Shell assembly and vehicle

A shell assembly and shell technology, applied in vehicle parts, roofs, transportation and packaging, etc., can solve the problems of large occupied space, large power source power, slow folding speed, etc., and achieve small occupied space and power source power. Small, fast folding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

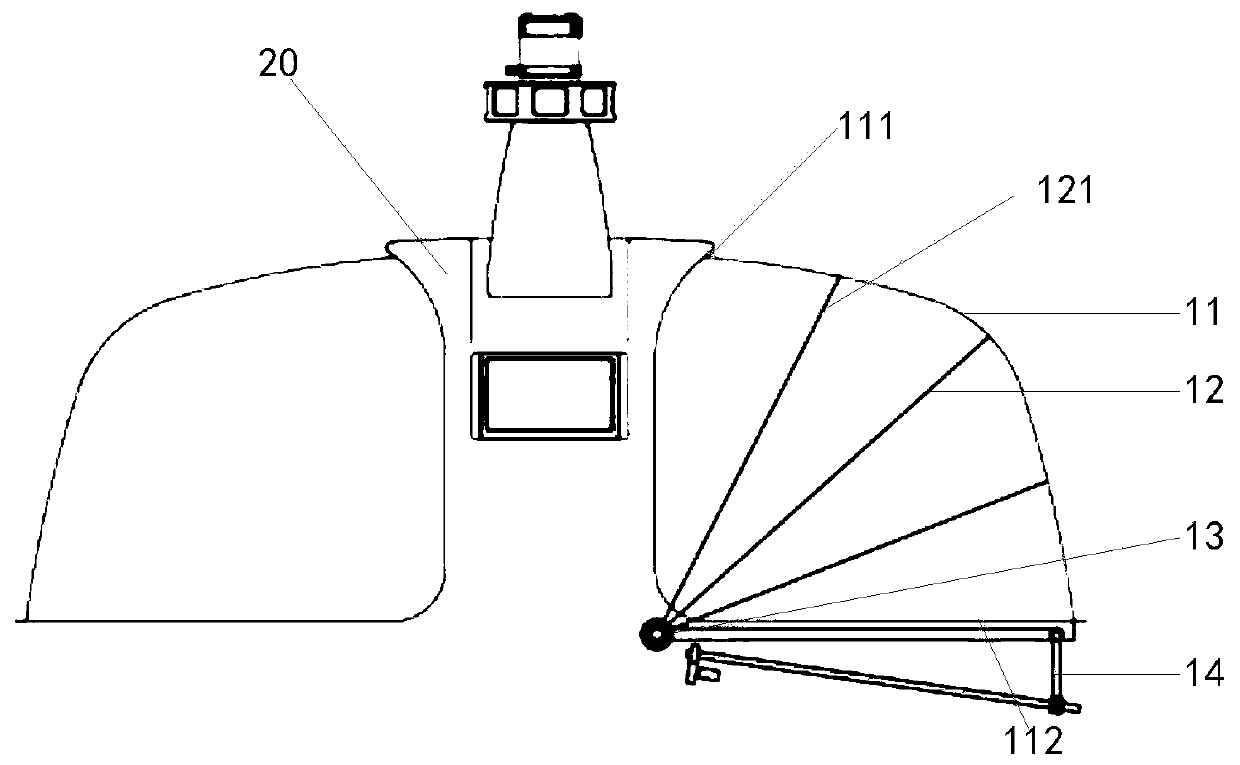

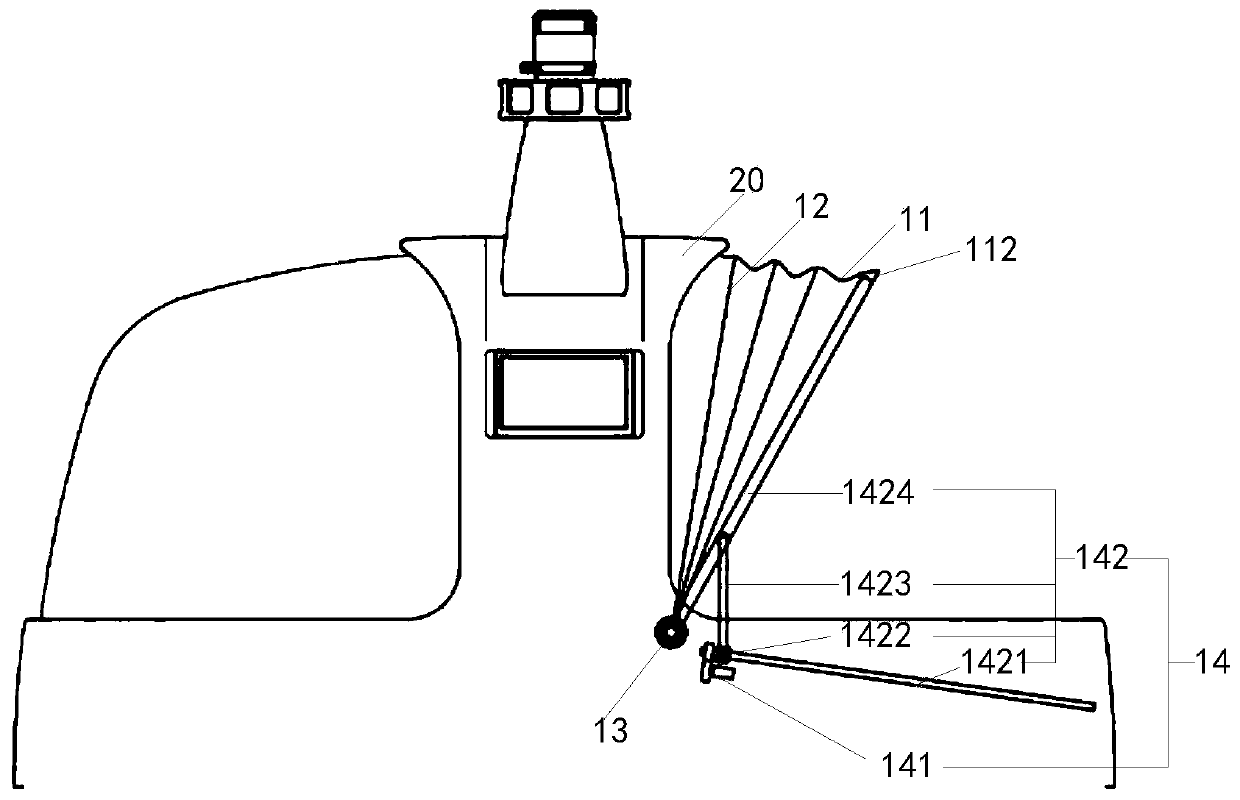

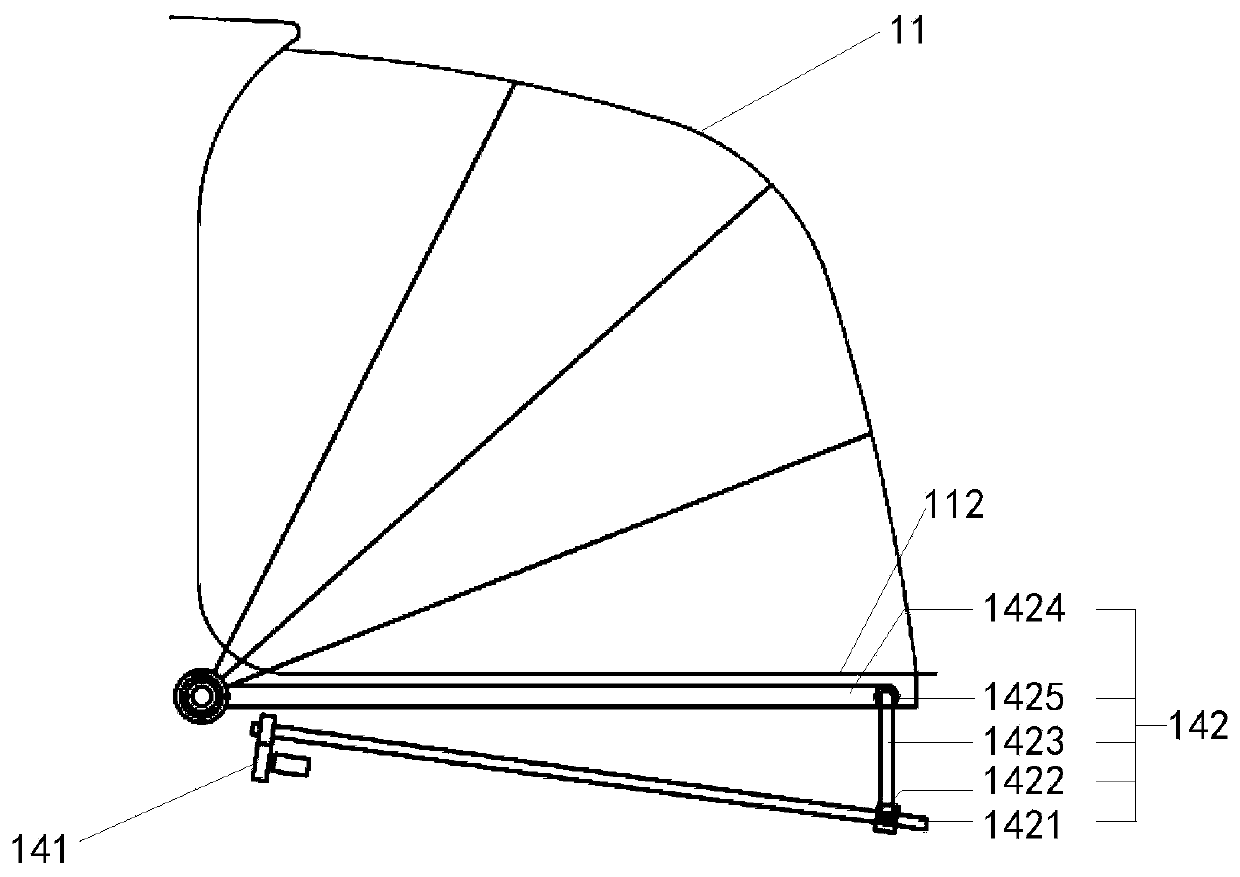

[0022] refer to figure 1 and figure 2 , the embodiment of the present invention provides a shell assembly, which is applied to a vehicle, and the shell assembly includes: a shell 11, a shell lining skeleton 12, a torsion spring 13, a driving mechanism 14, and a buffer pad;

[0023] The housing 11 is a foldable housing. The housing 11 includes a fixed end 111 and a free end 112. The fixed end 111 is provided with the buffer pad. The fixed end 111 is connected to the vehicle body 20 of the vehicle. fixed connection;

[0024] The shell 11 is provided with the shell lining skeleton 12 on the side facing the inside of the vehicle body 20, and the shell lining skeleton 12 is connected with the shell 11;

[0025] The casing lining skeleton 12 includes a plurality of lining ribs 121, and one end of the plurality of lining ribs 121 is jointly hinged;

[0026] One end of the torsion spring 13 is fixedly connected to the body 20 of the vehicle, and the other end of the torsion spring...

Embodiment 2

[0061] refer to Figure 4 , an embodiment of the present invention provides a vehicle, and the vehicle includes the casing assembly described in Embodiment 1.

[0062] Specifically, as Figure 4 As shown, a vehicle provided in the embodiment of the present invention includes the shell assembly of the first embodiment. The shell assembly is connected with the body of the vehicle. In the process of logistics transportation, the vehicle mainly plays the role of delivering goods. When the staff or users access the goods, the shell assembly can realize automatic opening and closing, making the access to the goods more convenient. In order to be convenient and reliable, and the mass of the casing is small, the delivery efficiency of the vehicle can be improved. Of course, those skilled in the art can set parameters such as the connection mode between the vehicle and the shell assembly, the type and size of the vehicle according to actual needs. It can be understood that the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com