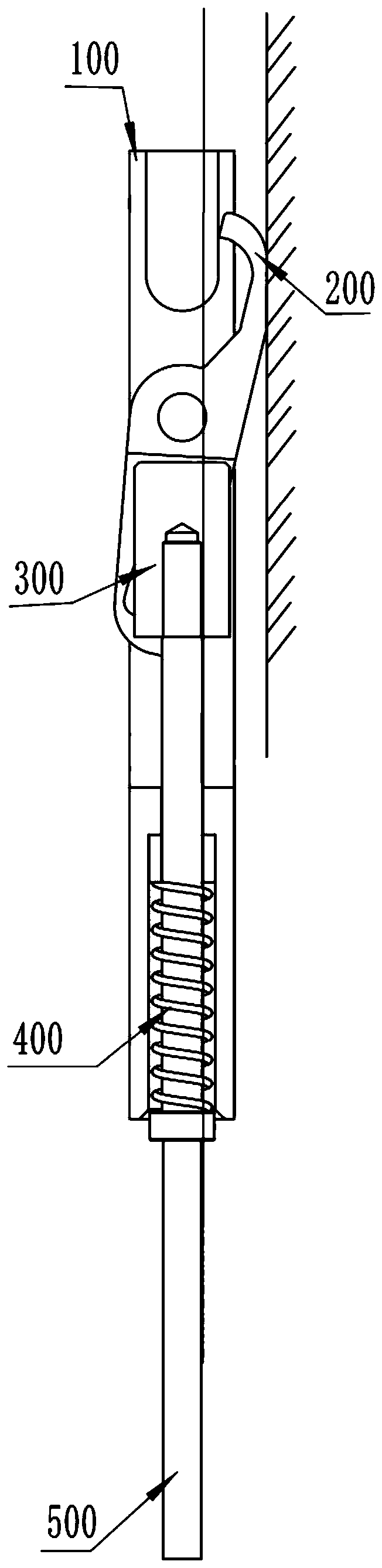

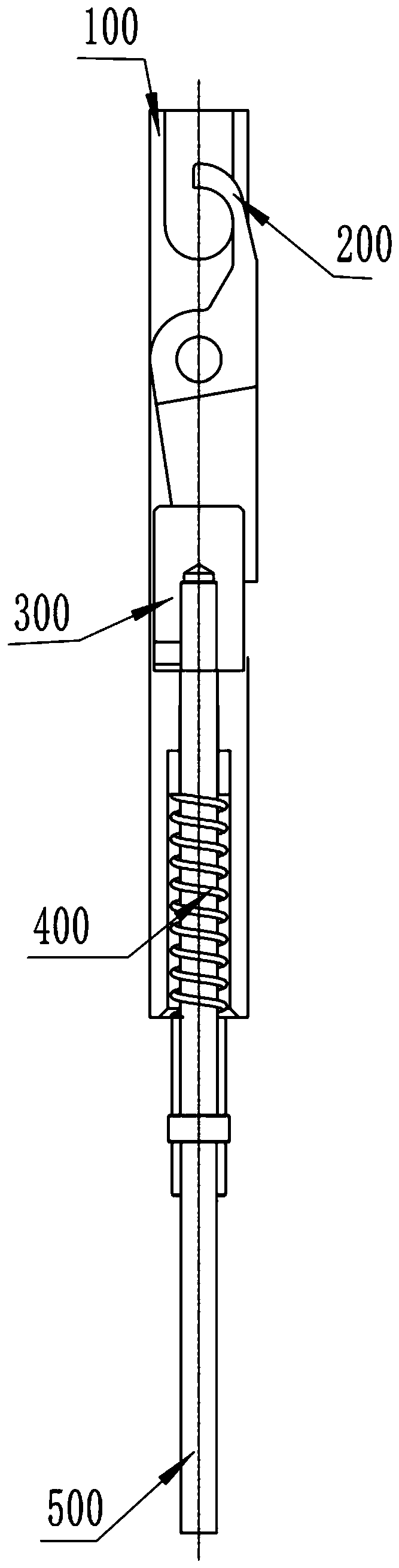

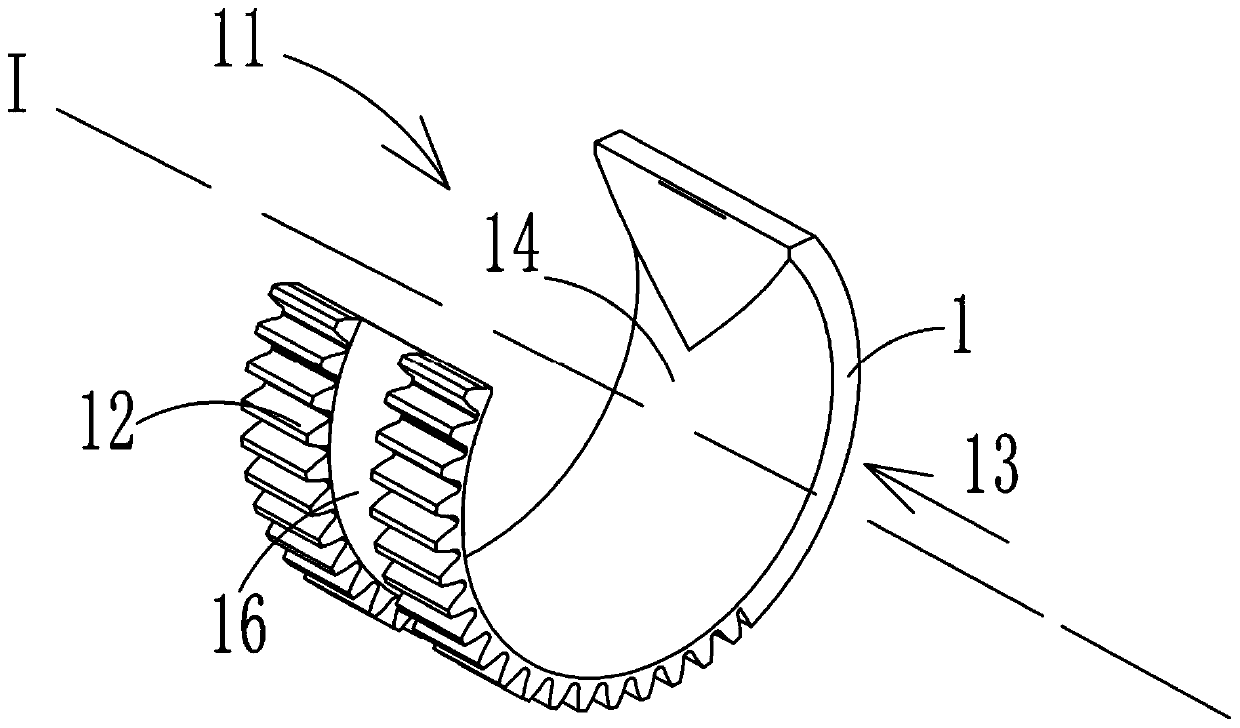

[0031] See Figure 3 to Figure 7 , Figure 3 to Figure 7 Disclosed is a rotary lock, including a rotary lock body 1 with an opening 11 in the radial direction, and a channel 13 for a workpiece 900 to pass through in the axial direction I of the rotary lock body 1, and the opening 11 and the channel 13 In communication, the outer surface of the rotary lock body 1 is provided with teeth 12 . In this embodiment, during specific use, the rotary lock cooperates with the seat (not visible in the figure) that can fix the workpiece, and the rotary lock rotates counterclockwise. When the opening 11 of the rotary lock is facing upward, it is in an open state. After clamping the workpiece 900 in the channel 13 of the rotary lock, drive the rotary lock to rotate clockwise until the opening 11 of the rotary lock rotates to a non-upward state. At this time, the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com