Device and method for measuring air leakage rate of power station boiler air pre-heater under medium and low loads

An air preheater and low-load technology, which can solve the problems of increasing test errors by measuring the rate of increase and deceleration of the fluid, by detecting the appearance of the fluid at the leak point, and using the liquid/vacuum degree for liquid tightness measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] In order to make the objectives, technical solutions, and advantages of the present invention clearer and more comprehensible, the following further describes the present invention in detail in conjunction with embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0111] 1. Establish a testing platform.

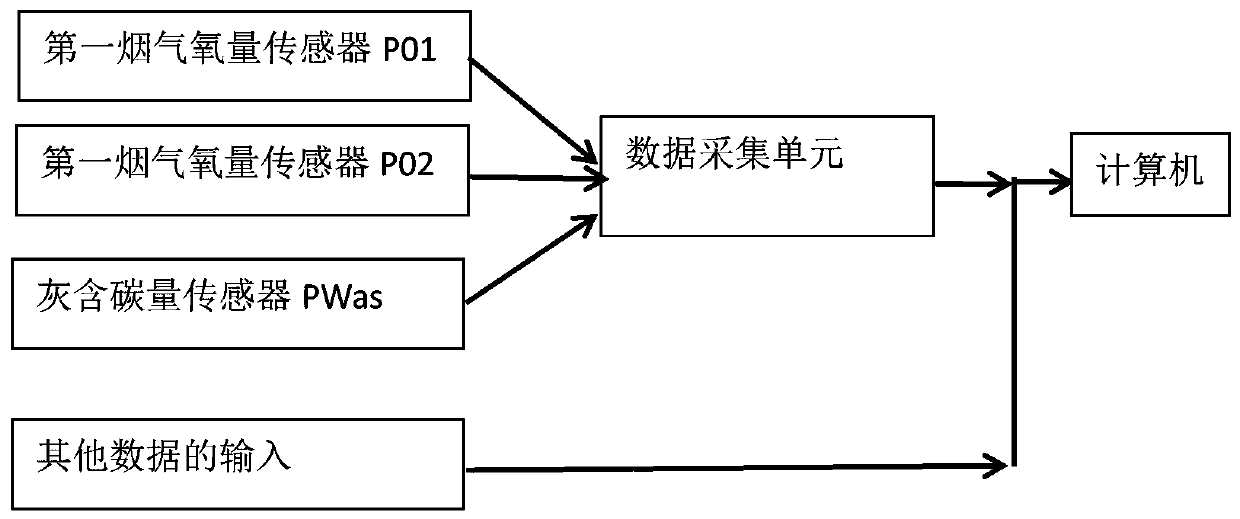

[0112] The detection platform includes a first flue gas oxygen content sensor PO1 installed at the inlet of the air preheater, a second flue gas oxygen content sensor PO2 installed at the outlet of the air preheater, and carbon content in fly ash installed at the outlet of the air preheater The output terminals of the first flue gas oxygen content sensor PO1, the second flue gas oxygen content sensor PO2, and the fly ash carbon content PWas are respectively connected to the data collection unit The corresponding input port of the data acquisition unit; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com