Roller-skating type buffering bracket

A roller-skating, bracket technology, applied in the direction of external frames, containers to prevent mechanical damage, containers, etc., can solve the problems of uneven force on the lifting point, inconvenient operation, easy to damage cylindrical products, etc., to achieve good drying effect, The effect of reducing the chance of bumping and the labor-saving process of transferring cylindrical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

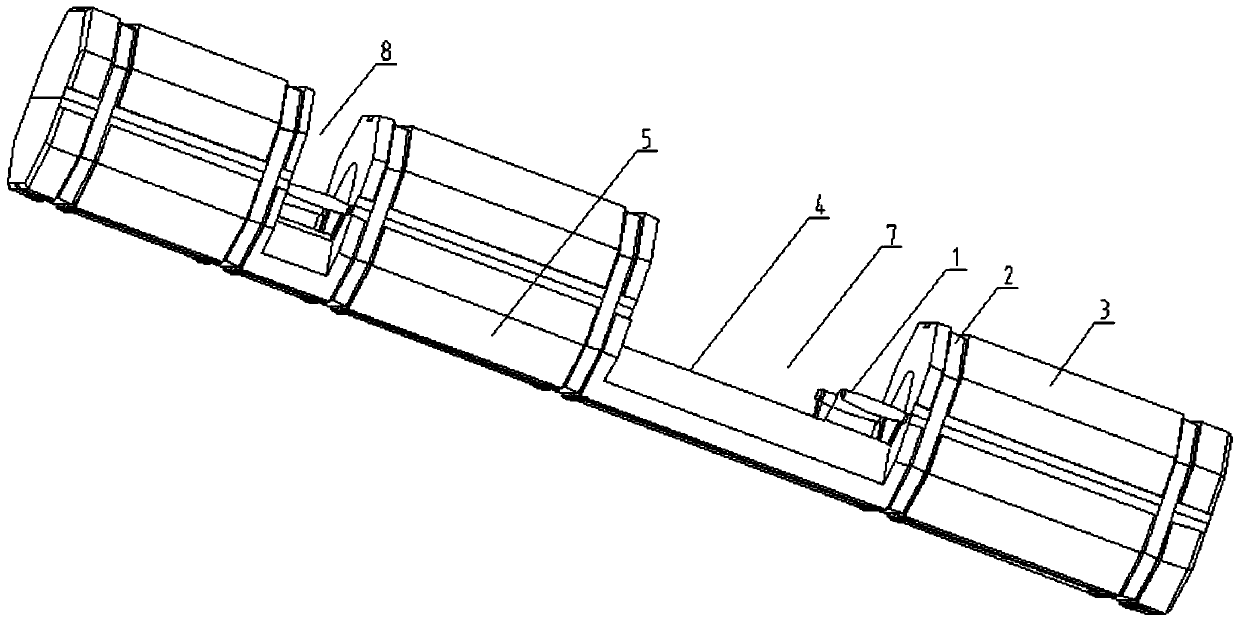

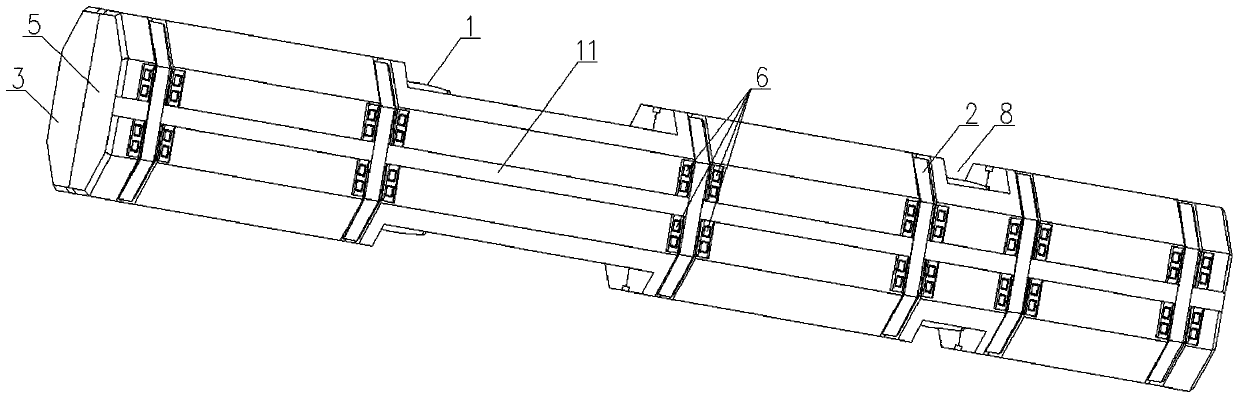

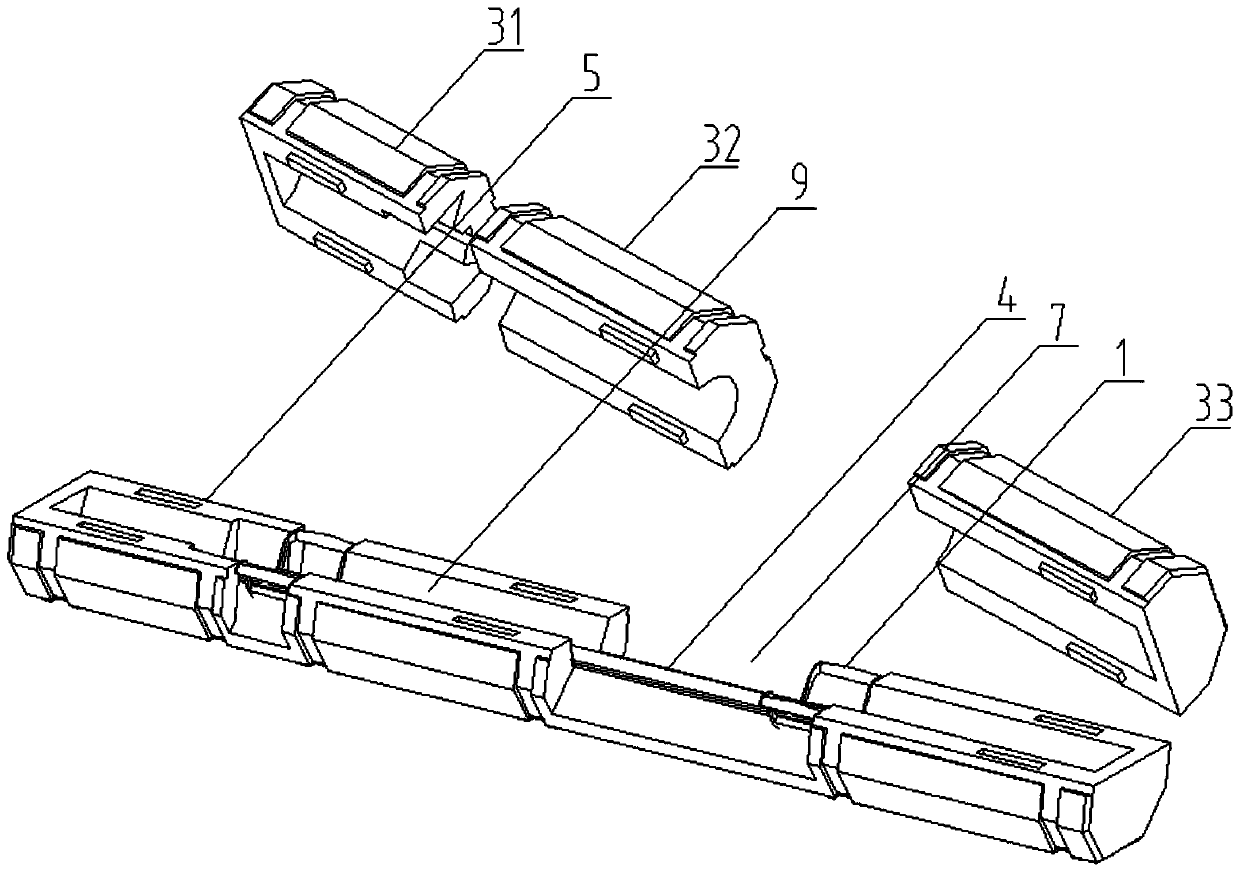

[0023] see Figure 1 to Figure 5 , a wheel-sliding buffer bracket, including an upper buffer cover 3 and a lower buffer cover 5, the upper buffer cover 3 and the lower buffer cover 5 are respectively provided with inner recesses 9, when the upper buffer cover 3 and the lower buffer cover 5 are closed Finally, the inner recess 9 of the upper buffer cover 3 and the inner recess 9 of the lower buffer cover 5 jointly constitute a space for accommodating cylindrical products; a roller skating assembly is also provided at the bottom of the lower buffer cover 5 . The roller skating assembly includes a mounting plate 10 arranged at the bottom of the lower buffer cover 5, a wheel groove is arranged on the mounting plate 10, and the wheel groove is fixedly arranged on a rotating shaft, and a roller 6 is arranged on the rotating shaft.

[0024] In this embodiment, the buffer cover is made of foam material, and the mounting plate 10 is glued to the foam material.

[0025] In this embodim...

Embodiment 2

[0033] A wheel-sliding buffer bracket, comprising an upper buffer cover and a lower buffer cover, the upper buffer cover and the lower buffer cover are respectively provided with inner concave parts, when the upper buffer cover and the lower buffer cover are closed, the inner part of the upper buffer cover The concave part and the inner concave part of the lower buffer cover jointly constitute a space for accommodating cylindrical products; a roller skating assembly is also arranged at the bottom of the lower buffer cover. The roller skating assembly includes a mounting plate arranged at the bottom of the lower buffer cover, a wheel groove is arranged on the mounting plate, and the wheel groove is fixedly arranged on a rotating shaft, and a roller is arranged on the rotating shaft.

[0034] In this embodiment, the buffer cover is made of foam material, and the mounting plate is firmly connected with the foam material.

[0035] In this embodiment, two mounting plates are arrang...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap