Multistage control algorithm for optimizing dynamic characteristics of high-voltage wide-range X-ray power source

A technology of dynamic characteristics and control algorithm, applied in the direction of X-ray equipment, electrical components, etc., can solve the problems of no control optimization, difficult PI algorithm, no segmentation, etc. in the rising edge process, and achieve fast rising control with high precision and achieve rising edge. Control, the effect of fast rising edge control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

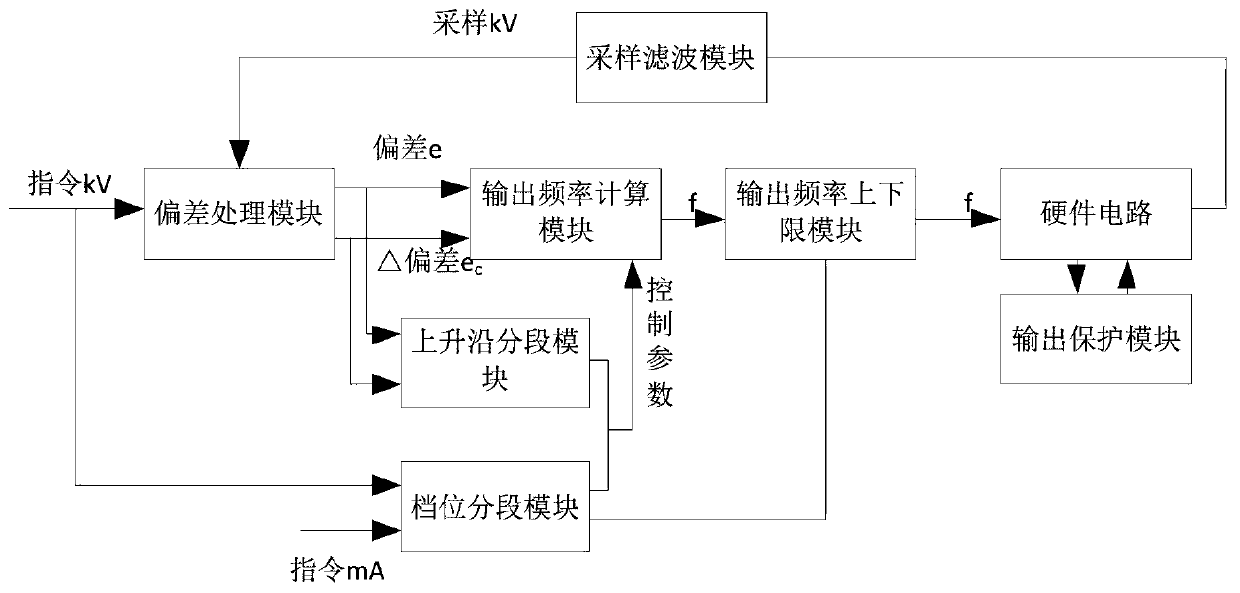

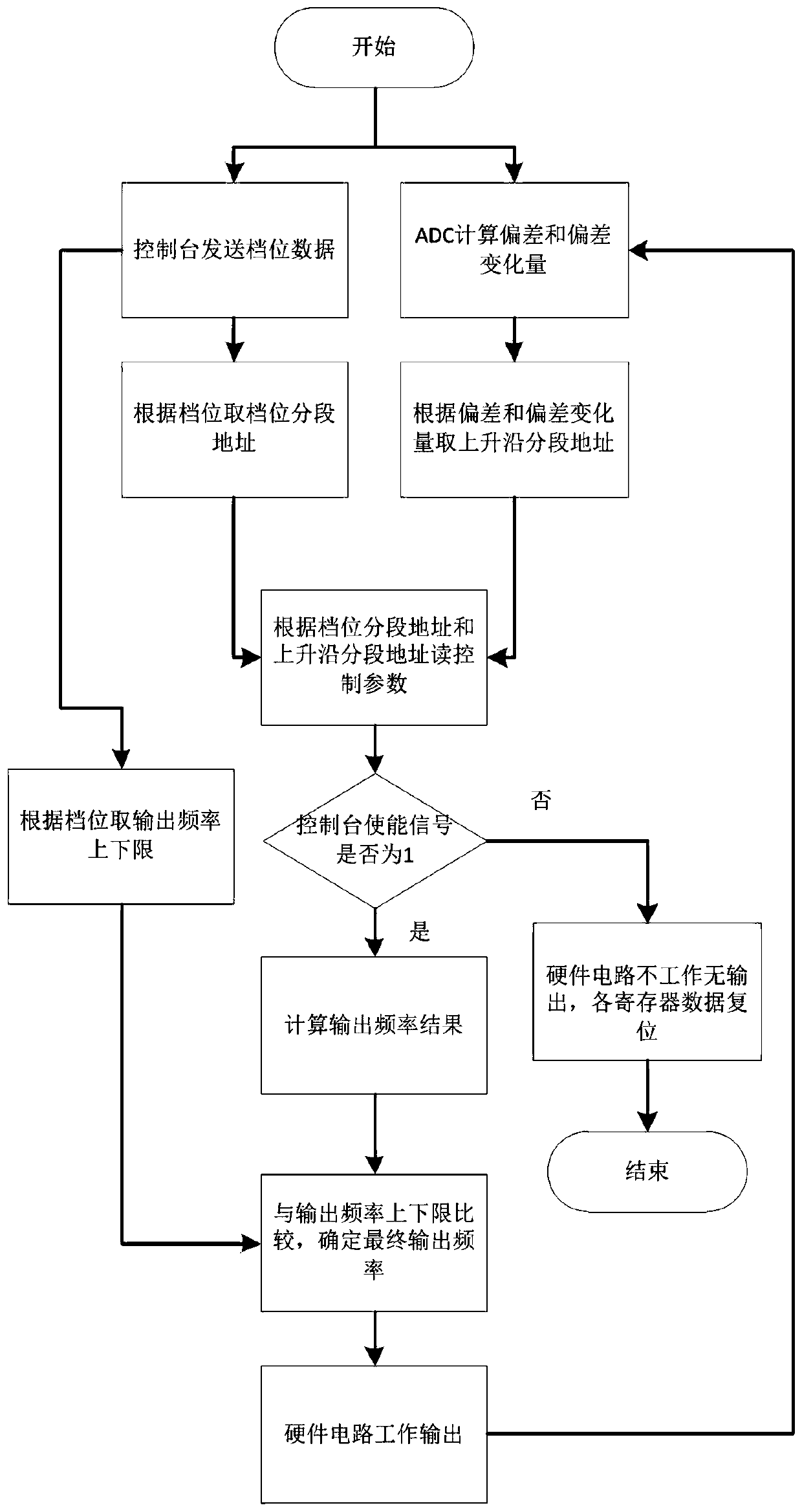

[0059] Such as figure 2 Shown, the concrete implementation process of control algorithm of the present invention is as follows:

[0060] Step 1: The console sends the corresponding voltage output (hereinafter referred to as kV) and current output (hereinafter referred to as mA) of the gear to be output to the high voltage power supply controller.

[0061] Step 2: The high-voltage power supply controller judges the gear segment it is in according to the required output gear, and obtains the Gear address corresponding to the gear segment from the multi-segment control parameter address library.

[0062] Step 3: The high-voltage power supply controller judges the gear segment it is in according to the required output gear, and obtains the upper limit and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com