An emergency monitoring and processing device for electrical primary equipment defects

A technology for primary equipment and emergency monitoring, applied in TV, mechanical equipment, color TV, etc., can solve the problems of abnormal heat, short battery power supply time, fused joints, etc., to slow down metal oxidation, realize wireless power supply, and solve security problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

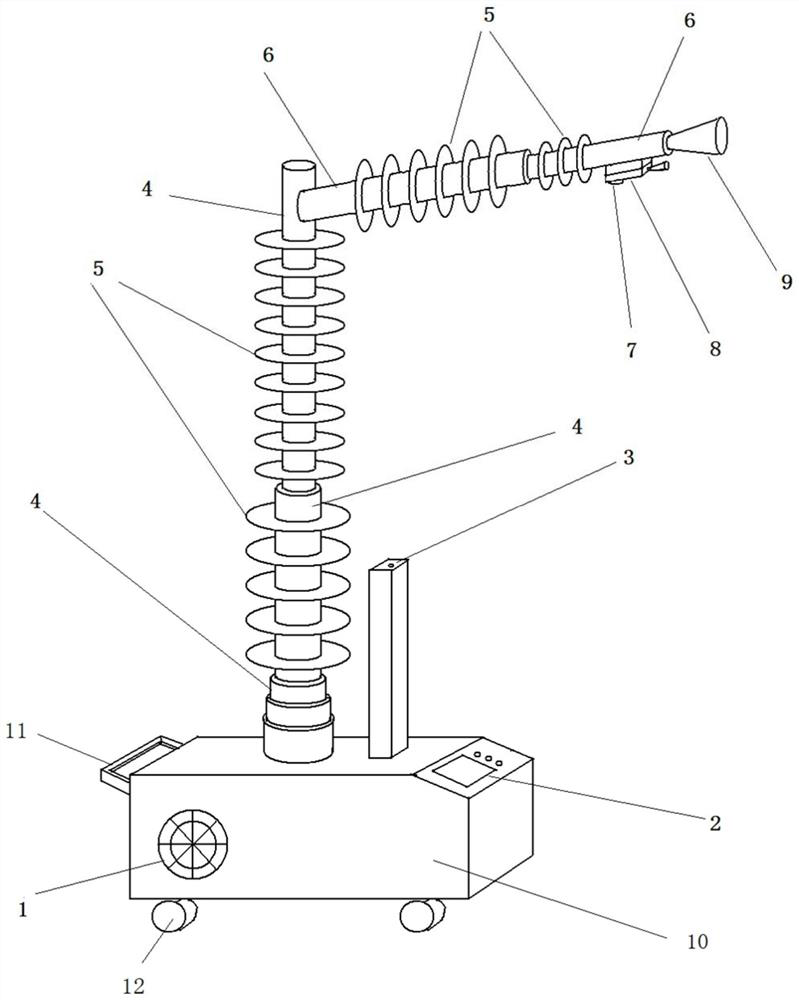

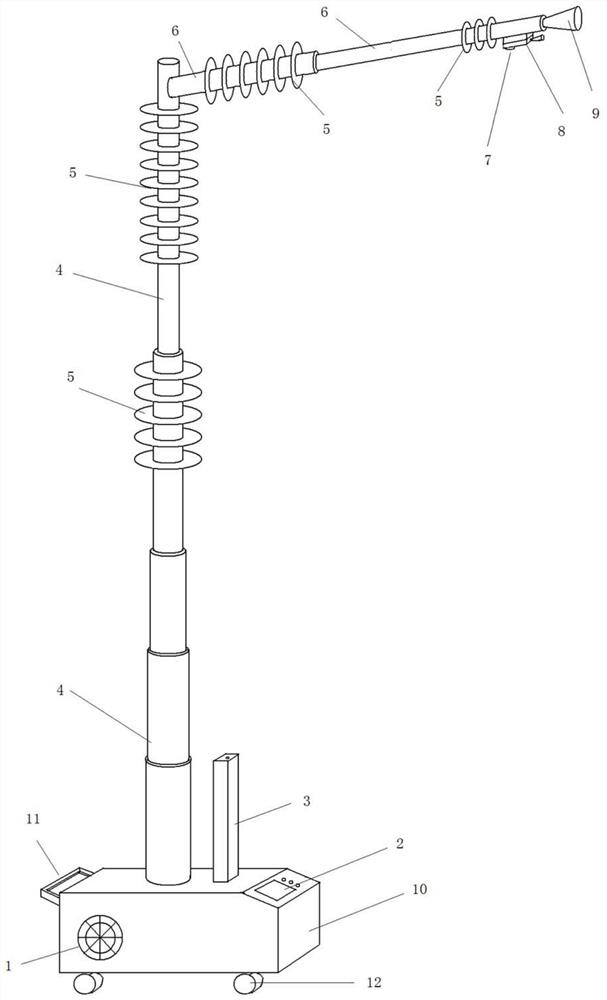

[0024] like figure 1 As shown, the present invention relates to an emergency monitoring and processing device for defects in electric primary equipment, including a trolley base 10, a longitudinal insulating telescopic rod 4, a centrifugal fan 1, a ground image display system 2, a laser power supply and communication module 3, and an insulating shed 5 , a transverse insulating telescopic rod 6, a laser power receiving and communication module 7, a dual image capturing module 8 and an air nozzle 9.

[0025] The trolley base 10 is provided with a trolley handle 11 and rollers 12 . The ground image display system 2 and the laser power supply and communication module 3 are arranged on the upper surface of the cart base 10 . The centrifugal fan 1 is arranged on the cart base 10 , and the insulating telescopic rod 4 is a hollow cylindrical rod structure with one end closed, and its bottom is fixed on the cart base 10 . The impeller of the centrifugal fan 1 is exposed from the oute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap