Intelligent screwing and assembling system based on crawler type six-axis robots

A six-axis robot and assembly system technology, applied in the direction of manipulator, metal processing, metal processing equipment, etc., can solve the problems of increasing workload, high dependence on operators, reducing the number of workpieces placed, etc., to improve work efficiency, improve Work efficiency, the effect of saving work steps and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

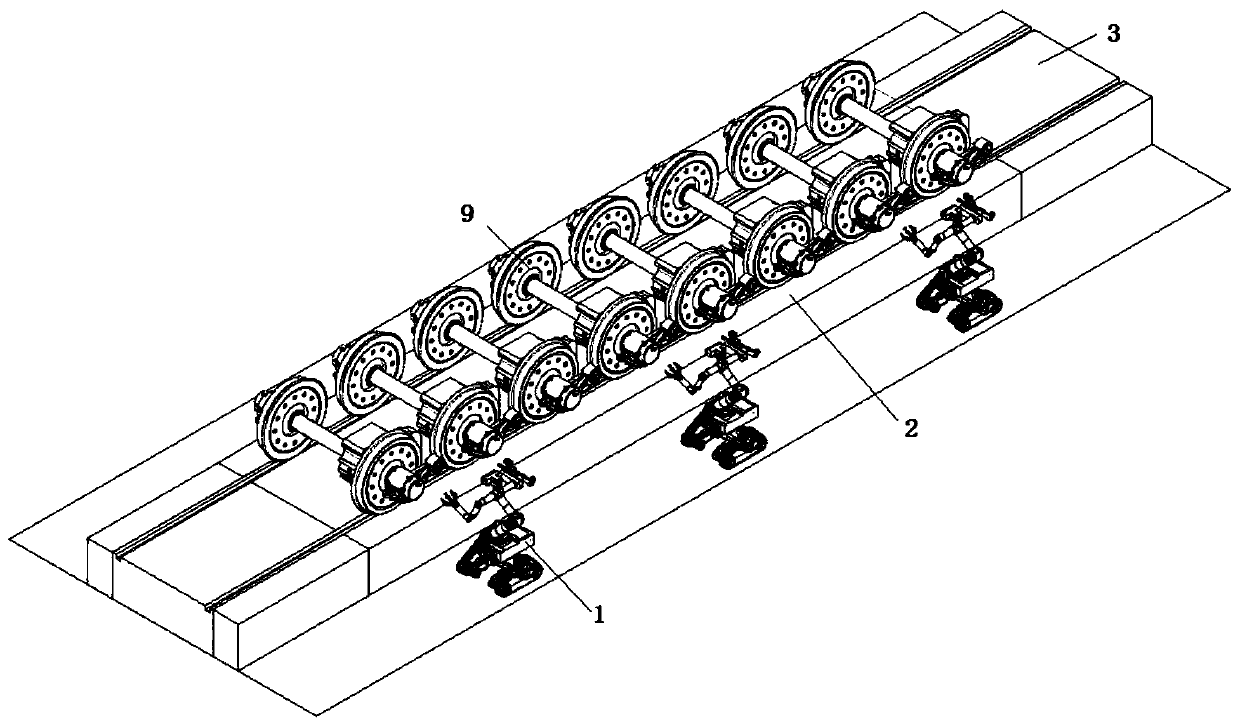

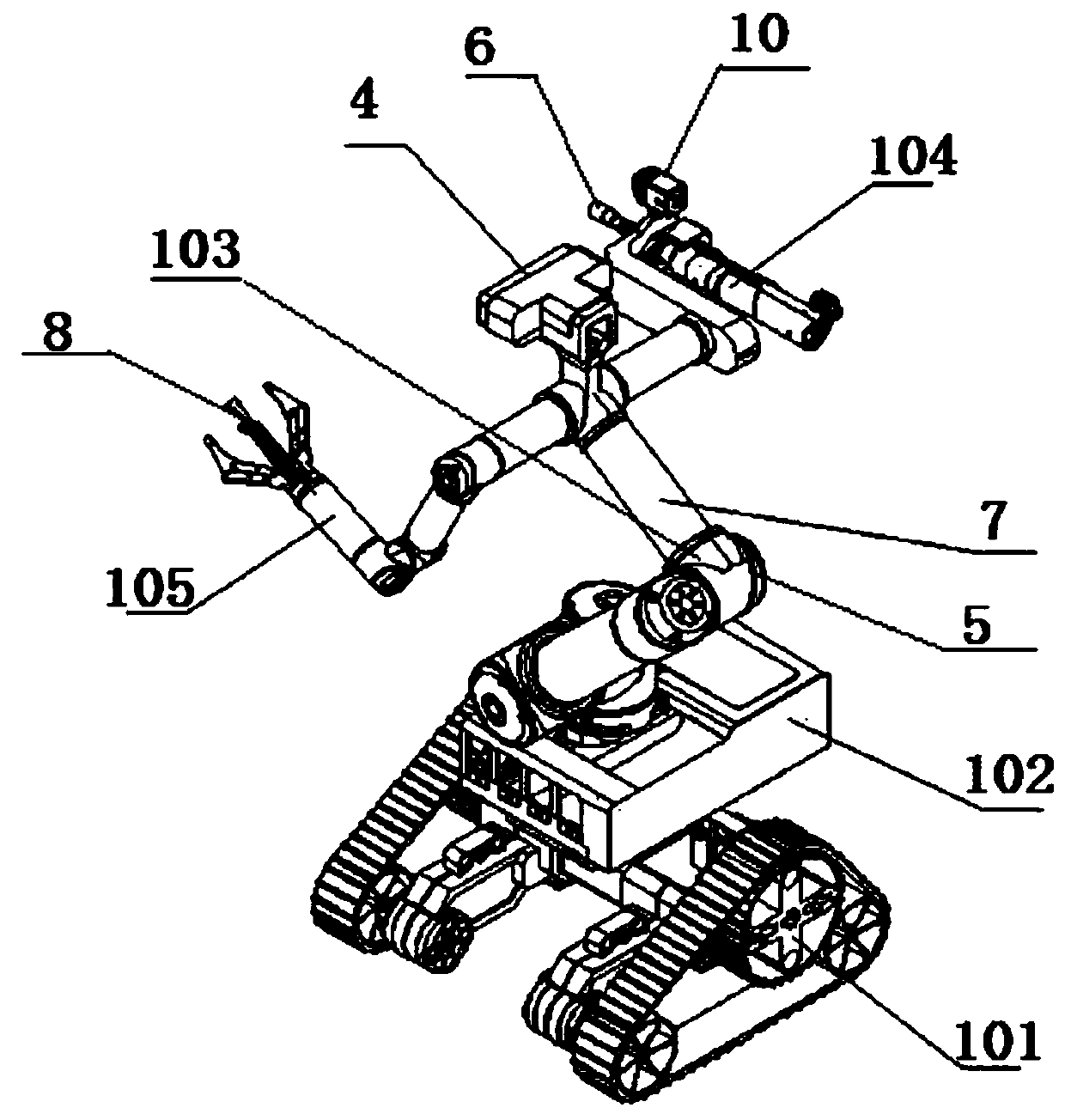

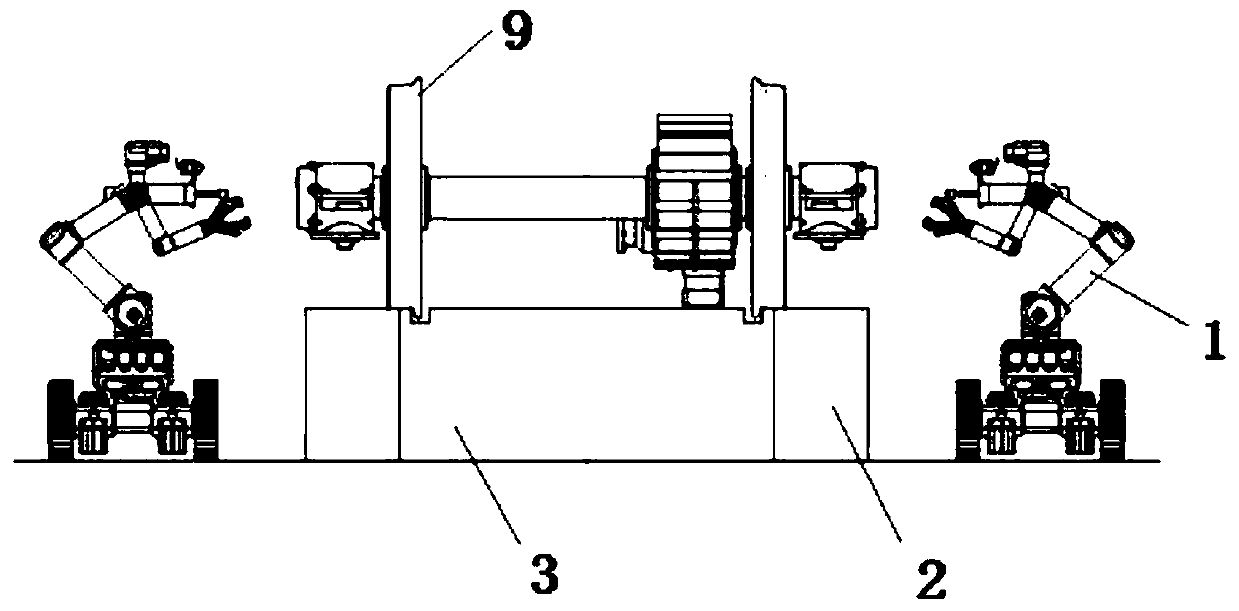

[0030] see Figure 1 to Figure 3 , an intelligent tightening assembly system based on a crawler-type six-axis robot 1 includes: a robot 1, a transport line, and an identification system 4; the transport line includes: a small parts transport line 2 and a wheel set workpiece transport line 3. A small parts conveying line 2 is arranged on both sides of the workpiece conveying line 3, and a robot 1 is arranged on one side of the small parts conveying line 2, and an identification system 4 is arranged on the robot 1.

[0031]Further, the robot 1 is a crawler-type six-axis robot 1, and the robot 1 includes: a crawler drive module 101, a central control and energy supply module 102, a robot body 103, a tightening shaft 104, and a manipulator 105; the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com