Novel simple vertical lathe worktable spindle structure

A workbench and simple technology, applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of increasing the price of vertical lathes, large size of end bearings, and increasing the burden on enterprises, etc., to achieve small eccentricity and high precision , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

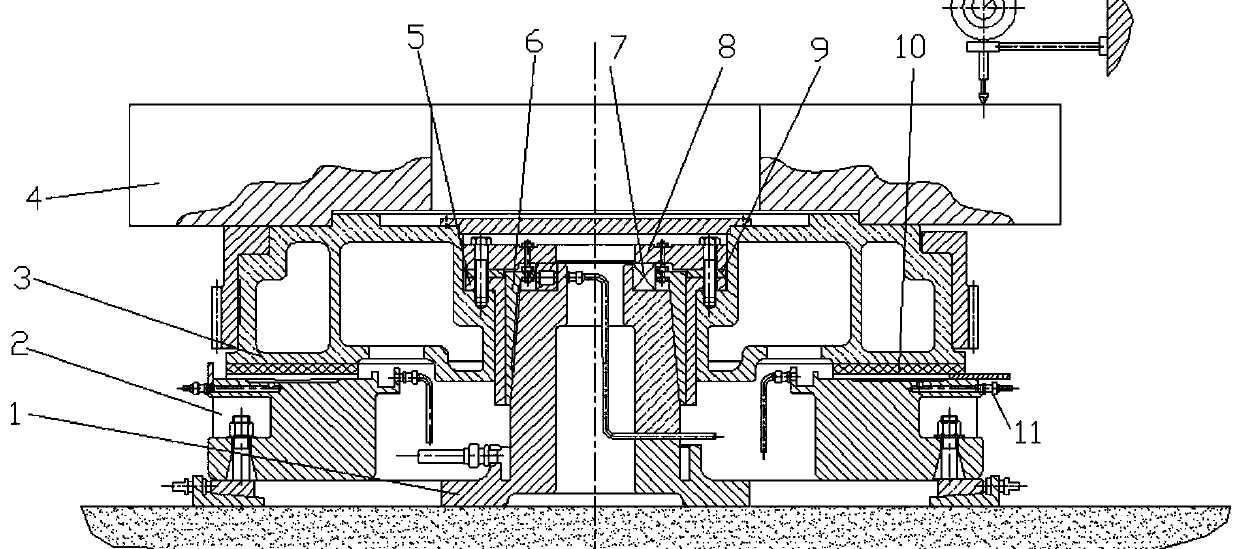

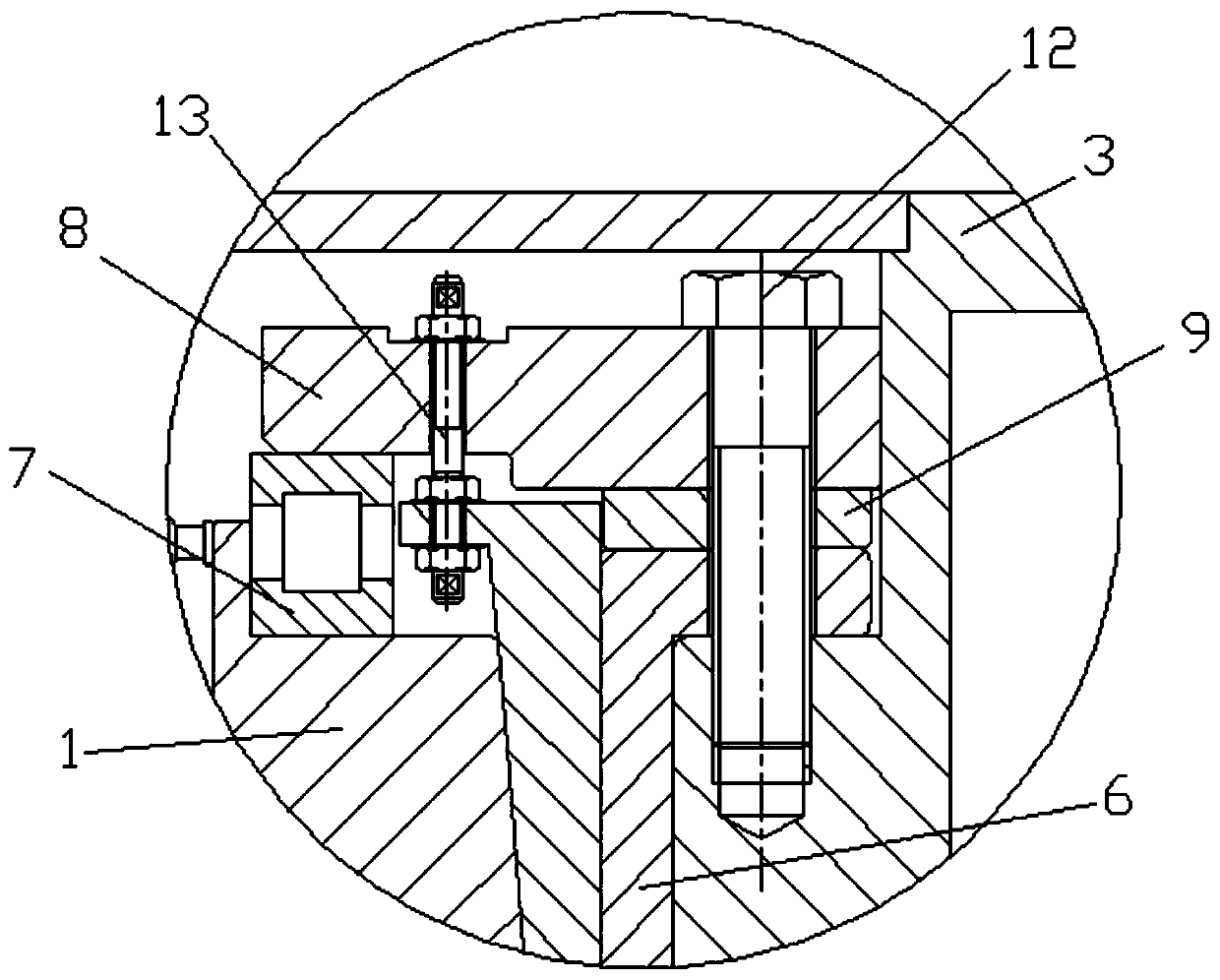

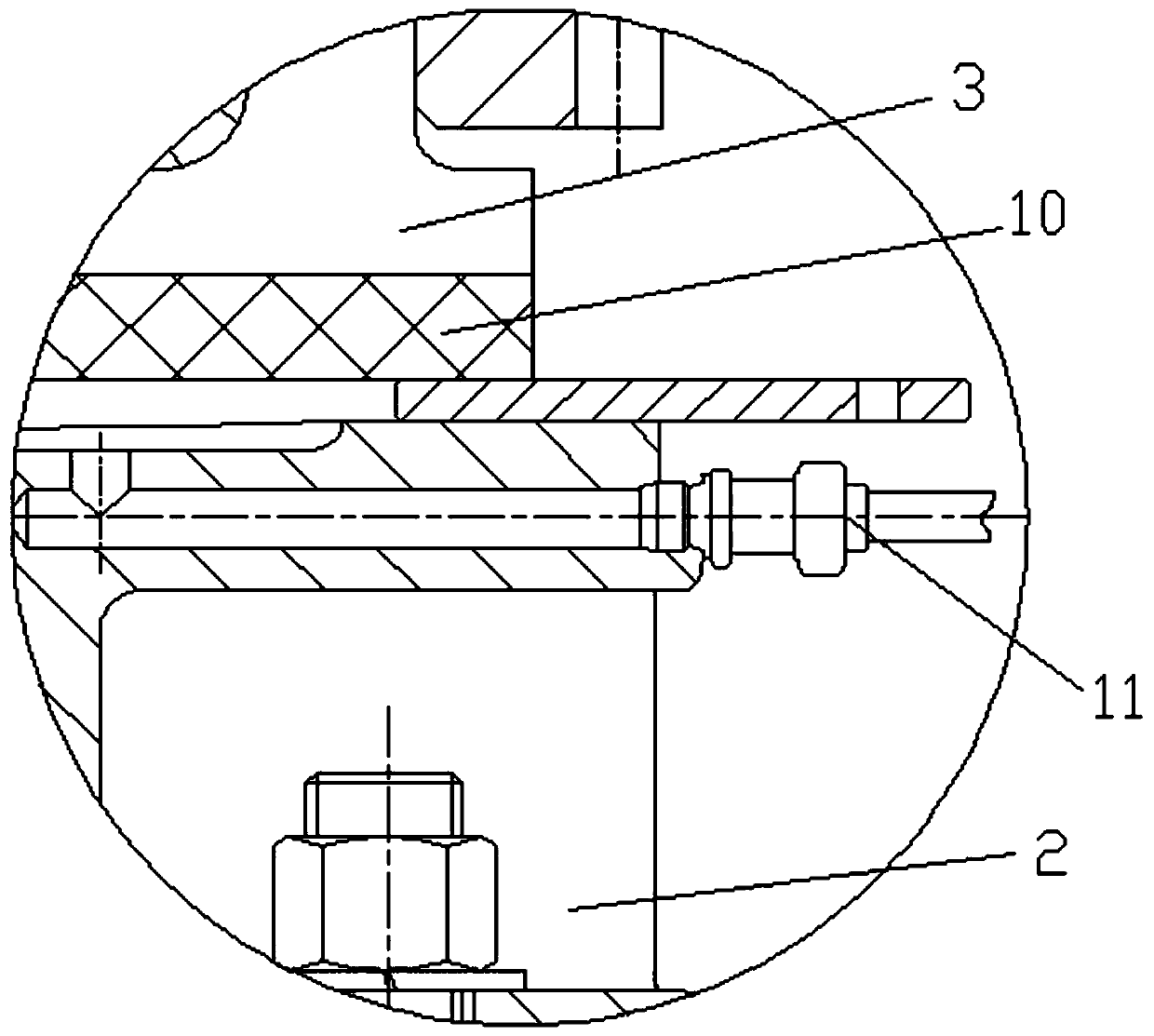

[0023] Example: such as Figure 1 to Figure 7 As shown, including the base 2, the base 2 is cylindrical, the middle of the base 2 is provided with a vertically upward central axis 1, the central axis 1 runs through the base 2 and the top of the central axis 1 is higher than the top of the base 2, the center axis 1 and the base 2 The bottom surface is even and fixed on the concrete bottom surface. The top surface of the base 2 is provided with a plurality of end sliding bearing guide rail blocks 10 along the circumference, and the upper part of the end sliding bearing guide rail block 10 is provided with a workbench 3. The diameters of 2 are suitable, and the middle part of the workbench 3 is provided with a vertical through hole. The part of the central axis 1 beyond the top surface of the base 2 is in the shape of a circular platform, and the diameter of the lower part is large, and the diameter of the top is small. Sliding bearing tapered sleeve 6, radial sliding bearing tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com