Automobile disc brake spraying production line and production method thereof

A technology for production lines and automobiles, applied in coatings, spray booths, spraying devices, etc., can solve problems such as uneven heating, excessive local temperature, and large differences in fixed-line effects, and achieve the goal of improving utilization efficiency and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

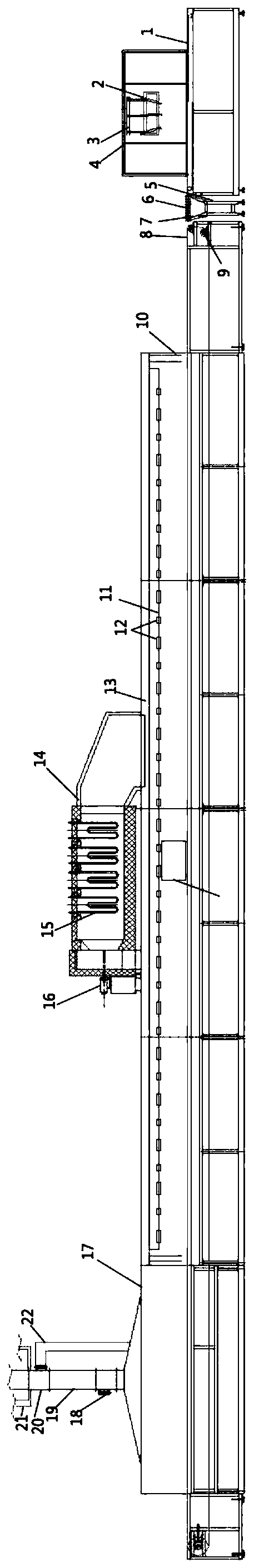

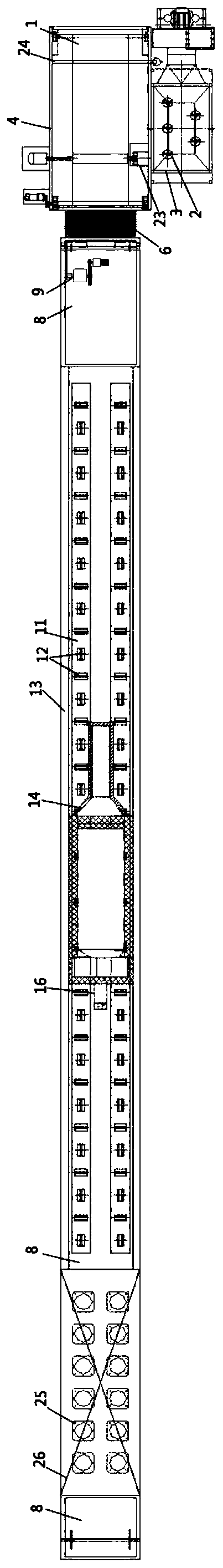

[0061] A kind of automobile disc brake spraying production line (see attached figure 1 And attached figure 2 ),

[0062] Automatic coating unit, spraying the automotive disc brake parts to be processed;

[0063] High-temperature curing furnace, which uses a controllable distributed heating method to cure the coating of the automotive disc brake parts after the spraying step;

[0064] The cooling device 17 is used to cool down the automobile disc brake parts whose coating is solidified;

[0065] The main conveyor belt, for the transmission of the automobile disc brake parts to be processed, is set at the high temperature curing furnace and the cooling device.

[0066] More specifically include:

[0067] The closed chamber 4 is generally in the shape of a cuboid, and there are rectangular protrusions on the top of the sides, which are used to prevent environmental pollution caused by paint powder overflow. One side is provided with a material placement port, and the opposit...

Embodiment 2

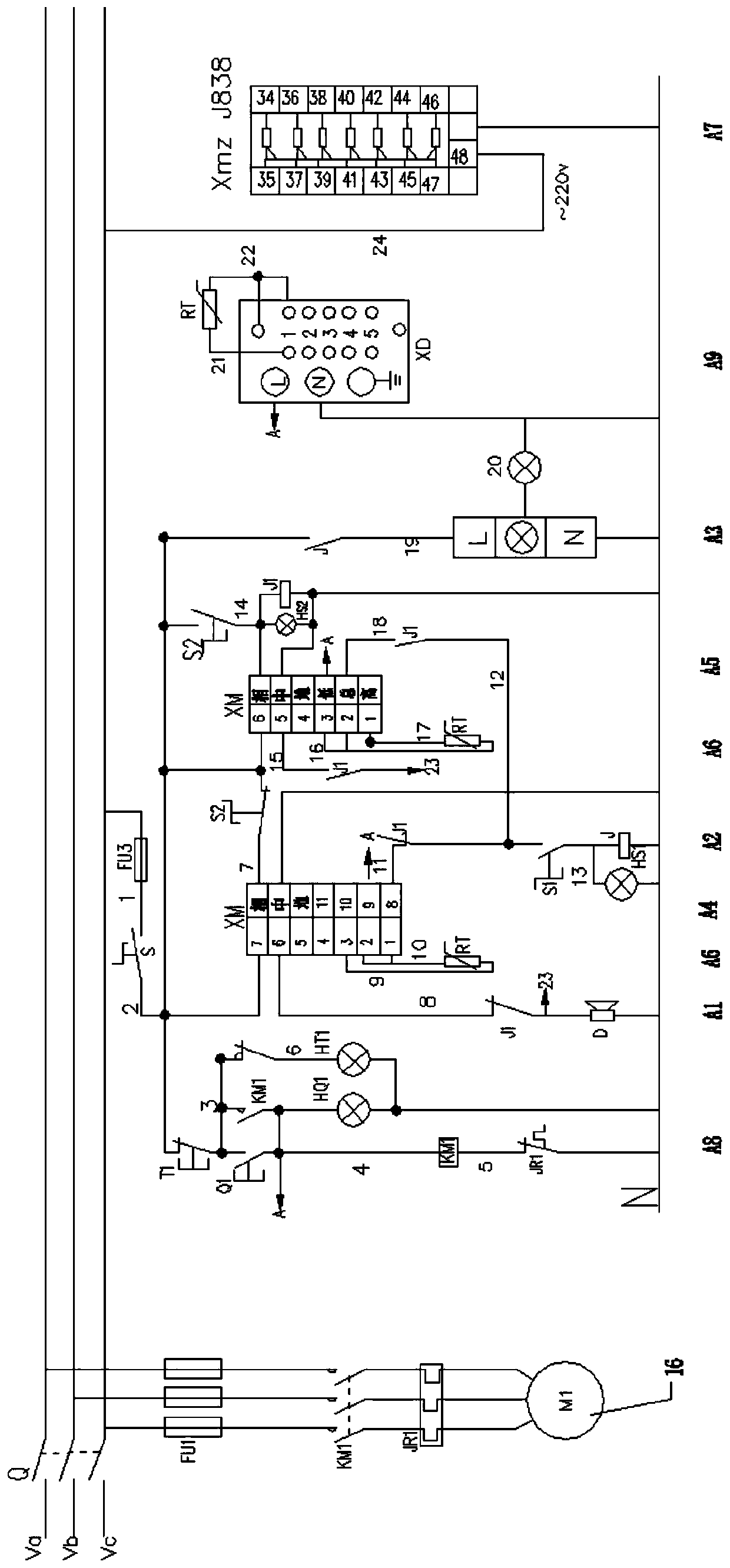

[0112] An automobile disc brake spraying production line, which is basically the same as Embodiment 1, the difference is that the heating chamber in this application adopts the way of fuel heating, and its main control circuit includes: ultra-high temperature alarm A1, ignition switch A2, Heating equipment starting circuit A3, temperature controller A4, digital display temperature controller A5, temperature sensor A6, inspection instrument A7, heating room fan starting circuit A8 and temperature recorder A9. Specifically its control circuit (see attached image 3 ), the AC contactor in the starting circuit of the fan in the heating room is connected to the power supply, the temperature controller and the digital display temperature controller are both XMTA temperature controllers, and the fan in the heating room is controlled with an ultra-high temperature alarm, The ignition switch and the heating equipment starting circuit, the temperature controller and the digital display ...

Embodiment 3

[0114] An automobile disc brake spraying production line, which is basically the same as Embodiment 1 or Embodiment 2, the difference is that in this embodiment, all controllable horizontal air outlets and controllable longitudinal air outlets are equipped with adjustable openings. In this implementation, the device with adjustable opening is an electric control shutter, and the control end of the electric control shutter is connected with the on-site control equipment in the automobile disc brake spraying production line. The on-site control equipment in this embodiment is industrial control computer or connected to the upper industrial computer, the opening data of the controllable horizontal air outlet and the controllable longitudinal air outlet in this embodiment are directly set by the on-site control equipment, and realized through the drive of the electric control shutter.

[0115] A kind of automobile disc brake spraying production method corresponding to the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com