Method and device for manufacturing fitted bed sheets

A bed sheet and equipment technology, applied in bed sheets, sewing machines for sewing bedding, textiles and papermaking, etc., can solve problems that cannot be realized by machines or automatically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

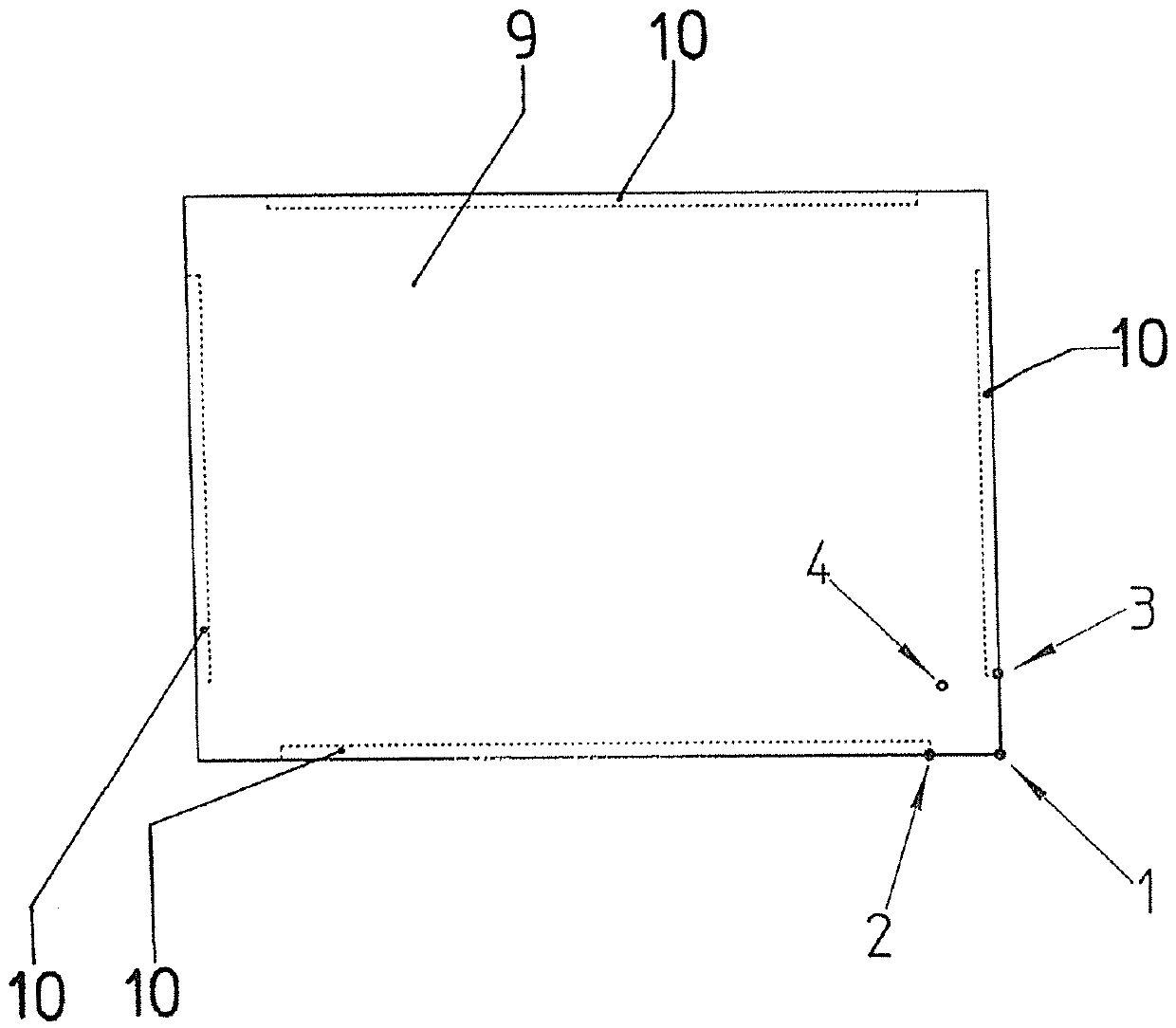

[0038] The figures serve to illustrate the method according to the invention for producing a tensioned sheet or similar protective cover. In this case, rectangular bed sheet parts 9 are cut out from the web material. Such a sheet may, for example, be hemmed all around. Also available as in figure 1 As explained in , the elastic band (Gummizüge) 10 is sewn together or on or into the seam allowance on the edge side.

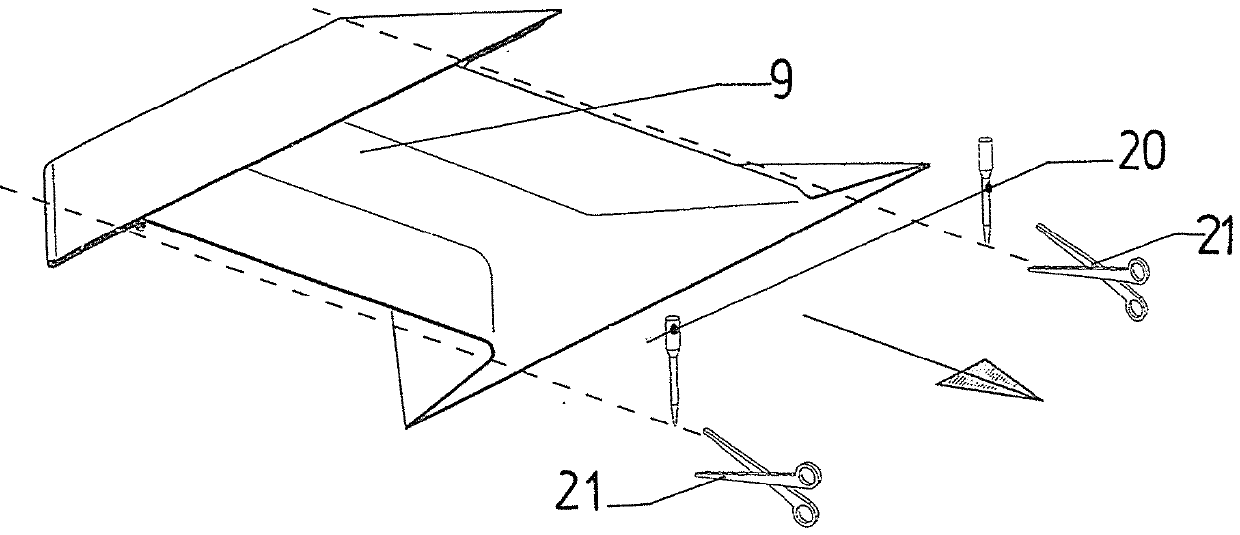

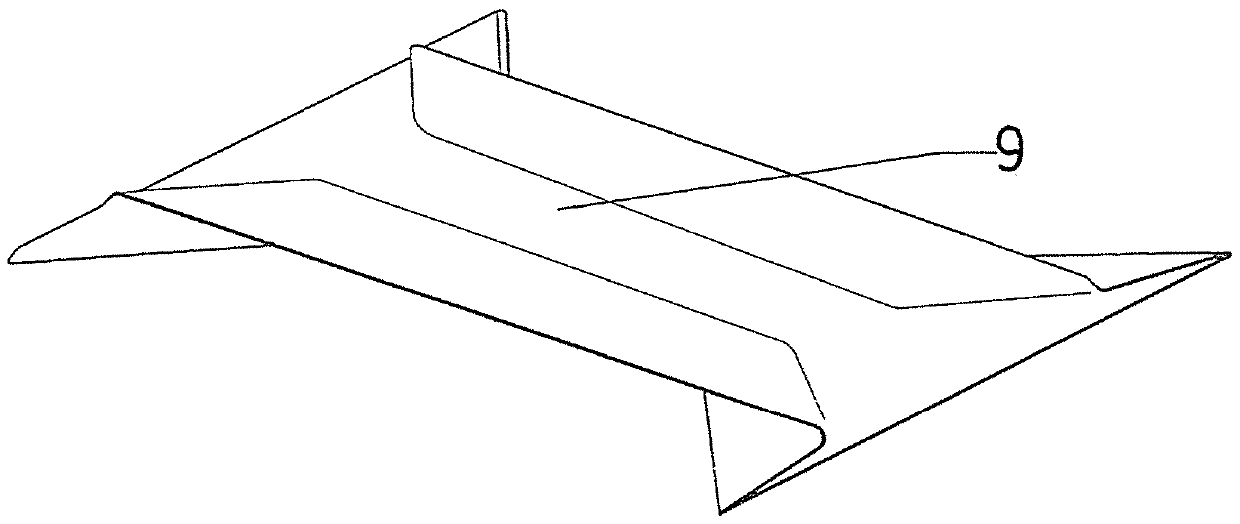

[0039] as it is figure 2 As shown in , the method according to the invention is determined and suitable for forming a square-like cover 11 from such a bed sheet 9 . The particular value here is that the bridging height, ie the height of the part 11, can be determined in a simple manner and that the corner area runs exactly vertically, ie at figure 2 The line indicated by 12 in is directed vertically as precisely as possible.

[0040] In the design according to the present invention, the bed sheet 9 is spaced apart from the corner 1,5 in the area of each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com