Rotating bearing assembly method

A technology of slewing bearings and assembly methods, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of difficult adjustment of meshing, waste of time, etc., and achieve the effect of rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

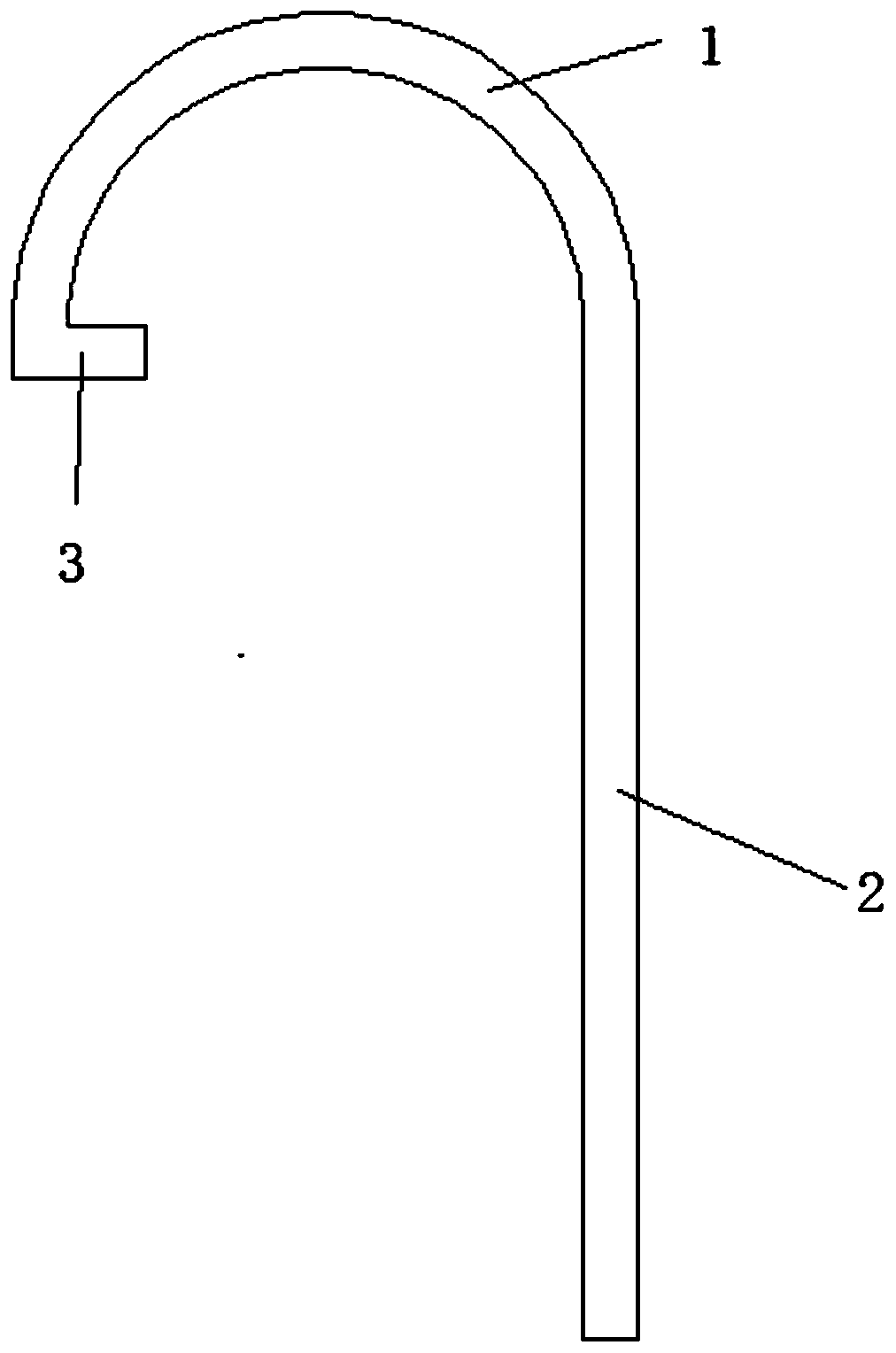

[0053] figure 1 A schematic diagram of the adjustment hook according to the present embodiment is shown.

[0054] like figure 1 As shown, the slewing bearing assembly method includes the steps:

[0055] 1) A first positioning pin hole and a first guide hole are arranged on the slewing bearing, the first guide hole is a light hole, and the inner ring of the slewing bearing is fixed on the chassis;

[0056] 2) Install the locating pin in the first locating pin hole;

[0057] 3) A second positioning pin hole and a second guide hole are arranged on the rotary platform;

[0058] 4) Lift the slewing platform to the top of the slewing bearing;

[0059] 5) Install the guide pin in the second guide hole through the thread, and make the tapered end of the guide pin face the slewing bearing;

[0060] 6) Lower the rotary platform and adjust the direction of the rotary platform so that the guide pin is inserted into the first guide hole;

[0061] 7) Continue to lower the slewing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com