Die-casting forming device for aluminum product

A technology of die-casting and aluminum products, which is applied in the field of aluminum product processing, can solve the problems of inconvenient material removal, etc., and achieve the effect of improving convenience and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

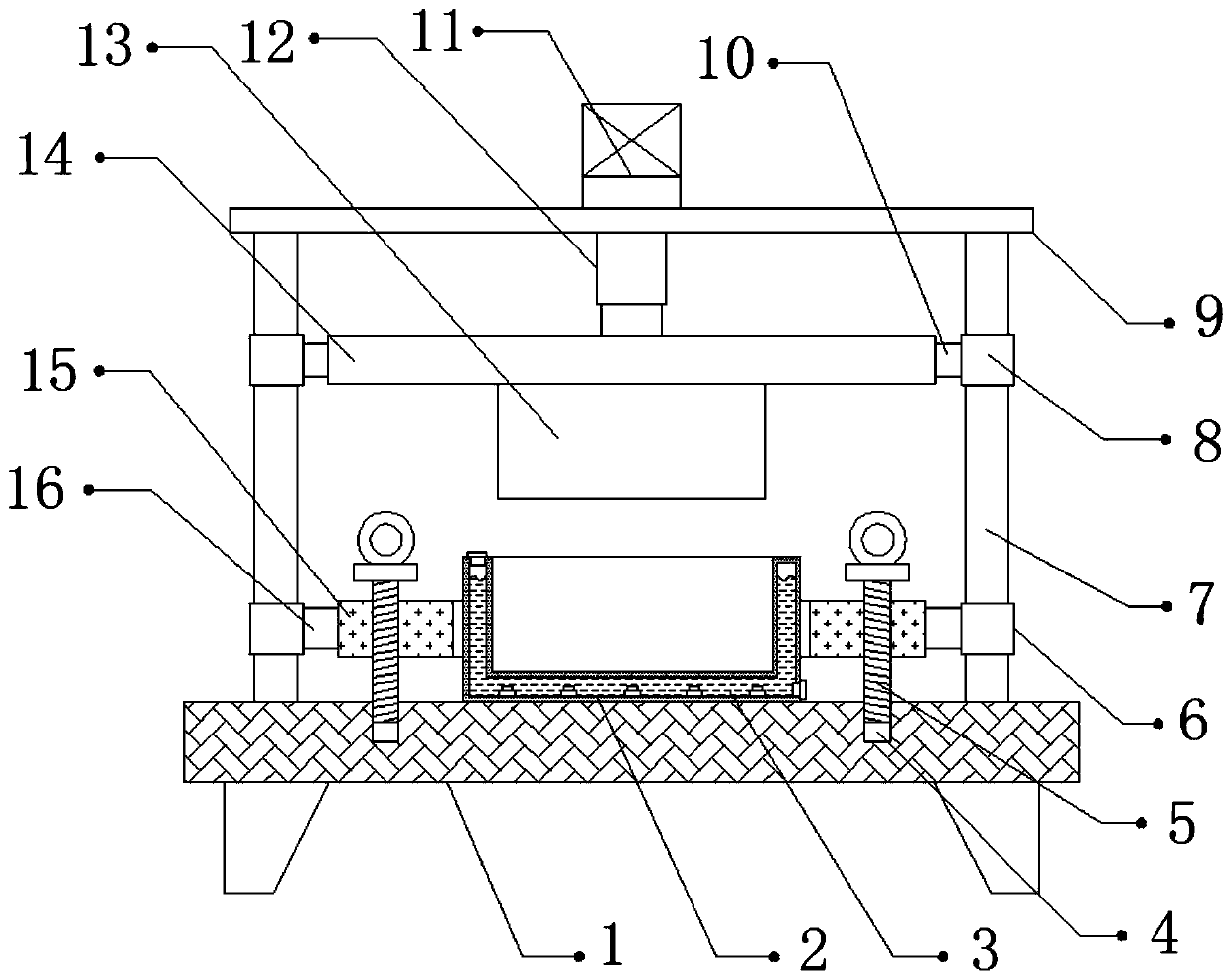

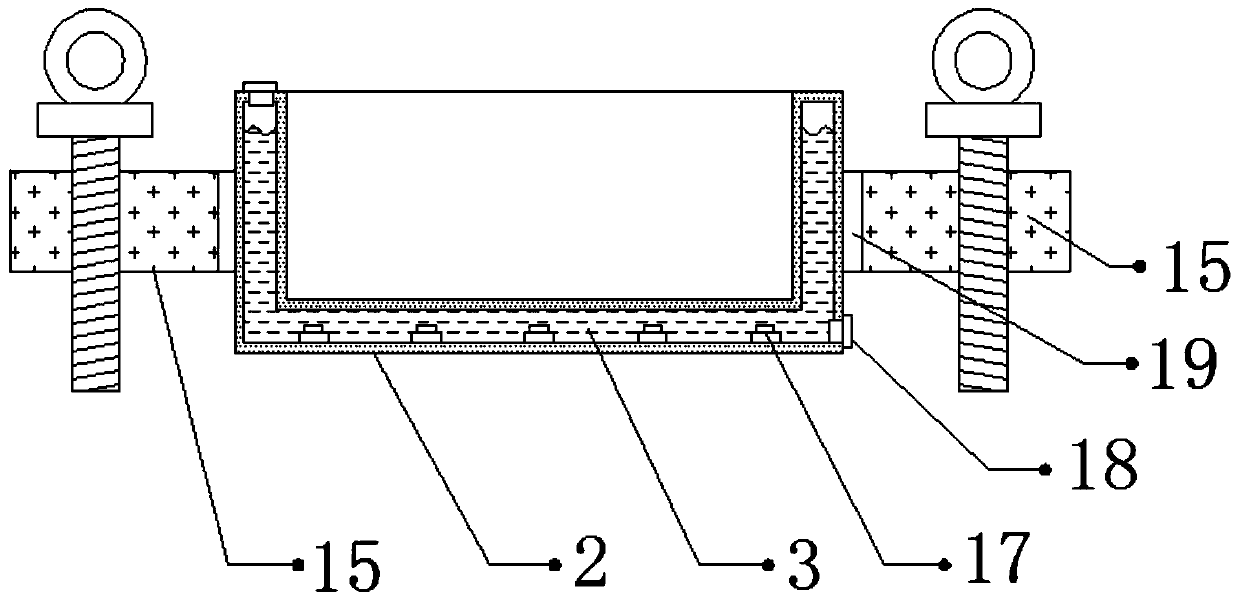

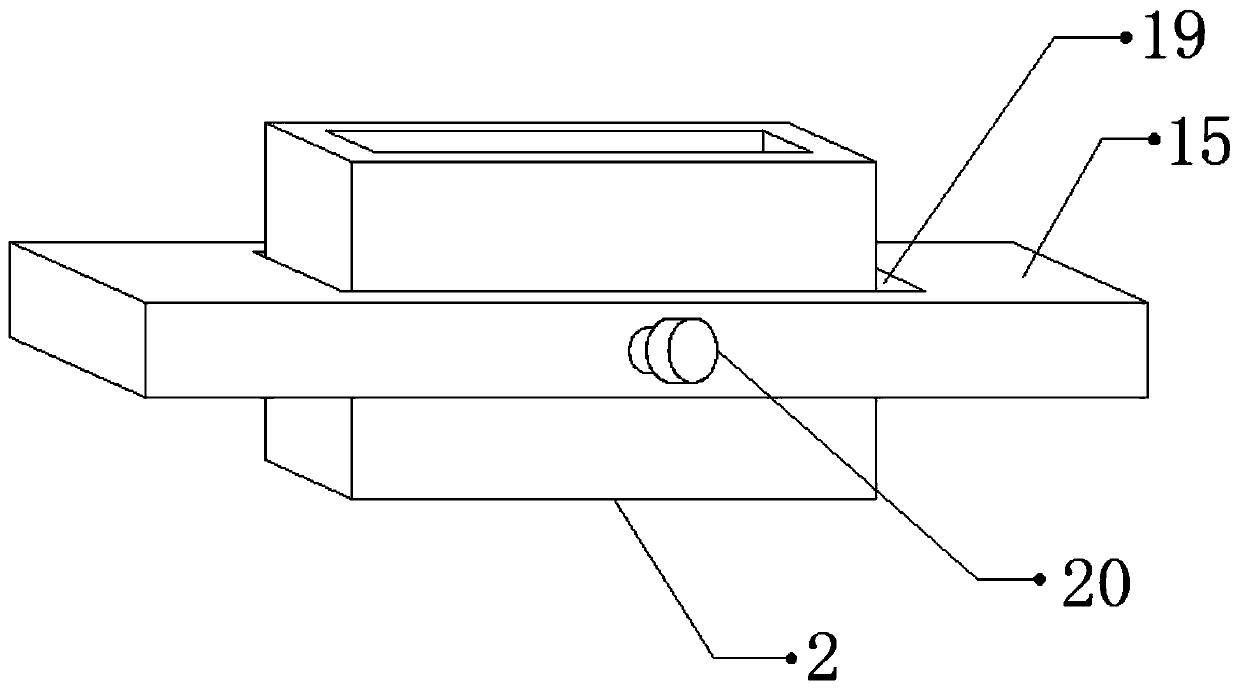

[0029] Reference Figure 1-3 , A die-casting molding device for aluminum products, comprising a fixing base 1. Both sides of the outer wall of the top of the fixing base 1 are connected with fixing columns 7 by bolts, and the outer walls of the two fixing columns 7 are slidably connected with a first sliding sleeve 6, two The outer walls on the opposite side of the first sliding sleeve 6 are all rotatably connected with a rotating shaft 16 through a bearing, and the outer walls on the opposite side of the two rotating shafts 16 are both connected with a fixing plate 15 by bolts, and the top outer wall of the fixing plate 15 is fixed. There is a template 2 inside the fixed port 19, the top outer wall of the template 2 is provided with a mold groove, the top outer walls of the two fixed columns 7 are connected with a support plate 9 by bolts, and the bottom outer wall of the support plate 9 is connected by bolts There is a cylinder 12, the bottom outer wall of the cylinder 12 is c...

Embodiment 2

[0039] Reference Figure 4-5 , A die-casting molding device for aluminum products. Compared with Embodiment 1, this embodiment has a plurality of limiting grooves 22 on the outer wall of the top of the fixing seat 1, and the inner wall of the bottom of the limiting groove 22 is bonded with a cushion 23, a template The bottom outer wall of 2 is provided with a plurality of protrusions 21, and the protrusions 21 are matched with the limiting groove 22.

[0040] Working principle: When in use, the liquid is injected into the mold groove. After the injection is completed, the air pump 11 is started to make the cylinder 12 drive the pressure head 13 downward, so that the pressure head 13 performs die-casting treatment on the liquid, and passes through the second sliding sleeve 8. And the fixed column 7 can guide the downward movement of the indenter 13 to prevent the displacement of the indenter 13 due to shaking during the movement and affect the die casting of aluminum products. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com