Adaptive installing device of sleeve

An installation device and self-adaptive technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, and achieve the effect of low scrap rate, high work efficiency, self-adaptive pre-positioning and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

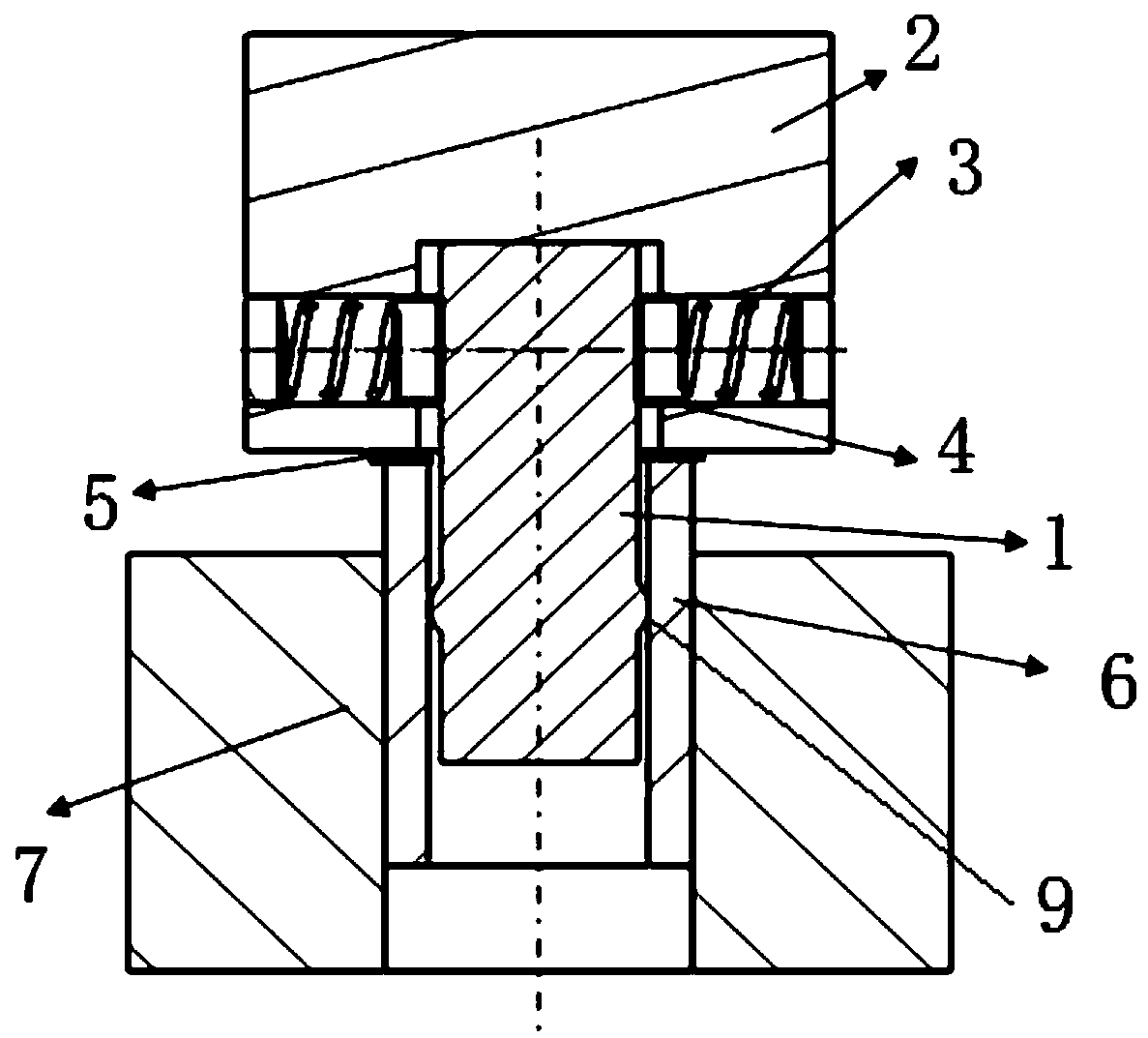

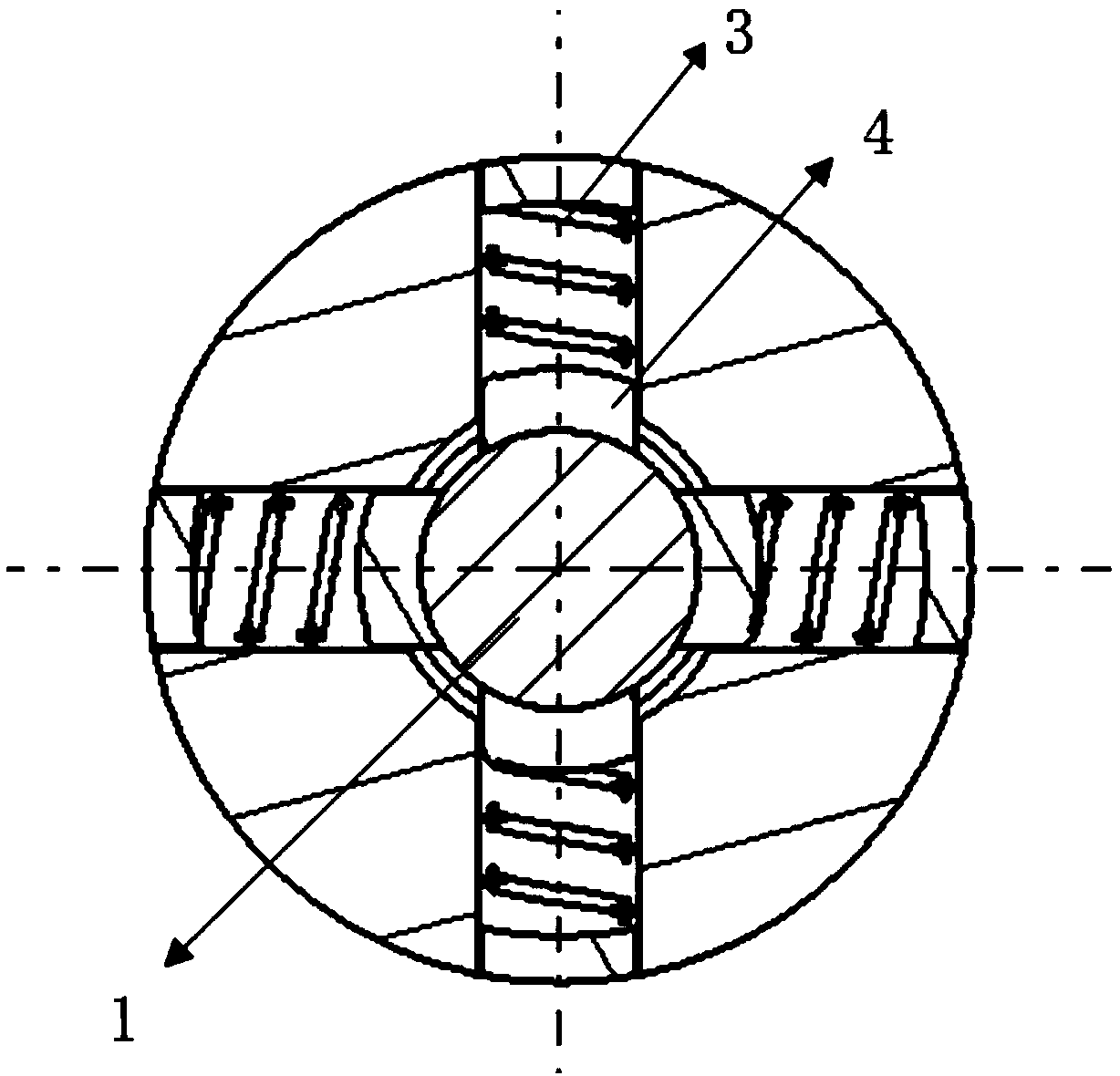

[0020] A kind of adaptive sleeve 6 installation device, its structure is as figure 1 , 2 As shown, it includes a sleeve installation head 1 inserted inside the sleeve 6, a support block 2 arranged on the top of the sleeve installation head 1, and an adaptive self-adaptive device arranged inside the support block 2 for adjusting the position of the sleeve installation head 1. Adjustment unit, when installing, insert the bottom of the sleeve installation head 1 into the inside of the sleeve 6, press down on the top of the support block 2, the support block 2 moves down until it contacts the top of the sleeve 6, and drives the sleeve 6 down together Movement, through the adaptive adjustment unit to fine-tune the position of the sleeve installation head 1, so that the sleeve 6 is aligned with the plastic part 7, so that the sleeve 6 is inserted into the plastic part 7.

[0021] The self-adaptive adjustment unit includes four telescopic elements arranged on the outside of the top ...

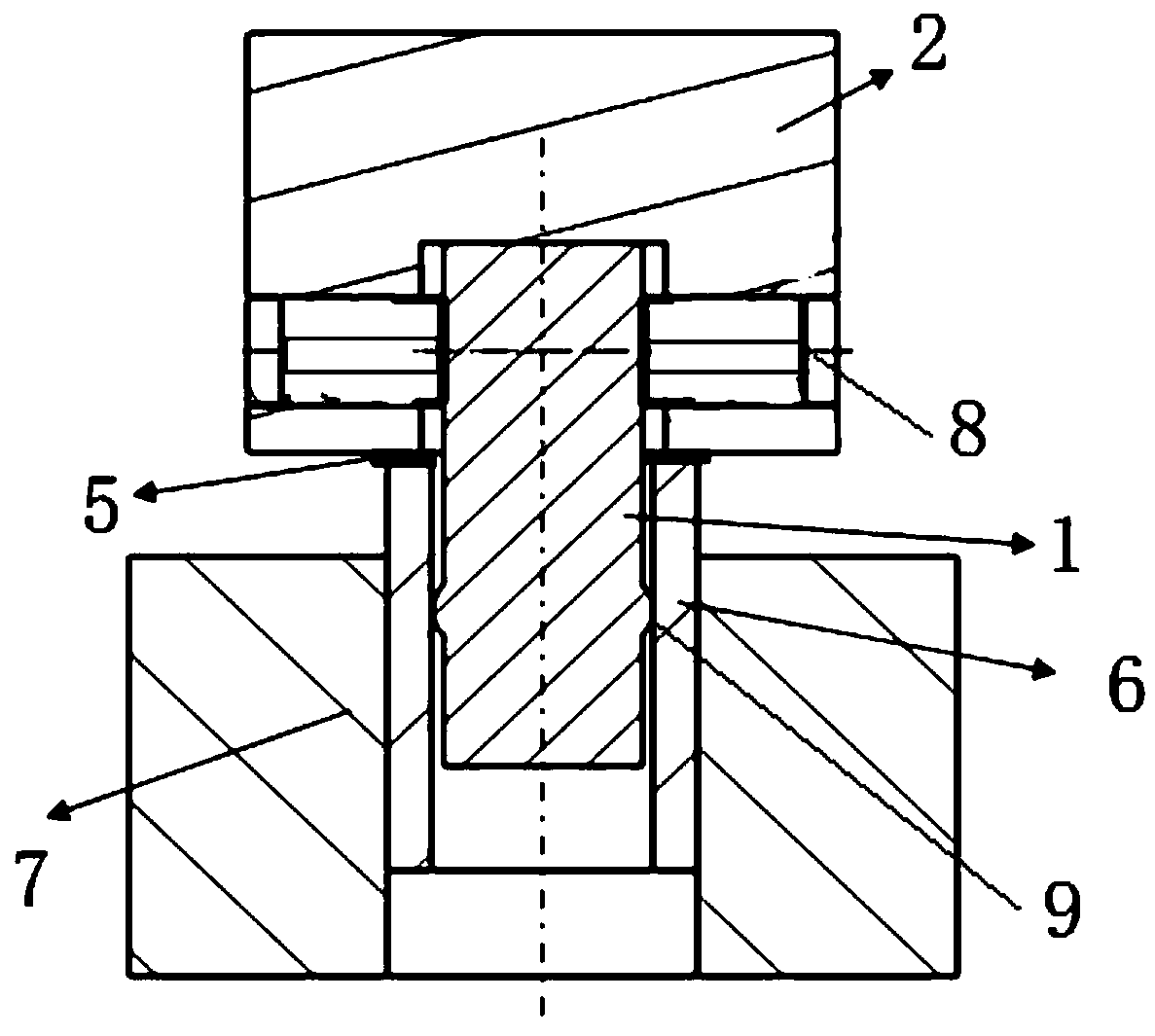

Embodiment 2

[0025] The structure similar to the embodiment is adopted, the difference is that the telescopic part is a telescopic cylinder 8, the tail end of the telescopic cylinder 8 abuts against the tail end of the tunnel, and the top of the telescopic cylinder 8 abuts against the side wall of the sleeve installation head 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com