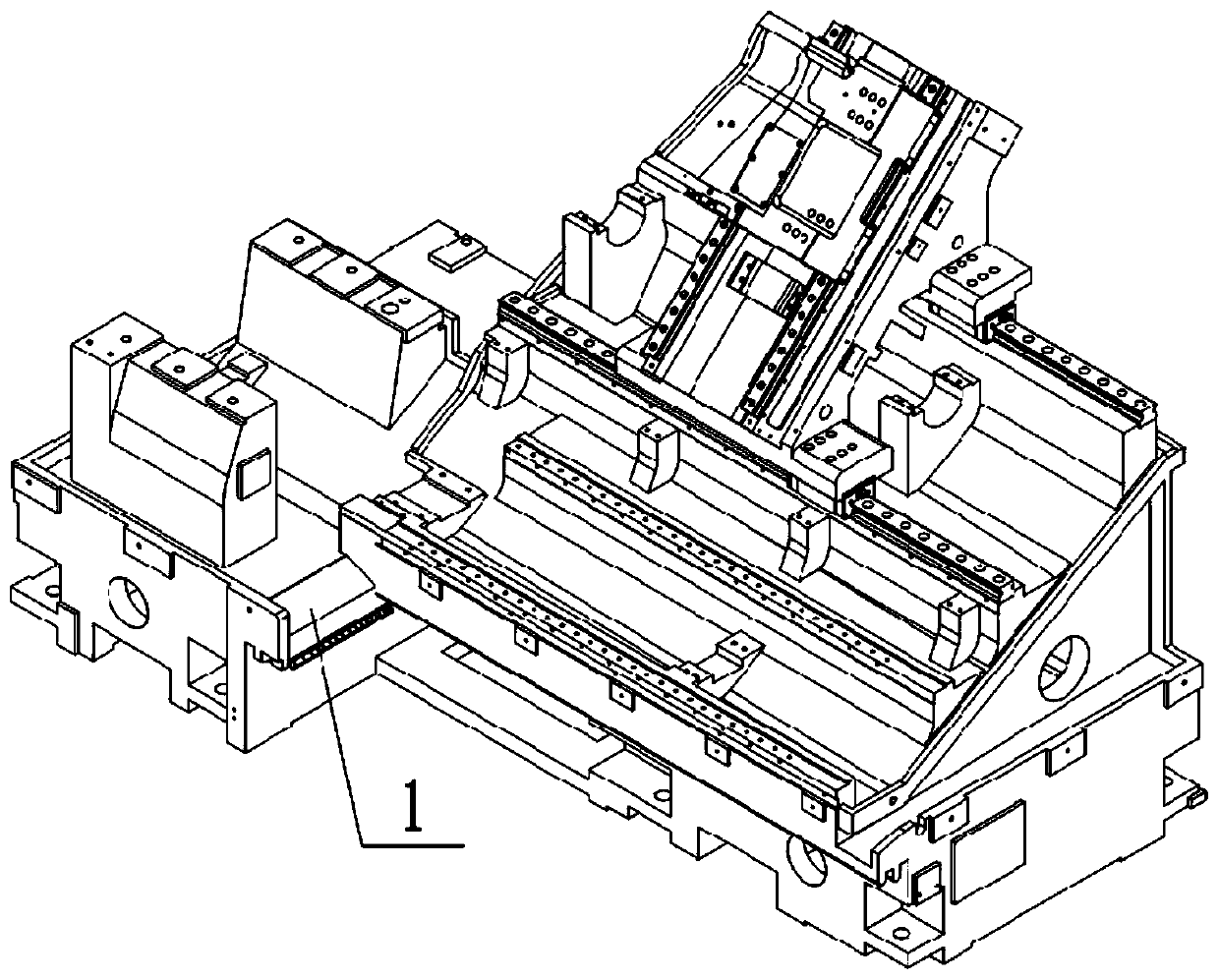

Detachable splash-proof mechanism

A detachable, splash-proof plate technology, applied in the field of machine tool bed, can solve the problems of inconvenient cleaning of splash-proof plates and deflectors, and achieve the effect of reducing the probability of contaminating the positioning plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

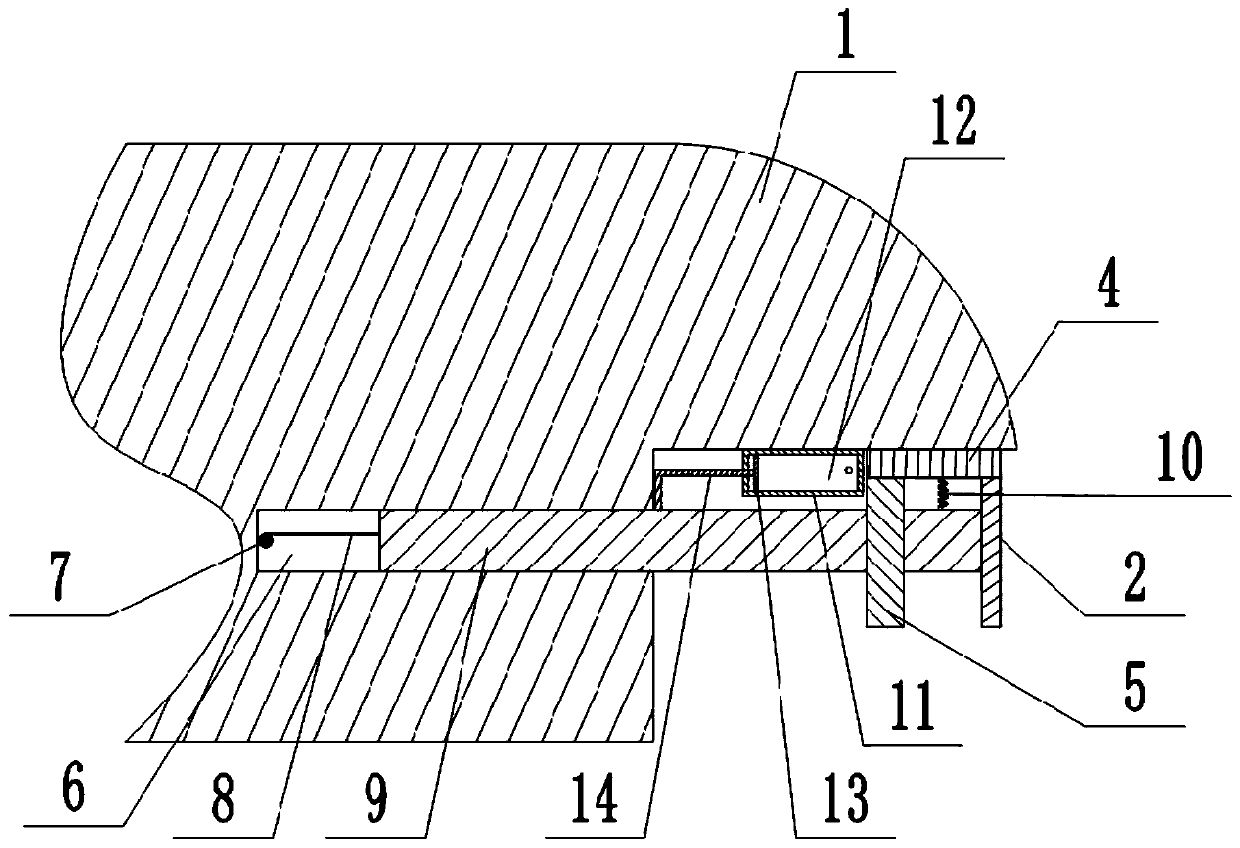

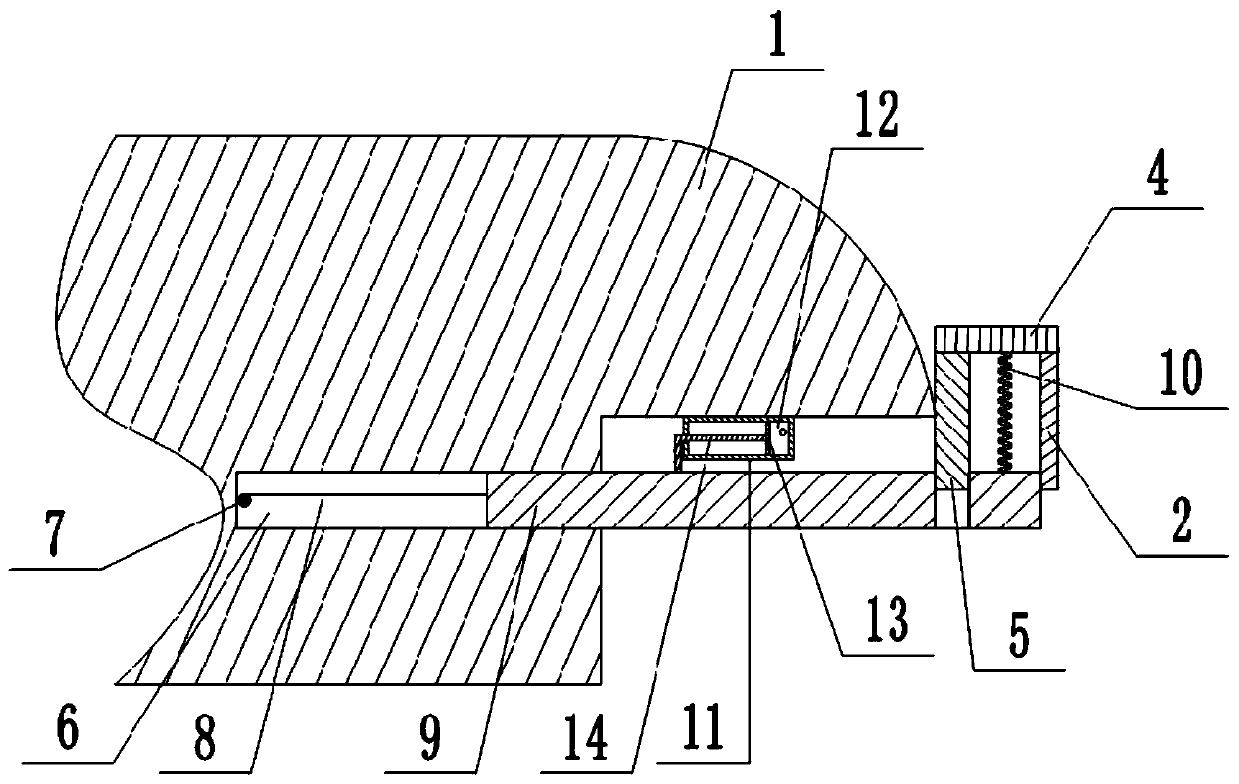

[0036] The detachable anti-splash mechanism is mainly composed of a chute 6, a positioning plate 9, a spring 10, an anti-splash unit, a flushing unit and a reset unit. combined with figure 1 And attached figure 2 As shown, the chute 6 is provided on the side wall of the machine tool, and a positioning plate 9 is horizontally slidably connected in the chute 6. The side of the locating plate 9 away from the chute 6 is provided with a positioning hole, and a spring 10 is welded on the positioning plate 9. , the spring 10 is located on the right side of the positioning hole.

[0037] The reset unit is arranged in the chute 6 for resetting the positioning plate 9; the reset unit is mainly composed of a rotating shaft 7, a torsion spring and a pull rope 8, the rotating shaft 7 is connected in the chute 6 in rotation, and one end of the torsion spring is fixed on the rotating shaft 7 On, the other end of torsion spring is fixed on the chute 6 inner wall. One end of stay cord 8 is...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is: in this embodiment, in combination with the attached Figure 4 And attached Figure 5 As shown, the deflector 2 is mainly composed of a guide portion 21 and a flow diversion portion 22, and a plurality of leakage holes 3 are evenly distributed on the flow diversion portion 22. The splitter part 22 is arranged obliquely, and the direction of inclination is inclined from the guide part 21 to the direction away from the guide part 21, and the inclination angle is 15°-25°. During operation, the two ends of the splitter part 22 are respectively located under the two sides of the cooling water artesian part 1 .

[0046] In this solution, the guide part 21 can guide the flow direction of the cooling water, so that the cooling water flowing down from the cooling water flow part 1 flows into the water tank along the deflector 2 . The leak hole 3 on the splitter 22 can divide the cooling water flowing to the splitter 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com