Grid structure with lockable edges

A grid and edge locking technology, applied in the field of lockable grid structure, can solve the problems of poor edge locking effect and uneven heating of the grid locking edge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

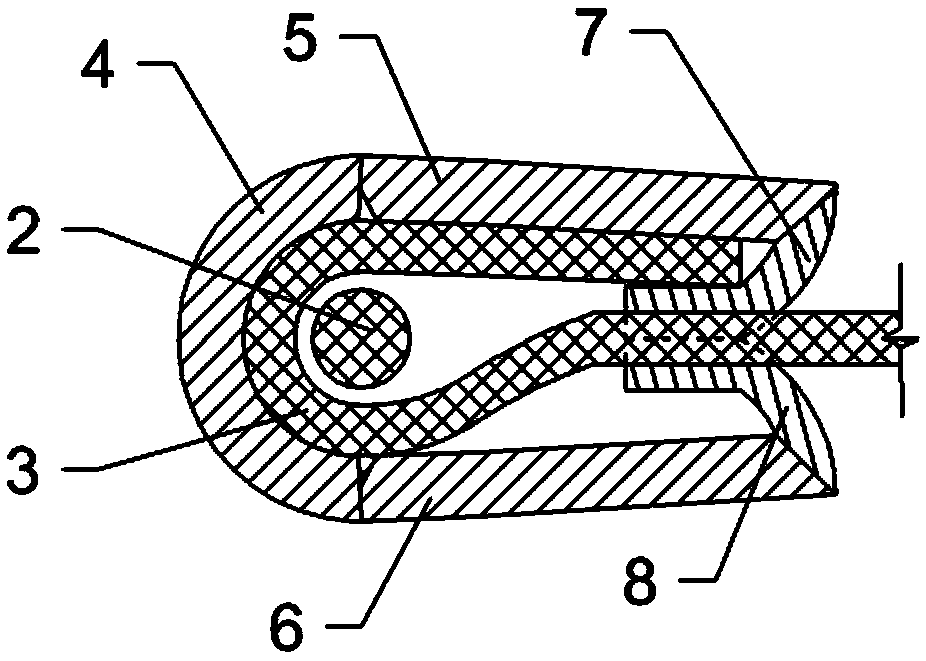

[0017] The reference signs in the accompanying drawings of the specification include: card strip 1, warp thread 2, weft thread 3, vertical plate 4, first side plate 5, second side plate 6, first baffle plate 7, first card slot 71, second The baffle plate 8 and the second card slot 81 .

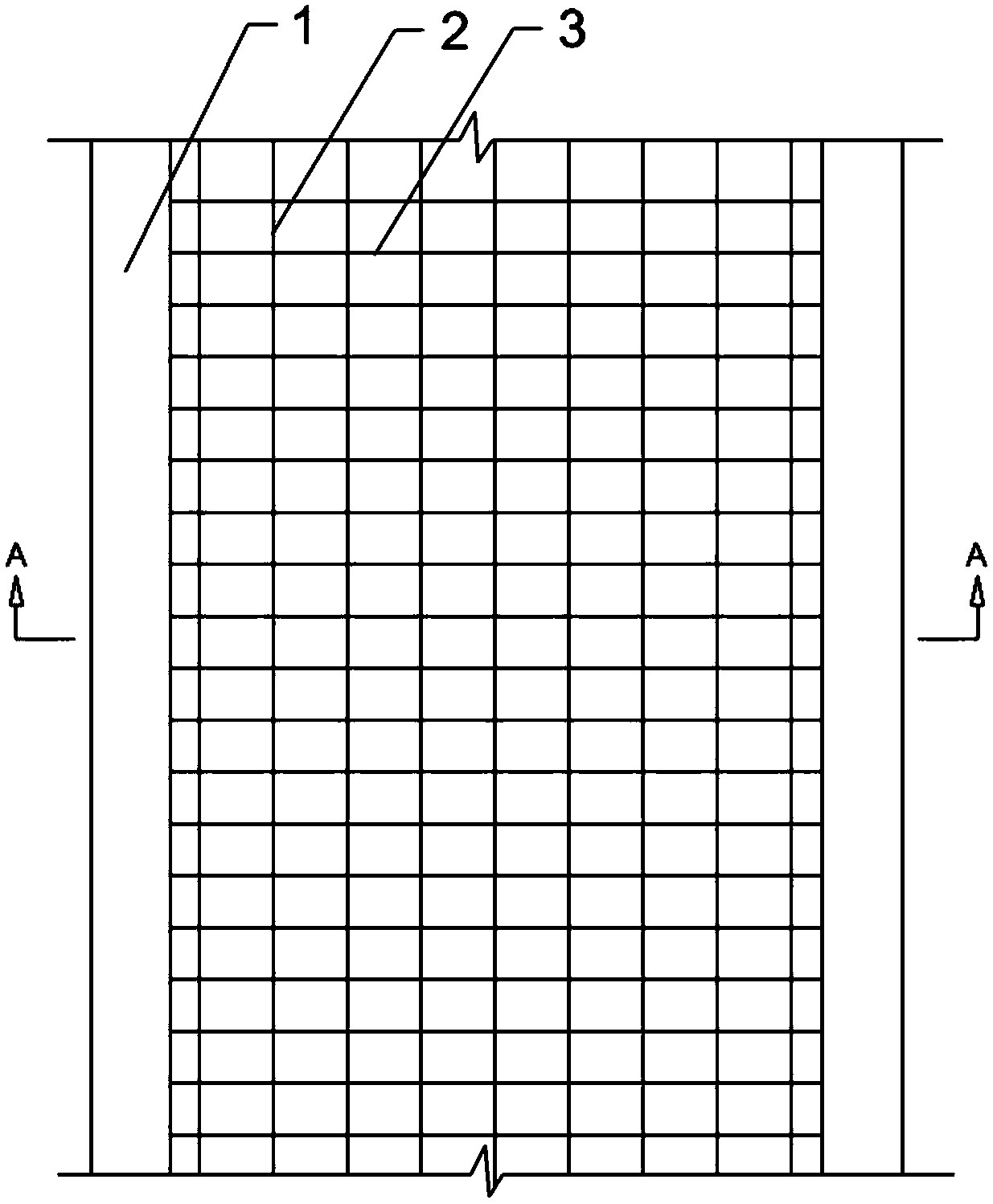

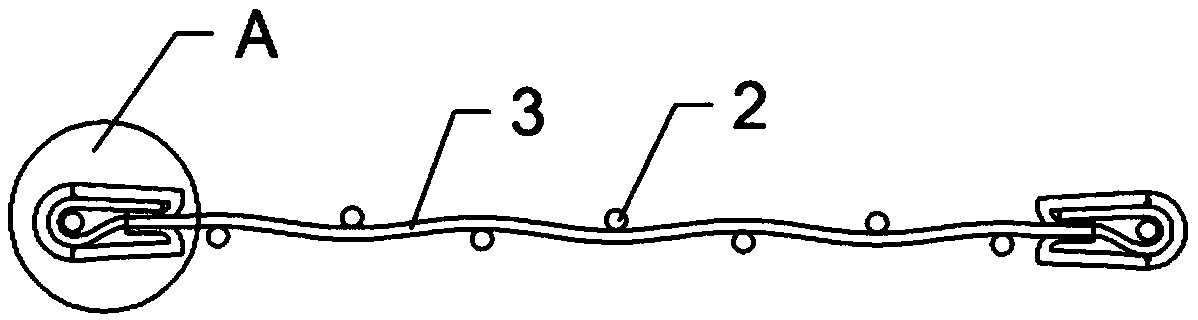

[0018] The embodiment is basically as attached figure 1 , figure 2 and image 3 Shown: the edge-lockable grid structure, including the grid body, the grid body includes the warp 2 and the weft 3, and the warp 2 and the weft 3 are woven in a cross pattern. The edge of the grid body is provided with clamping strips 1 , and the clamping strips 1 are arranged along a direction parallel to the meridian 2 . The clip 1 includes a first side plate 5, a second side plate 6 and a vertical plate 4, the first side plate 5 and the second side plate 6 are integrally formed with the vertical plate 4, the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com