Wireless communication device and measuring system for strip-shaped roller data measurement

A wireless communication device and data measurement technology, applied in signal transmission systems, instruments, etc., can solve the problems of difficult maintenance, insufficient stability and reliability of data transmission, and inability to upgrade communication protocols online, and achieve the realization of measurement and data transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

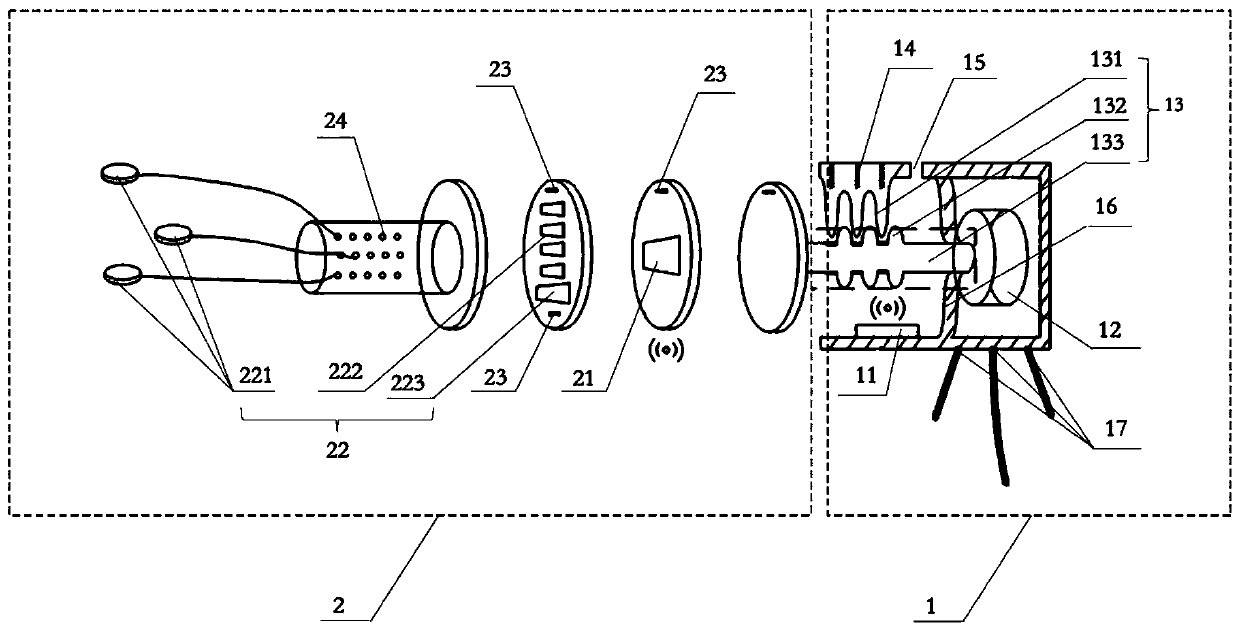

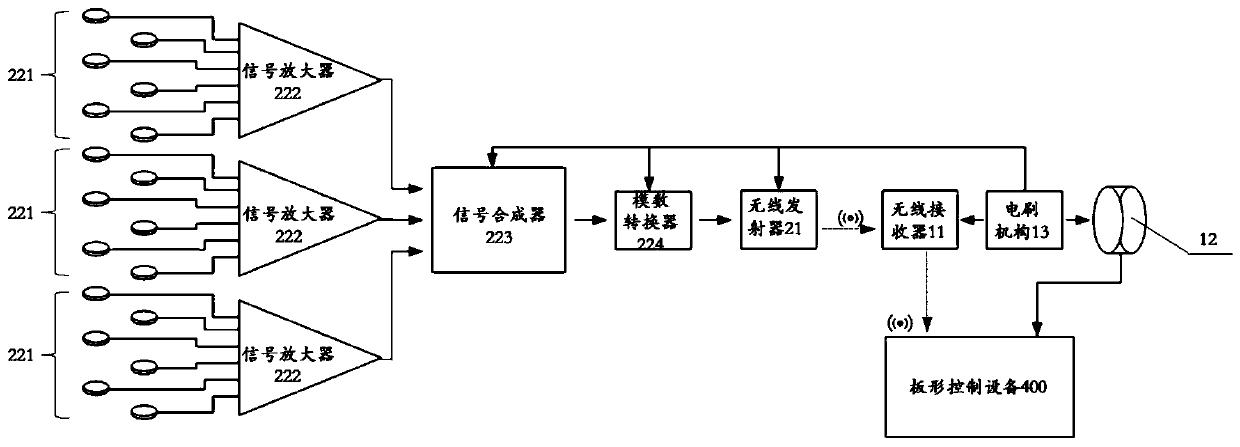

[0045] Embodiment one, as figure 1 As shown, a wireless communication device for data measurement of flat rolls includes a fixed end 1 and a rotating end 2 rotatably connected to the fixed end 1, and the rotating end 2 is also fixed to the rotatable flat roll connect;

[0046] The inside of the fixed end 1 is provided with a wireless receiver 11, a position encoder 12 and a brush mechanism 13, one end of the brush mechanism 13 is rotatably connected to the bottom inside the fixed end 1, and the brush mechanism The other end of 13 is fixedly connected to the bottom outside of the rotating end 2, the position encoder 12 is fixed on one end of the brush mechanism 13 rotatably connected to the bottom inside the fixed end 1, and the wireless The receiver 11 is arranged on the inner wall of the fixed end 1;

[0047] A circuit board and a wireless transmitter 21 and a force signal measurement circuit 22 arranged on the circuit board are arranged inside the rotating end 2;

[0048]...

Embodiment 2

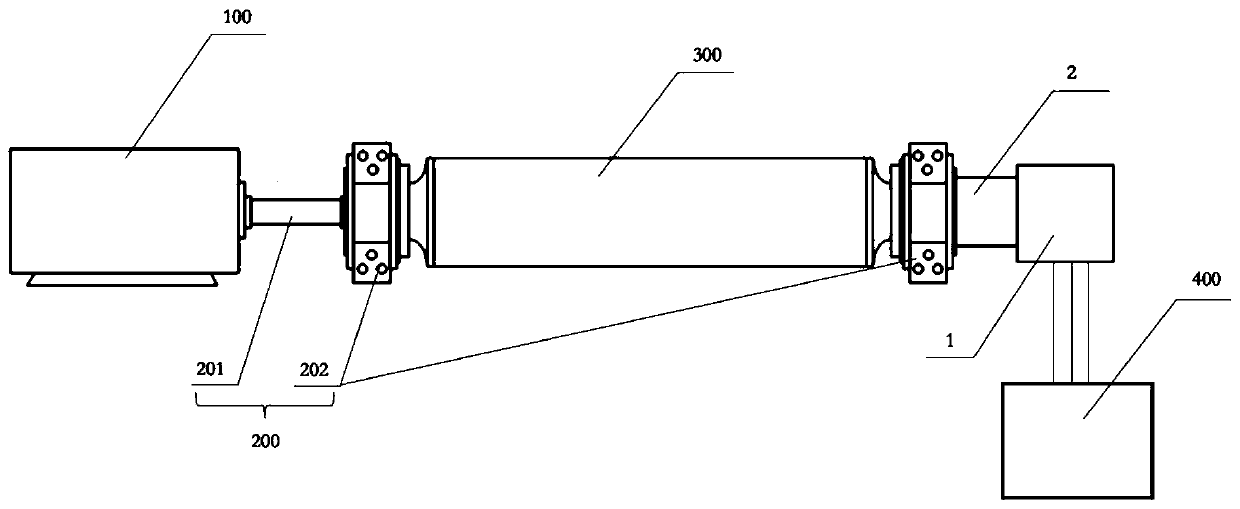

[0083] Embodiment two, such as image 3 As shown, a measurement system for flat roll data measurement includes the wireless communication device for flat roll data measurement in Embodiment 1, and also includes a power supply, drive motor 100, transmission mechanism 200, flat roll 300 and a shape control device 400 for adjusting the shape of the shape;

[0084] The driving motor 100 drives the plate-shaped roller 300 to rotate through the transmission mechanism 200, and drives the rotating end 2 to rotate together;

[0085] The power supply is electrically connected to the fixed end 1 , the drive motor 100 and the plate shape control device 400 respectively, and the fixed end 1 is electrically connected to the plate shape control device 400 .

[0086] The transmission mechanism connects the drive motor and the plate-shaped roller, so that the drive motor drives the plate-shaped roller to rotate and rotate together with the rotating end. When the plate-shaped roller rotates an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com