System and method for acoustic container volume calibration

A technology for containers and acoustic devices, used in volume measurement instruments/methods, container/cavity volume measurement, volume measurement testing/calibration, etc., to solve problems such as tank volume errors, few tank calibrations, loss of sales revenue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

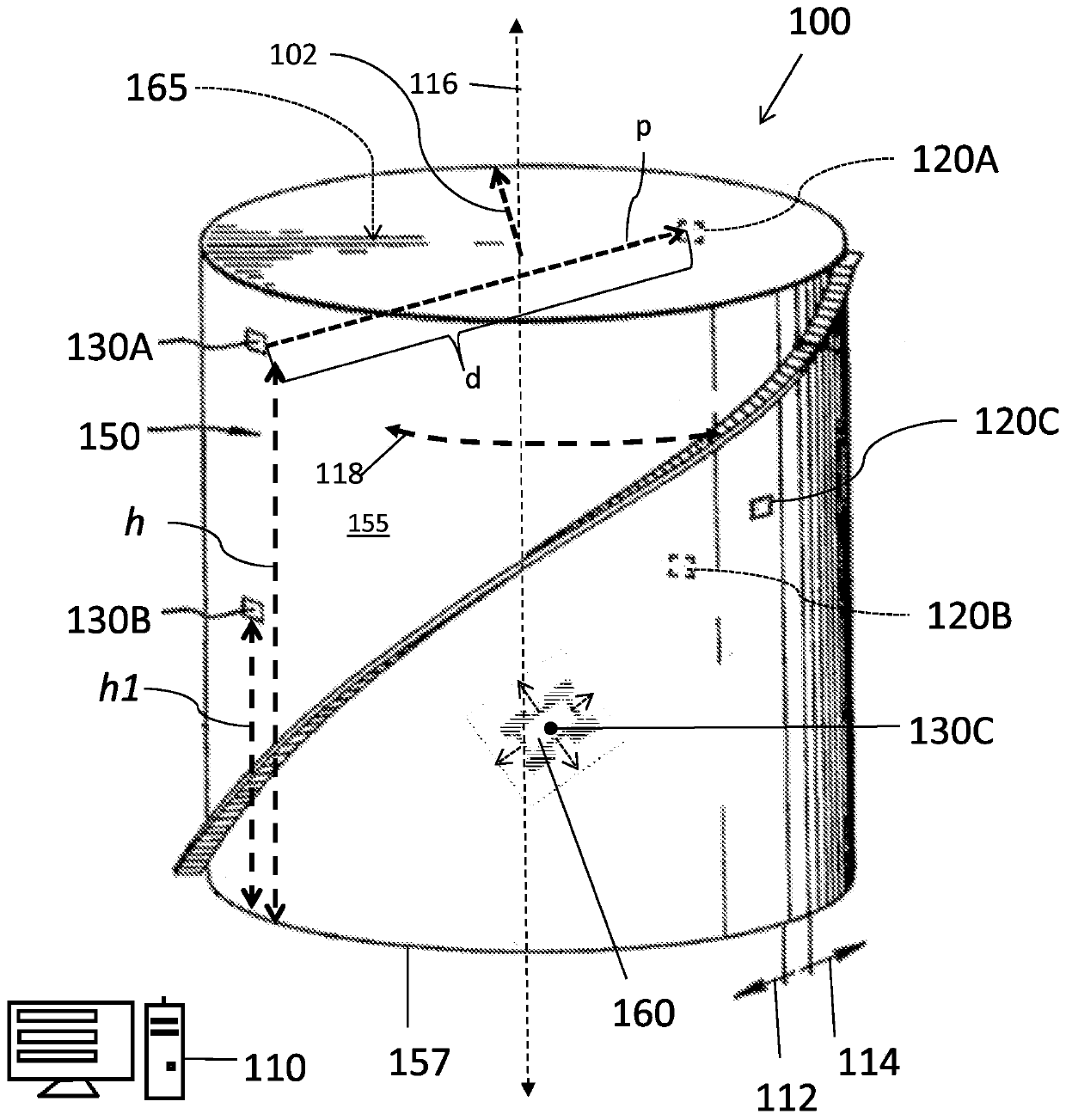

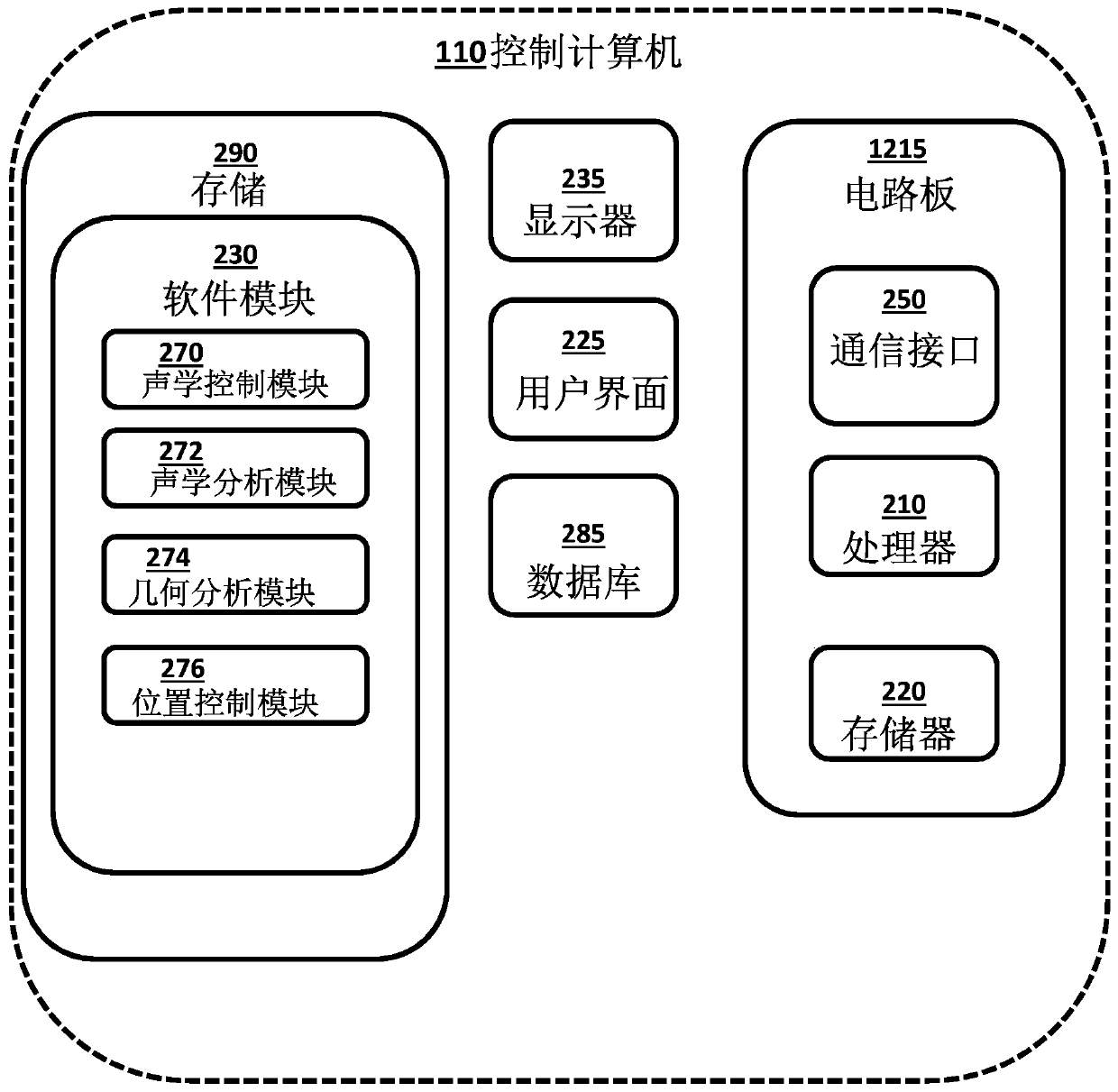

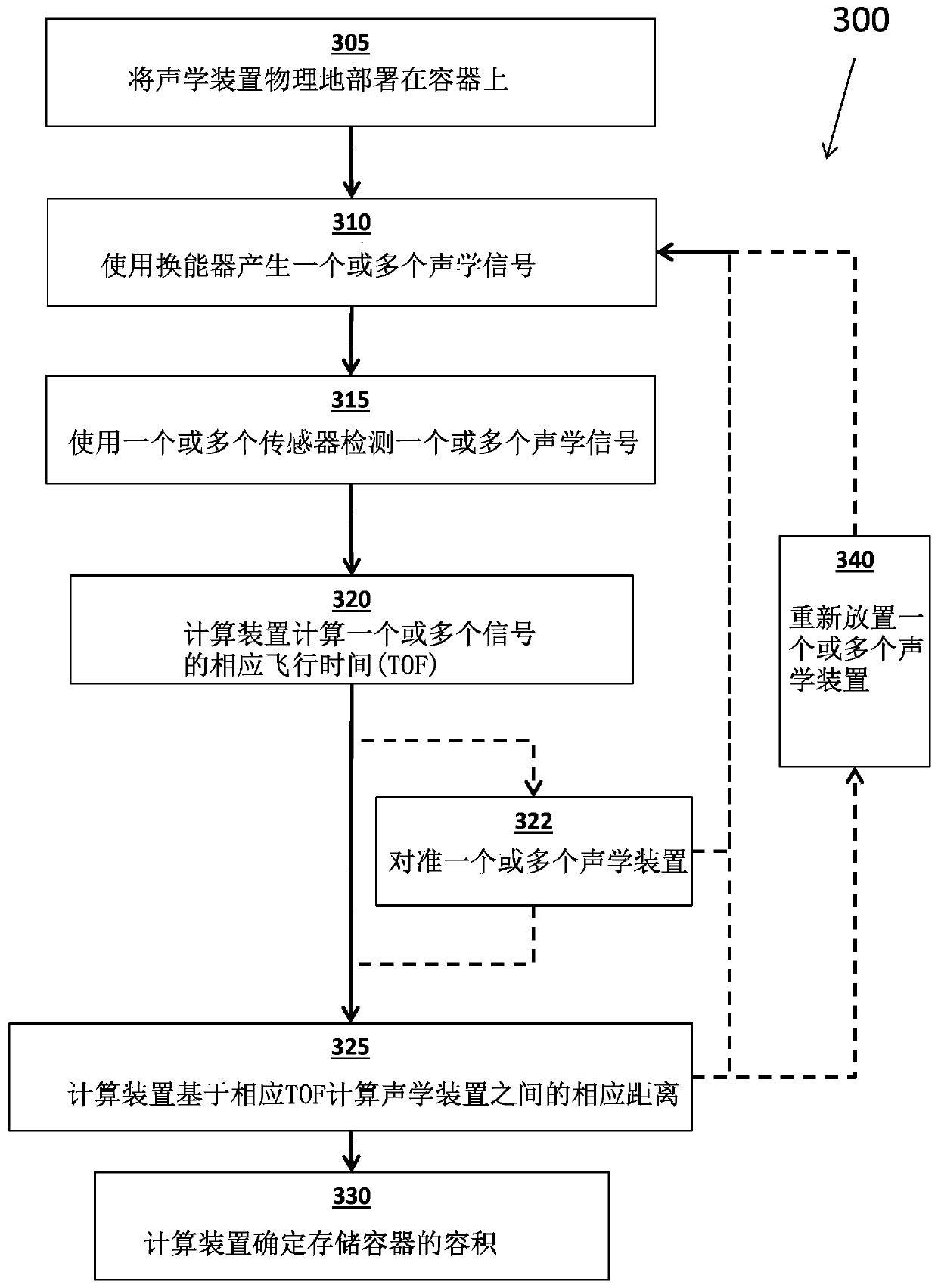

[0024] By way of overview and introduction, a system and method for calibrating the volume of a storage container is disclosed. More specifically, the systems and methods disclosed herein relate to measuring and dimensioning large petroleum storage tanks using ultrasonic inspection techniques to calculate the volume of such tanks. Preferably, the system is configured to perform calibration from outside the container as needed during use of the container in the field. "Calibration", ie knowing the exact volume of the storage container, plays a vital role when transferring product to and / or from said tank. Routine calibrations are necessary due to changes in external and internal conditions (eg temperature), aging of the tank and also due to the weight of the liquid product (eg hydrostatic pressure). For example, considering a storage capacity of 250,000 barrels, the volume of the container can vary by + / - 0.2%, which would result in a volume change of + / - 500 barrels.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com