Winding arrangement, method for producing winding arrangement and electric machine

A winding and multi-phase motor technology, applied in the field of manufacturing such winding devices and motors, can solve problems such as the negative impact of smooth motor operation, ohmic loss, and the negative impact of overall efficiency, to reduce ohmic losses, low material costs, and reduce longitudinal extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

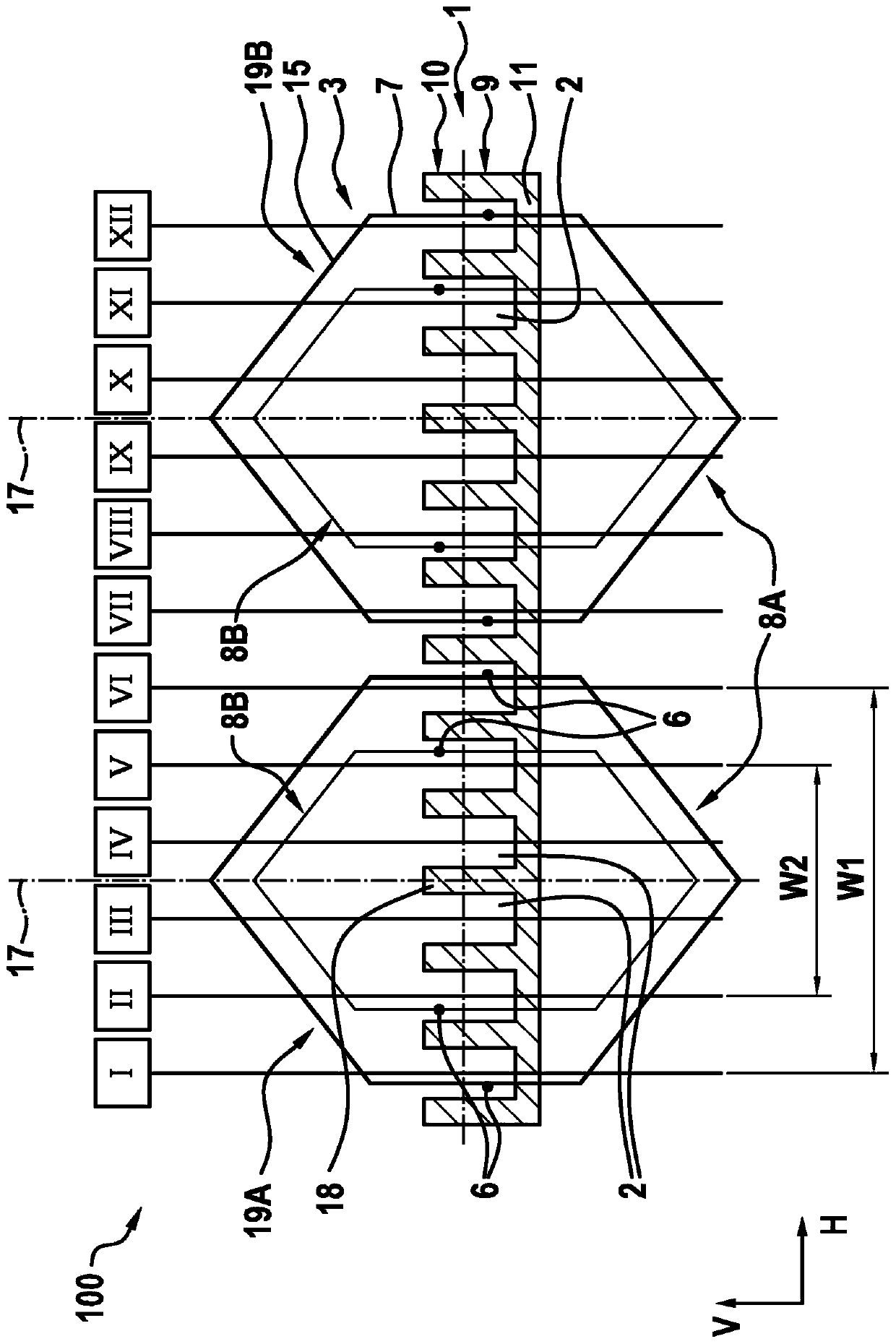

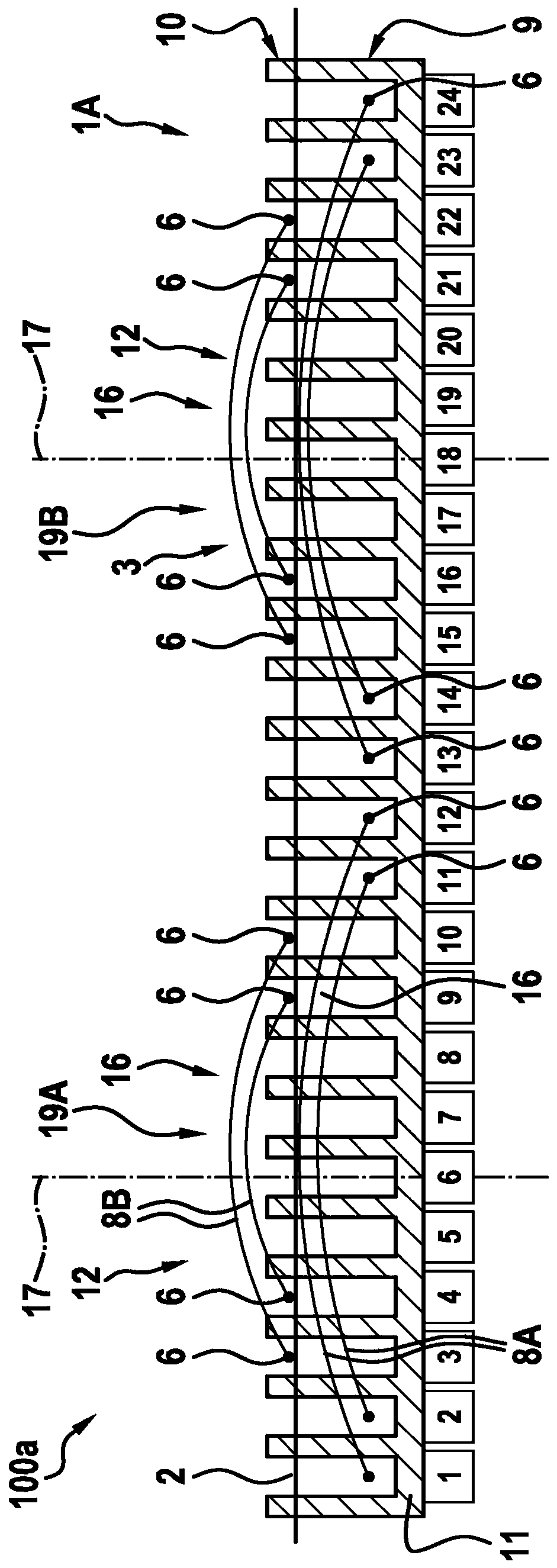

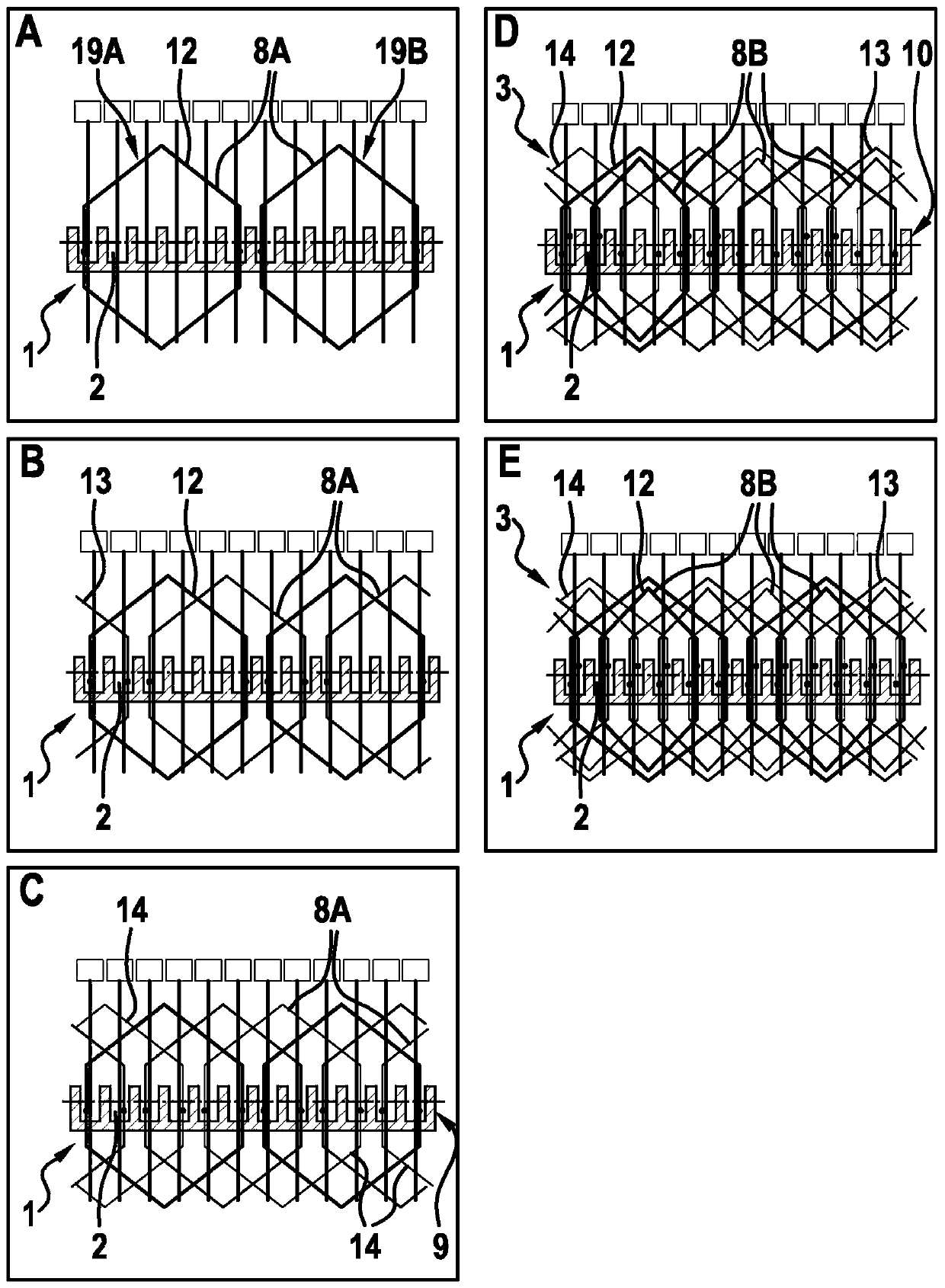

[0021] figure 1 A winding arrangement 3 according to the invention of a stator 1 of an electrical machine 100 having twelve stator slots 2 is shown (not otherwise shown). In order to illustrate the winding arrangement 3 , the stator 1 and the coils 8A, 8B arranged in the stator slots 2 are shown in a horizontal plane 11 in a representation expanded in the circumferential direction. The stator slots 2 arranged next to each other along the horizontal plane 11 are numbered from left to right in the illustration by unfolding, the first stator slot 2 being assigned the Roman numeral I in the figure, the last stator arranged on the far right Slot 2 has Roman numeral XII in the figure. To form the winding arrangement 3 , the coil sides 6 of the coils 8A, 8B formed from the coil wires 7 are inserted into the stator slot 2 in such a way that the two coil sides 6 of the coils 8A, 8B are either formed as a lower layer 9 deep in the stator slot 2 , or construct an upper layer 10 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com