Casing base aluminum alloy profile

A technology for aluminum alloy profiles and aluminum alloy materials, which is applied to the field of aluminum alloy profiles for the chassis base, can solve the problems that the installation position cannot be adjusted flexibly, the production process of cold-formed profiles is complicated, and the production technology and precision requirements are high, so as to achieve environmental protection, Low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

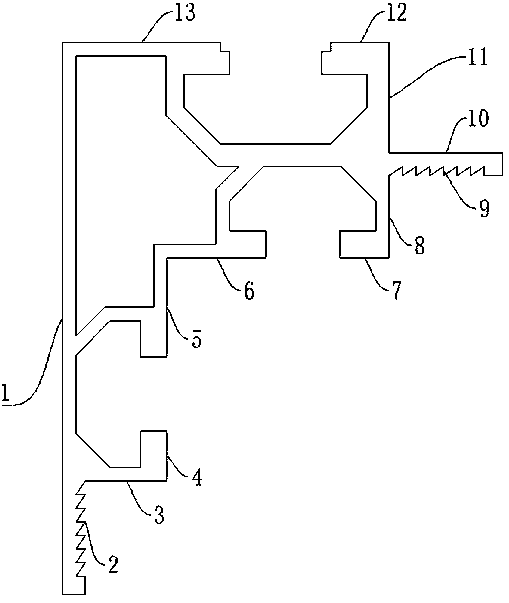

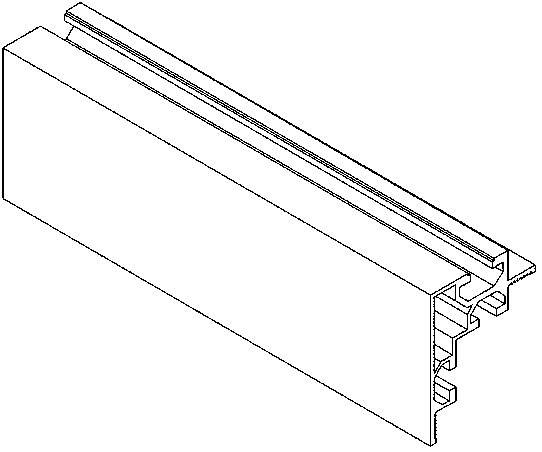

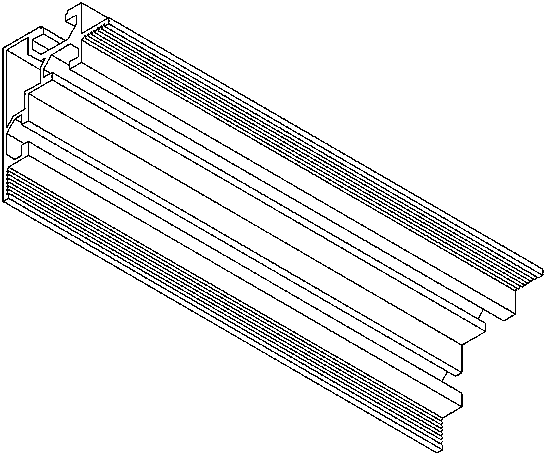

[0031] like figure 1 Shown is an aluminum alloy profile for the chassis base. An aluminum alloy profile for the chassis base is an aluminum alloy profile with an irregular cross-sectional shape and trapezoidal grooves and broken bridges extruded from an aluminum alloy material, including the display surface, the first Fold surface, first baffle surface, first broken bridge surface, second broken bridge surface, third broken bridge surface, fourth broken bridge surface, second baffle surface, second fold surface, bottom surface, step surface, first broken bridge surface The five broken bridge decks, the sixth broken bridge deck, the first broken bridge deck and the second broken bridge deck are on the same plane and form the first broken bridge opening, the first broken bridge opening is the first trapezoidal groove inward, the third broken bridge The bridge deck and the fourth broken bridge deck are on the same plane and form the second broken bridge opening, the second broken...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap