Preparation method of oral implant material, implant material and application

An oral implant and graphene technology, which is applied in the field of oral implant material preparation, can solve problems such as poor mechanical properties and limitations, and achieve high hardness, lively properties, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

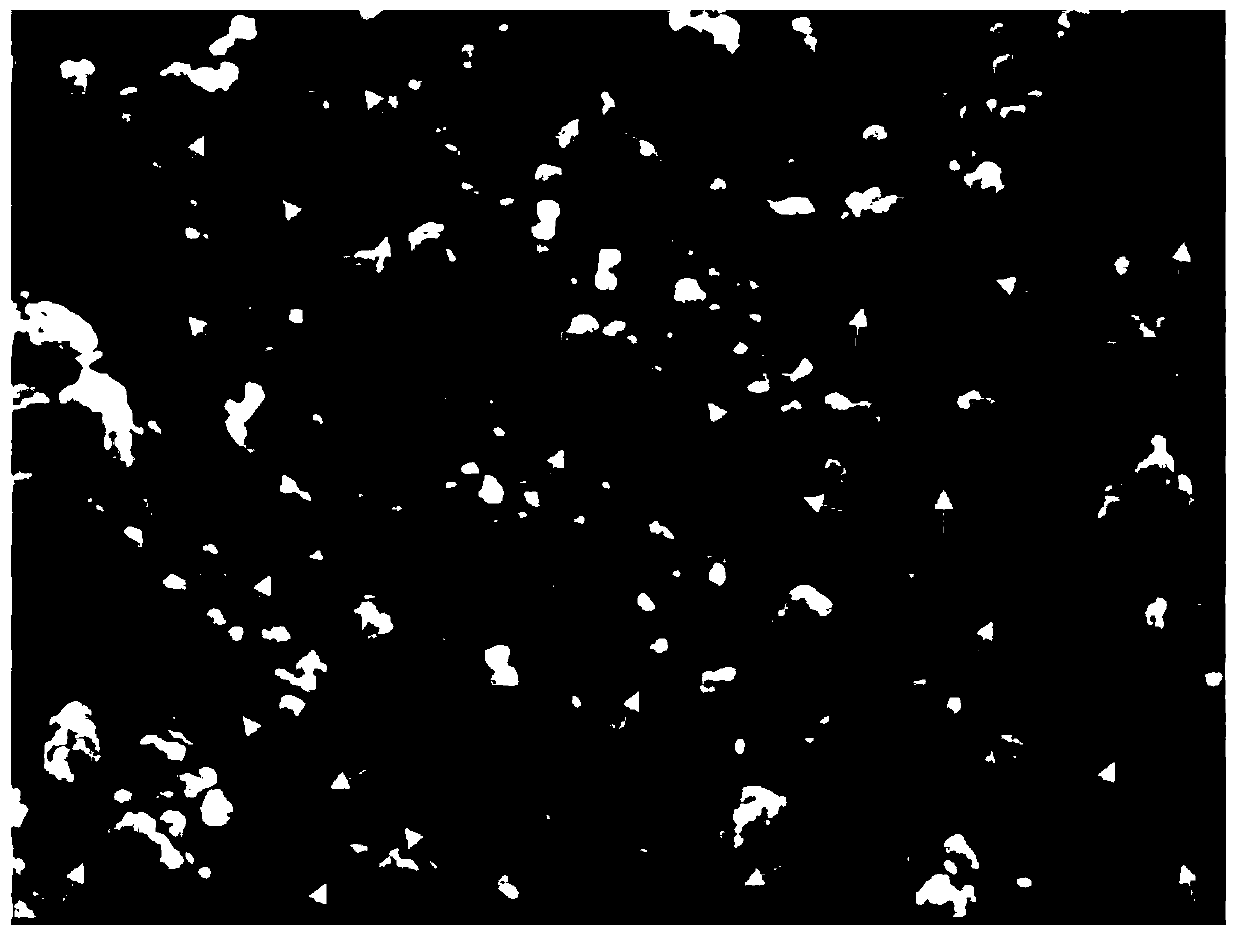

Image

Examples

preparation example Construction

[0030] In a typical embodiment of the present application, Example 1, a method for preparing an oral implant material comprises the following steps:

[0031] Step 1: the graphene oxide dispersion liquid and zirconia powder that mass ratio is 0.15 (the quality of graphene oxide dispersion liquid is m 1 , the mass of zirconia powder is m 2 , m 1 / m 2 =0.15) is dissolved in absolute ethanol to form a graphene oxide / zirconia suspension, wherein the graphene oxide dispersion has a purity of 99.8%, a sheet diameter of 0.5um, and a zirconia powder with a purity of 99.9%. The size is 0.5um.

[0032] Step 2: Put the graphene oxide / zirconia suspension obtained in step 1 in an environment of 30°C, use ultrasonic water bath method to mix the graphene oxide and zirconia in the suspension, and use a stirring rod to mix the suspension Stirring, the rotating speed of the stirring bar is 250rpm, and the stirring time is 1h. After the mixing and stirring is completed, a graphene oxide / zirc...

Embodiment 2

[0042] This embodiment discloses a preparation method of an oral implant material. In step 1, the mass ratio of graphene oxide dispersion to zirconia powder is 0.05, and the rest of the steps are the same as in embodiment 1.

[0043] The hardness value of the material obtained by the preparation method of Example 2 is 18.39Gpa, the flexural strength is 748.60Mpa, and the fracture toughness is 8.00Mpa.m 1 / 2 , the contact angle of the material is 77.0°.

Embodiment 3

[0045]This embodiment discloses a method for preparing an oral implant material. In step 1, the mass ratio of graphene oxide dispersion to zirconia powder is 0.1, and the rest of the steps are the same as in embodiment 1.

[0046] The hardness value of the material obtained by the preparation method of Example 3 is 18.96Gpa, the flexural strength is 1252.85Mpa, and the fracture toughness is 8.95Mpa.m 1 / 2 , the contact angle of the material is 55.0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com