Patents

Literature

34results about How to "Speed up workflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

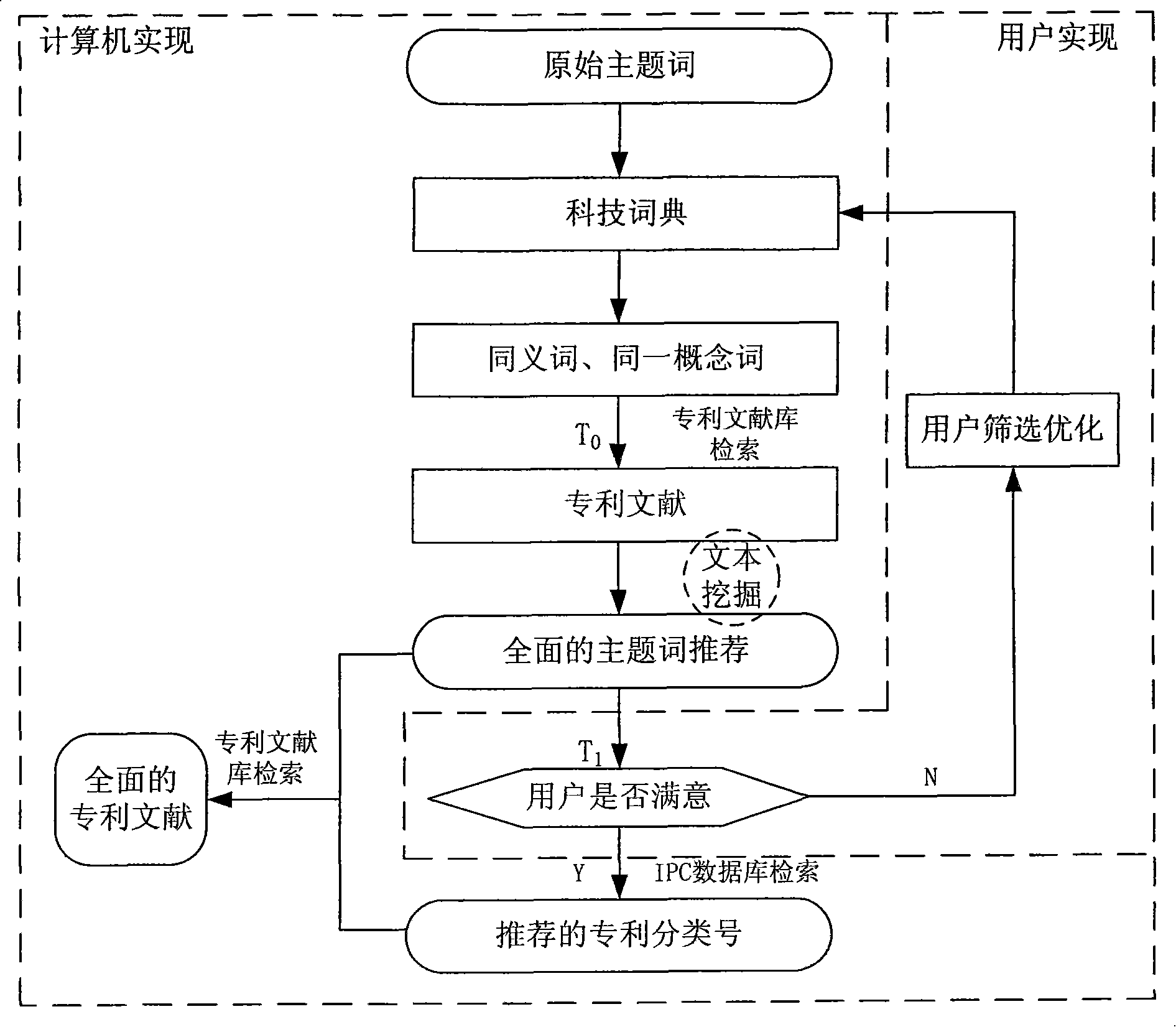

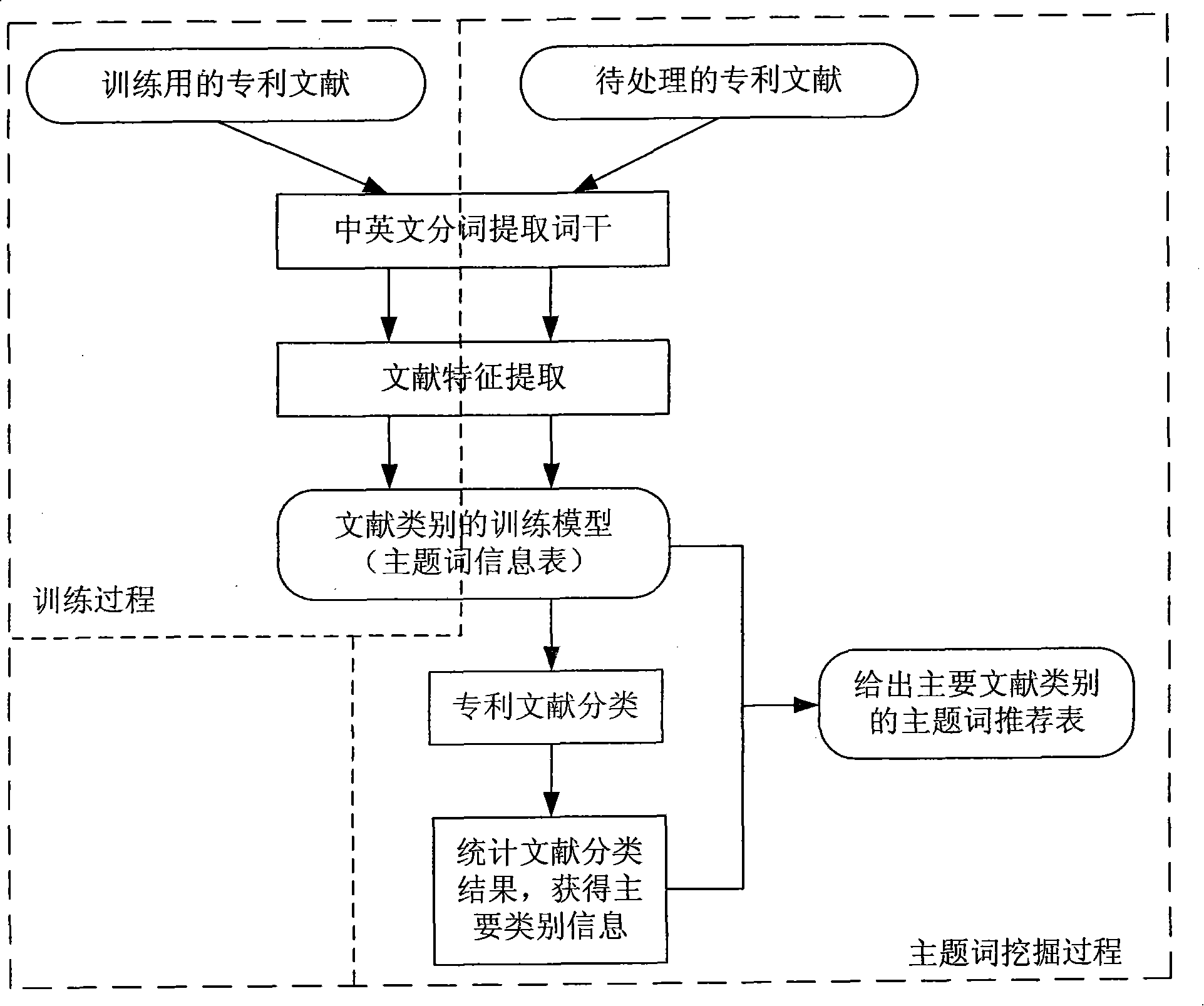

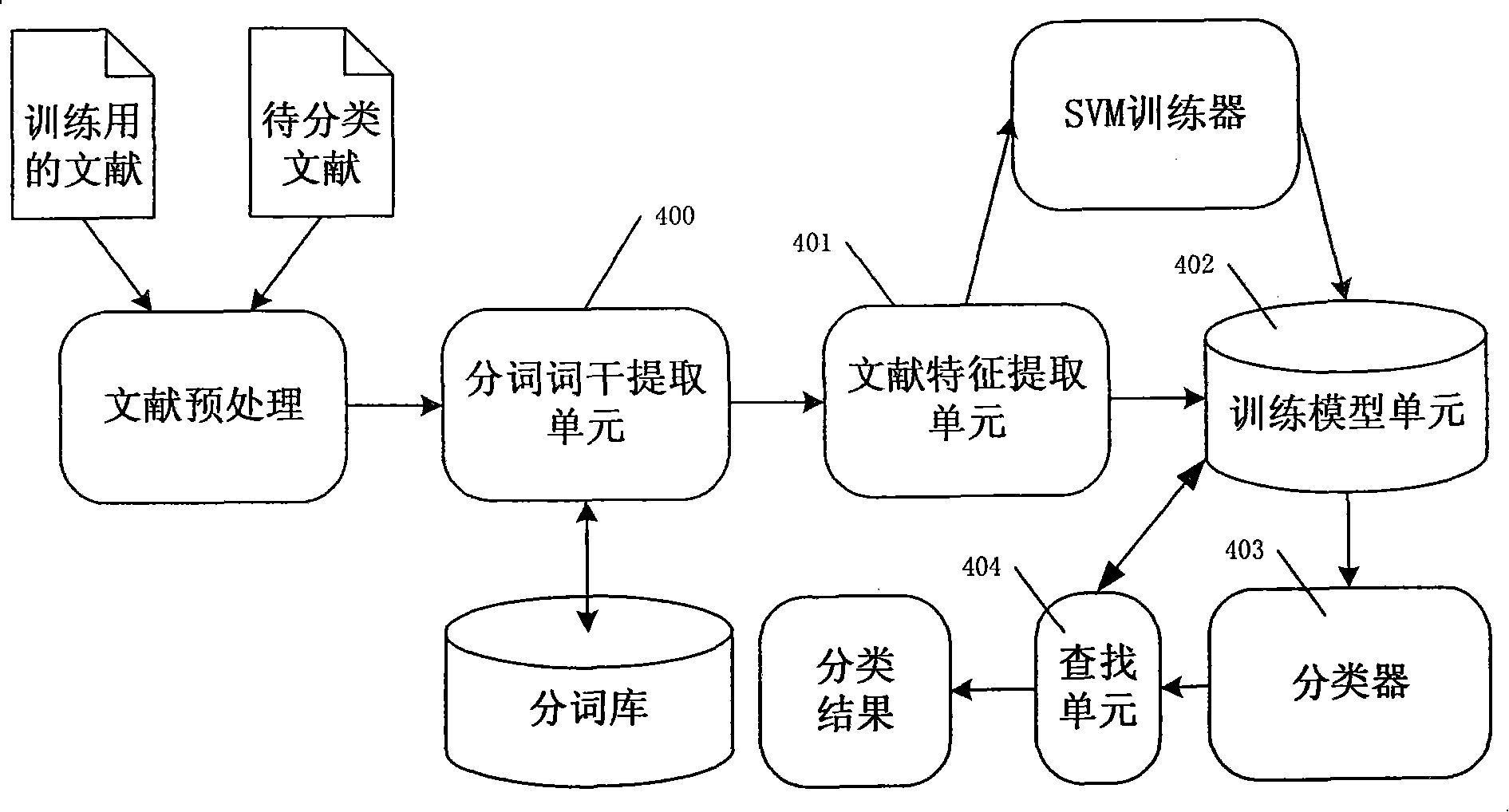

Method for creating index lexical item as well as data retrieval method and system

The invention discloses a method for generating a retrieve lemma, a data retrieval method and a data retrieval system, wherein, the method for generating the retrieve lemma comprises the following steps: A. related vocabularies are inquired according to a lemma of an original subject, and a related vocabulary recommendation table is established; B. a database is inquired by utilization of the related vocabulary recommendation table, and a literature summary is retrieved; C. text mining of the retrieved literature summary is performed, and a recommended lemma which is matched with the content of a key word is obtained; D. the recommended lemma is inserted into the related vocabulary recommendation table to form a key word recommendation table. The method for generating the retrieve lemma, the data retrieval method and the data retrieval system mainly apply the automatic text mining technique and the statistical technique and combine a little manual correction to obtain the overall key word recommendation table and utilize the table for retrieval of the database.

Owner:SHENZHEN INST OF ADVANCED TECH

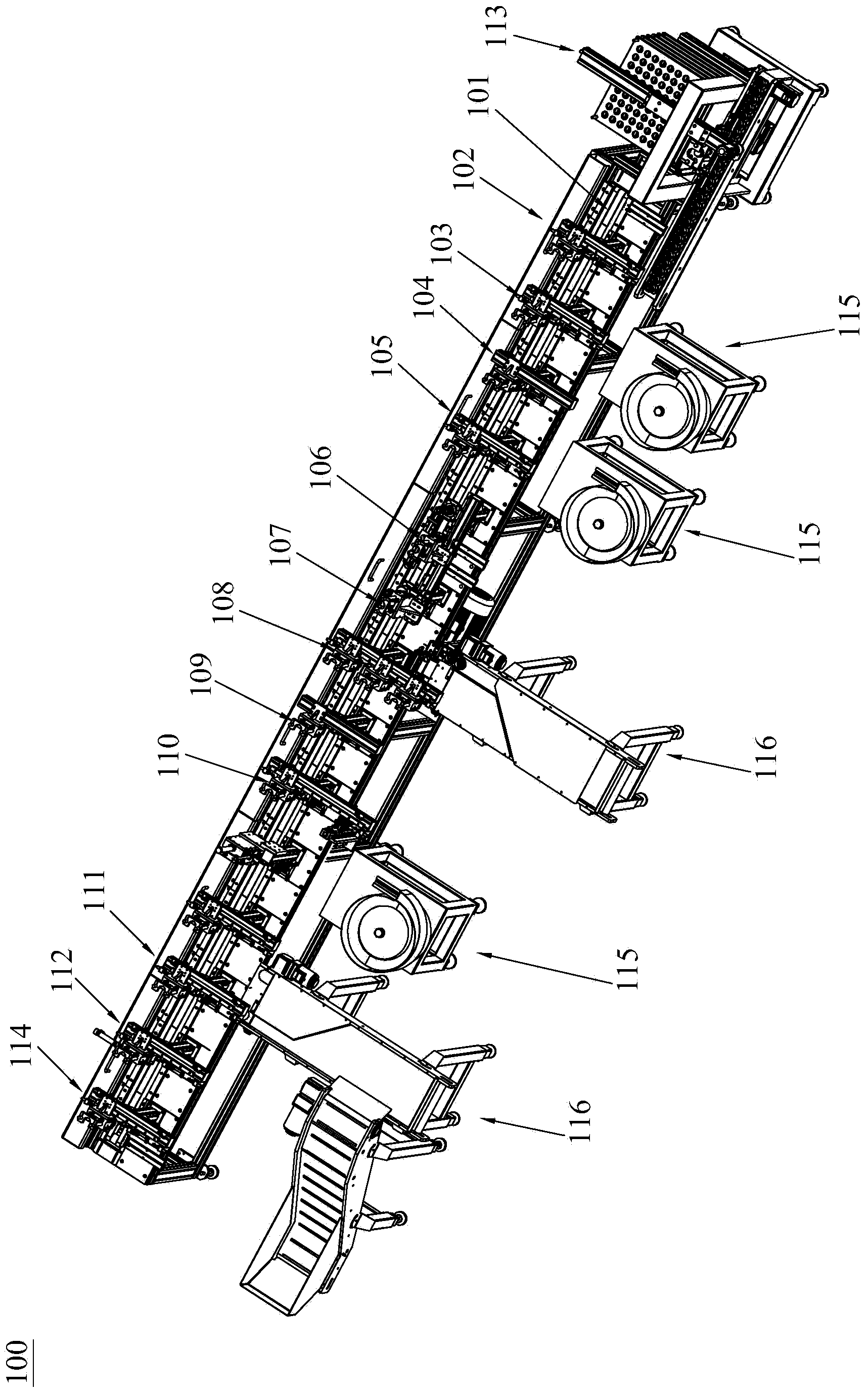

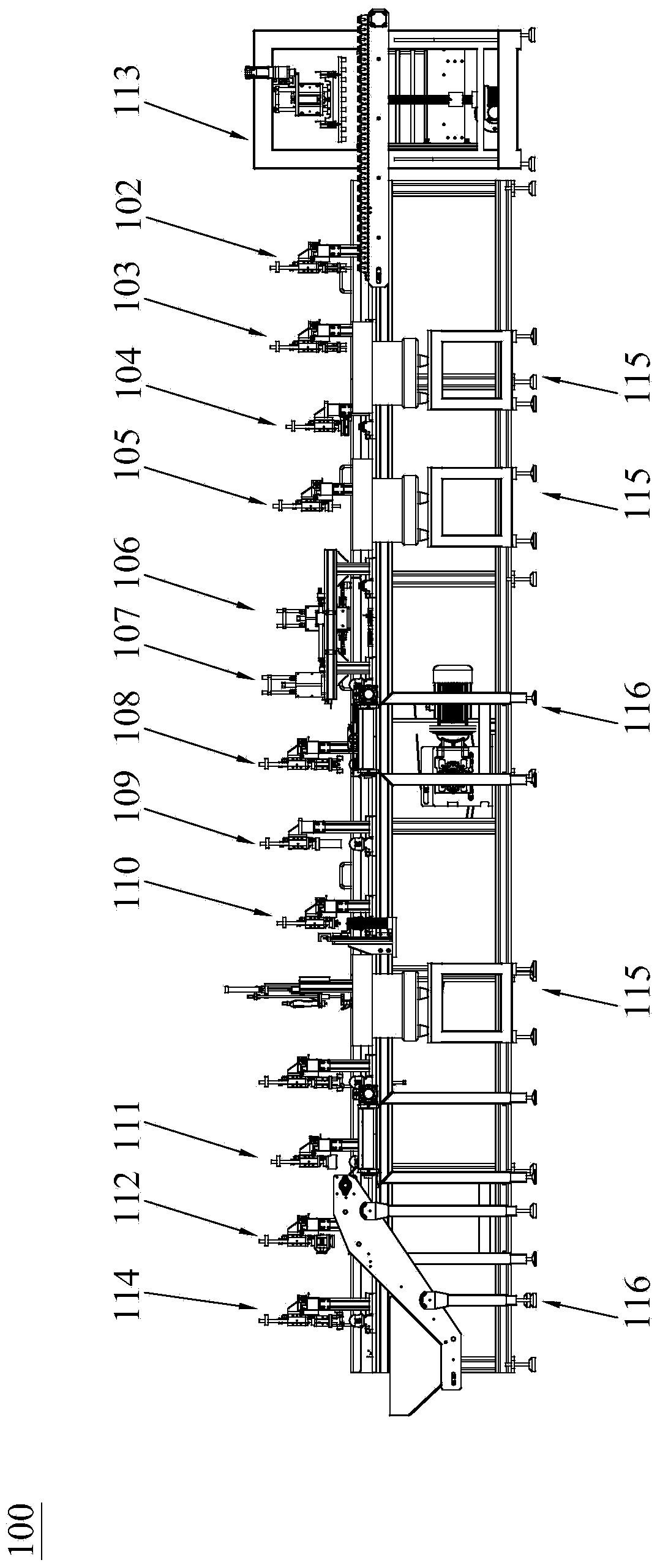

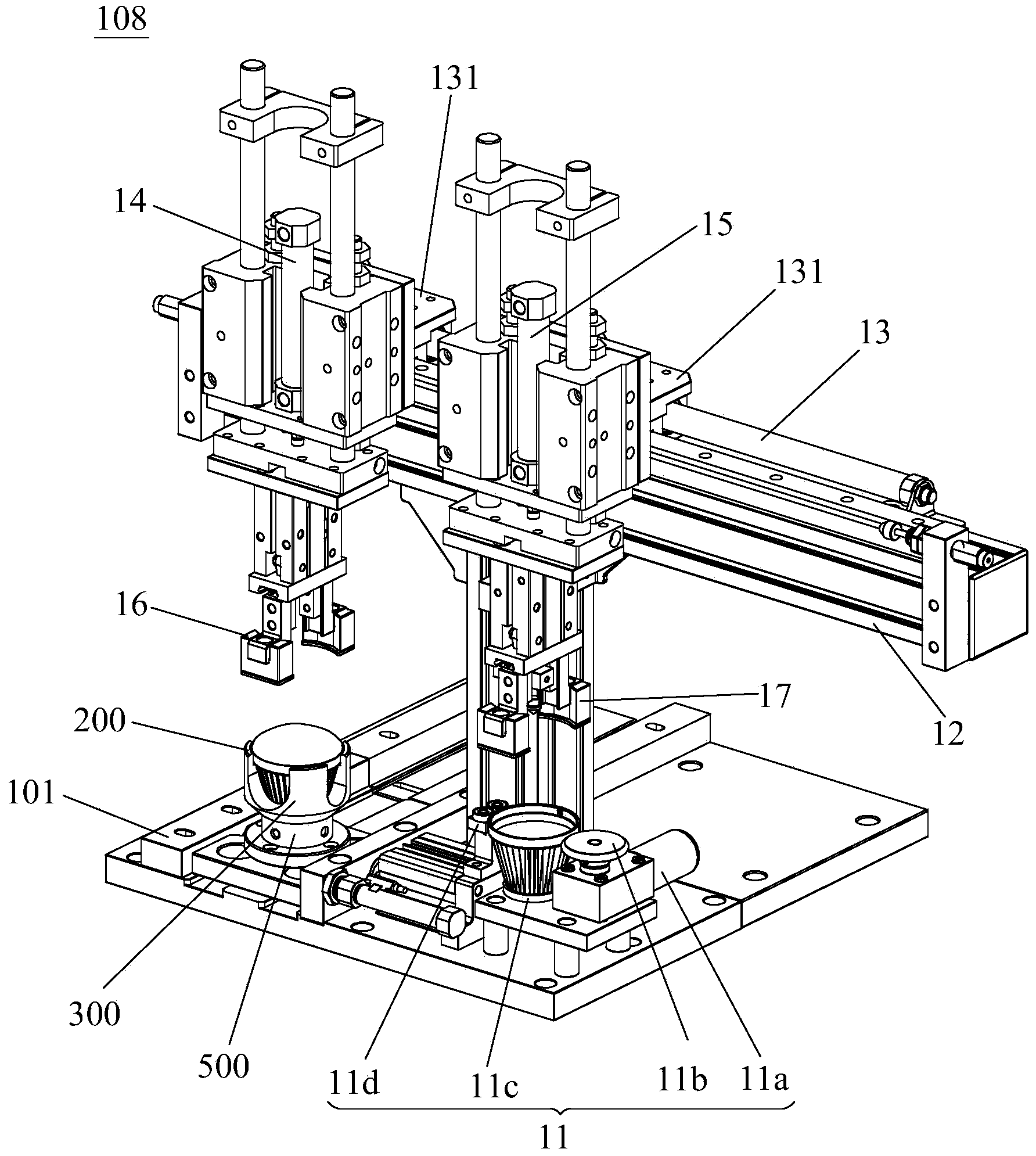

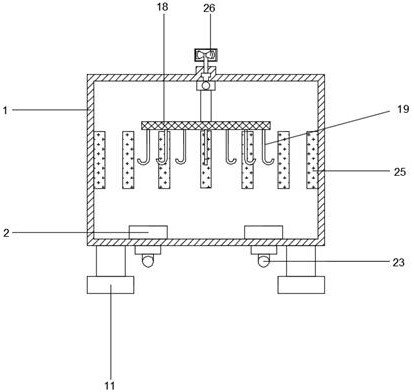

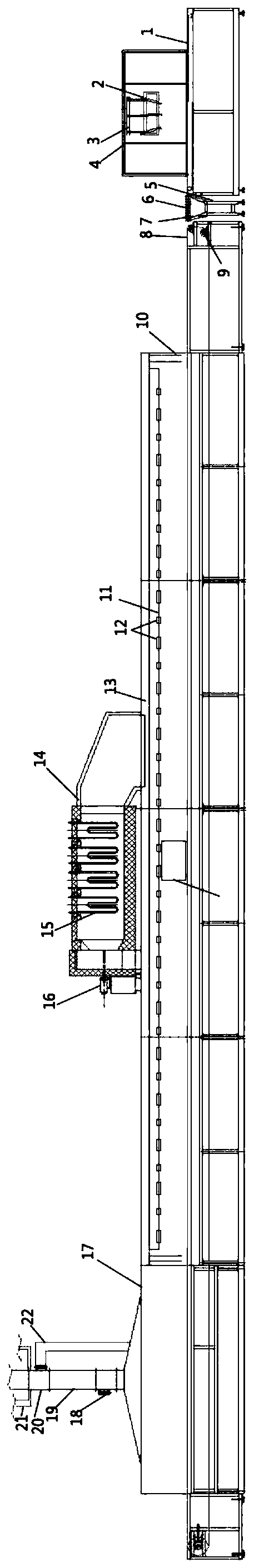

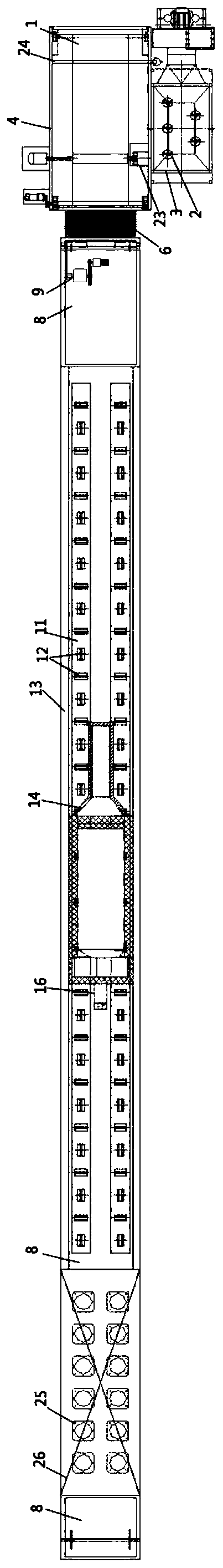

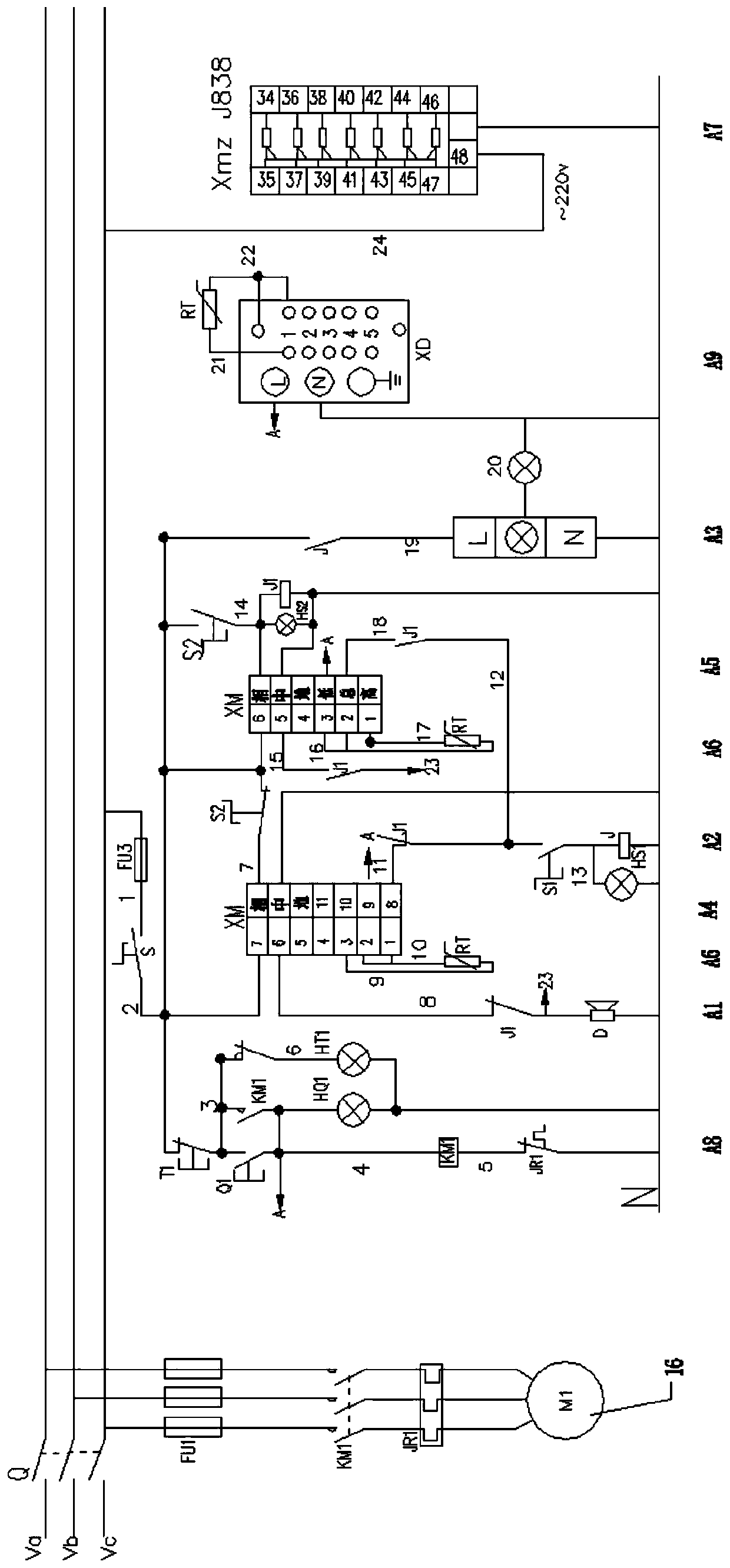

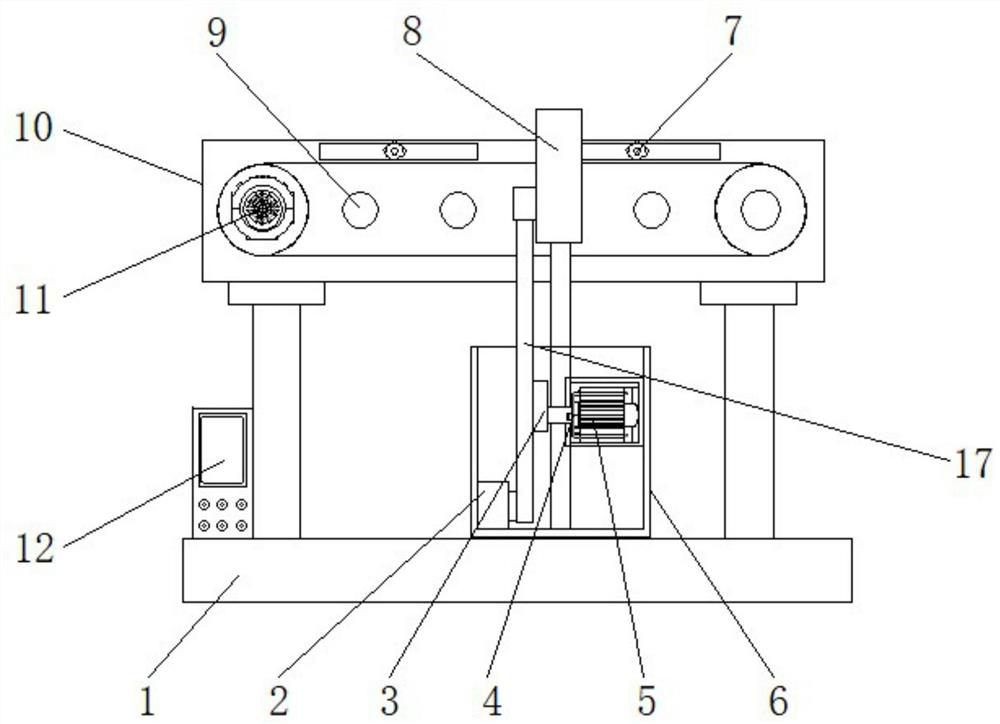

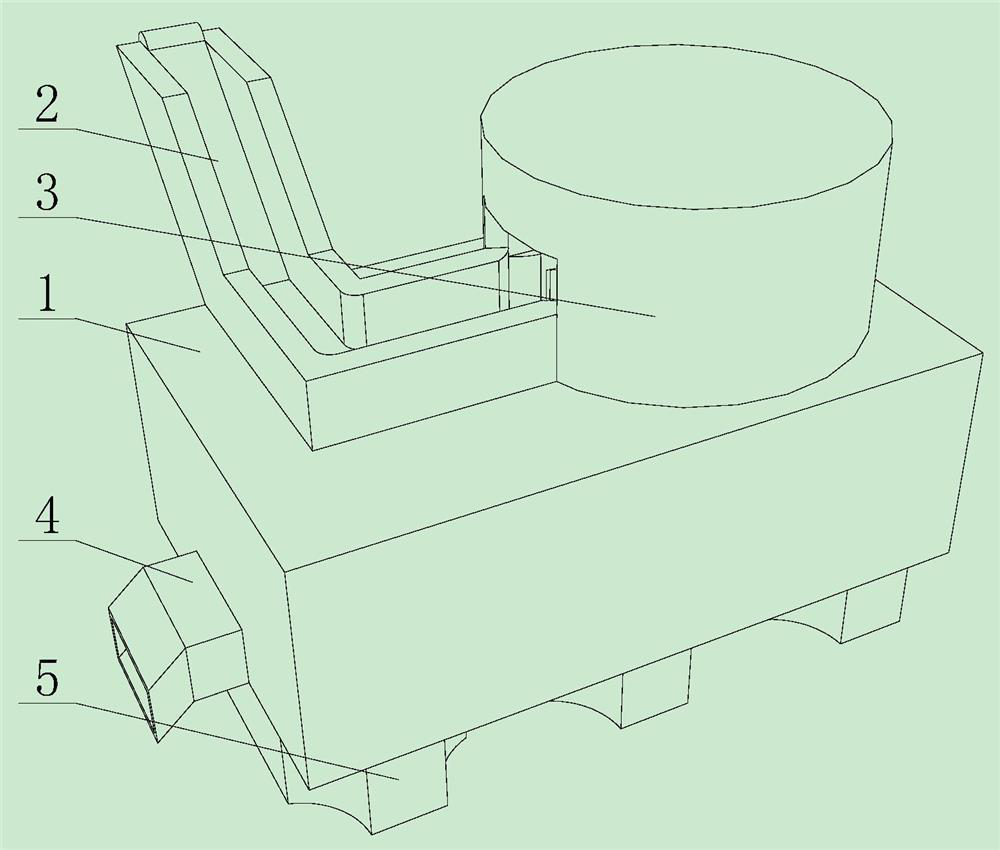

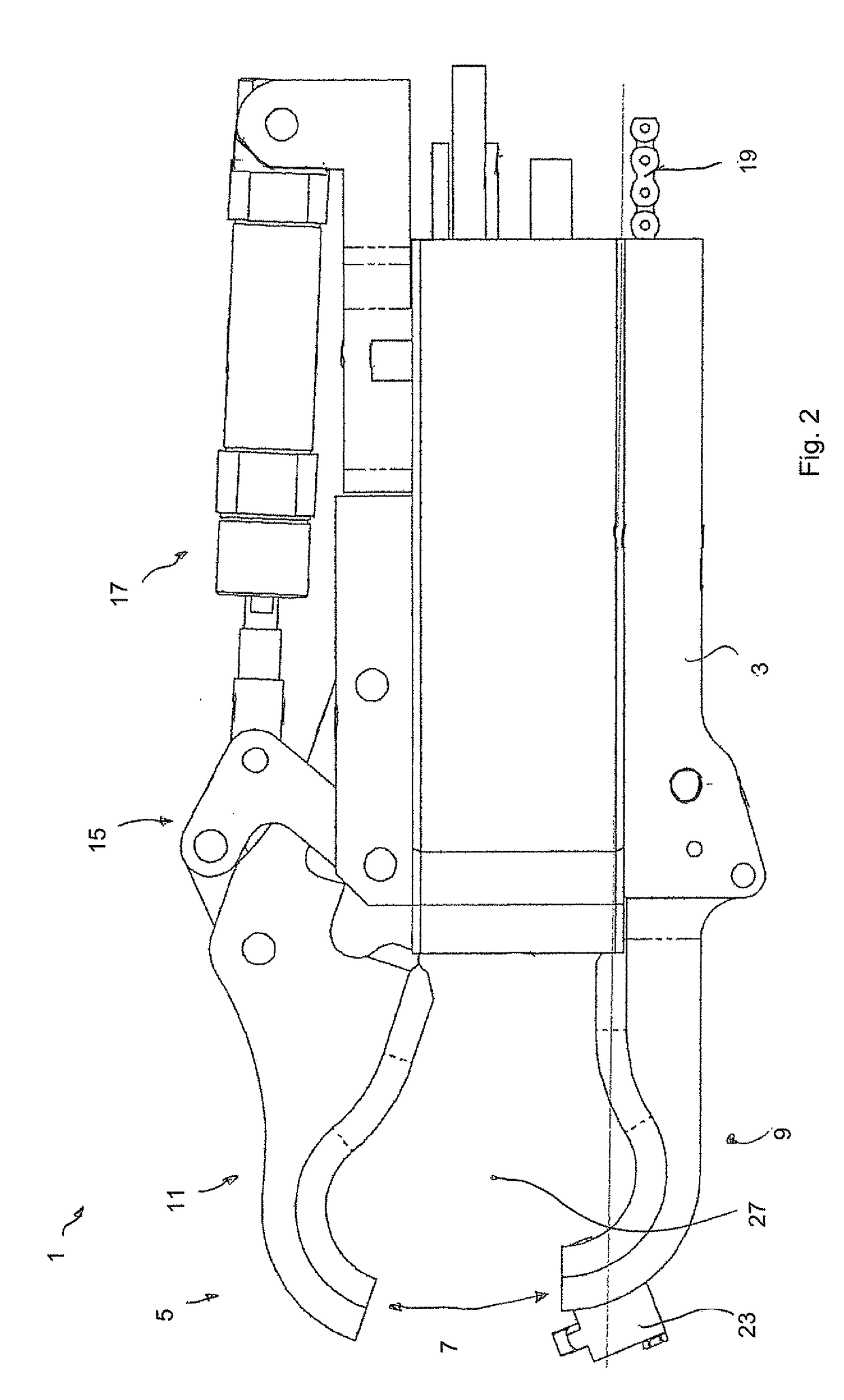

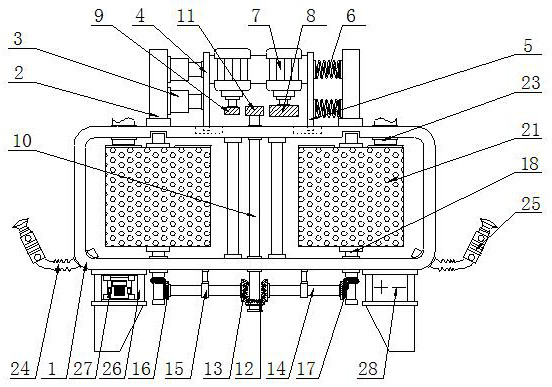

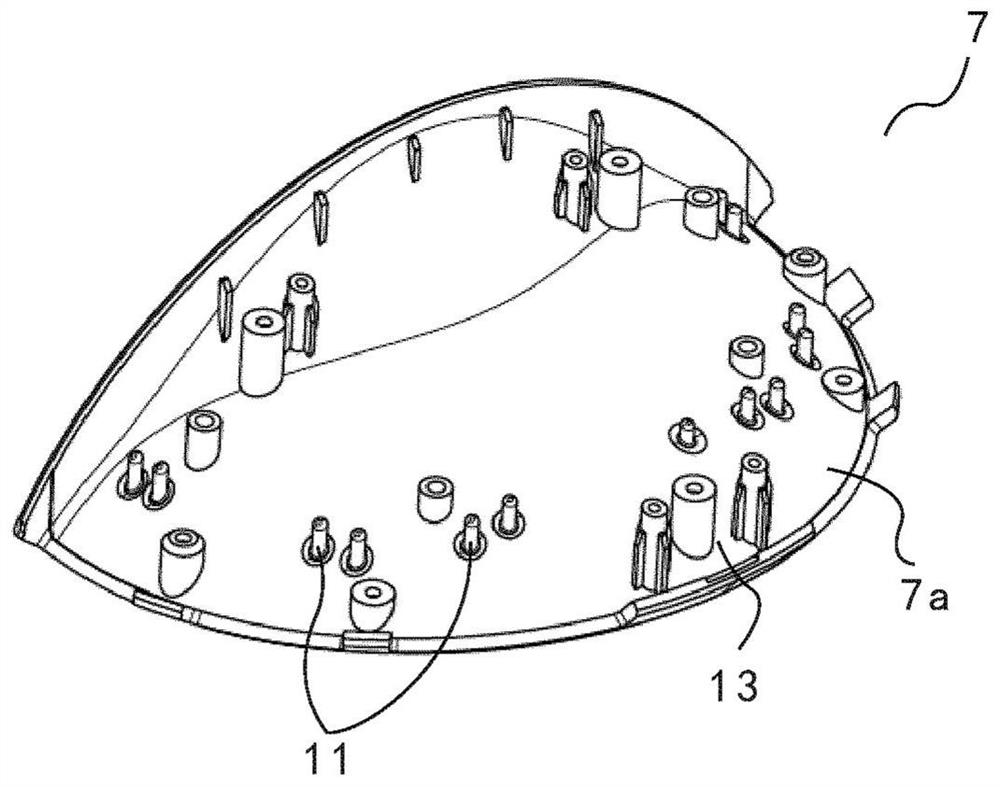

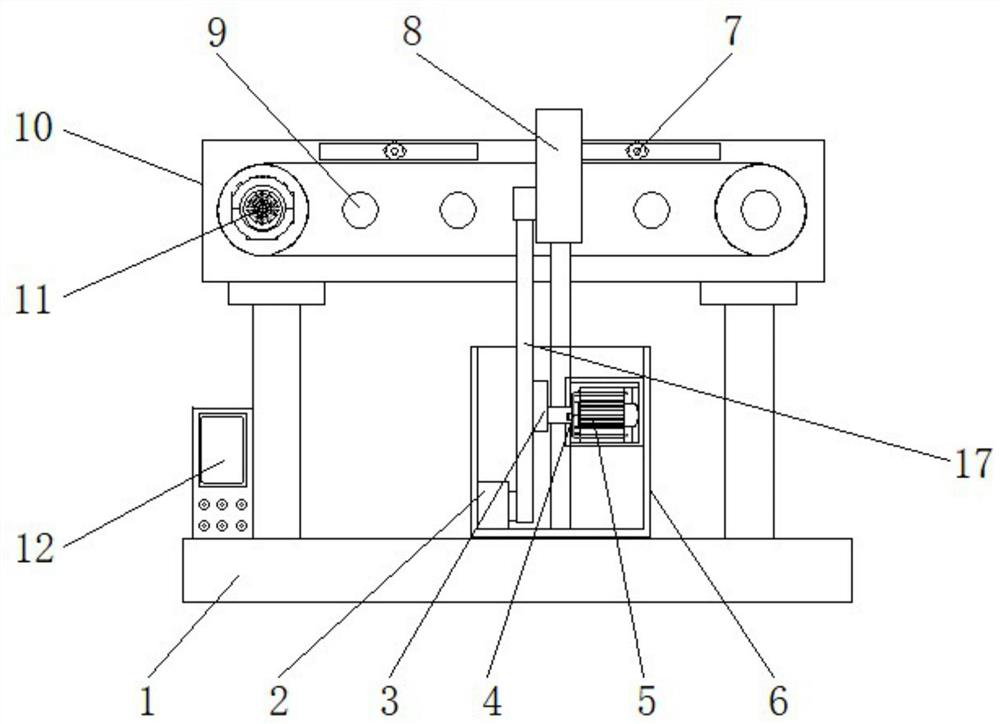

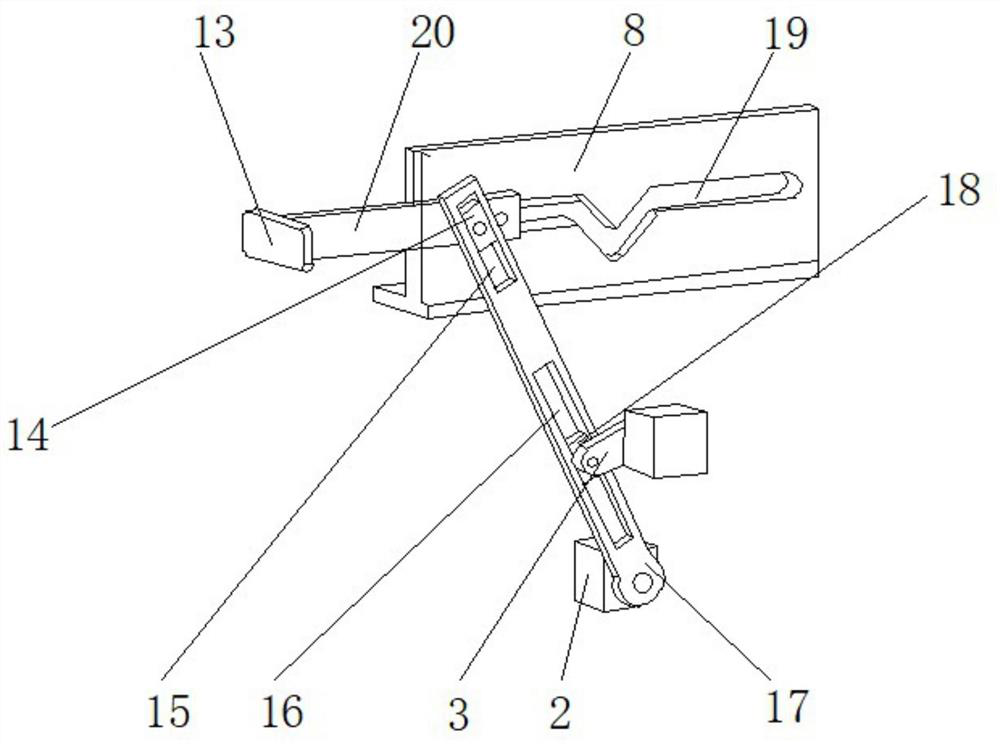

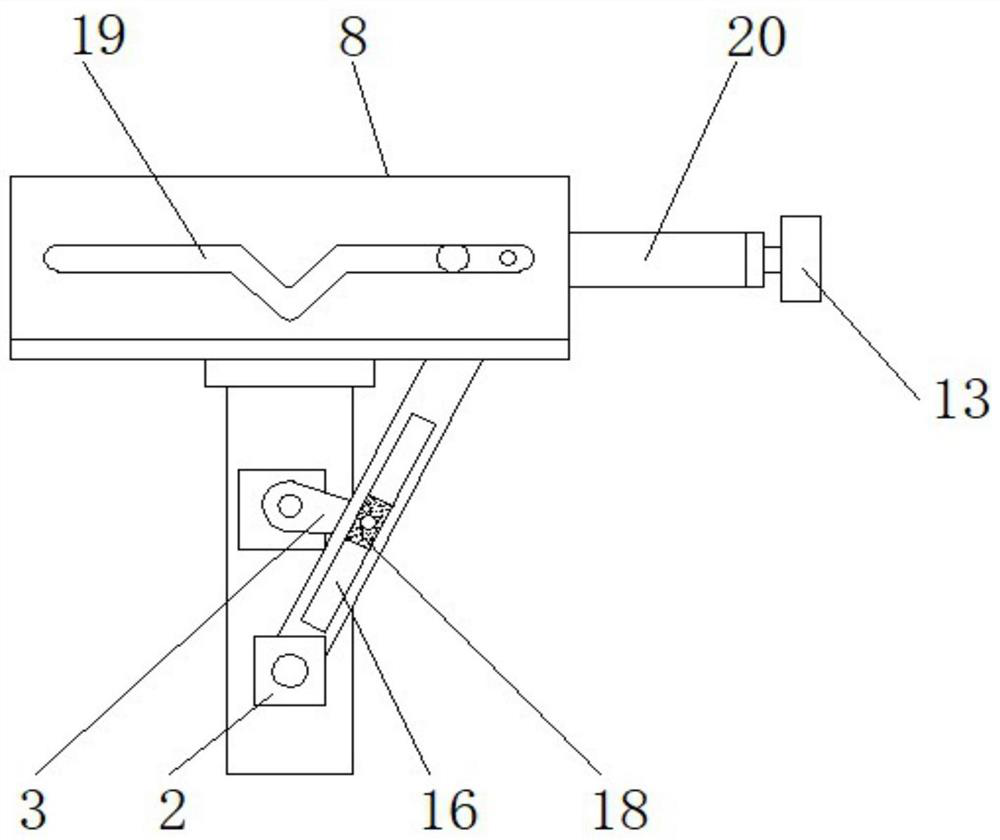

Spherical bulb production line

InactiveCN103681168ARealize automatic positioningQuality assuranceSequential operation station machinesDrive motorEngineering

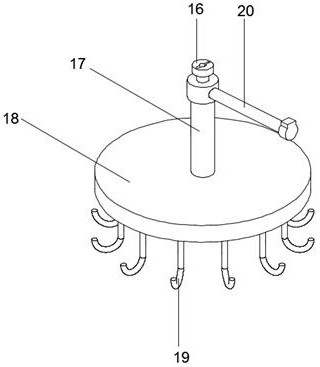

The invention discloses a spherical bulb production line which comprises a conveyor belt. The conveyor belt is provided with a lamp holder one-side locating device, a gluing device and a press-fit screwing device. The lamp holder one-side locating device comprises a lamp holder locating mechanism, a supporting beam, a first air cylinder, a second air cylinder, a third air cylinder, a first pneumatic finger and a second pneumatic finger. The lamp holder locating mechanism comprises a drive motor, a rotary table and a locating groove used for containing a lamp holder. The inner bottom surface of the locating groove is provided with two ejector pins used for locating the lamp holder, wherein the two ejector pins are arranged in a protruding and extending mode. The lamp holder is provided with a locating hole. The rotary table is in rolling contact with the upper edge of the outer side of the lamp holder. The first air cylinder is fixed to the supporting beam, and the second air cylinder and the third air cylinder are fixed to the output end of the first air cylinder. The first pneumatic finger and the second pneumatic finger are fixed to the output end of the second air cylinder and the output end of the third air cylinder respectively. The spherical bulb production line can be used for automatic assembly of a spherical bulb, thereby lowering labor intensity and production cost and improving production efficiency and product quality.

Owner:OUTRACE TECH

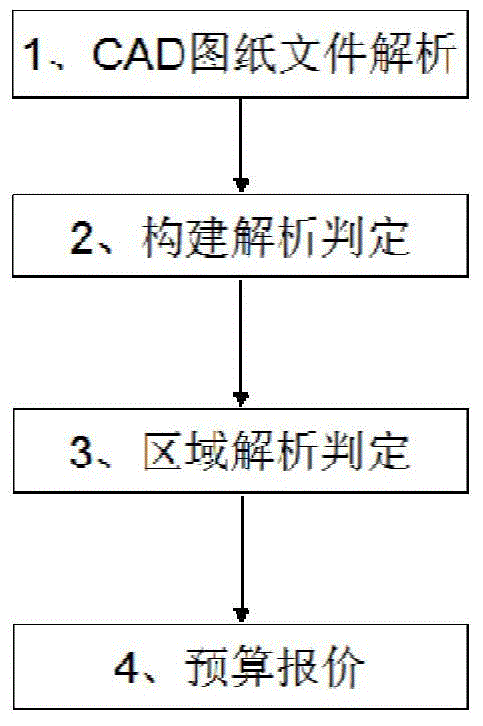

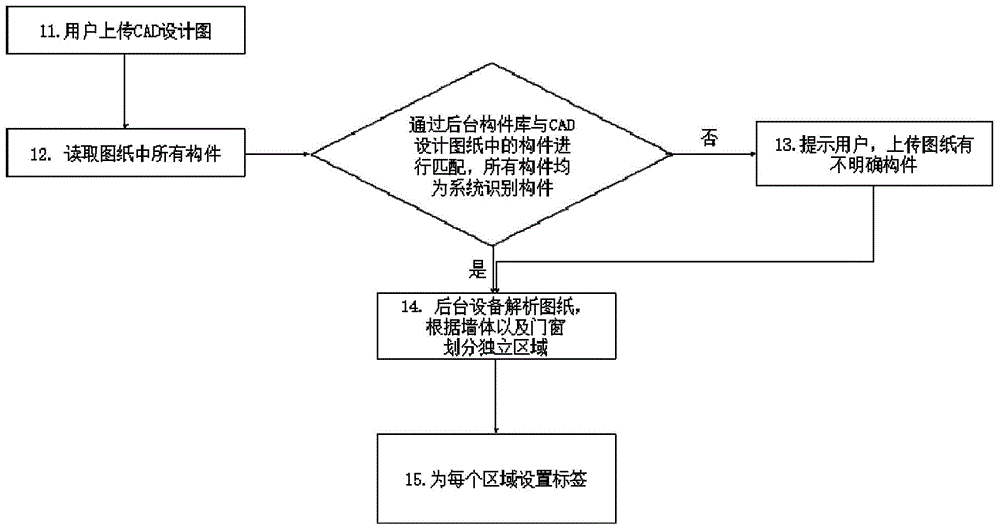

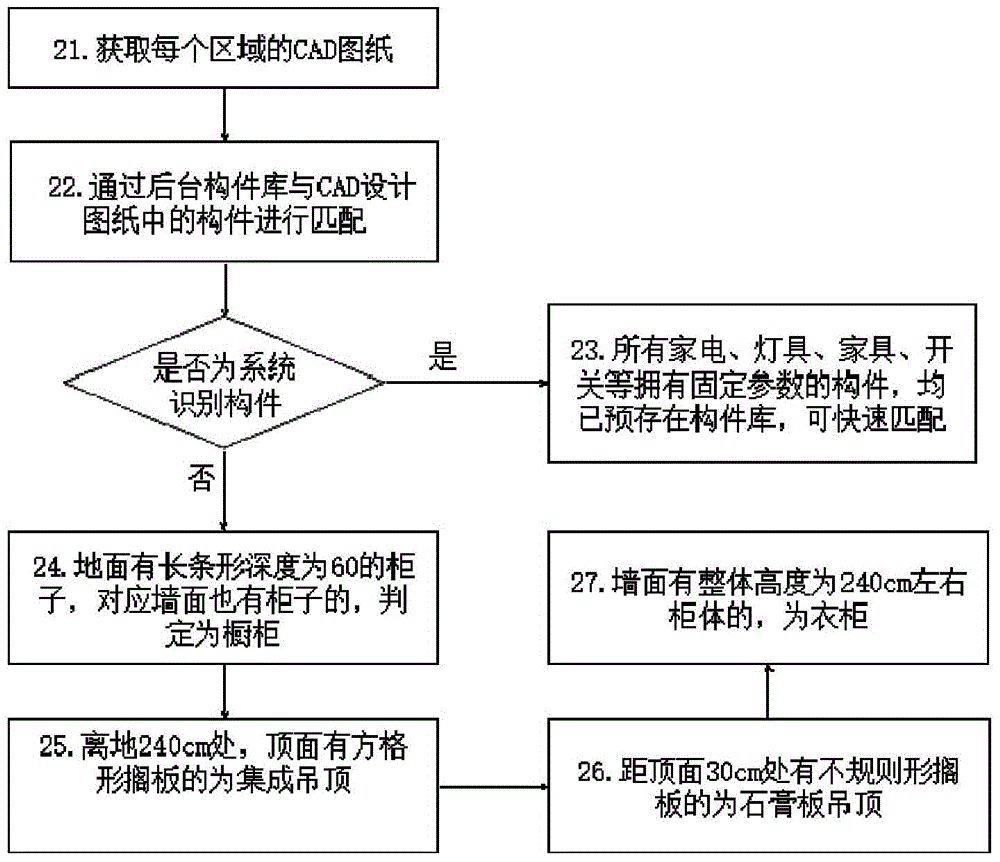

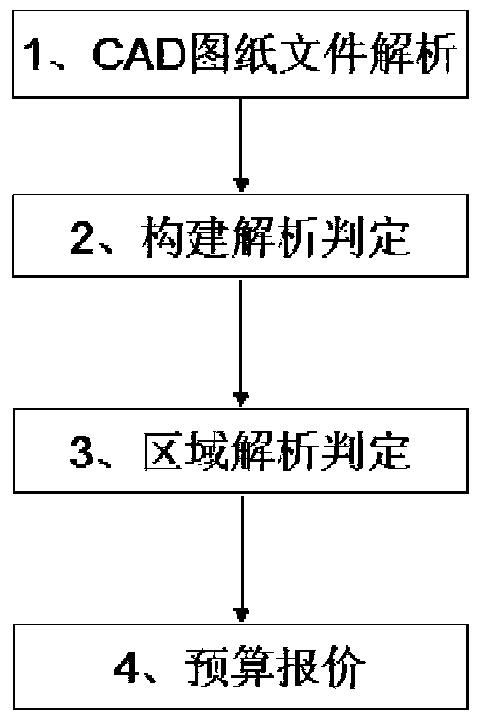

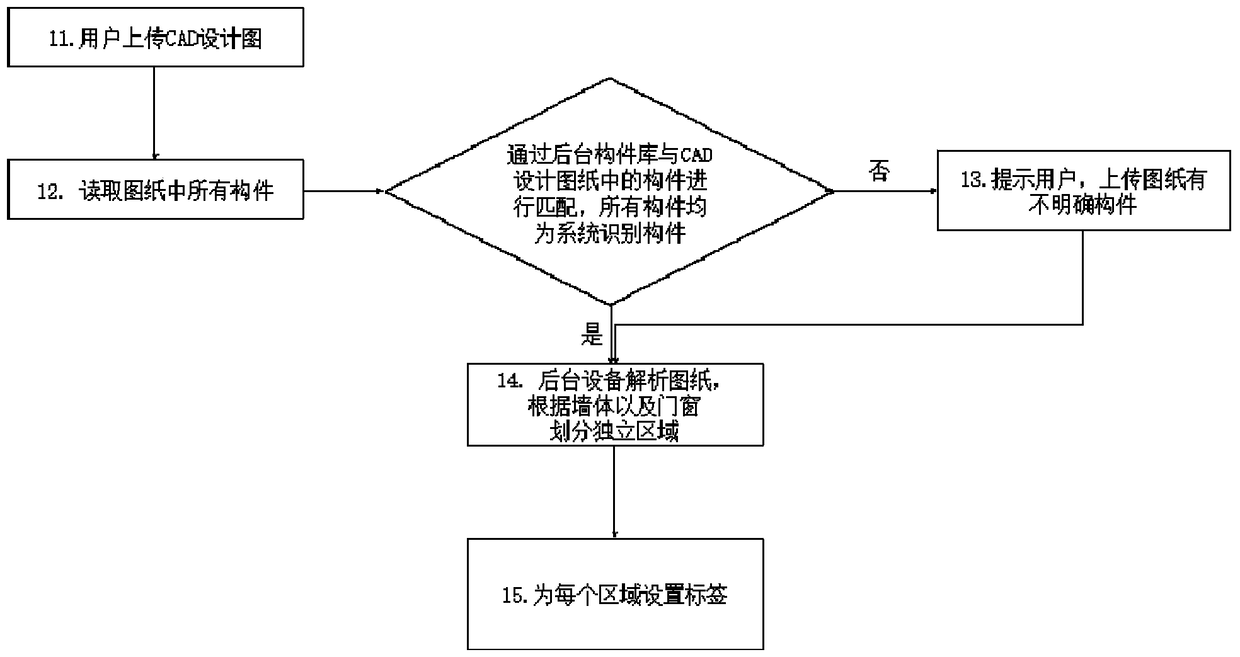

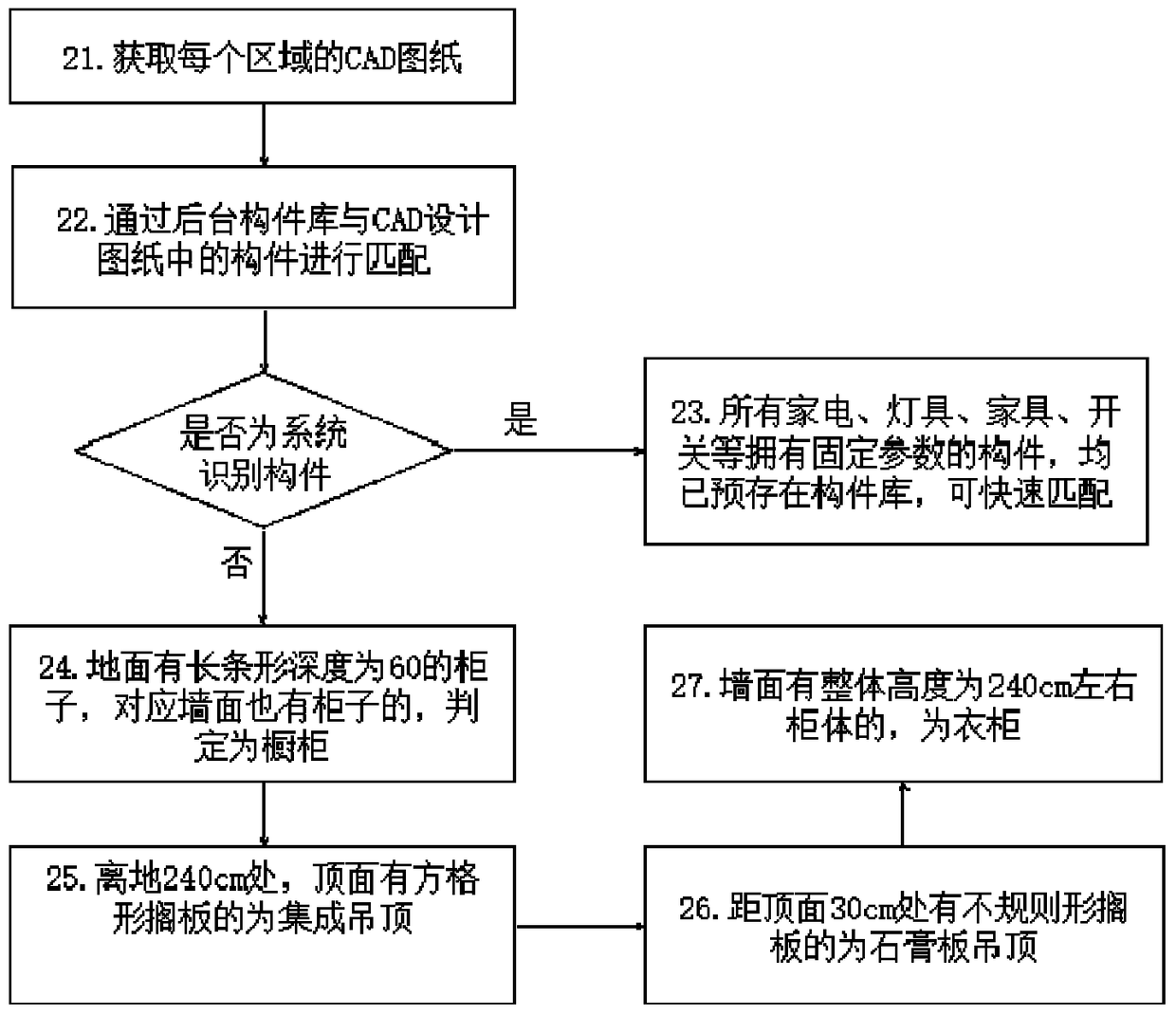

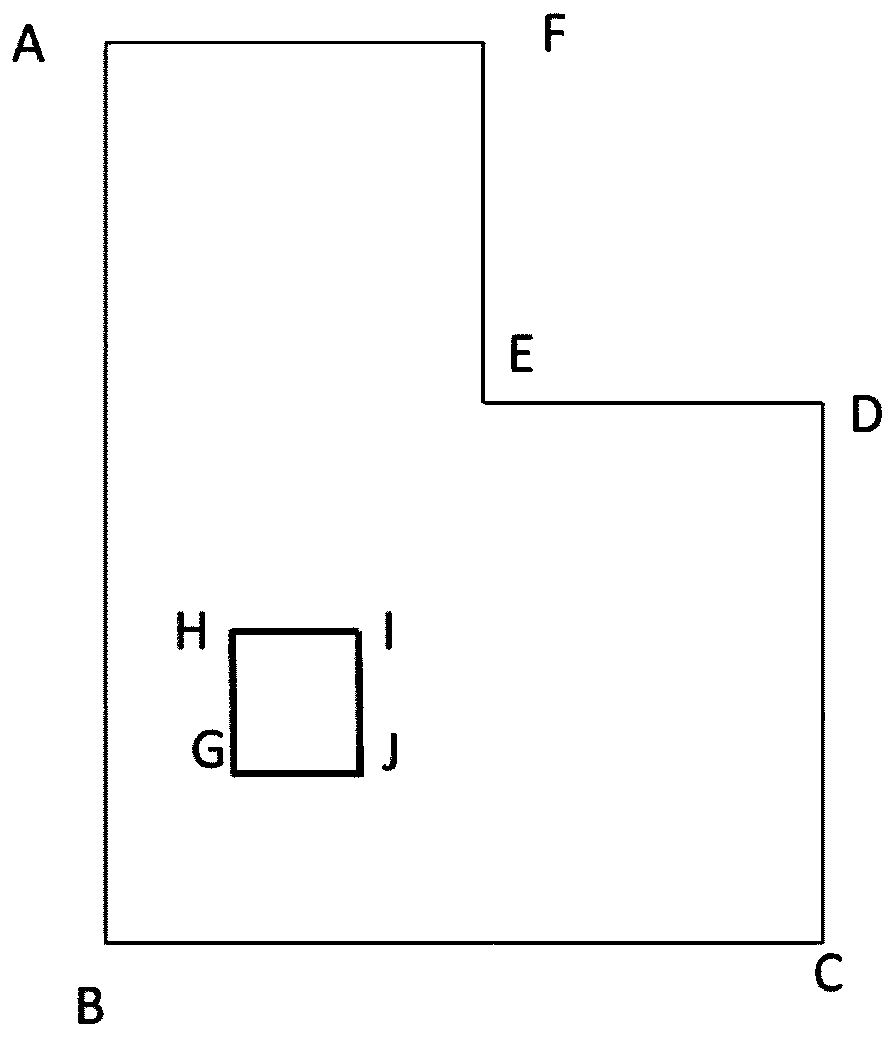

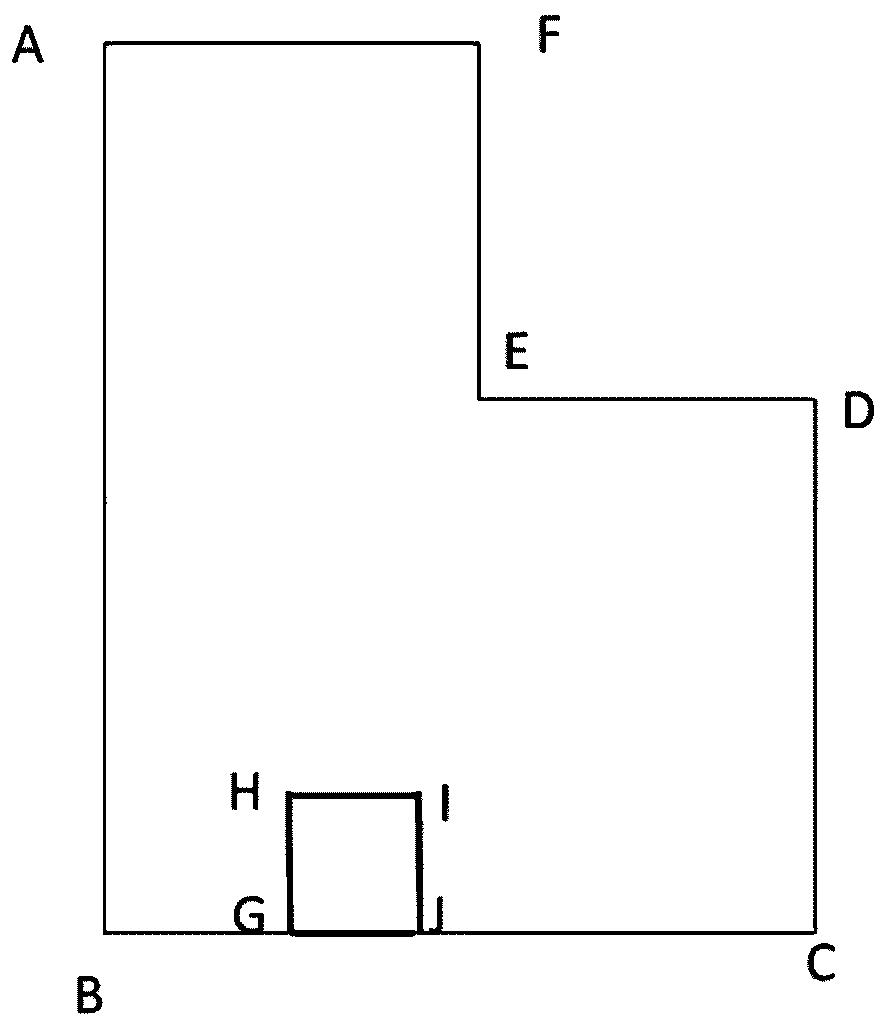

Method and system for automatically generating decoration budget price from CAD (Computer Aided Design) design drawings

ActiveCN104899403AOptimize architectureNo additional investmentSpecial data processing applicationsComputer Aided DesignThe Internet

The invention discloses a method and a system for automatically generating decoration budget price from CAD design drawings. The method comprises the steps: step 1, analyzing CAD drawing documents; step 2, analyzing and judging structures; step 3, analyzing and judging areas; step 4, giving the budget price. The system comprises client equipment, a background data collection and processing equipment and a budget price template library; the client equipment, the background data collection and processing equipment and the budget price template library can transmit and read data through the Internet. The method and the system disclosed by the invention are very intelligent; manual intervention is not needed, so that manpower cost can be greatly reduced; the method and the system are capable of helping a decoration and design company to accelerate working procedures; operation cost is reduced, and moreover, professional demand on giving the decoration budget is also reduced; the method and the system are applicable for house owners to take quotation for reference and rationally arrange decoration methods and has very wide purpose.

Owner:JIANGSU EHE DACHENG NETWORK TECH

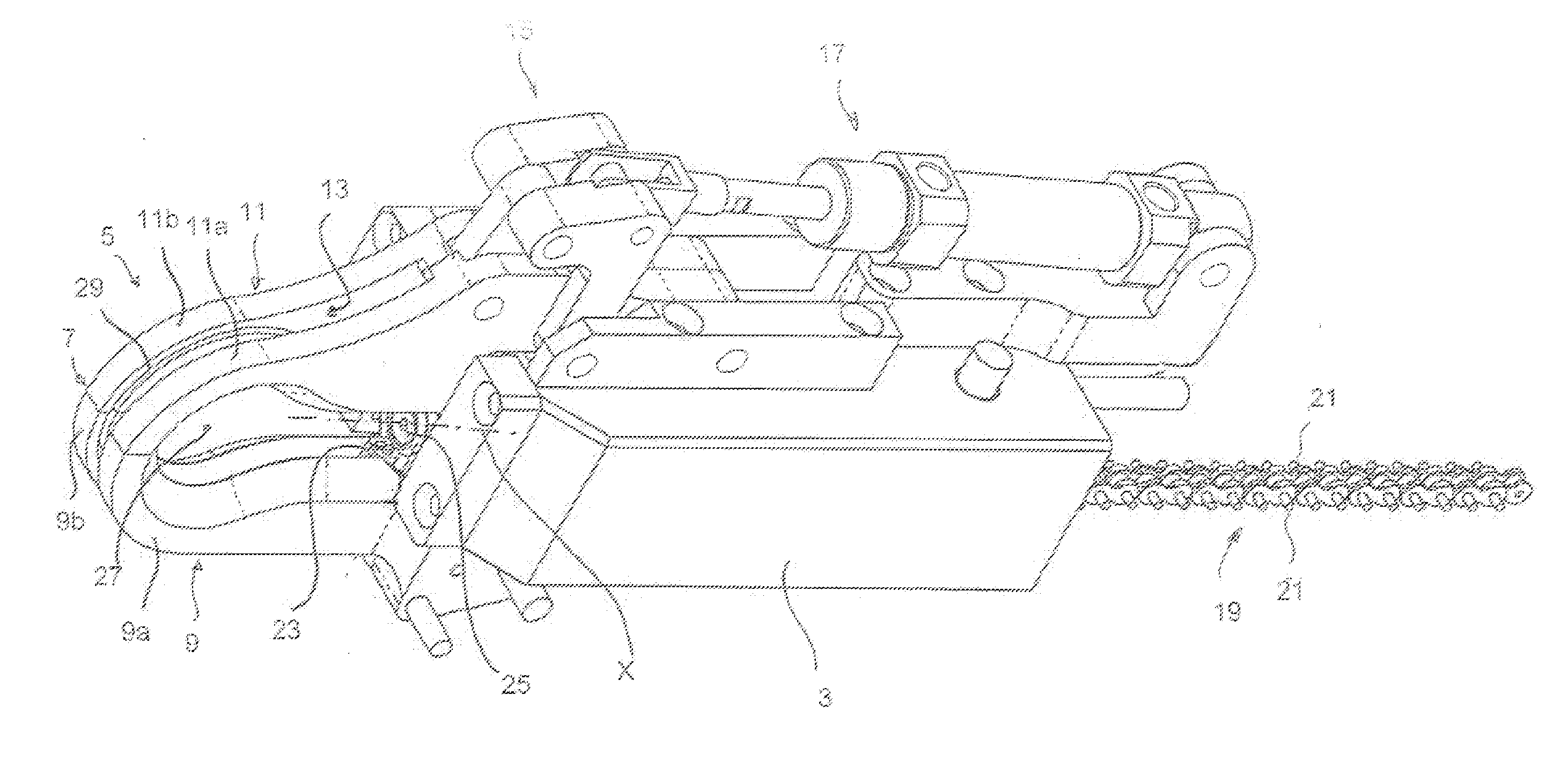

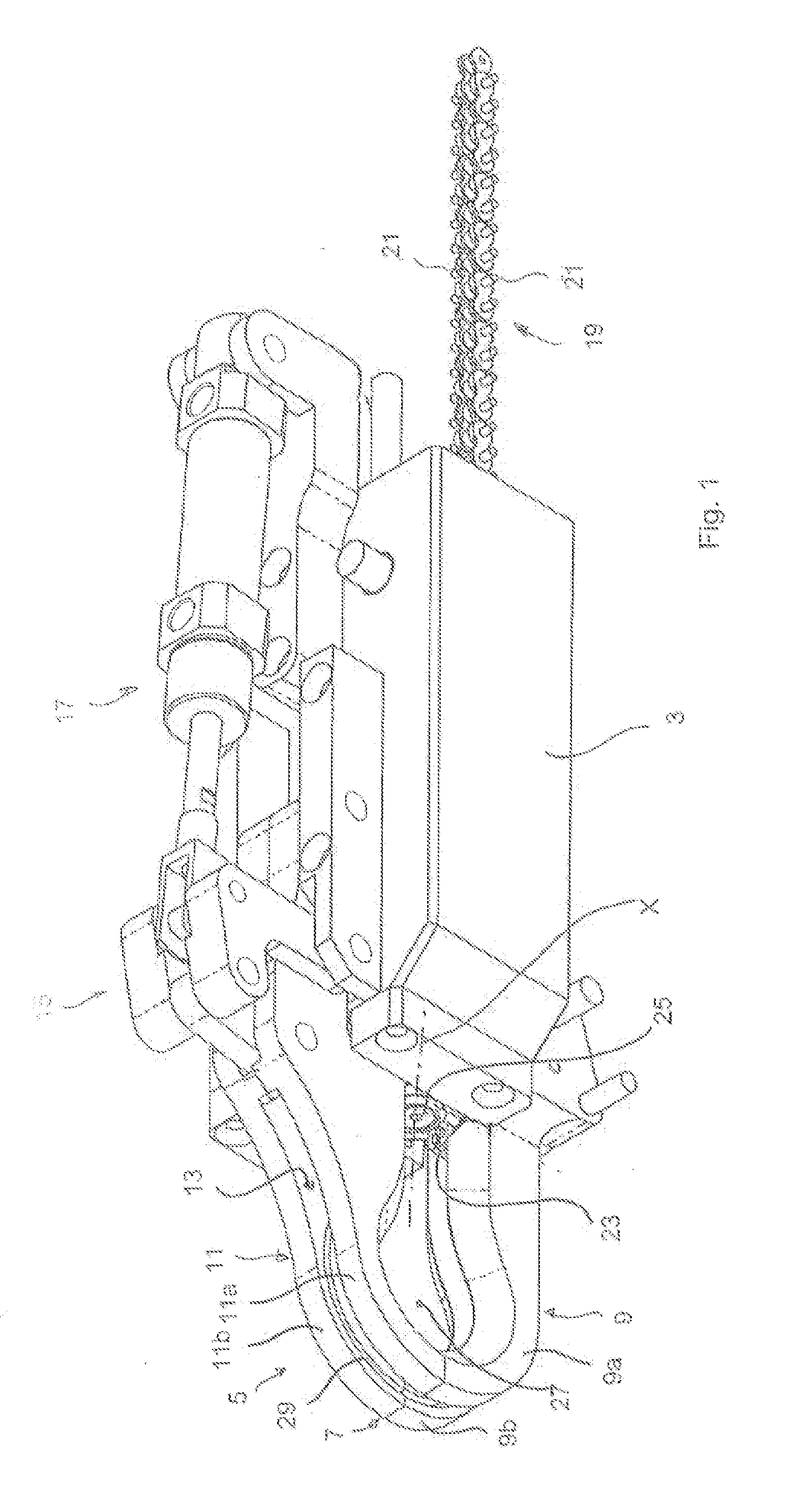

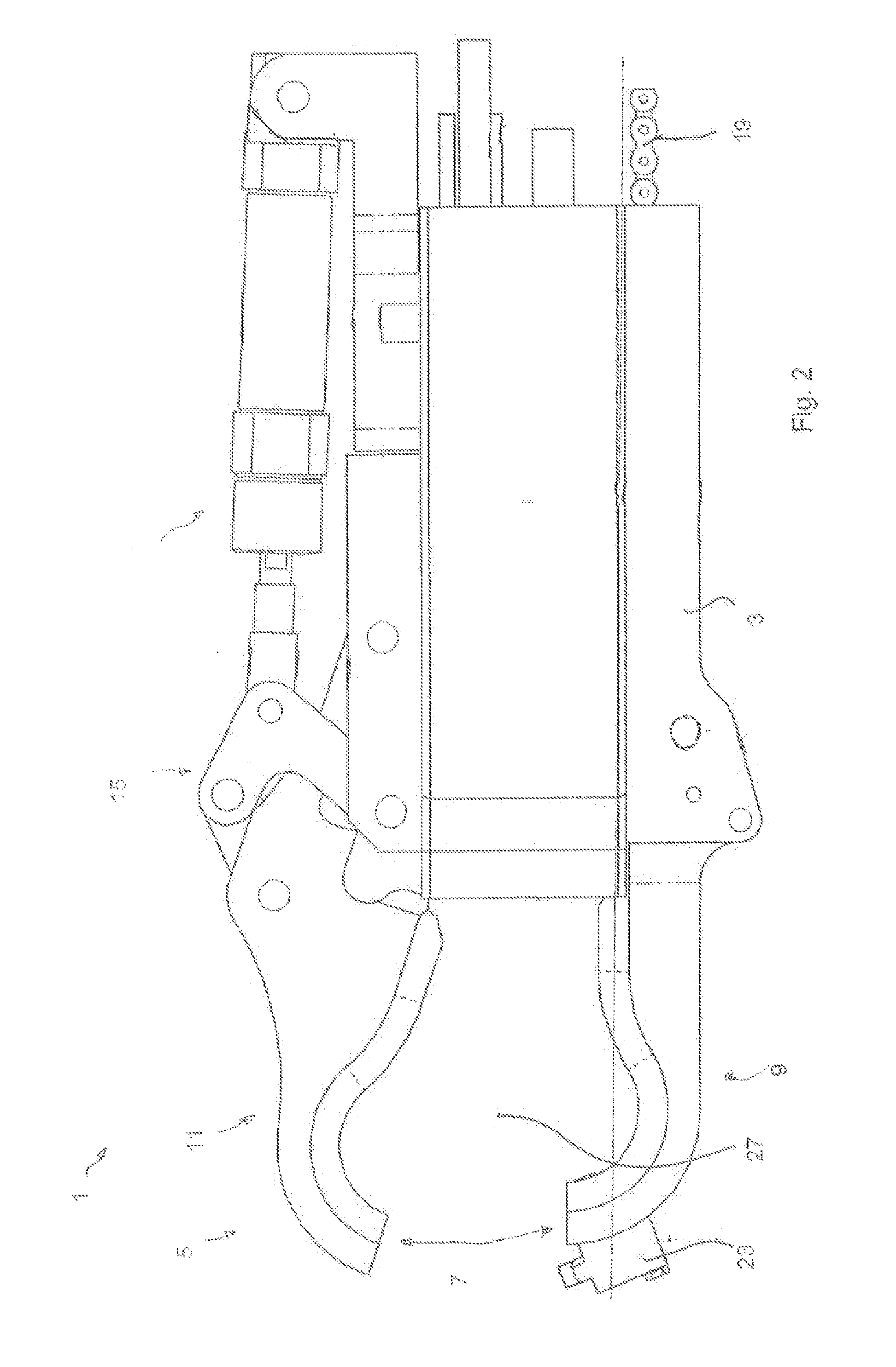

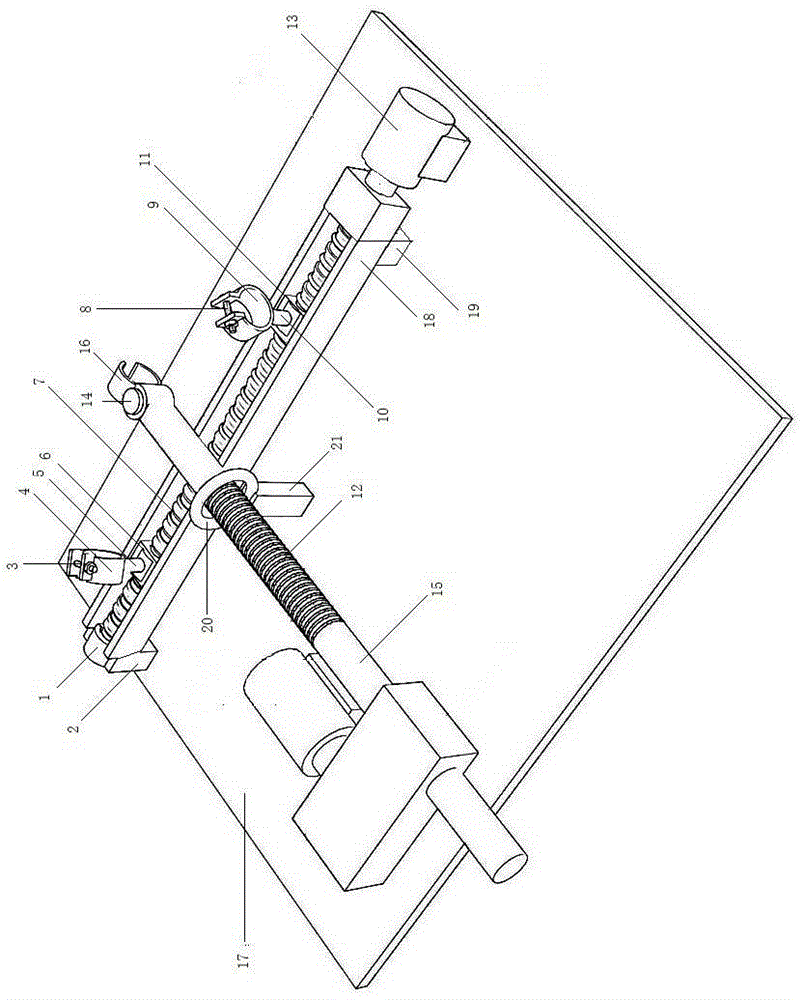

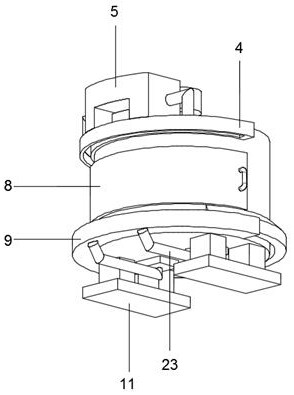

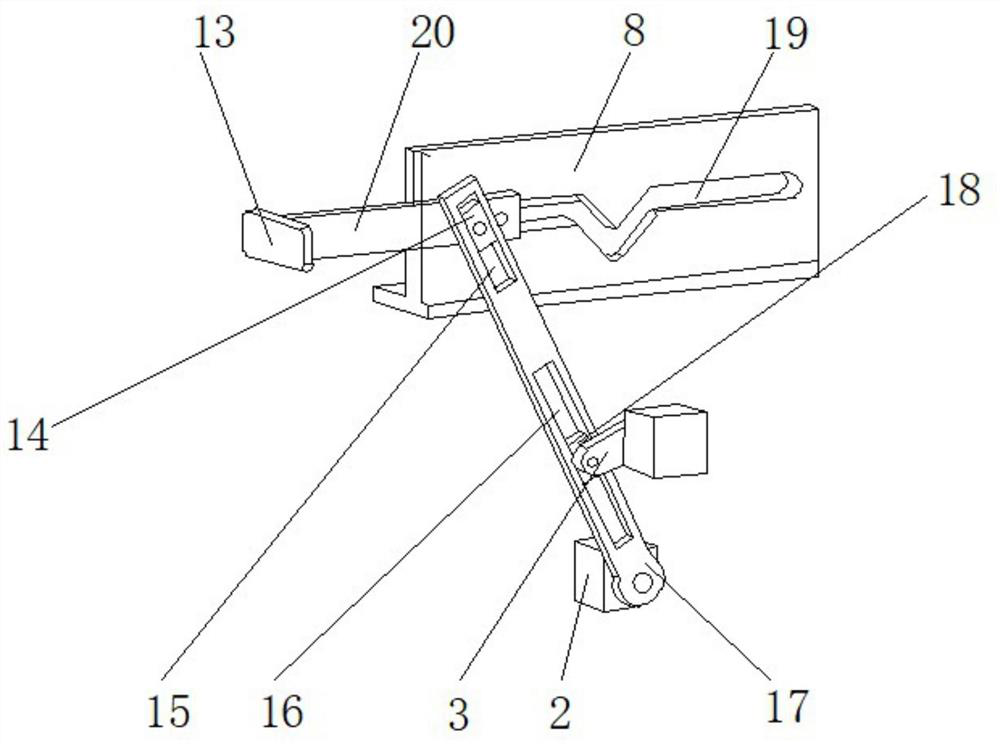

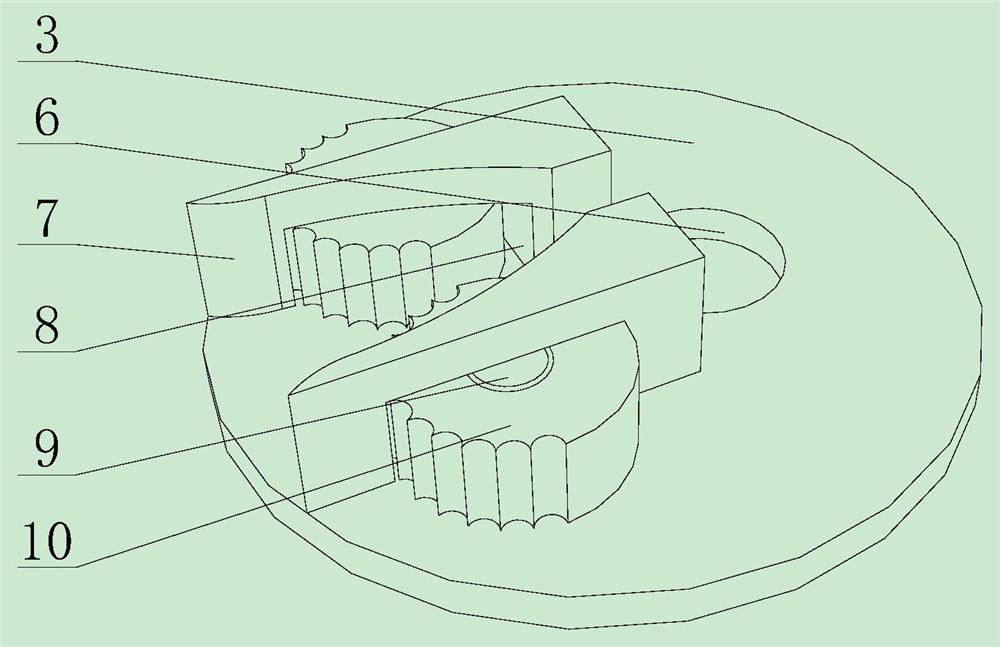

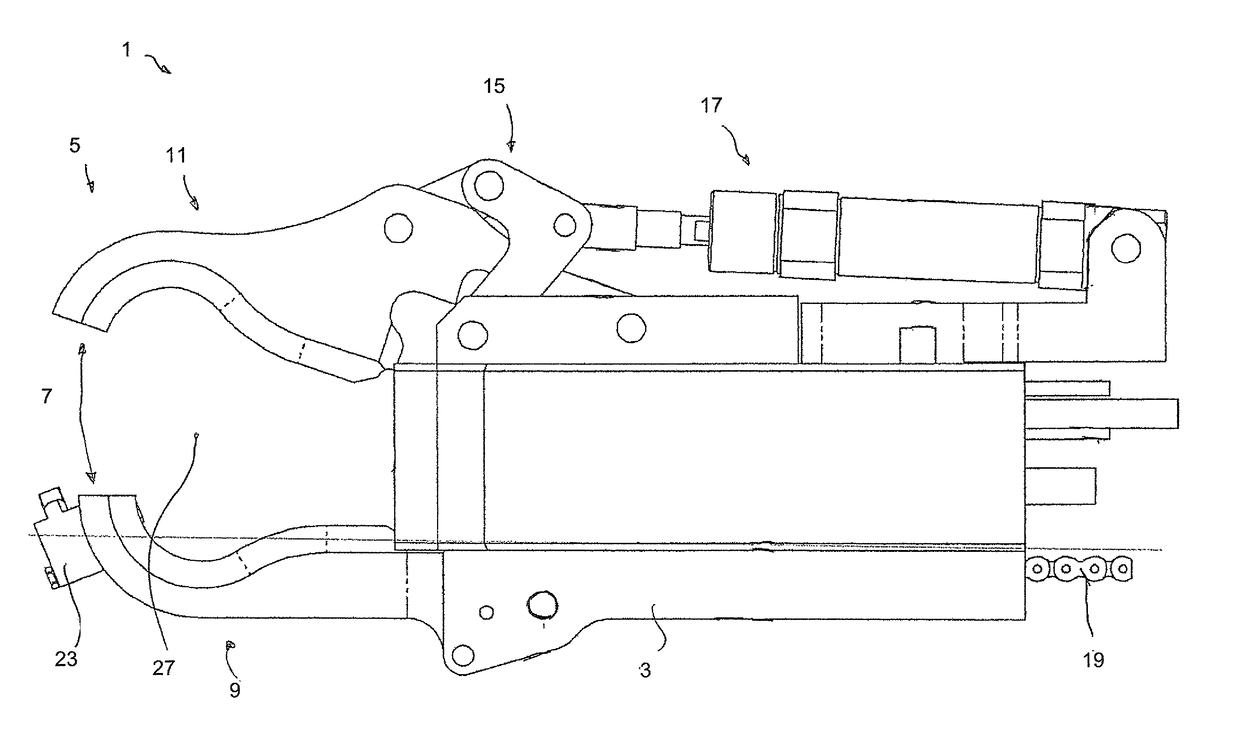

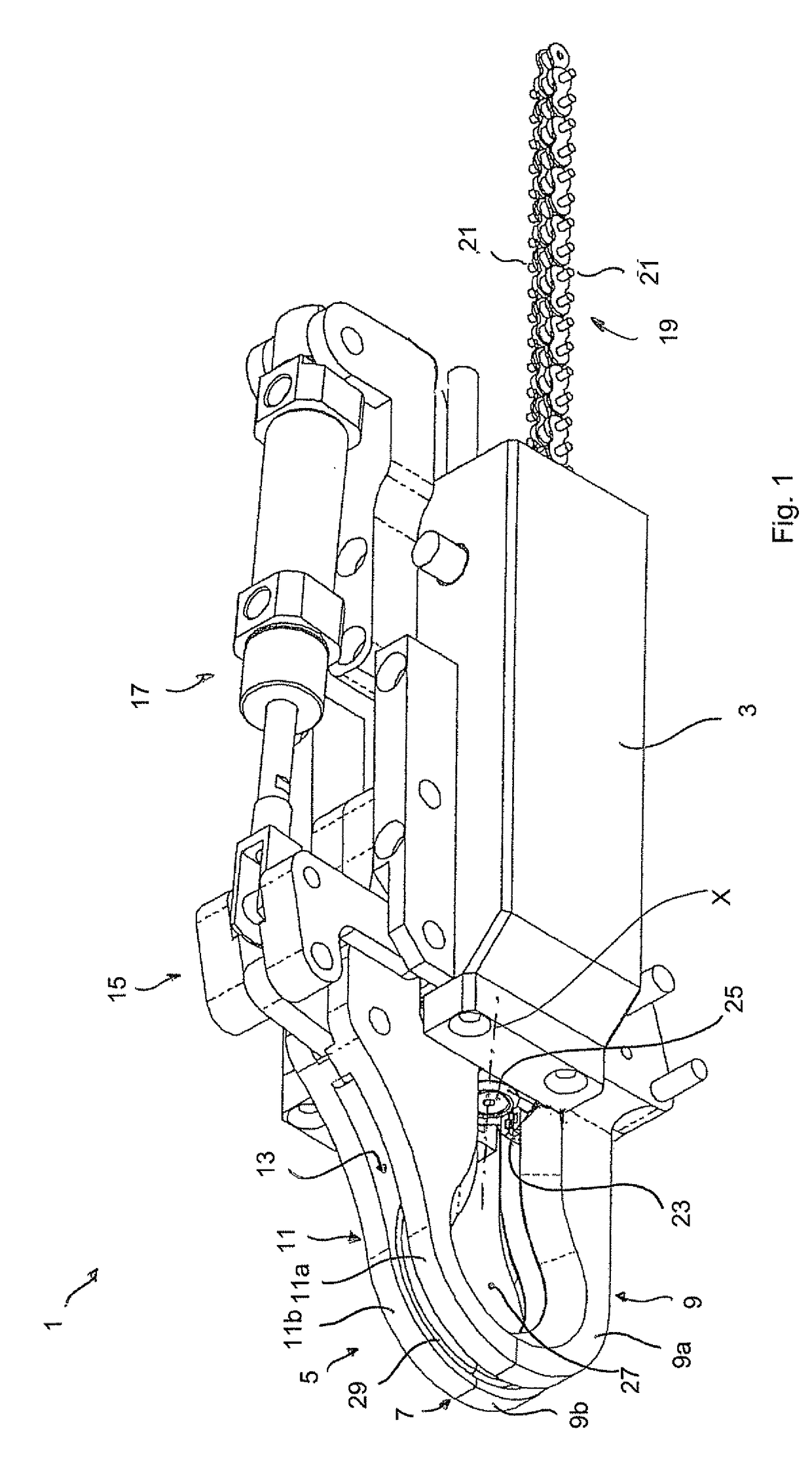

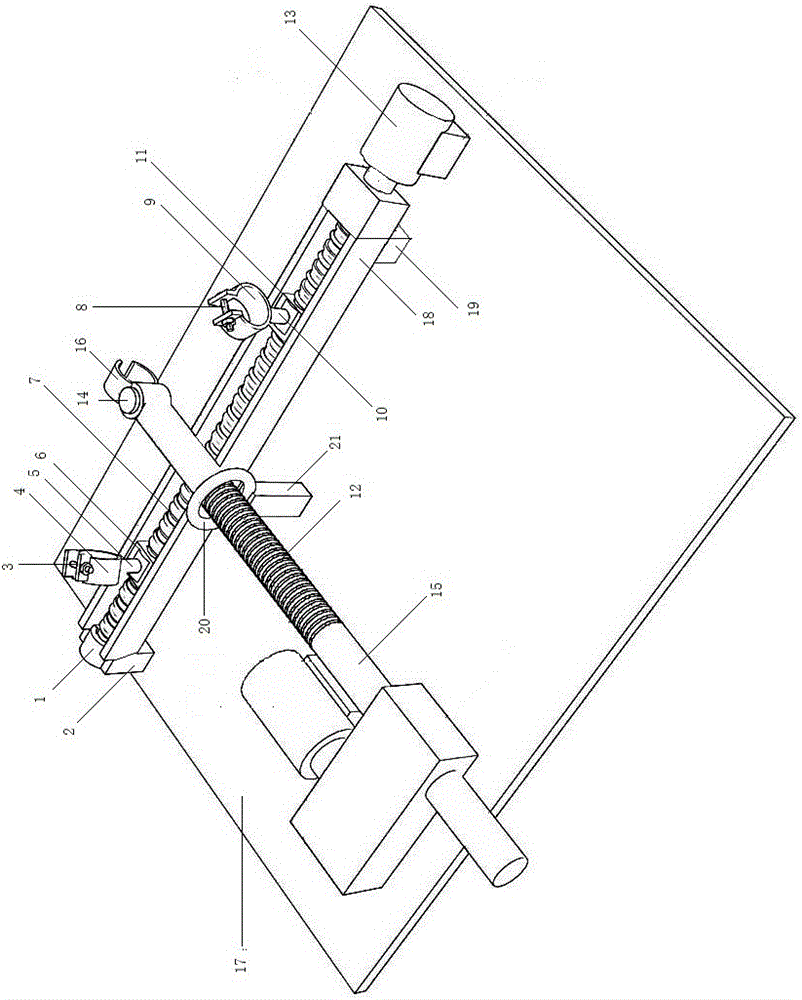

Device and method for automatically twisting metal wires, in particular for connecting adjacent, preferably mutually intersecting structure elements

InactiveUS20150266082A1Reduce decreaseSufficiently fixedWire articlesBuilding material handlingEngineeringStructuring element

The invention concerns an apparatus, a method and a use of the apparatus for automatically twisting metal wires. The invention concerns in particular such an apparatus for connecting adjacent, preferably mutually crossing structural elements, comprising a wire feed means for feeding wire, preferably endless wire, into the apparatus, an arcuate wire guide which has a selectively openable and closable opening and which is adapted to guide the fed wire in the closed position along the arcuate wire guide from a first side of the arcuate wire guide to a second side of the arcuate wire guide, that is in opposite relationship with respect to the opening, a pulling slider adapted to engage the fed wire on the first side of the arcuate wire guide and to pull it towards the second side of the arcuate wire guide, and a twisting unit adapted to engage the fed wire on both sides of the arcuate wire guide and to twist it by means of a rotational movement.

Owner:WOBBEN PROPERTIES GMBH

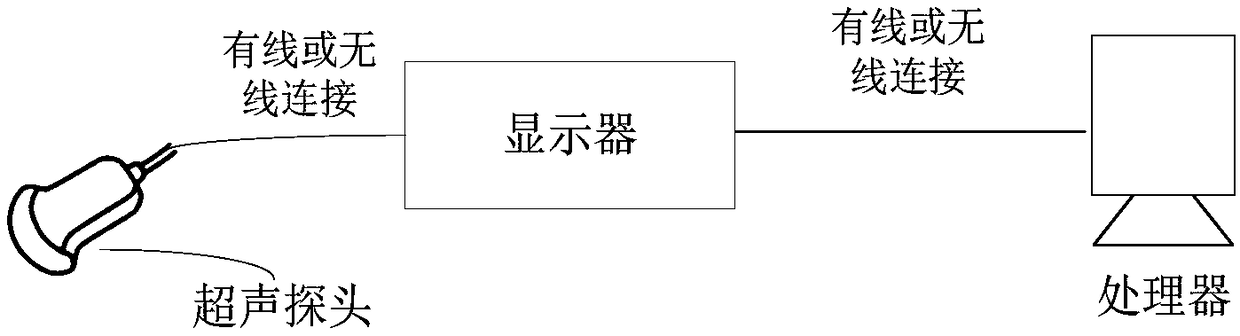

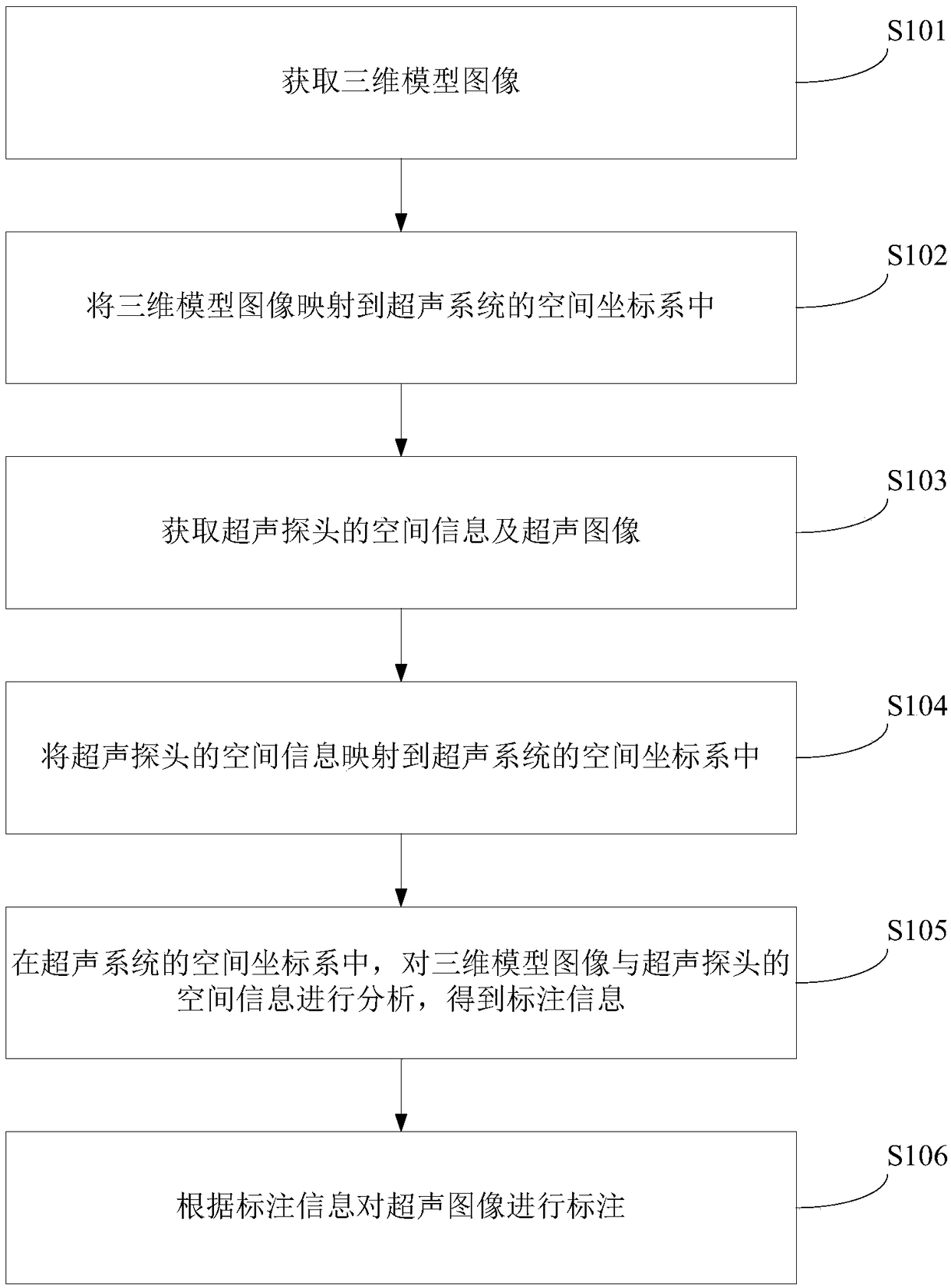

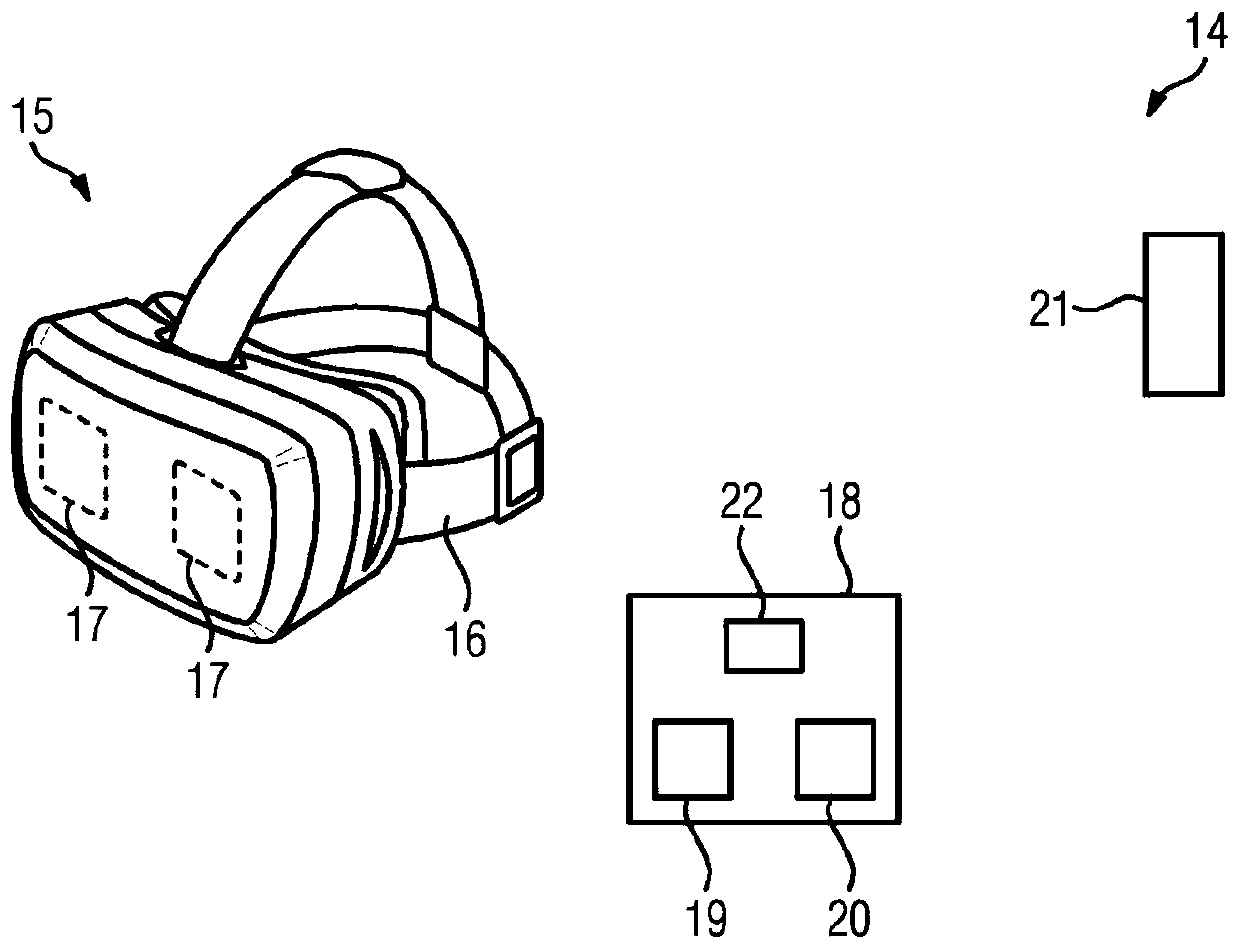

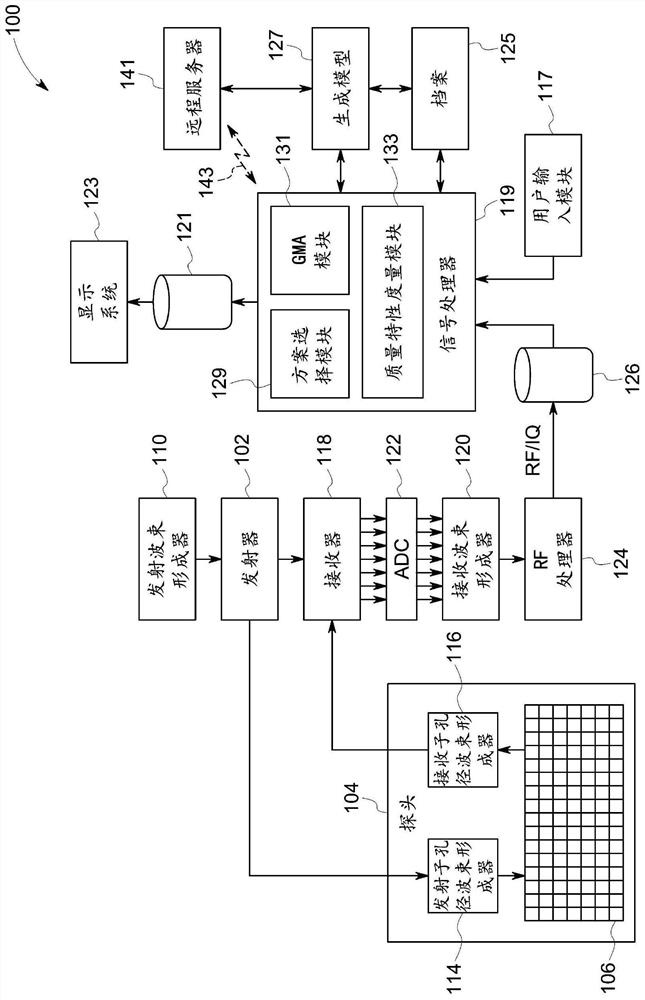

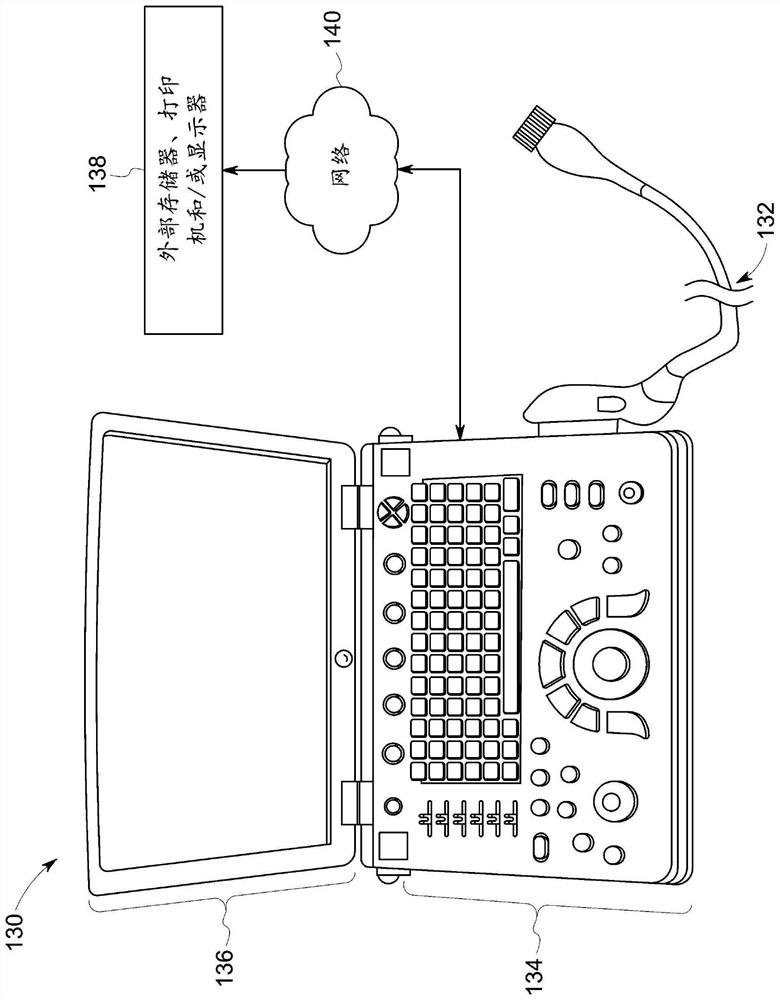

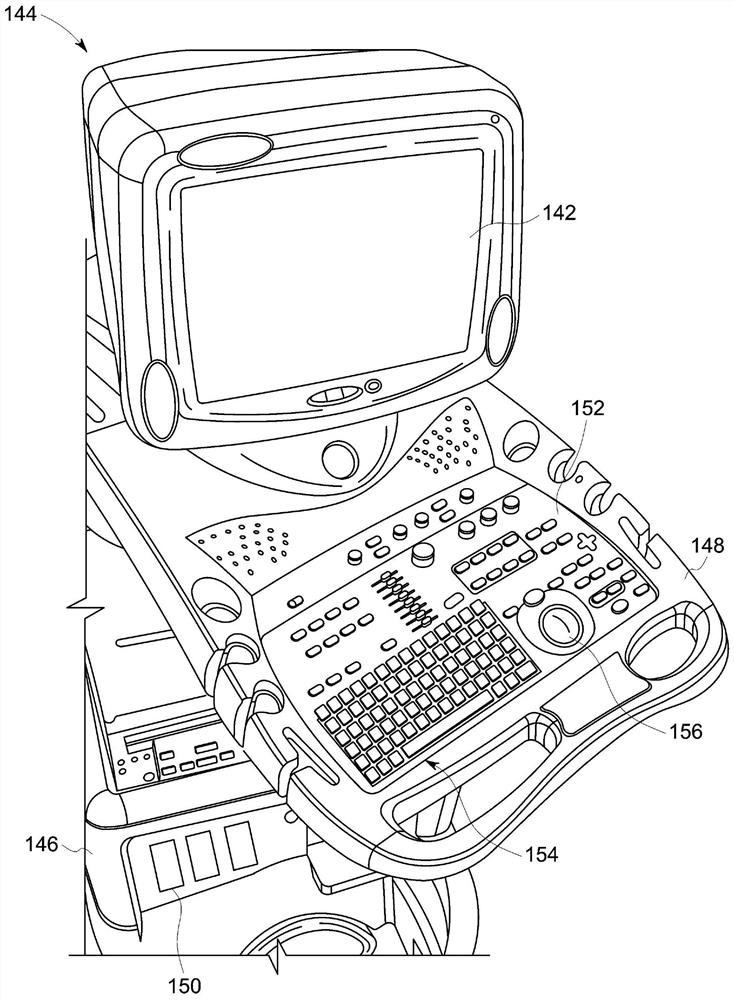

Ultrasonic image marking method and device, processor and readable storage medium

InactiveCN109044400ASpeed up workflowImprove labeling efficiency and consistencyUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsThree dimensional modelAutomatic processing

The invention provides an ultrasonic image marking method and device, a processor and a readable storage medium. The method includes the steps of obtaining a three-dimensional model image, the space information of an ultrasonic probe and an ultrasonic image, mapping the three-dimensional model image, the space information of the ultrasonic probe and the ultrasonic image into an ultrasonic scanningspace coordinate system, analyzing the three-dimensional model image and the space information of the ultrasonic probe to obtain marking information, and marking the ultrasonic image according to themarking information. The processor can automatically mark the ultrasonic image according to the obtained marking information, no manual operation is needed in the process, automatic processing can beconducted through the processor, the working process is accelerated, and the marking efficiency and consistency of the ultrasonic image are improved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

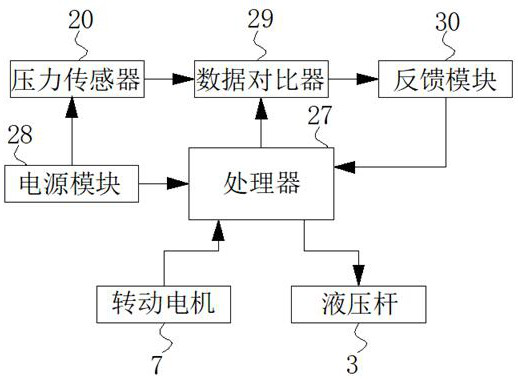

Electric type cable bending apparatus

InactiveCN105261990AAffectReduce laborCable installation apparatusElectric power transmissionEngineering

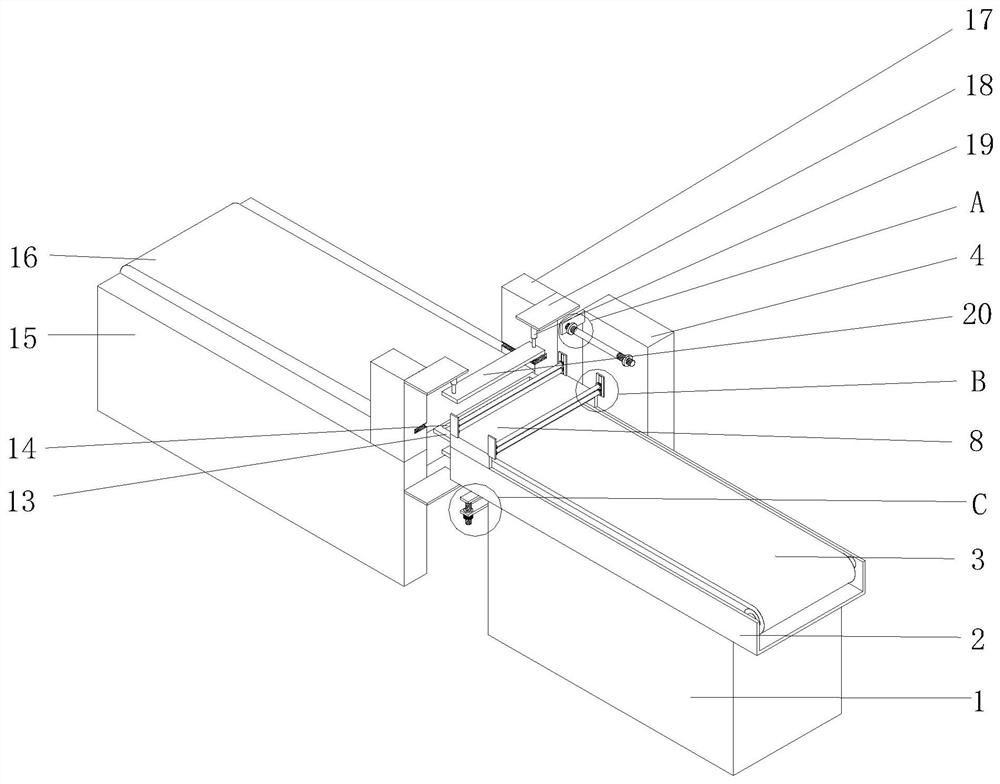

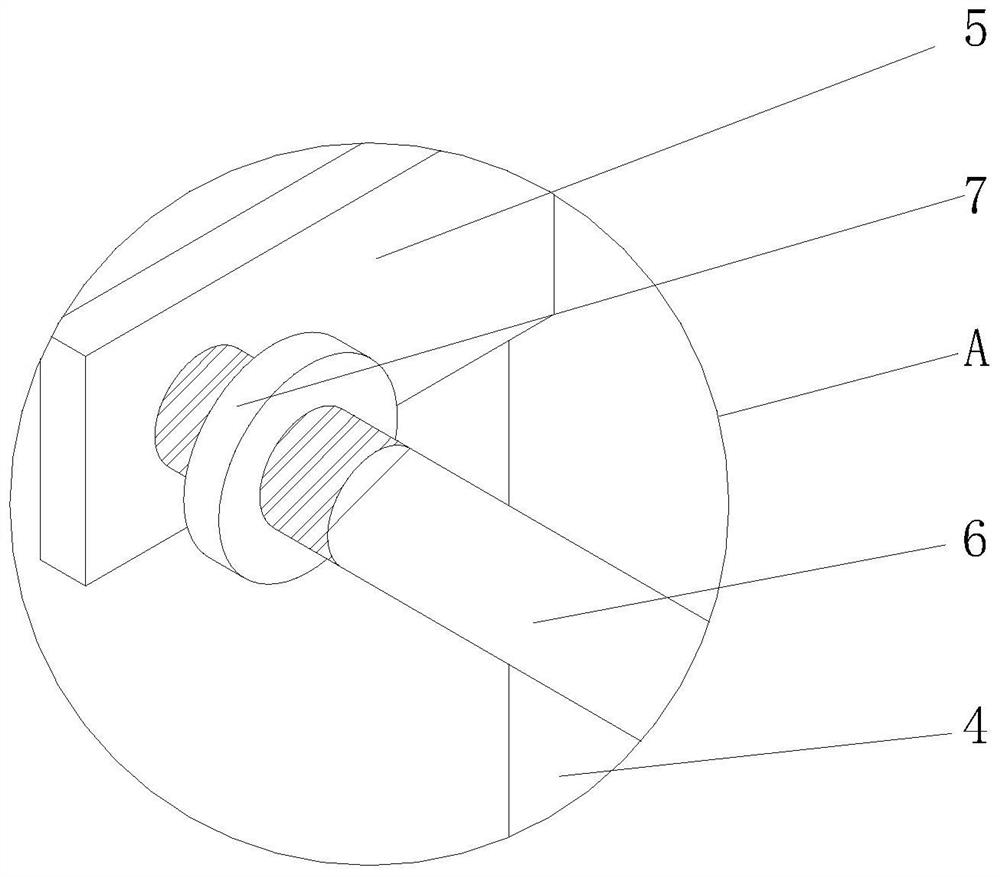

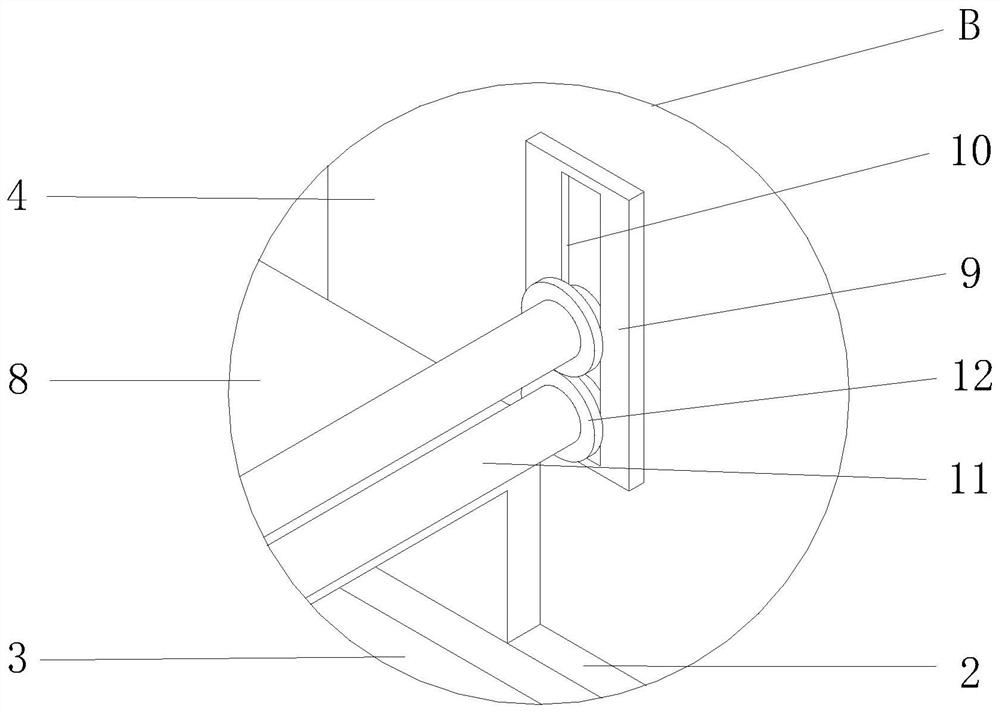

The present invention discloses an electric type cable bending apparatus, and relates to the technical field of electric power transmission equipment. The electric type cable bending apparatus comprises a sliding chute, wherein two ends of the sliding chute are fixed to a bottom plate respectively through an A supporting leg and a B supporting leg, an A slide block and a B slide block are slidably arranged in the sliding chute, the upper end face of the A slide block is fixedly provided with an A long rod, an A hold ring is rotatably arranged on the A long rod, an A bolt is connected between two protruded front edges of the upper portion of the A hold ring, the upper end face of the B slide block is fixedly provided with a B long rod, a B hold ring is rotatably arranged on the B long rod, a B bolt is connected between two protruded front edges of the upper portion of the B hold ring, an electric push rod is arranged in a horizontal plane where the A hold ring and the B hold ring locate, the electric push rod is arranged on the bottom plate and perpendicular to the sliding chute; the front end of the electric push rod is fixedly provided with a hold hoop. The electric type cable bending apparatus of the present invention has the beneficial effects of good adaptability, convenient use, standard operation, labor saving and time saving, etc.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +2

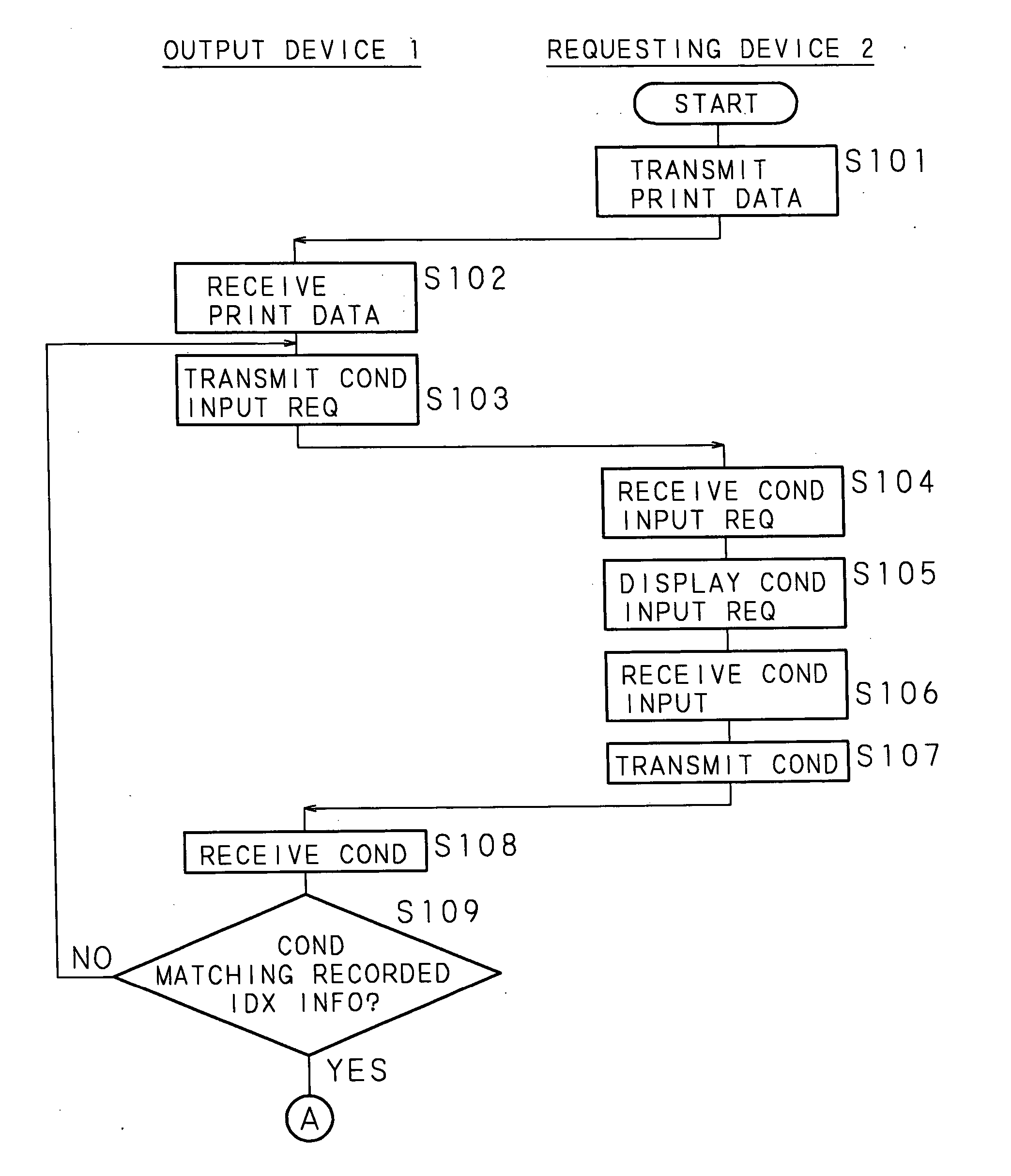

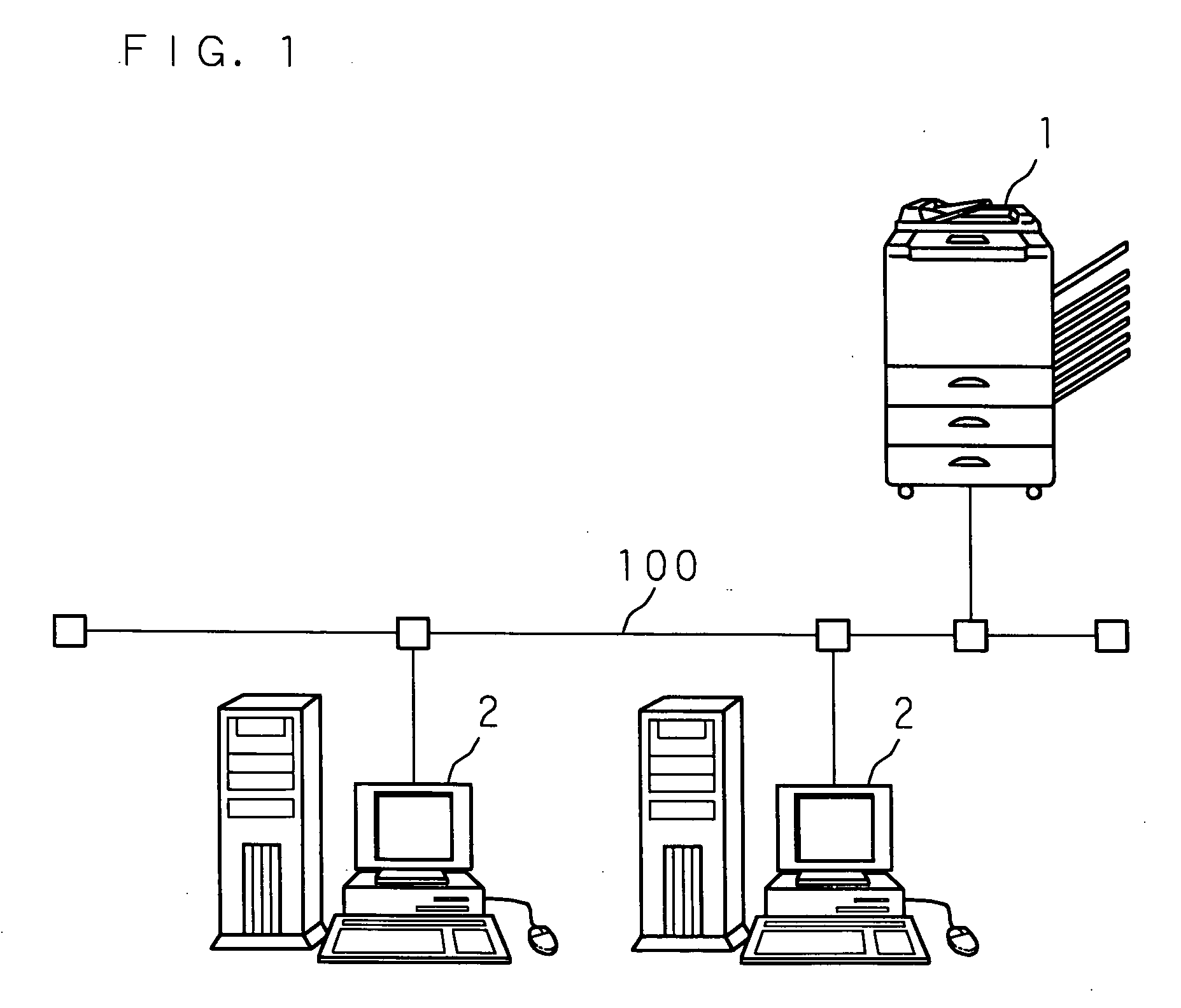

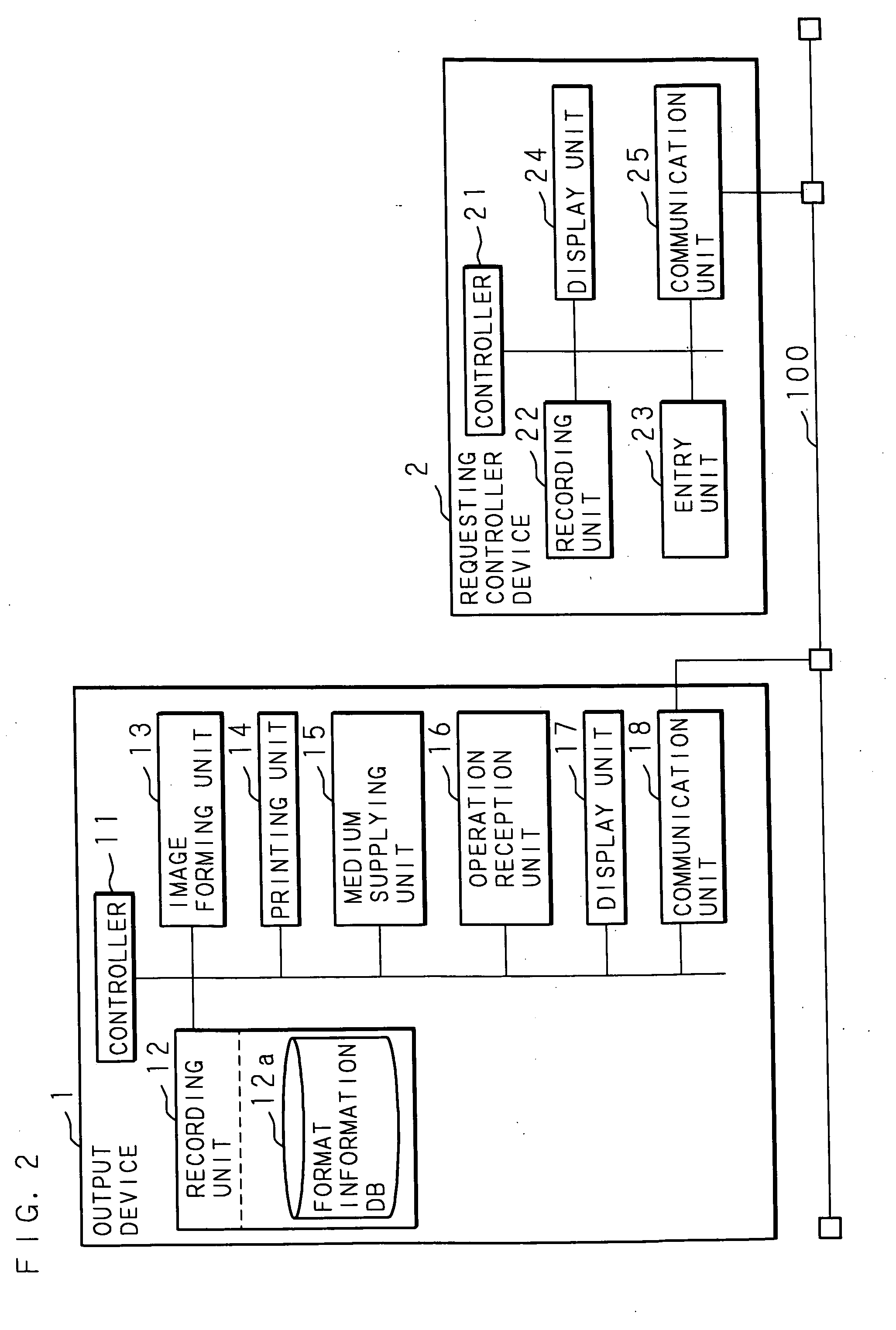

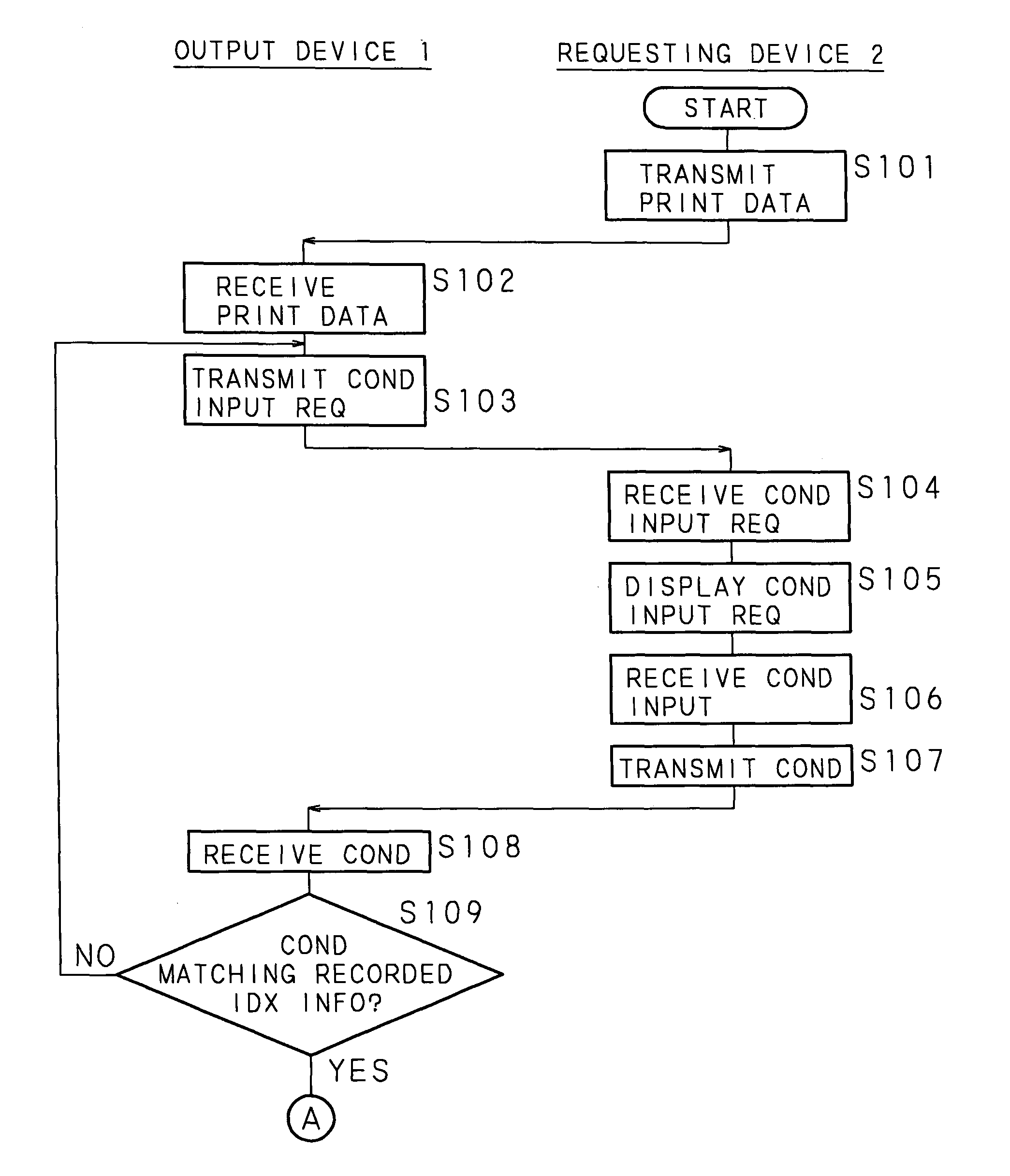

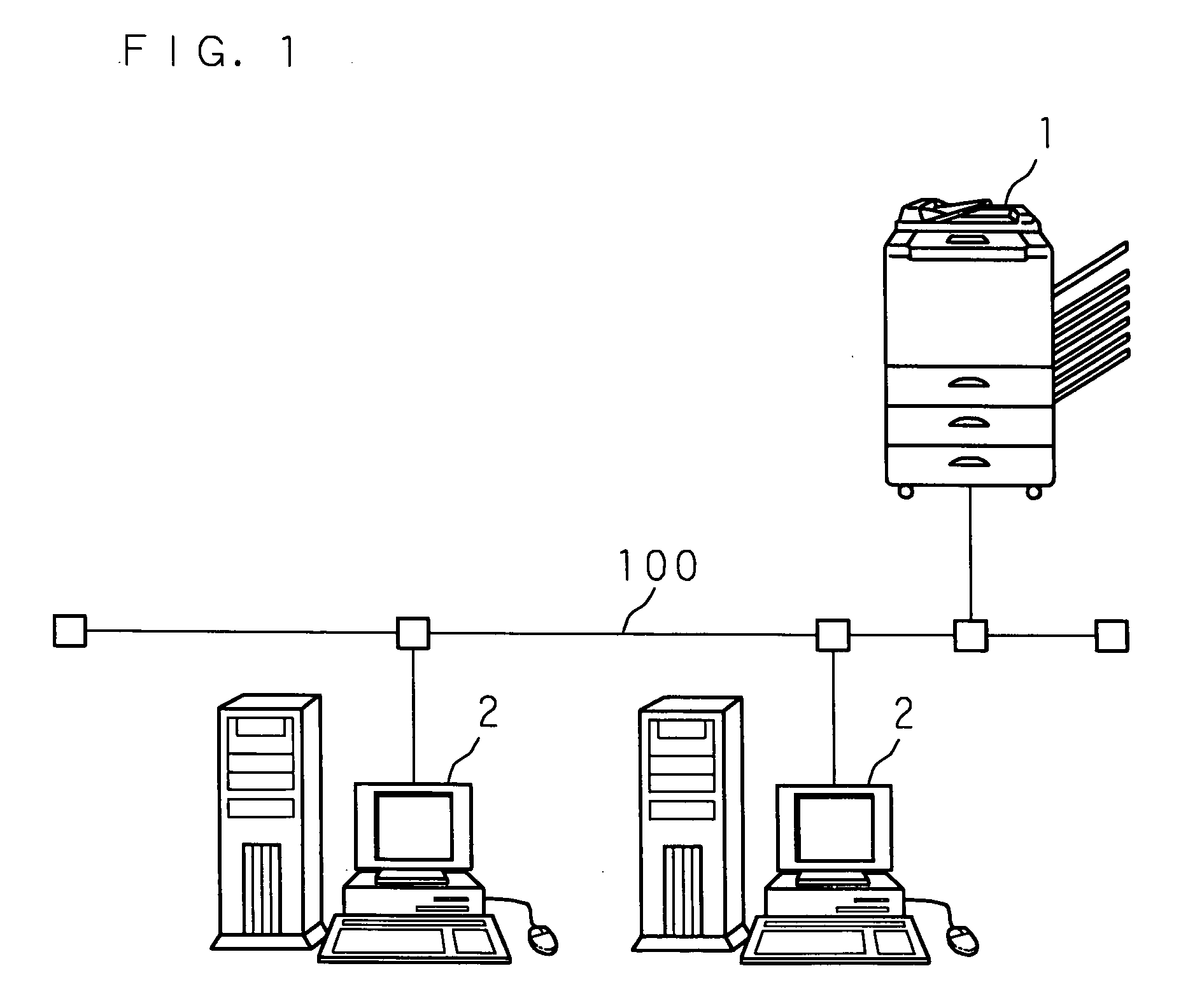

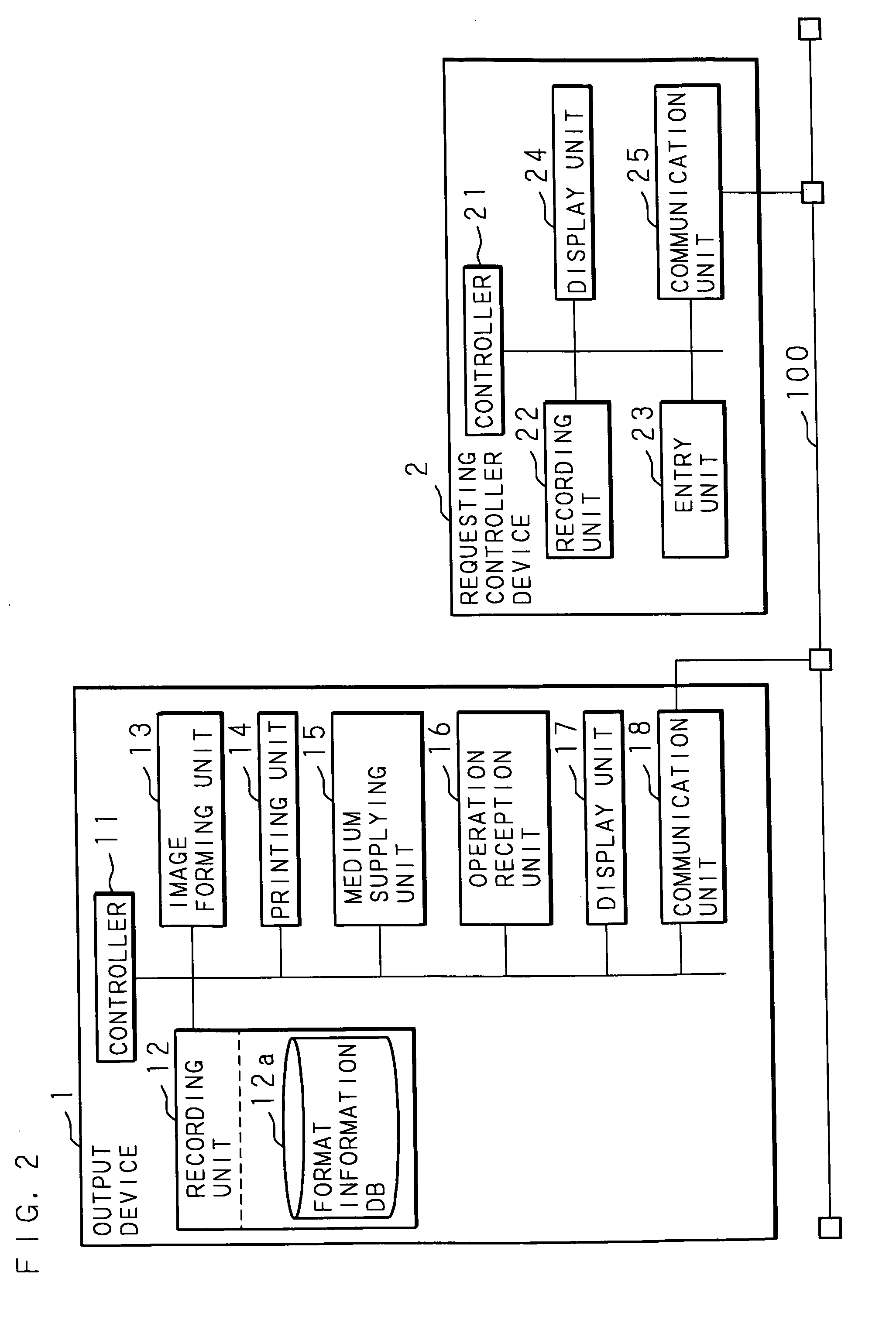

Output system and output device

ActiveUS20060282418A1Speed up workflowEasy to unifyDigitally marking record carriersDigital computer detailsOutput devicePersonal computer

To provide an output system and an output device capable of easily unifying a documentary form relating to an event without increasing the number of work processes, in a system wherein output data is transmitted to an output device such as a printer, via a communication network from a requesting device such as a personal computer, and printing based on the output data is performed at the output device. An output device 1 records in a format information database 12a format information showing an output format including the documentary form of printing, correspondingly to index information showing an event. A user using a requesting device 2 makes the requesting device 2 send the output data to the output device 1 and designate the index information. The output device 1 performs output based on the output data, in the output format shown by designated index information.

Owner:SHARP KK

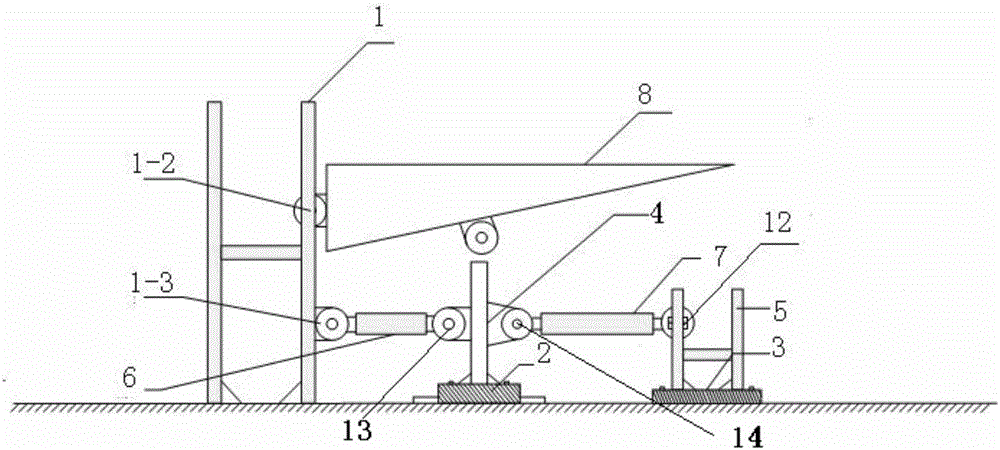

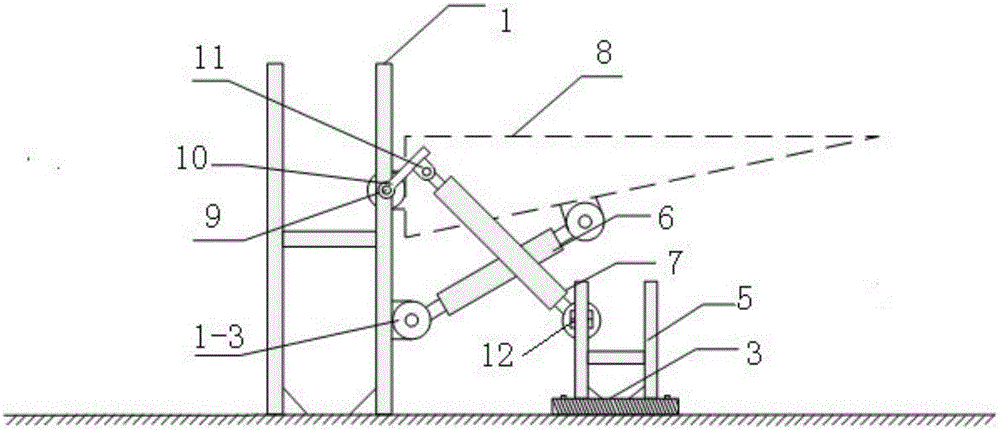

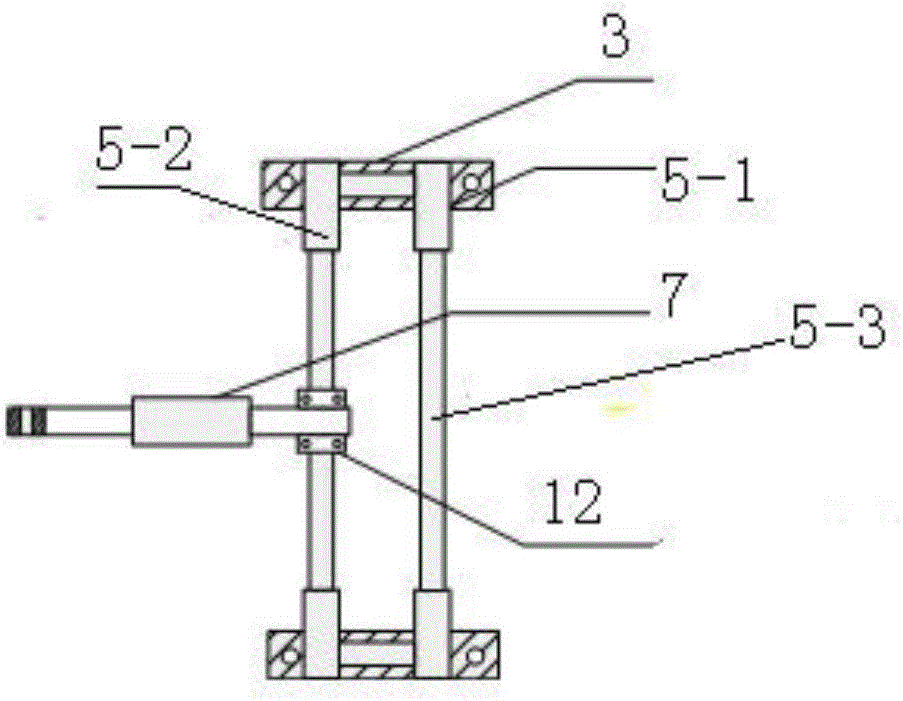

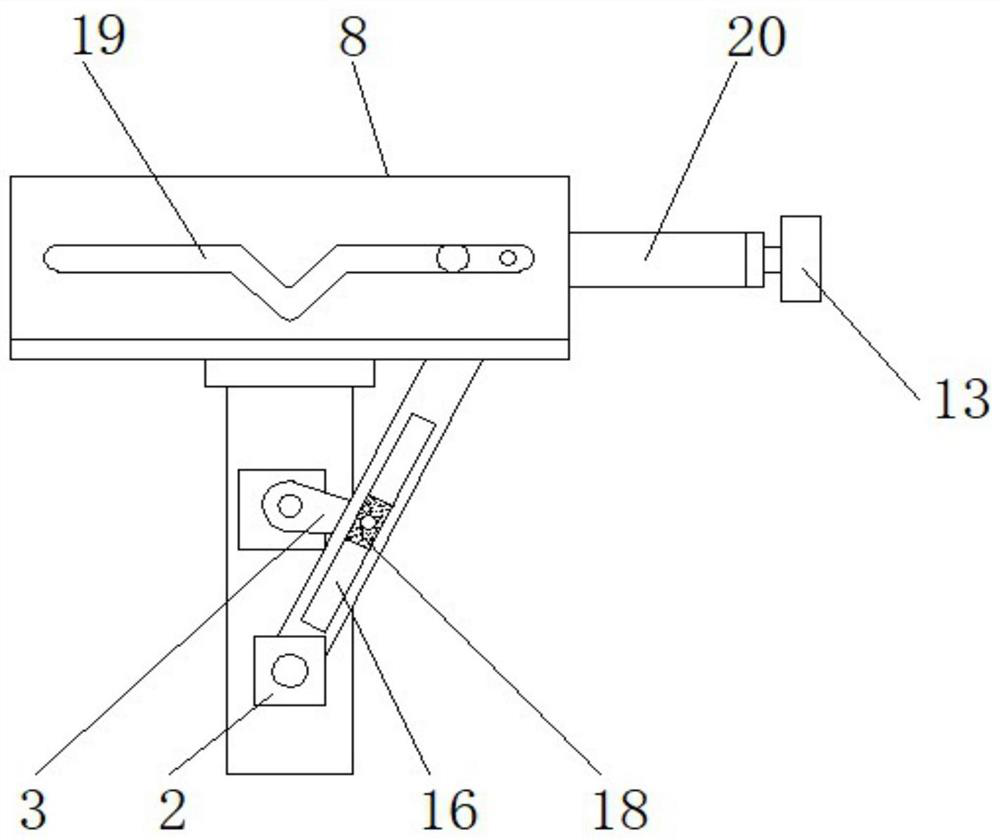

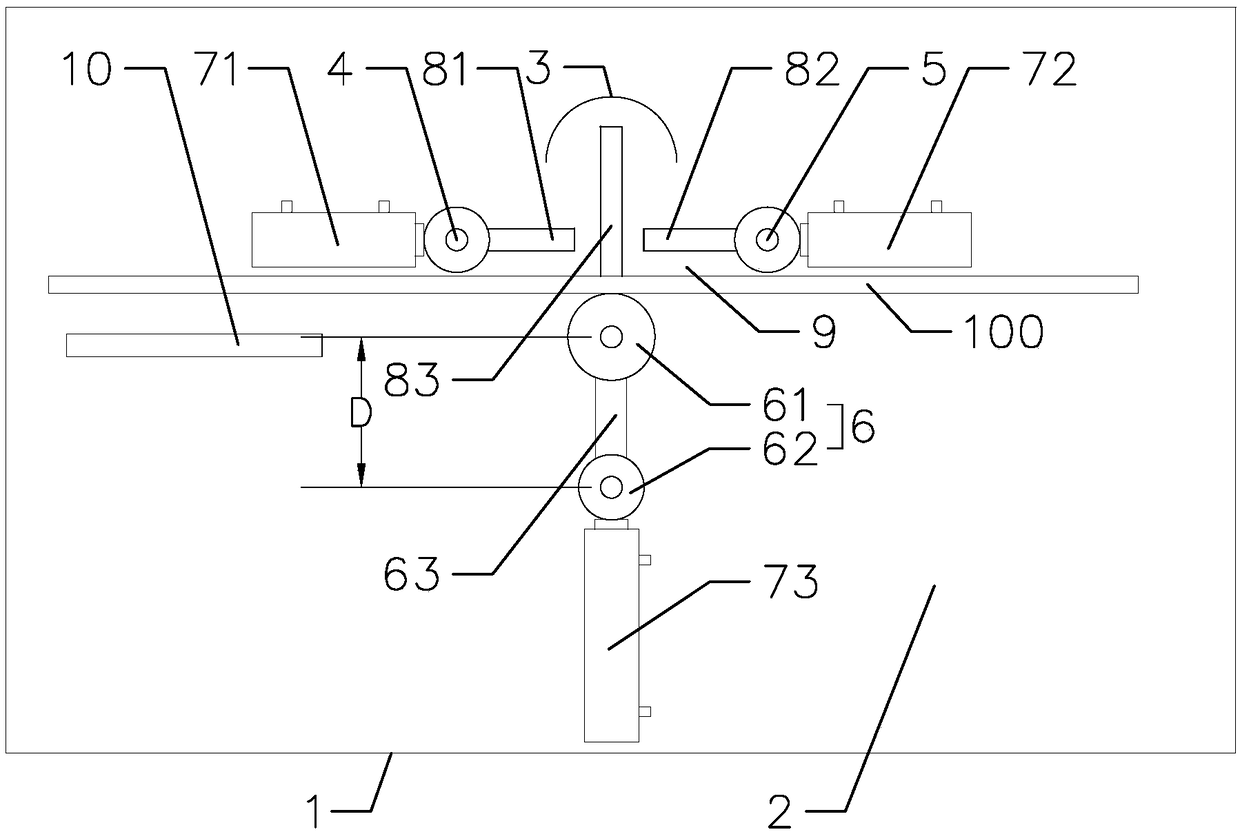

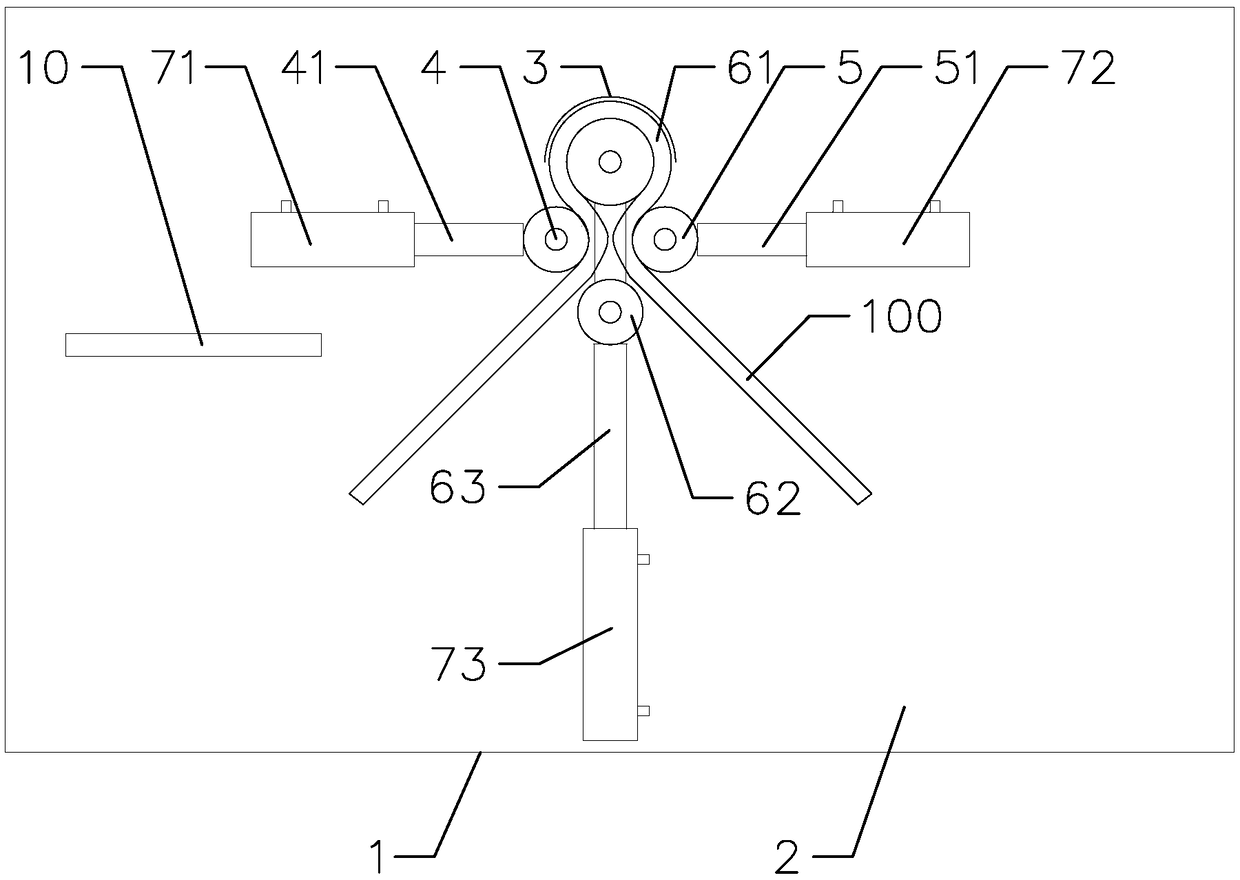

Aircraft actuation system load loading device

ActiveCN106347635ASave space resourcesSave resourcesMachine part testingAircraft controlAviationActuator

The invention belongs to the technical field of aviation and particularly relates to an aircraft actuation system load loading device applicable to an aircraft actuation system loading project. According to the device, a single-actuator loading device and an aircraft airfoil loading device are improved, double effects of applying one device to single-actuator performance parameter index evaluation and aircraft airfoil actuator joint loading are realized, and a novel loading device is provided for the aircraft actuation system. The loading device provided by the invention is simple and convenient, and meets two loading needs for top loading and airfoil loading in the field of aircraft actuation system load loading through a connecting mechanism, a slider mechanism and a bracket mechanism. The resources are saved; and two processes in the aircraft loading project are realized by one mechanism, thus the equipment resources as well as the space resources of a laboratory are saved. The workflow is accelerated; and through the technical scheme, the time period of original two processes can be effectively shortened, and the process of applying an actuator to the aircraft airfoil is accelerated.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Part paint baking device and method for machining

InactiveCN112058604AAvoid enteringAvoid pollutionPretreated surfacesCoatingsExhaust valveStructural engineering

The invention discloses a part paint baking device and method for machining. In order to solve the problems that an existing paint baking device cannot separate the inner environment from the outer environment, so that impurities such as dust in the outer environment easily enter paint baking equipment in the paint baking step to contaminate parts, and the painting effect of the parts is affected,the following scheme is now put forward. The part paint baking device comprises a shell, an exhaust valve, an air collecting groove and an air inlet groove. An air curtain machine is fixed to the outer wall of the top of the shell through bolts, an air inlet pipe is fixed to the outer wall of one side of the air curtain machine through screws, air spraying pipes are fixed to the outer walls of the two sides of the air curtain machine through screws, and one ends of the air spraying pipes are connected with the outer wall of the top of the air inlet groove through sleeving. A filtering mechanism is arranged on the air inlet pipe and the inner wall of a connecting box, air inside and air outside the shell are isolated through an air curtain generated by the air curtain machine, dust and thelike outside the shell are prevented from entering the inner wall of the shell, the parts are prevented from being contaminated by the dust, and the painting effect of the parts is guaranteed.

Owner:张玉梅

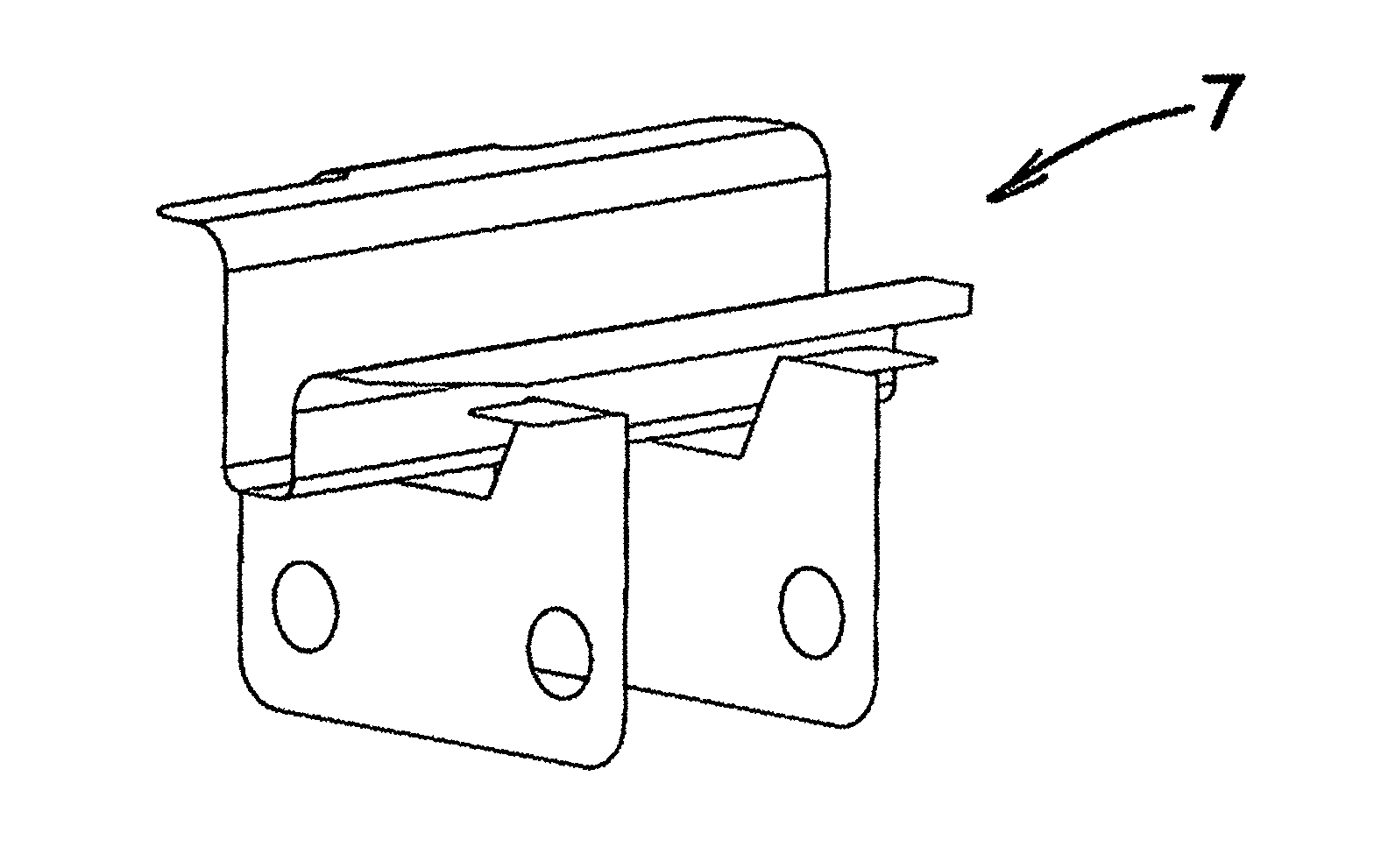

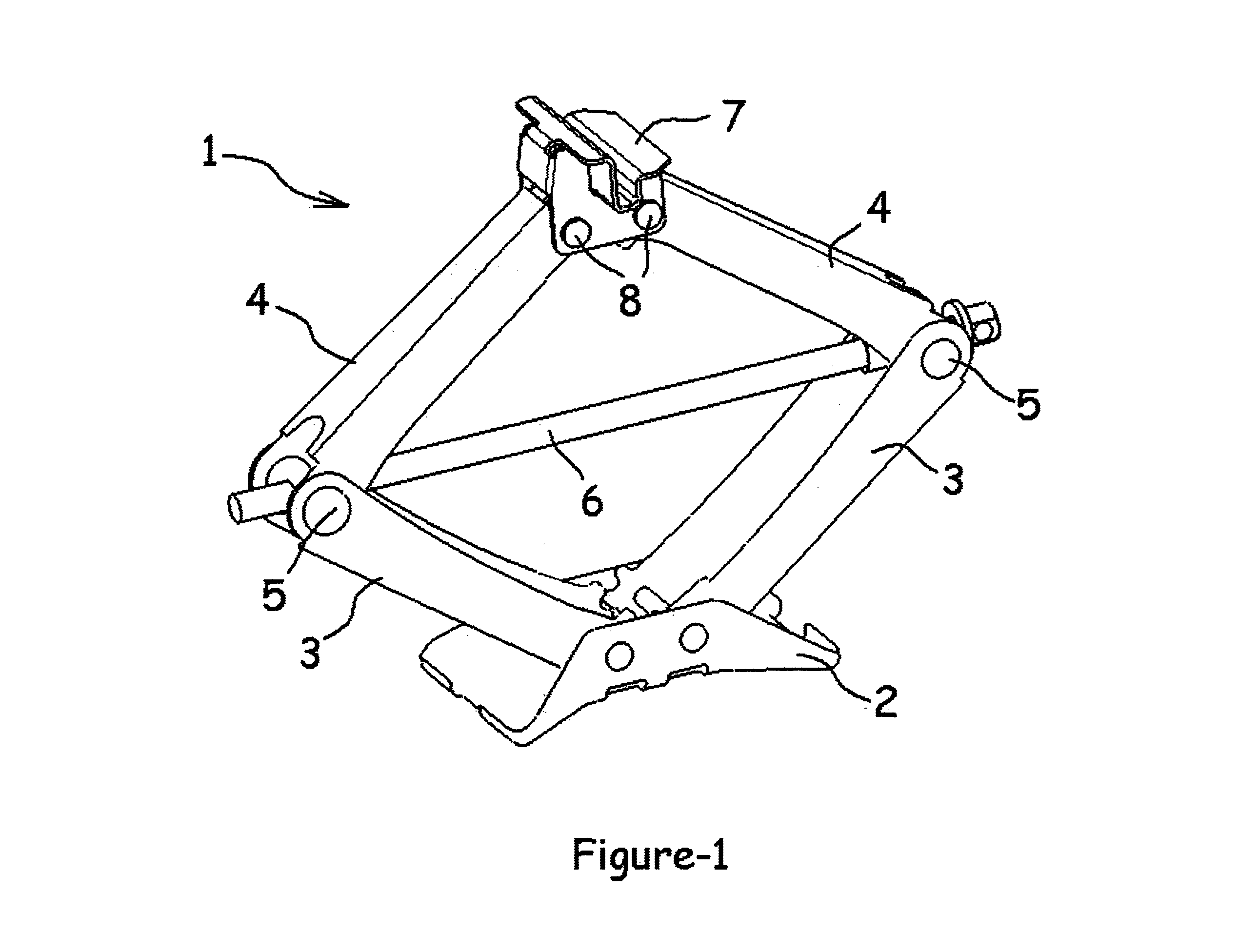

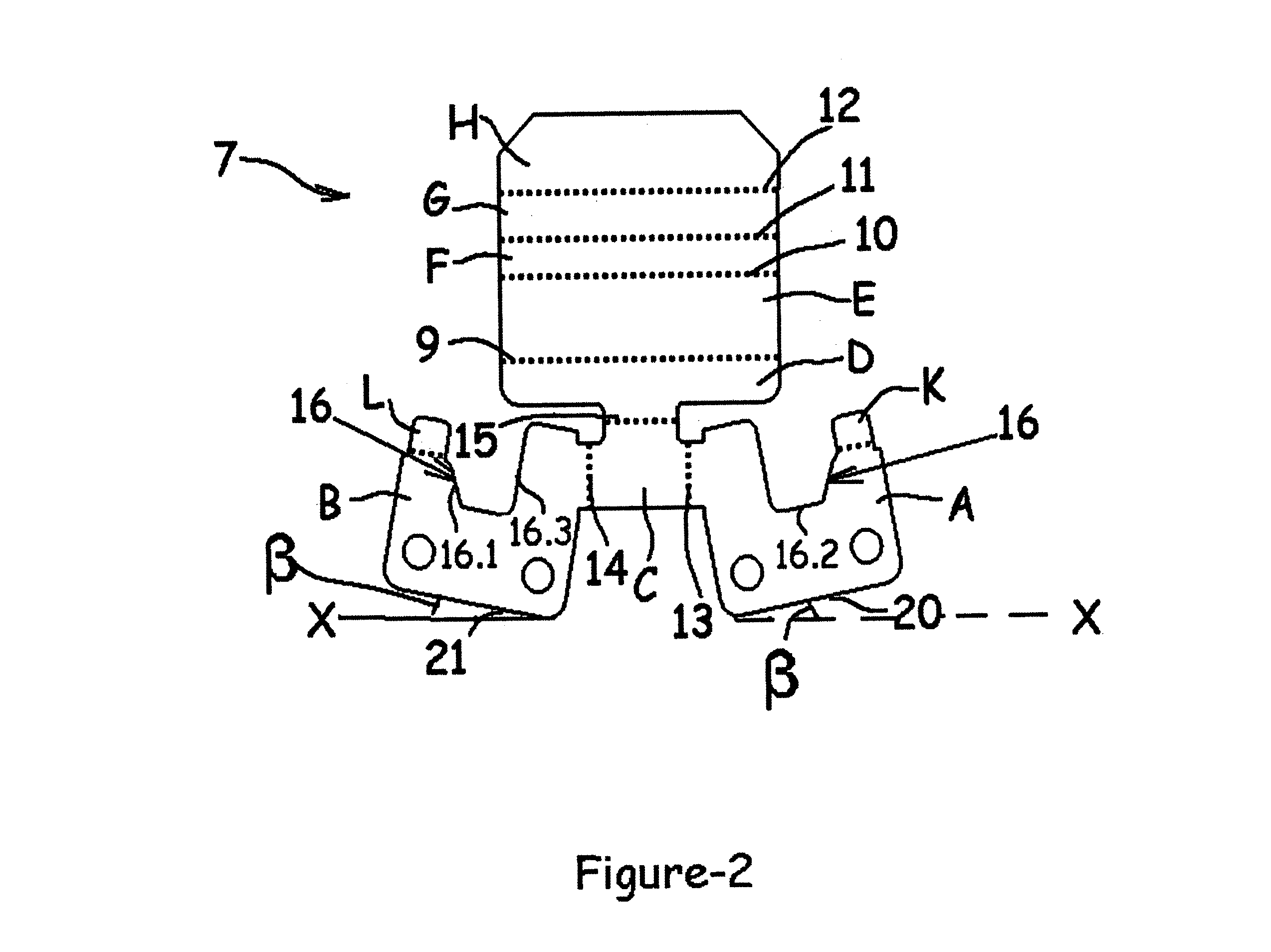

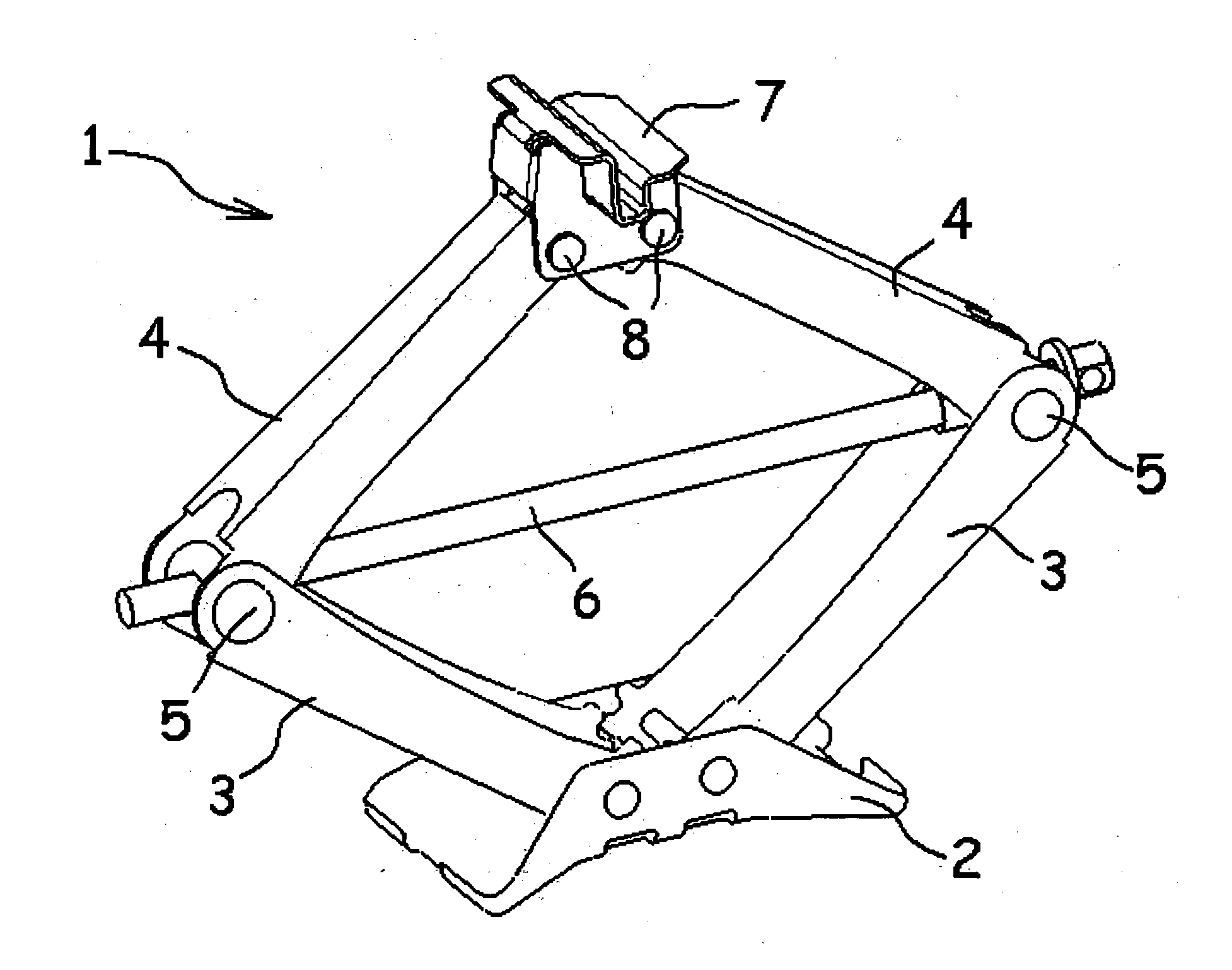

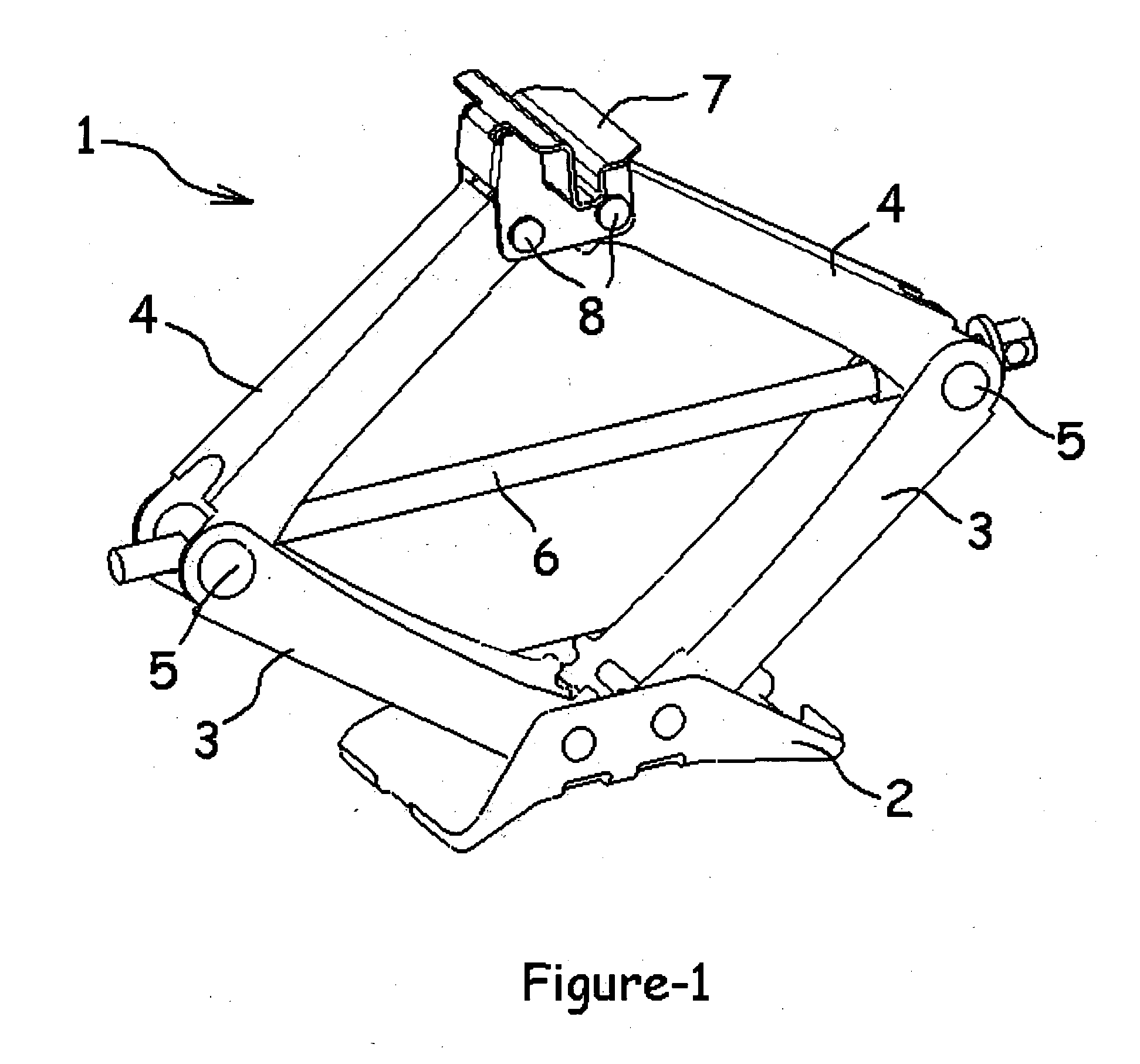

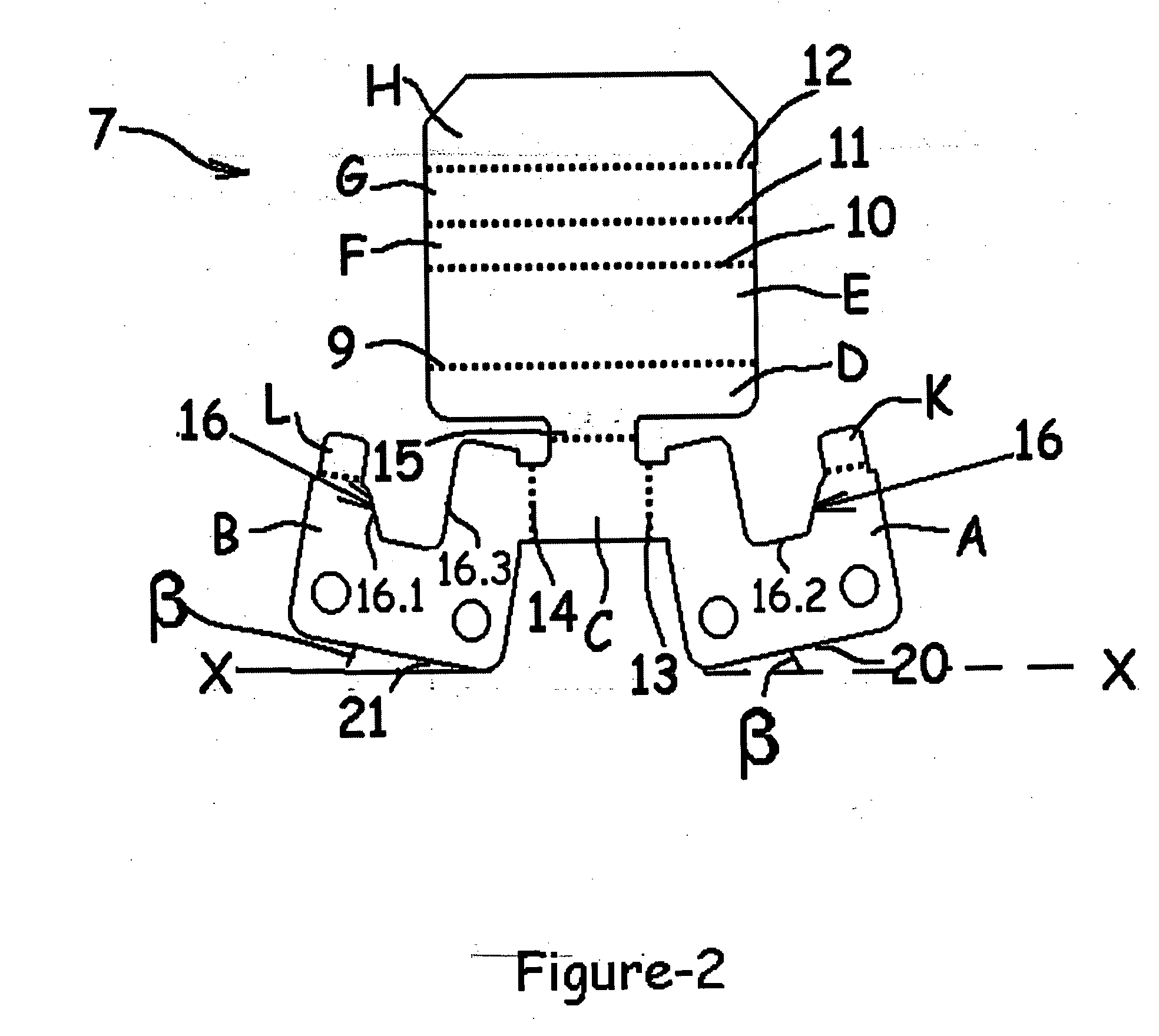

Integral load support for a jack formed of a sheet material bent to less than 180°

InactiveUS8579258B2Speed up workflowNail extractorsLifting devicesStructural engineeringSheet material

Owner:ARIKAN KRIKO & MAKINA SANAYI TICARET ANONIM SIRKETI

Output system for unifying a documentary form relating to an event

ActiveUS8164781B2Speed up workflowEasy to unifyDigitally marking record carriersDigital computer detailsOutput deviceInformation representation

To provide an output system and an output device capable of easily unifying a documentary form relating to an event without increasing the number of work processes, in a system wherein output data is transmitted to an output device such as a printer, via a communication network from a requesting device such as a personal computer, and printing based on the output data is performed at the output device. An output device 1 records in a format information database 12a format information showing an output format including the documentary form of printing, correspondingly to index information showing an event. A user using a requesting device 2 makes the requesting device 2 send the output data to the output device 1 and designate the index information. The output device 1 performs output based on the output data, in the output format shown by designated index information.

Owner:SHARP KK

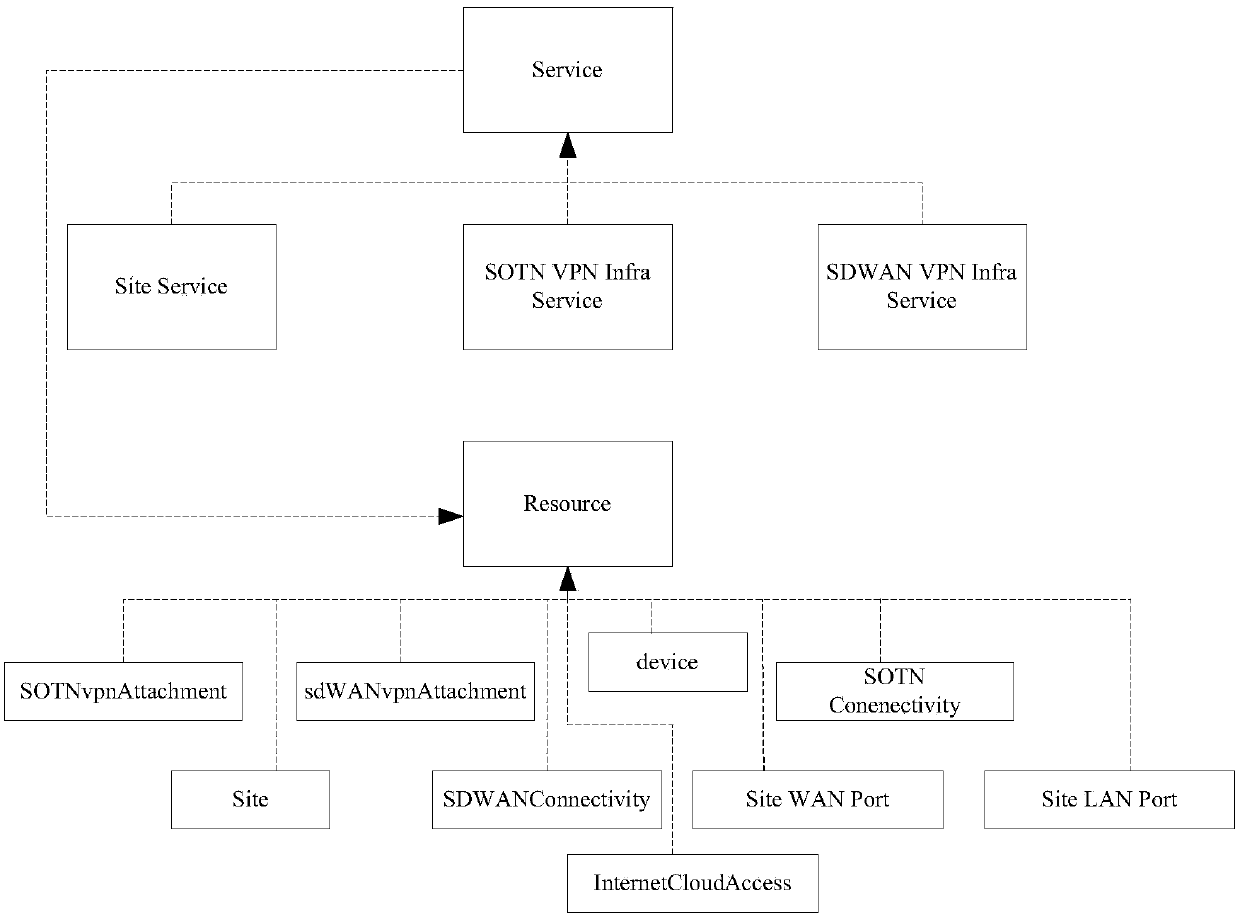

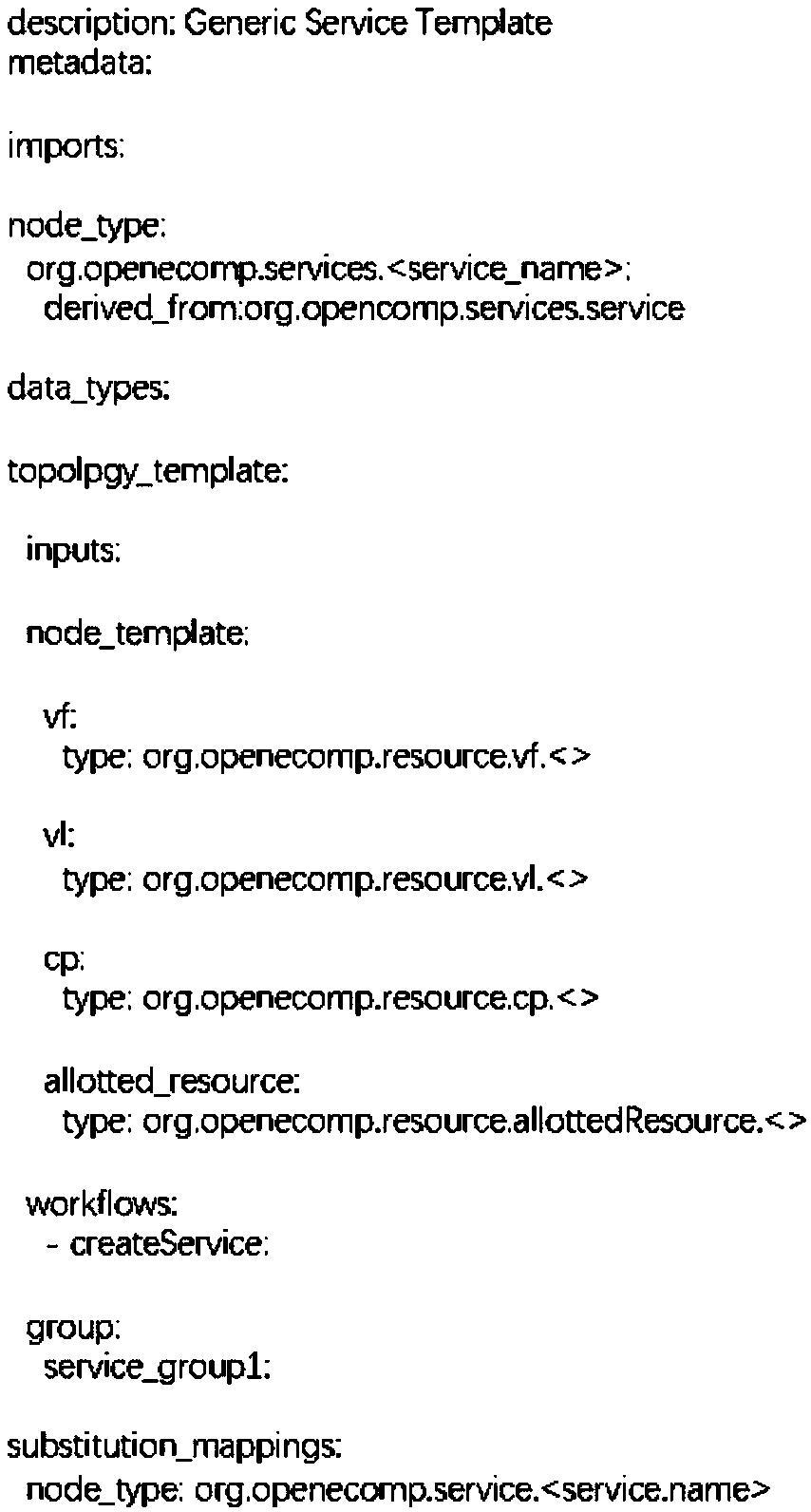

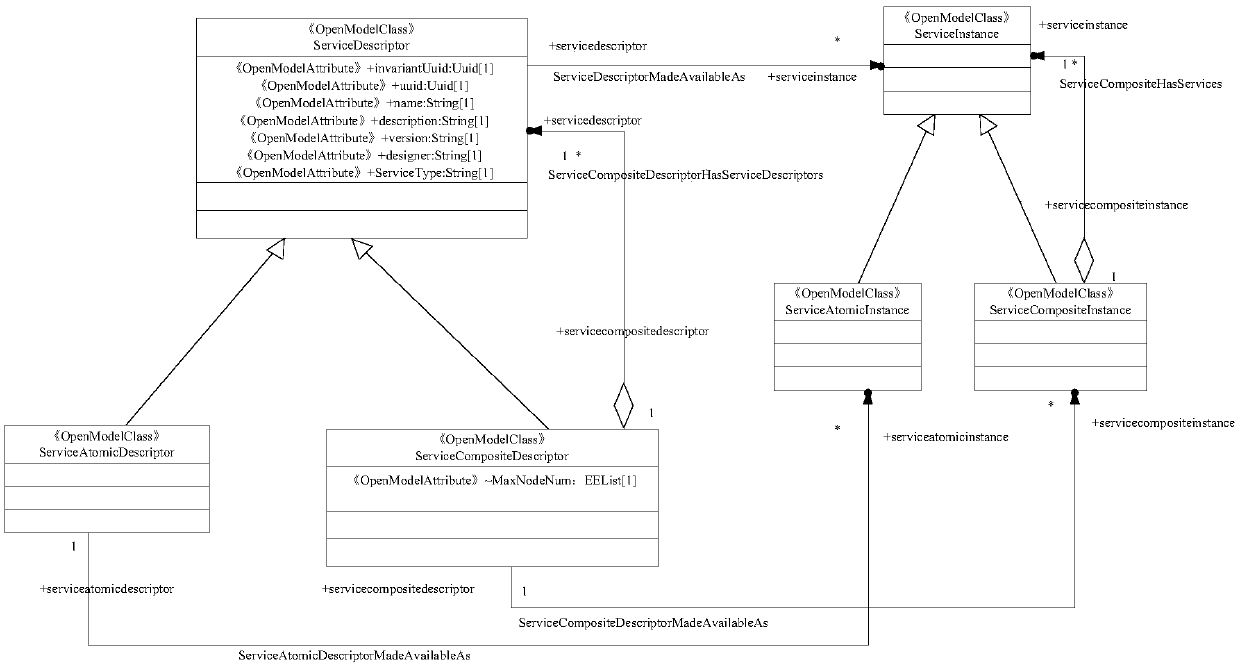

Workflow implementation method and device

ActiveCN111061723ADynamically increase workflowSpeed up workflowOffice automationDatabase indexingComposite servicesSoftware engineering

The invention provides a workflow implementation method and a device, and belongs to the field of ONAP service models. The workflow implementation method is applied to an instantiation template of anend-to-end service. The instantiation template allows a plurality of resource instances to be dynamically instantiated as required; the simple service is a resource of the composite service; resourceinstances in the composite service instantiation data record are stored in a list structure; wherein the instantiation template comprises a maximum resource quantity parameter and describes the upperlimit quantity of resources needing to be instantiated in the composite service, and the upper limit quantity comprises the steps of dynamically increasing the quantity of the resources of the instantiation template and judging whether the quantity of the resources can be dynamically increased according to the quantity limit of the maximum resource quantity parameter. By means of the method, onlyone unified template needs to be designed for complex services, multiple service templates do not need to be designed, the solidification limitation of the service templates on the number of resourcesis changed, the flexibility is enhanced, and workflow for guiding the service arrangement module to dynamically update the services is increased.

Owner:CHINA MOBILE COMM LTD RES INST +1

A method and system for automatically generating decoration budget quotations from CAD design drawings

ActiveCN104899403BOptimize architectureNo additional investmentSpecial data processing applicationsSpatially resolvedThe Internet

Owner:JIANGSU EHE DACHENG NETWORK TECH

Automobile disc brake spraying production line and production method thereof

The invention discloses an automobile disc brake spraying production line and a production method thereof, and the automobile disc brake spraying production line comprises: an automatic coating unit for spraying a to-be-processed automobile disc brake part; a high-temperature curing oven is used for carrying out coating curing on the automobile disc brake part subjected to the spraying step in a controllable distributed heating mode; a cooling device that is used for cooling the automobile disc brake part subjected to paint particle curing; and a main conveying belt that is used for conveyingthe automobile disc brake part to be processed and is arranged at the high-temperature curing oven and the cooling device. The automatic coating unit is integrally closed, so that leakage of paint powder is avoided, and static electricity is prevented from hurting an operator; a matched device for paint powder recycling is arranged, redundant paint powder is recycled, materials are saved, the overall working process is accelerated through high-temperature curing oven assembly line heating, the automation efficiency is improved, and errors caused by manual operation are reduced; subsequent aircooling can accelerate cooling of the parts, the parts can be conveniently taken down from the conveying belt, meanwhile, recovered heat can be used for other purposes, and energy is saved on the whole.

Owner:杭州新舟机械设备有限公司

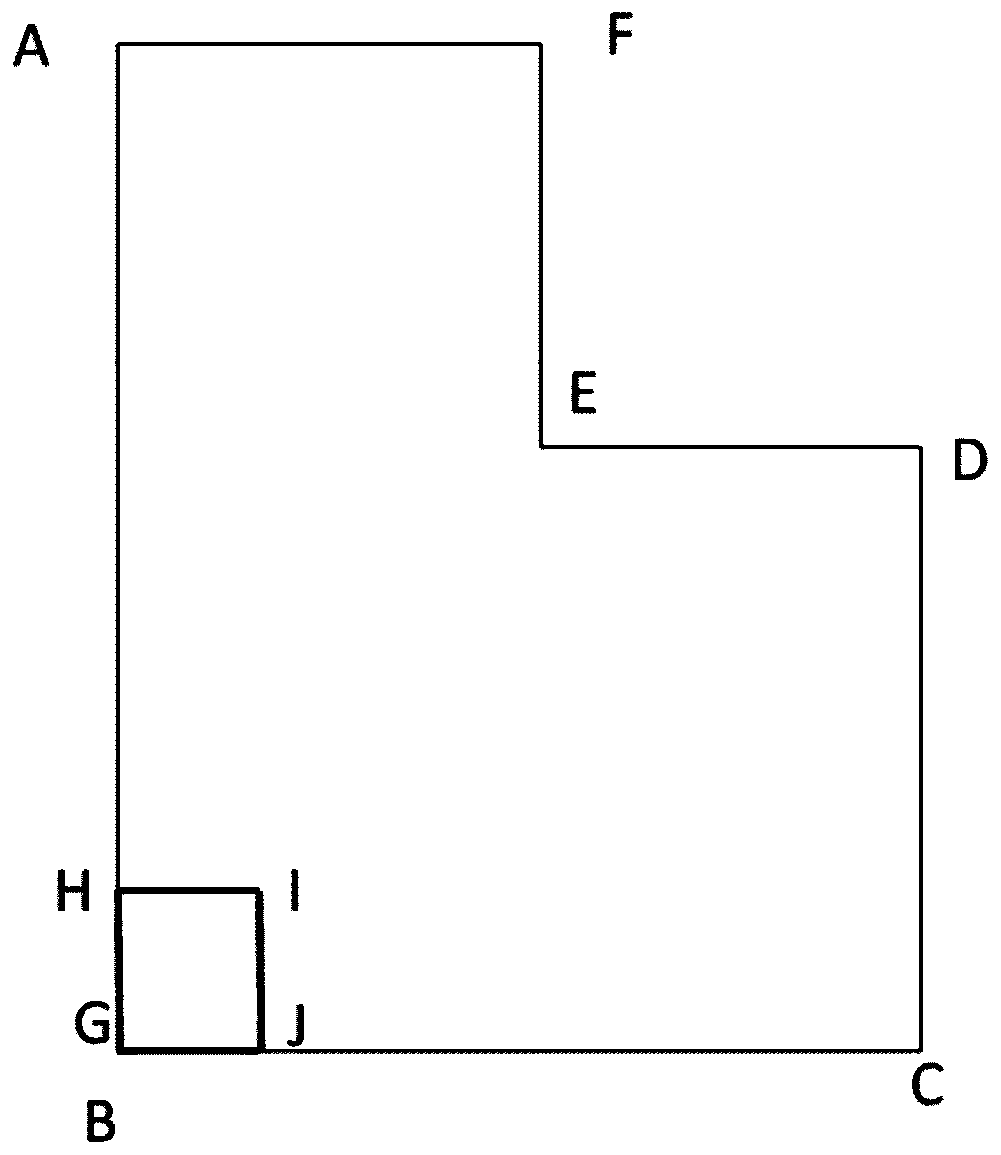

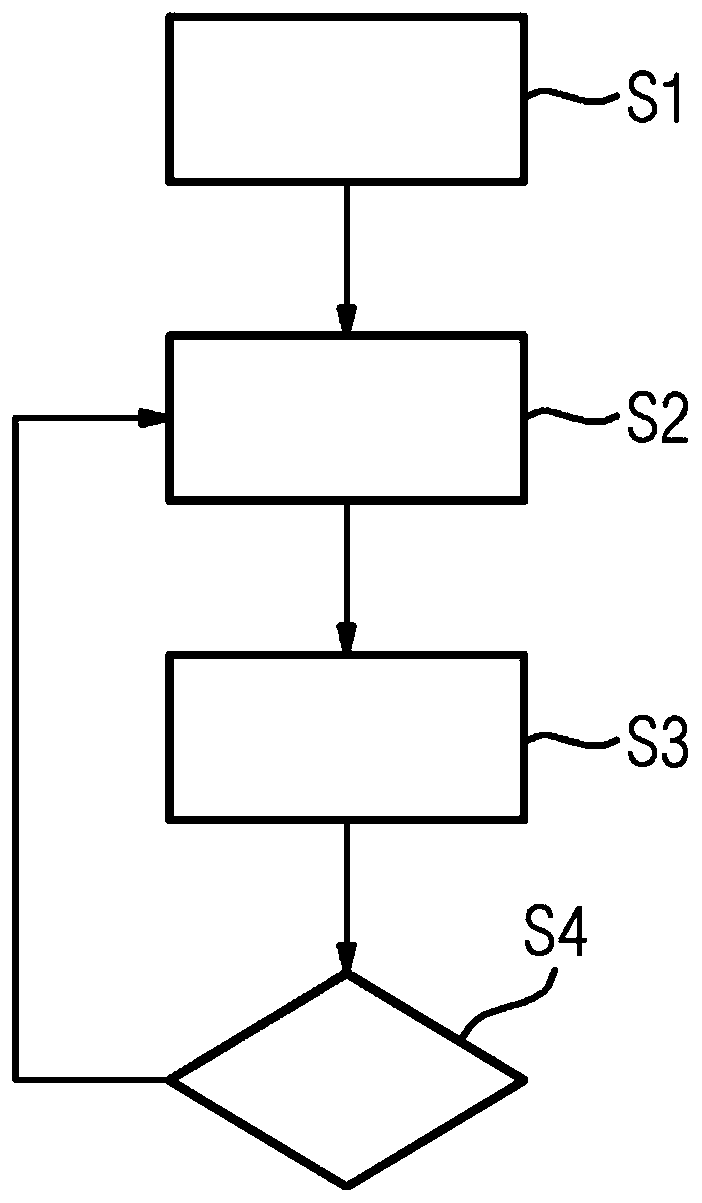

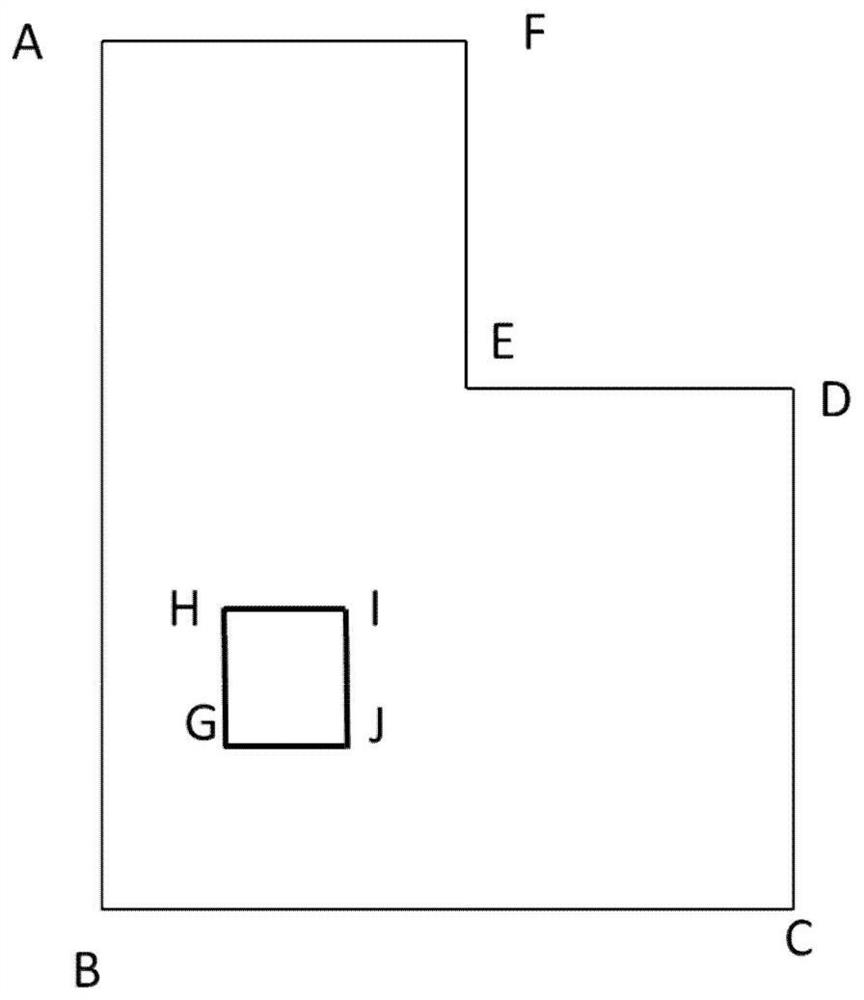

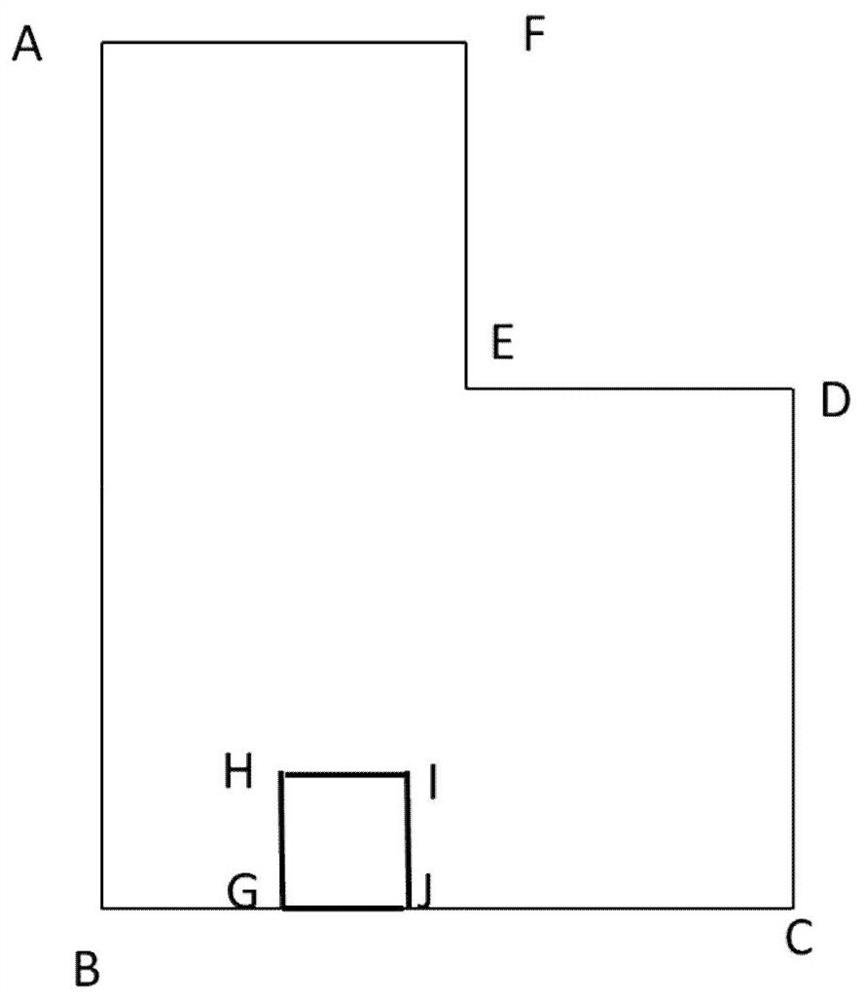

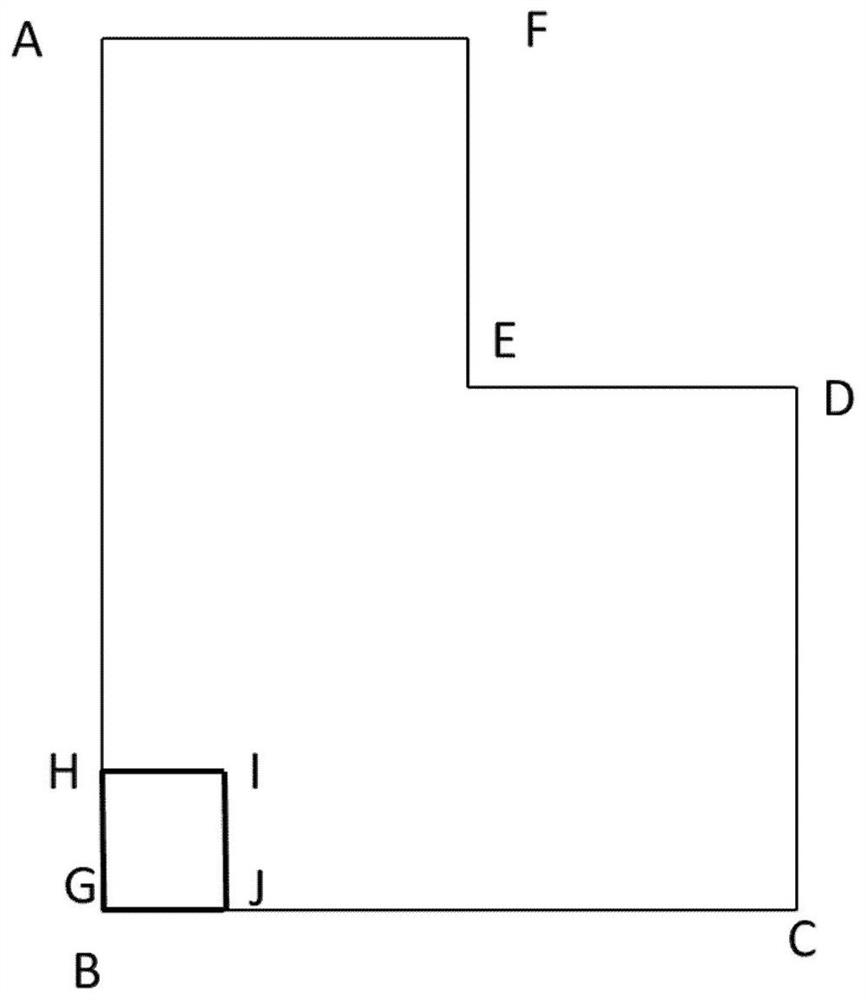

Method for processing regional edge and regional built-in component bottom in home decoration design

ActiveCN111063014AImprove work efficiencyMeet the needs of actual home improvement3D-image renderingProcess engineeringHome improvement

The invention discloses a method for processing a regional edge and a regional built-in component bottom in home decoration design, which comprises the following steps: S1, loading a scheme, and acquiring a ground region and component information of the scheme; S2, calculating component affiliation area information; S3, sequentially fitting the components with the edges of the affiliated areas; and S4, updating an area result after fitting. According to the invention, in the process that a designer designs home decoration, the fitting condition of the area and the bottom area of the componentcan be automatically processed; the processed area can better meet the requirements of actual home decoration, for example, a designer needs to generate skirting lines at the edge of the bottom of thecomponent and does not hope to generate skirting lines at the edge of the original area; and by means of the area edge and area built-in component bottom processing method, the design process is moreintelligent, workflow is accelerated, and the working efficiency of the designer is improved.

Owner:江苏艾佳家居用品有限公司

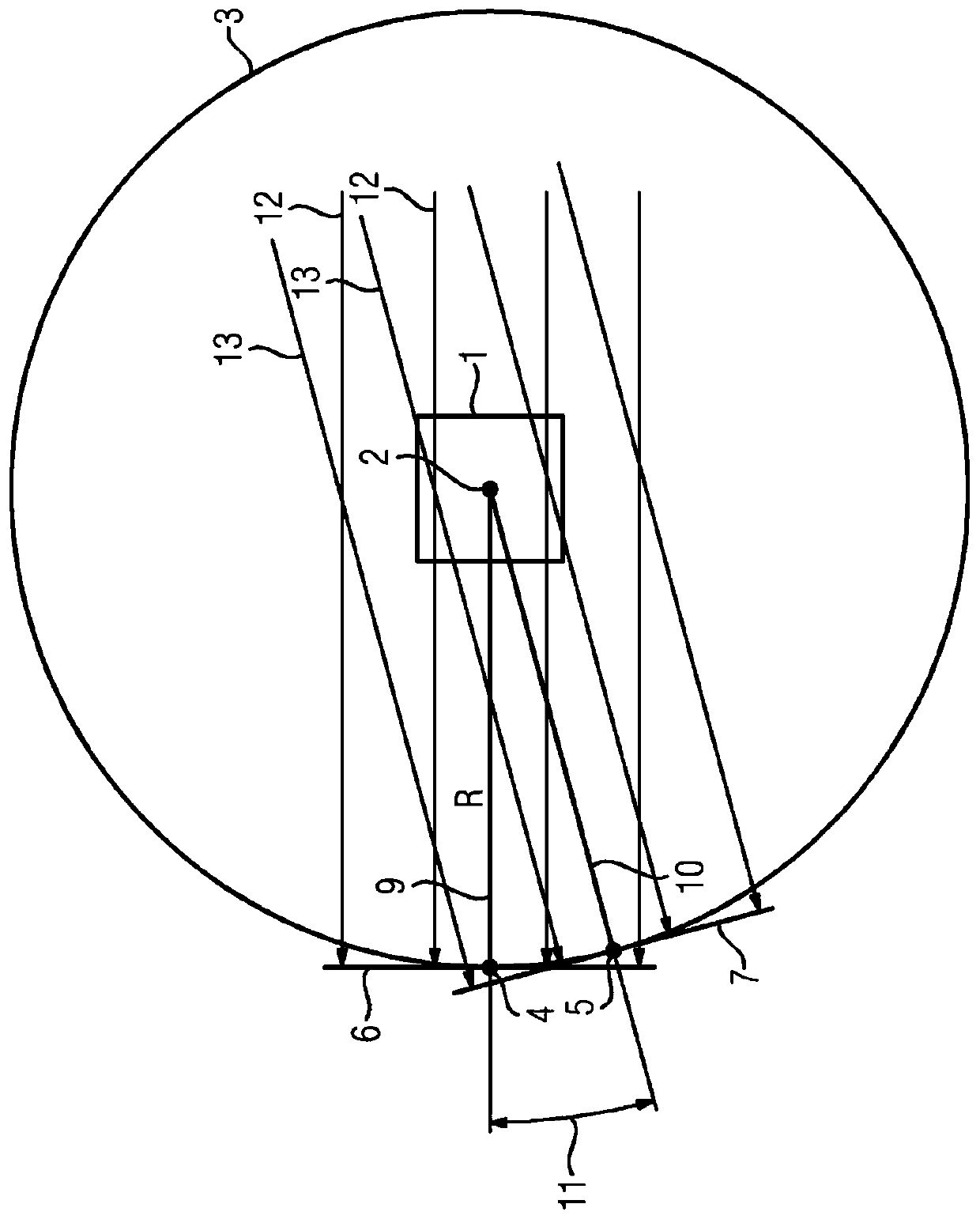

Method and presentation device for post processing and displaying a three-dimensional angiography image data set

PendingCN110660470AQuick calculationImproved 3D perceptionUltrasonic/sonic/infrasonic diagnosticsReconstruction from projectionDisplay deviceMr angiography

The invention provides a method and a presentation device for post processing and displaying a three-dimensional angiography image data set. The invention provides a method for post processing and displaying a three-dimensional angiography image data set of a blood vessel tree of a patient, wherein two-dimensional display images are rendered from the angiography image data set and displayed, wherein two display images are rendered from the angiography image data set using viewing directions (9, 10) forming an angle (11) suited for stereoscopic perception of the display images and both displayimages are simultaneously displayed on a display device (15) such that each display image is displayed to one eye of a user.

Owner:SIEMENS HEALTHCARE GMBH

A coding device based on digital products

ActiveCN113211982BFast deliveryFast coding jobTypewritersPower drive mechanismsProduction lineElectric machine

The invention discloses a coding device based on digital products, which includes a base, a power box, a transmission frame and a control panel. A power box is installed on the top of the base, and a first Motor, the output end of the first motor is equipped with a first rotating shaft through a coupling, the side of the first rotating shaft away from the first motor is provided with a rotating cam, and a second sliding block is installed on one side of the rotating cam , one side of the inner bottom of the power box is provided with a fixed block, the top of the base above the power box is provided with a transmission frame, and a second motor is installed on the outer wall of the transmission frame, and the output of the second motor The end is equipped with a second rotating shaft through a coupling. The invention not only realizes the fast delivery of the products by the conveying device, but also guides and limits the coding of the packaging boxes according to the type and size of the products on the production line, and performs fast coding work on the products.

Owner:浙江致立智能科技有限公司

Vertical ultrasonic bottle washing machine capable of stably feeding and discharging

PendingCN114798583AStable supportEasy to cleanNon-rotating vibration suppressionDrying solid materials without heatProcess engineeringWash bottle

The invention discloses a vertical ultrasonic bottle washing machine capable of stably loading and unloading, which belongs to the technical field of ultrasonic bottle washing and comprises a bottle washing machine main body, a bottle conveyor belt, a bottle protection cover and a main body support pile. By combining the bottle conveying belt, the bottle protection cover, the bottle input groove, the bottle inner guide plate, the rotating groove, the rotating shaft, the quantitative input rolling shaft, the bottle cleaning box, the ultrasonic oscillation equipment, the vertical drain pipe frame and the bottle centralized input pipeline, the problem that in the using process of an existing bottle cleaning machine, the bottle cleaning efficiency is high is solved conveniently; according to the bottle washing machine, the problems that bottles needing to be washed cannot be stably and quantitatively input into equipment for washing, so that the bottles are always input into the equipment during washing, and the washing effect on the bottles is reduced are solved. Bottles needing to be cleaned can be stably and quantitatively input into the equipment to be cleaned, so that the equipment can stably feed and discharge materials, and the cleaning effect on the bottles is improved.

Owner:浙江润和生物科技有限公司

Ball bulb production equipment

InactiveCN103681168BRealize automatic positioningQuality assuranceSequential operation station machinesProduction lineDrive motor

The invention discloses a spherical bulb production line which comprises a conveyor belt. The conveyor belt is provided with a lamp holder one-side locating device, a gluing device and a press-fit screwing device. The lamp holder one-side locating device comprises a lamp holder locating mechanism, a supporting beam, a first air cylinder, a second air cylinder, a third air cylinder, a first pneumatic finger and a second pneumatic finger. The lamp holder locating mechanism comprises a drive motor, a rotary table and a locating groove used for containing a lamp holder. The inner bottom surface of the locating groove is provided with two ejector pins used for locating the lamp holder, wherein the two ejector pins are arranged in a protruding and extending mode. The lamp holder is provided with a locating hole. The rotary table is in rolling contact with the upper edge of the outer side of the lamp holder. The first air cylinder is fixed to the supporting beam, and the second air cylinder and the third air cylinder are fixed to the output end of the first air cylinder. The first pneumatic finger and the second pneumatic finger are fixed to the output end of the second air cylinder and the output end of the third air cylinder respectively. The spherical bulb production line can be used for automatic assembly of a spherical bulb, thereby lowering labor intensity and production cost and improving production efficiency and product quality.

Owner:OUTRACE TECH

Device and method for automatically twisting metal wires, in particular for connecting adjacent, preferably mutually intersecting structure elements

InactiveUS9808854B2Easy to moveSpeed up workflowBuilding material handlingEngineeringStructuring element

The invention concerns an apparatus, a method and a use of the apparatus for automatically twisting metal wires. The invention concerns in particular such an apparatus for connecting adjacent, preferably mutually crossing structural elements, comprising a wire feed means for feeding wire, preferably endless wire, into the apparatus, an arcuate wire guide which has a selectively openable and closable opening and which is adapted to guide the fed wire in the closed position along the arcuate wire guide from a first side of the arcuate wire guide to a second side of the arcuate wire guide, that is in opposite relationship with respect to the opening, a pulling slider adapted to engage the fed wire on the first side of the arcuate wire guide and to pull it towards the second side of the arcuate wire guide, and a twisting unit adapted to engage the fed wire on both sides of the arcuate wire guide and to twist it by means of a rotational movement.

Owner:WOBBEN PROPERTIES GMBH

A multi-effect purification device for sewage pretreatment

ActiveCN108543345BImprove purification efficiencyReduce power consumptionMoving filtering element filtersSewageSewage treatment

The invention discloses a sewage pretreatment multi-effect purification device, which comprises a casing, wherein a support plate is fixedly connected onto the left side of the top of the casing; thebottom of a movable plate is glidingly connected with the top of the casing; the top and the bottom of the right side of the movable plate are fixedly connected with connection springs; the right sideof the connection springs is fixedly connected with the top of the casing through a support rod; the sewage pretreatment multi-effect purification device relates to the technical field of sewage treatment purification. The sewage pretreatment multi-effect purification device is characterized in that the support plate is fixedly connected onto the left side of the top of the casing; the viscosityof the water in a barrel can be judged according to the detected sewage weight; then, the rotating speed of a rotating rod is regulated according to different viscosities, so that a filtering barrel can be driven to rotate at the optimal rotating speed to filter the sewage; therefore, the sewage purification efficiency is improved; the power consumption is reduced; great convenience is brought tothe use by people. The problem that the existing sewage pretreatment multi-effect purification device cannot realize the optimal purification on the sewage according to the viscosity of the sewage.

Owner:SHAOTAN CHEM FIBER

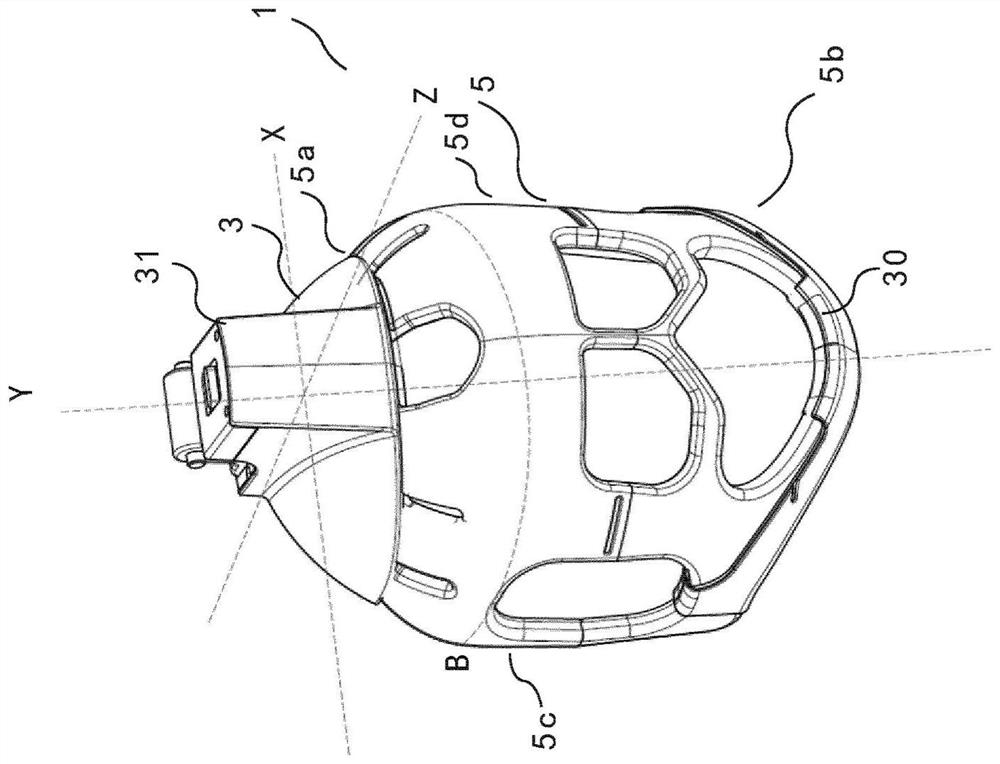

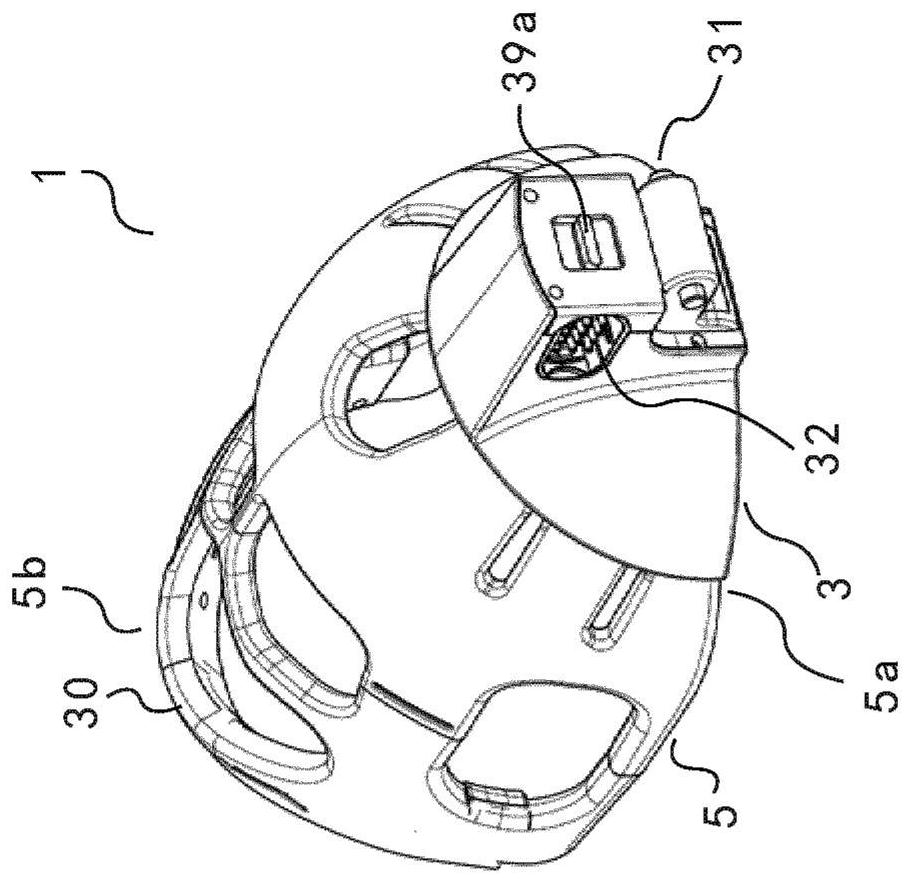

RF coil assembly and MRI apparatus

PendingCN113785213ARapid positioningSpeed up workflowSensorsTelemetric patient monitoringEngineeringMechanical engineering

Owner:KONINKLJIJKE PHILIPS NV

Gypsum board packaging machine

PendingCN112298647ASpeed up workflowEasy to operateWrapper supporting apparatusWrappingStructural engineeringScrew cap

The invention relates to the technical field of packaging machines and discloses a gypsum board packaging machine which comprises a base. A bracket is fixedly connected to the top of the base, a firstcaterpillar band is arranged in the bracket, a packaging rack is arranged on the right side of the bracket, a fixed plate is fixedly connected to the left side of the packaging rack, a paper drum isfixedly connected to the front side of the fixed plate, a paper tensioning cone is connected to the outer surface of the paper drum in a threaded manner, a packaging film conveying device is arrangedon the upper side of the bracket, a packaging film fixing device is arranged at the bottom of the bracket, a connecting plate is fixedly connected to the back side of the bracket, and sealing devicesare arranged on the front sides of two sealing machine bodies. According to the gypsum board packaging machine, a packaging film passing between two conveying rollers passes between a first film pressing plate and a second film pressing plate along the top of a bag opener, and then a nut is screwed to rotate through a bearing to further drive the second film pressing plate to move upward, so thatthe packaging efficiency is improved effectively.

Owner:临沂周兴建材有限公司

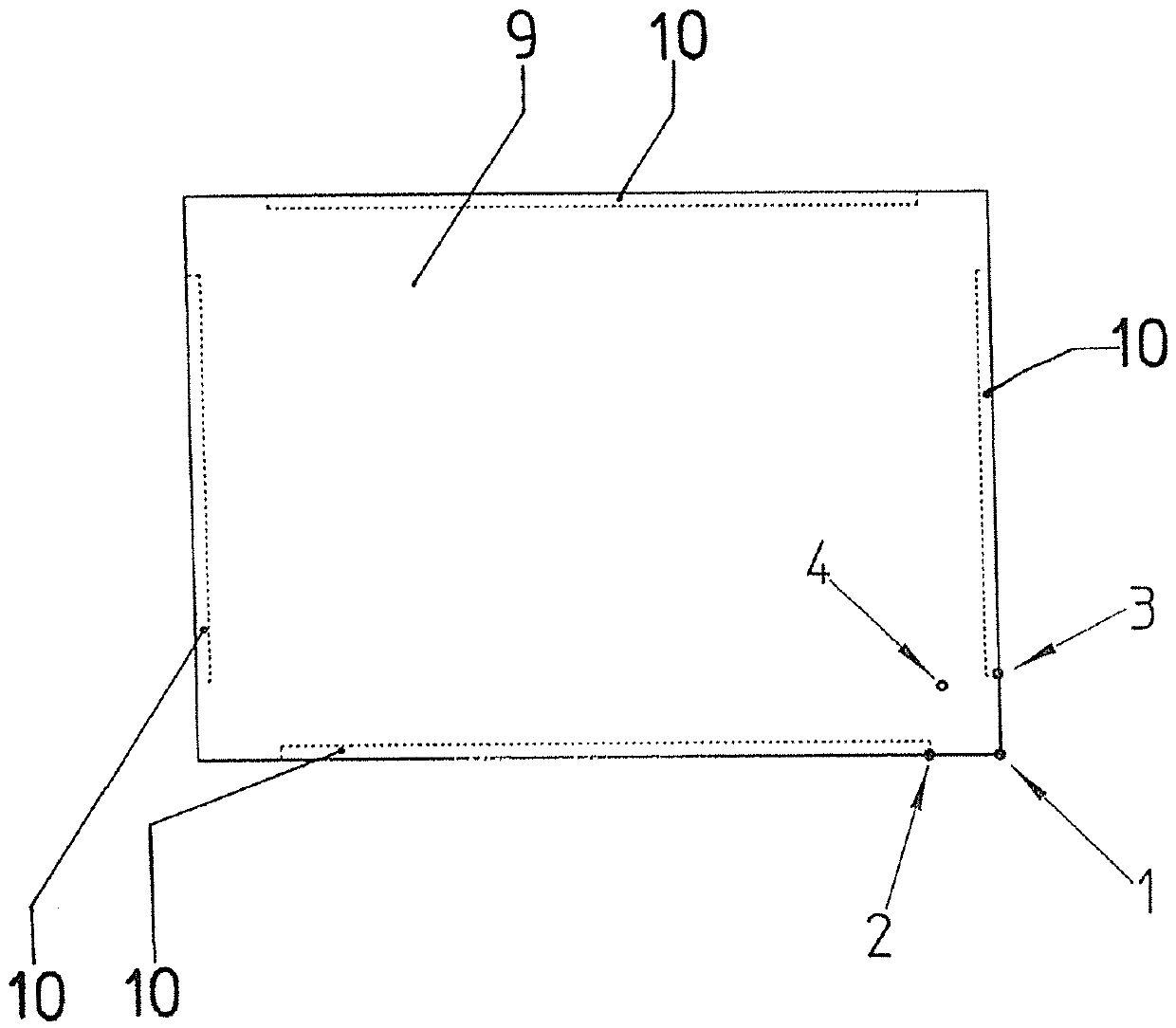

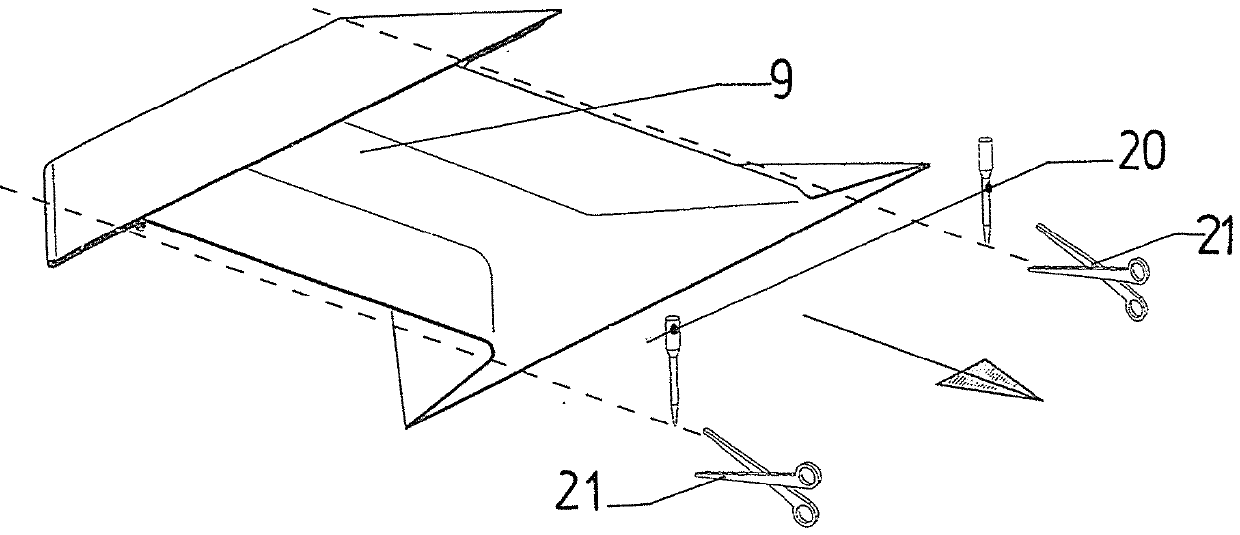

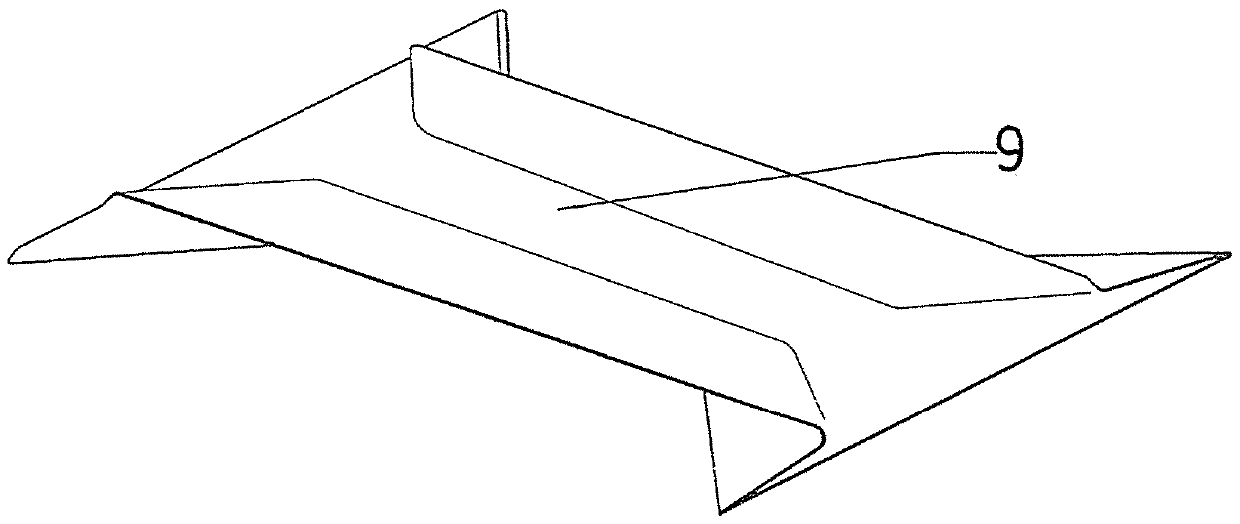

Method and device for manufacturing fitted bed sheets

ActiveCN110891463AEasy to controlRealize overlapping processingBlanketBed linenRight triangleEngineering

The invention relates to a method for manufacturing fitted bed sheets, in which: rectangular sheet pieces (9) are cut; each corner (1,5) of the sheet pieces (9) is folded in on itself, the portions that are folded in on themselves are joined by a seam at a distance from the tip of the corner (1,5) of the sheet piece; and the tip projecting beyond the seam is cut off, forming a rectangular-shaped sheet piece (11), wherein the sheet piece (9) is held at each corner (1,5) at two holding points (2, 3; 6, 7), the first holding point (2; 6) on the first peripheral edge (13,13') is moved parallel toa plane covered by the sheet piece to the second holding point (3; 7) on the second peripheral edge (14,14'), together with the associated portion of the sheet piece (9); and the holding points (2',3;6', 7) are held one on top of the other and a sheet flap in the shape of a right-angled triangle is formed, said sheet flap being provided with the seam (18) along the second leg (17) of the trianglethen being cut off next to the seam (18) following the line of the latter.

Owner:SCHMALE HLDG GMBH

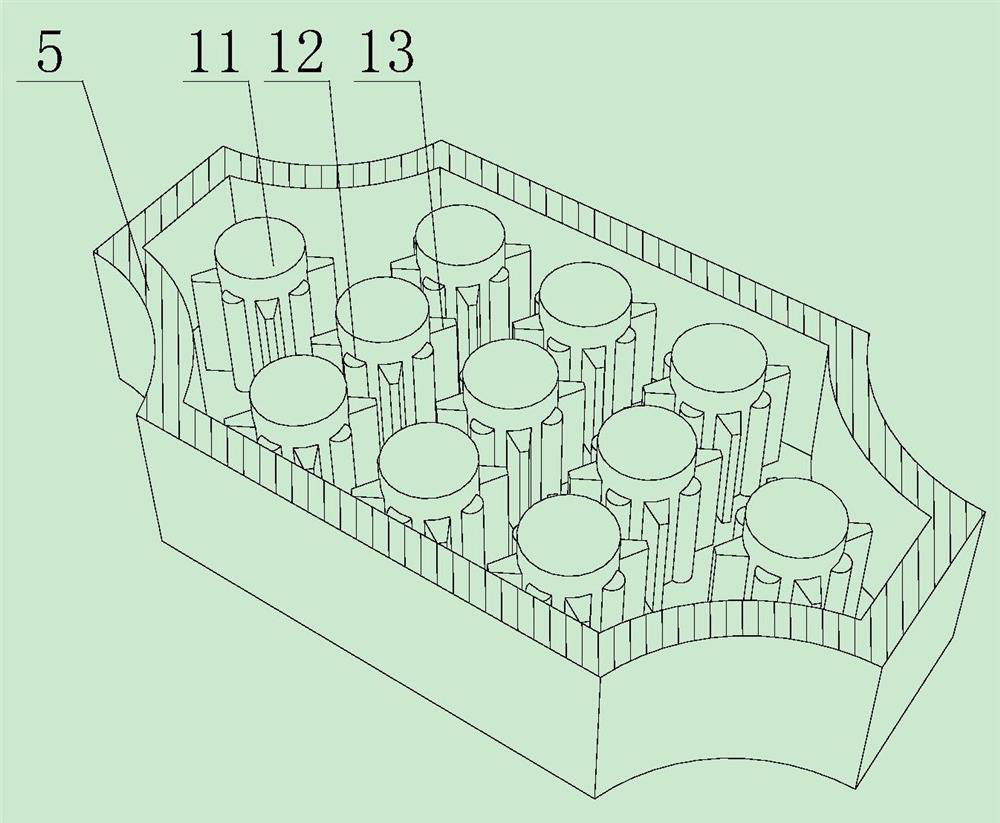

Code spraying device based on digital products

ActiveCN113211982ASpeed up workflowGood guidance and positioningTypewritersPower drive mechanismsEngineeringCam

The invention discloses a code spraying device based on digital products. The code spraying device comprises a base, a power box, a conveying frame and a control panel, the power box is mounted at the top end of the base, a first motor is arranged in one side of the power box, and a first rotating shaft is mounted at the output end of the first motor through a coupling. A rotating cam is arranged on the side, away from the first motor, of the first rotating shaft, a second sliding block is installed on one side of the rotating cam, a fixing block is arranged on one side of the bottom end in the power box, the conveying frame is arranged at the position, above the power box, of the top end of the base, and a second motor is installed on the outer wall of the conveying frame. A second rotating shaft is mounted at the output end of the second motor through the coupling. According to the code spraying device, products can be rapidly conveyed through a conveying device, guiding and limiting are conducted when code spraying is conducted on packaging boxes of the products according to the types and sizes of the products on a production line, and rapid code spraying work is conducted on the products.

Owner:浙江致立智能科技有限公司

Electric cable bending device

InactiveCN105261990BAffectReduce laborCable installation apparatusElectric power transmissionEngineering

The present invention discloses an electric type cable bending apparatus, and relates to the technical field of electric power transmission equipment. The electric type cable bending apparatus comprises a sliding chute, wherein two ends of the sliding chute are fixed to a bottom plate respectively through an A supporting leg and a B supporting leg, an A slide block and a B slide block are slidably arranged in the sliding chute, the upper end face of the A slide block is fixedly provided with an A long rod, an A hold ring is rotatably arranged on the A long rod, an A bolt is connected between two protruded front edges of the upper portion of the A hold ring, the upper end face of the B slide block is fixedly provided with a B long rod, a B hold ring is rotatably arranged on the B long rod, a B bolt is connected between two protruded front edges of the upper portion of the B hold ring, an electric push rod is arranged in a horizontal plane where the A hold ring and the B hold ring locate, the electric push rod is arranged on the bottom plate and perpendicular to the sliding chute; the front end of the electric push rod is fixedly provided with a hold hoop. The electric type cable bending apparatus of the present invention has the beneficial effects of good adaptability, convenient use, standard operation, labor saving and time saving, etc.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +2

Method and system for managing image quality utilizing a generative model

PendingCN113628158AImprove diagnostic accuracyAvoiding the challenges of non-standard image qualityImage enhancementImage analysisData setImaging quality

The subject of the invention are a method and system for managing image quality utilizing a generative model. Systems, methods and computer program products are provided to collect ultrasound (US) data. A processor is configured to acquire the US data along one or more acquisition scan planes. The US data defines a plurality of image frames that have a first image quality. The processor is further configured to apply a generative model to at least one of the US data or plurality of image frames to generate a synthetic scan plane image along a synthetic scan plane. The generative model is defined based on one or more training ultrasound data sets. The synthetic scan plane image has an image quality that is common with the first image quality of the plurality of image frames. The system further comprises a display configured to display the synthetic scan plane image.

Owner:GE PRECISION HEALTHCARE LLC

A method for processing the bottom of area edge and area built-in components in home improvement design

ActiveCN111063014BImprove work efficiencyMeet the needs of actual home improvement3D-image renderingProcess engineeringHome improvement

The invention discloses a method for processing the edge of an area and the bottom of an area built-in component in a home improvement design. The method includes steps S1: loading a plan, and acquiring the ground area and component information of the plan; S2: calculating the component belonging area information; S3: sequentially assigning the components to their belonging The edge of the area is fitted; S4: Update the result of the fitted area. The present invention allows designers to automatically handle the fit between the area and the bottom area of the component during the home improvement design process, and the processed area can better meet the needs of actual home improvement. For example, the designer needs to generate a skirting line on the bottom edge of the component, Instead of generating all of the original area edges, the method for processing the area edges and the bottom of the built-in components in the area of the present invention makes the design process more intelligent, speeds up the workflow, and improves the work efficiency of designers.

Owner:江苏艾佳家居用品有限公司

Integral load support for a jack formed of a sheet material bent to less than 180 degrees

InactiveUS20110210297A1Eliminate disadvantagesEnhanced advantageNail extractorsLifting devicesStructural engineeringEngineering

Owner:ARIKAN KRIKO & MAKINA SANAYI TICARET ANONIM SIRKETI

Cable bending machine with high working efficiency

InactiveCN109365672ACompact structureReduce volumeMetal working apparatusDrive wheelReciprocating motion

The invention provides a cable bending machine with high working efficiency. The cable bending machine comprises a machine box, an operation table arranged above the machine box, a wire bending mold arranged on the operation table, a first auxiliary wheel, a second auxiliary wheel and a driving wheel, the first auxiliary wheel is driven by a first hydraulic air cylinder, the second auxiliary wheelis driven by a second hydraulic air cylinder, the driving wheel is driven by a third hydraulic air cylinder, the first hydraulic air cylinder, the second hydraulic air cylinder and the third hydraulic air cylinder are all arranged in the machine box, a first sliding groove, a second sliding groove and a third sliding groove which allow the first auxiliary wheel, the second auxiliary wheel and thedriving wheel to do reciprocating motion correspondingly are arranged on the operation table. The electric power is used for replacing manpower, so that the labor force is liberated, the labor amountof workers is reduced, compared with the manual work, the hydraulic air cylinders can be used for bending thicker and larger cable, so that the operation range is expanded, moreover, the cable bending work is standardized and procedural, then the working efficiency is improved, and the working process is accelerated.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com