Ore crusher

A crusher and ore technology, applied in the field of ore machinery, can solve the problems of rising air turbidity, aggravating the consumption of internal lubricating oil, affecting the external working environment, etc., and achieving the effect of reducing the air concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] as attached figure 1 to attach Figure 8 Shown:

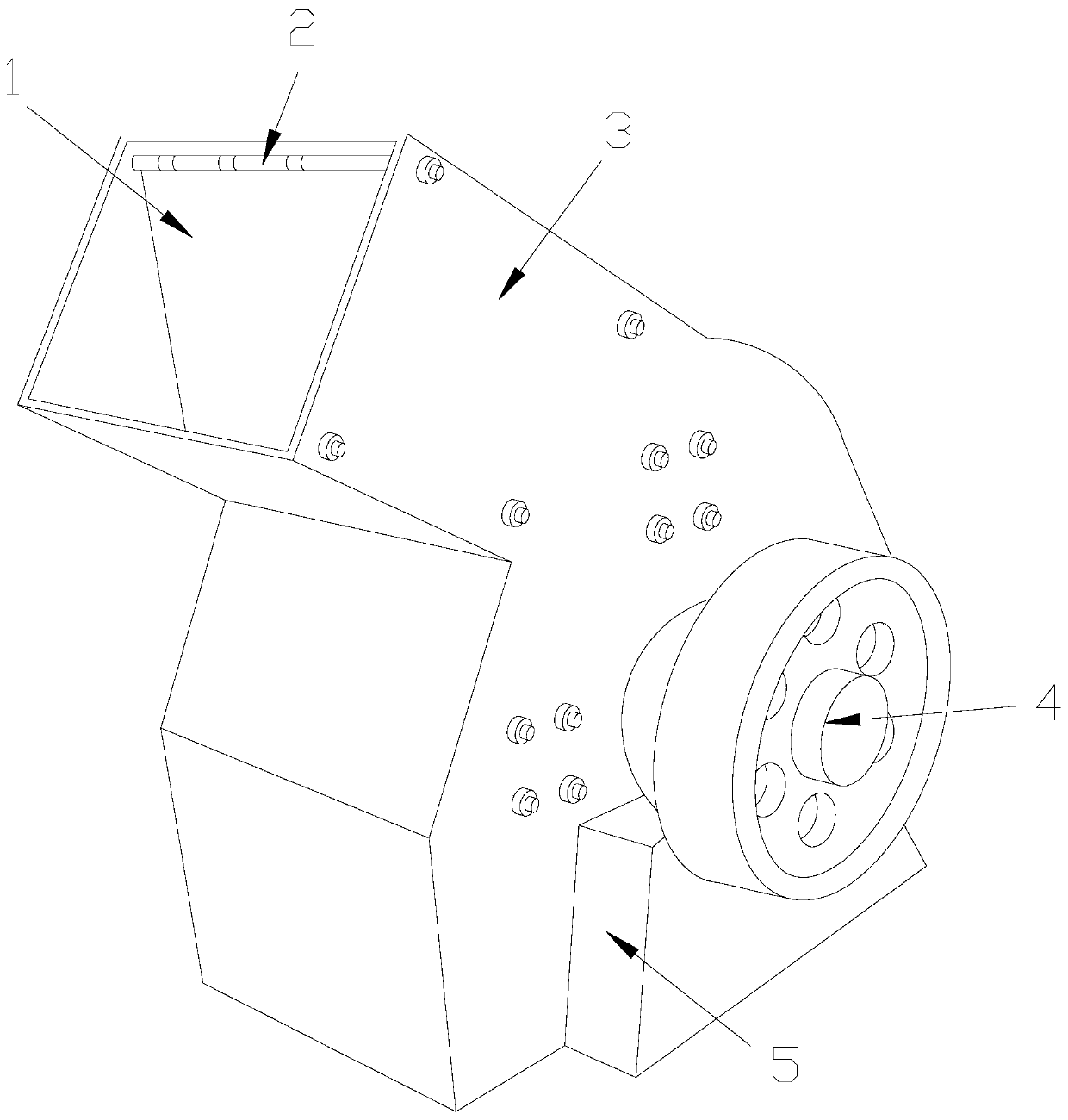

[0029] The invention provides an ore crusher, the structure of which includes a baffle plate 1, a rotating shaft 2, a crusher 3, an external power attachment wheel 4, a side seat plate 5, a dust suppression and crushing device 6, and a convex pressure roller 7, and the convex pressure roller 7 Engaged with the dust reduction and crushing device 6, the top of the baffle plate 1 is movably connected with the crusher 3 through the rotating shaft 2, the external power attachment wheel 4 is installed on the right side of the crusher 3 by embedding, and the side seat There are two plates 5 and they are welded and fixed on the left and right sides of the crusher 3 , and the dust suppression and crushing device 6 is installed inside the crusher 3 by means of embedding.

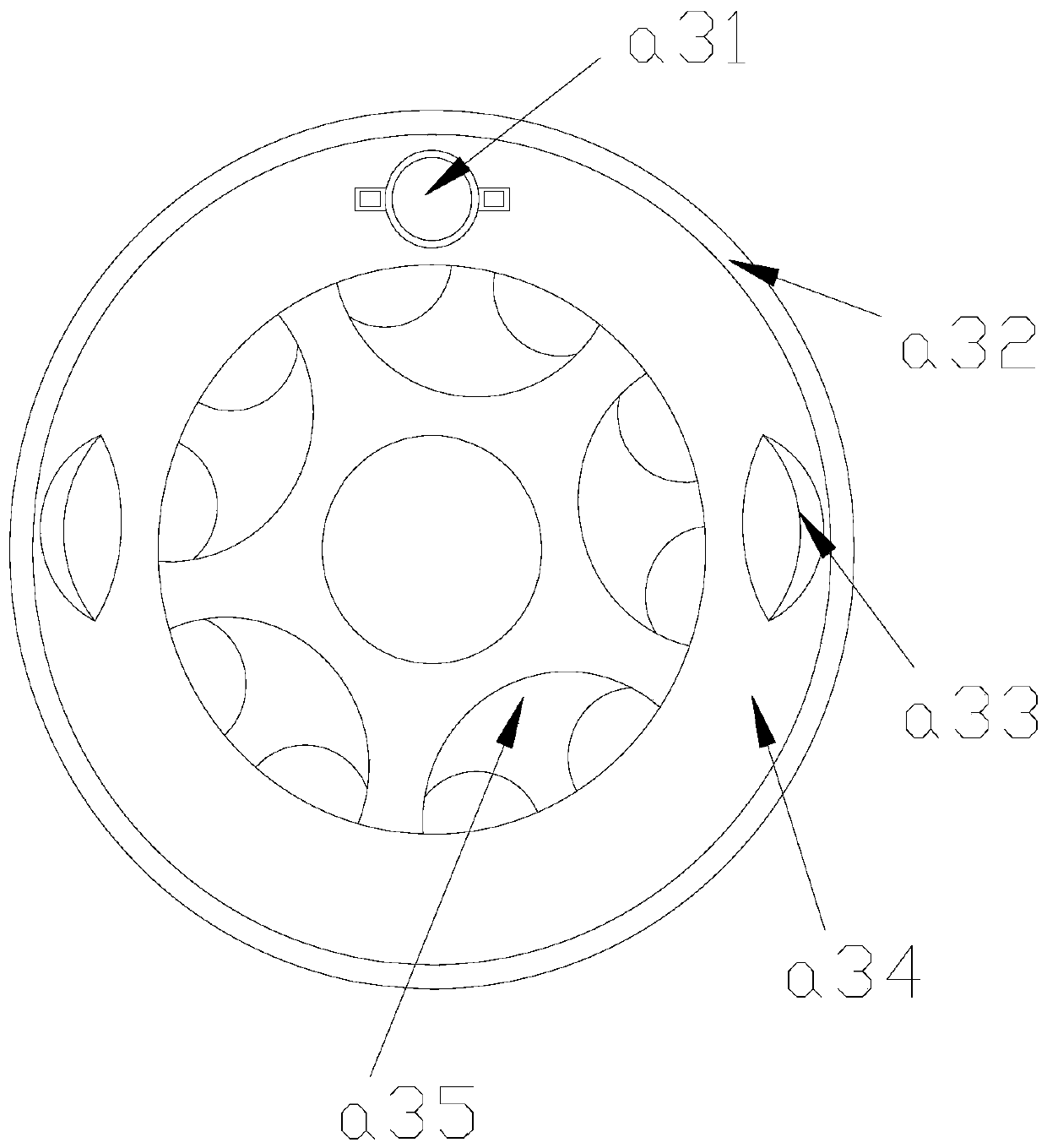

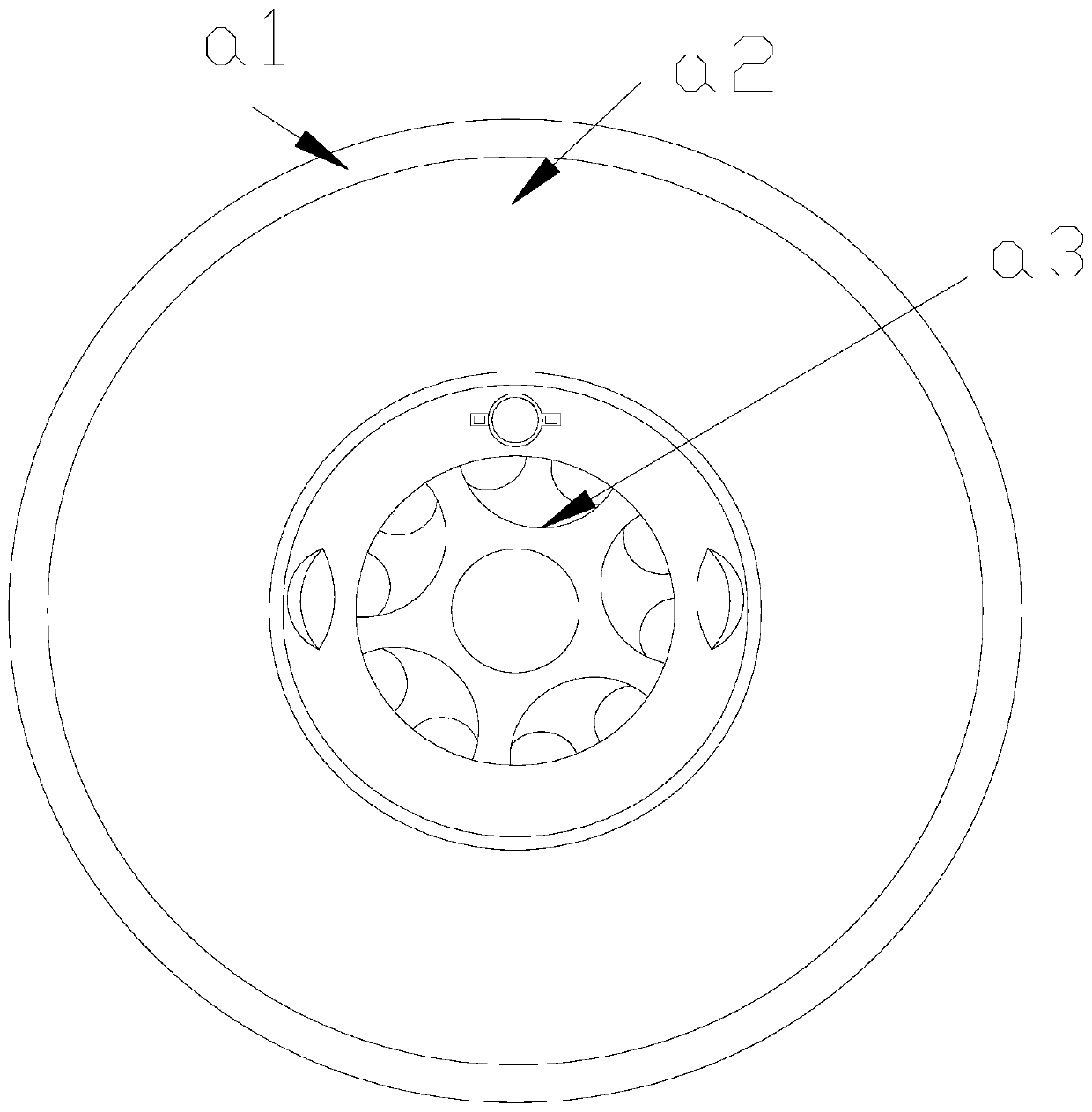

[0030] The dust-reducing and crushing device 6 includes an outer wheel cover a1, a dust-removing drum a2, and a dredging side disc a3. Inside the dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com