Cable bending machine with high working efficiency

A technology of work efficiency and wire bending machine, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the bending workload of power cables, affecting the effect of cable bending, and low work efficiency, etc., to achieve The bending effect is good, the work efficiency is improved, and the labor load is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

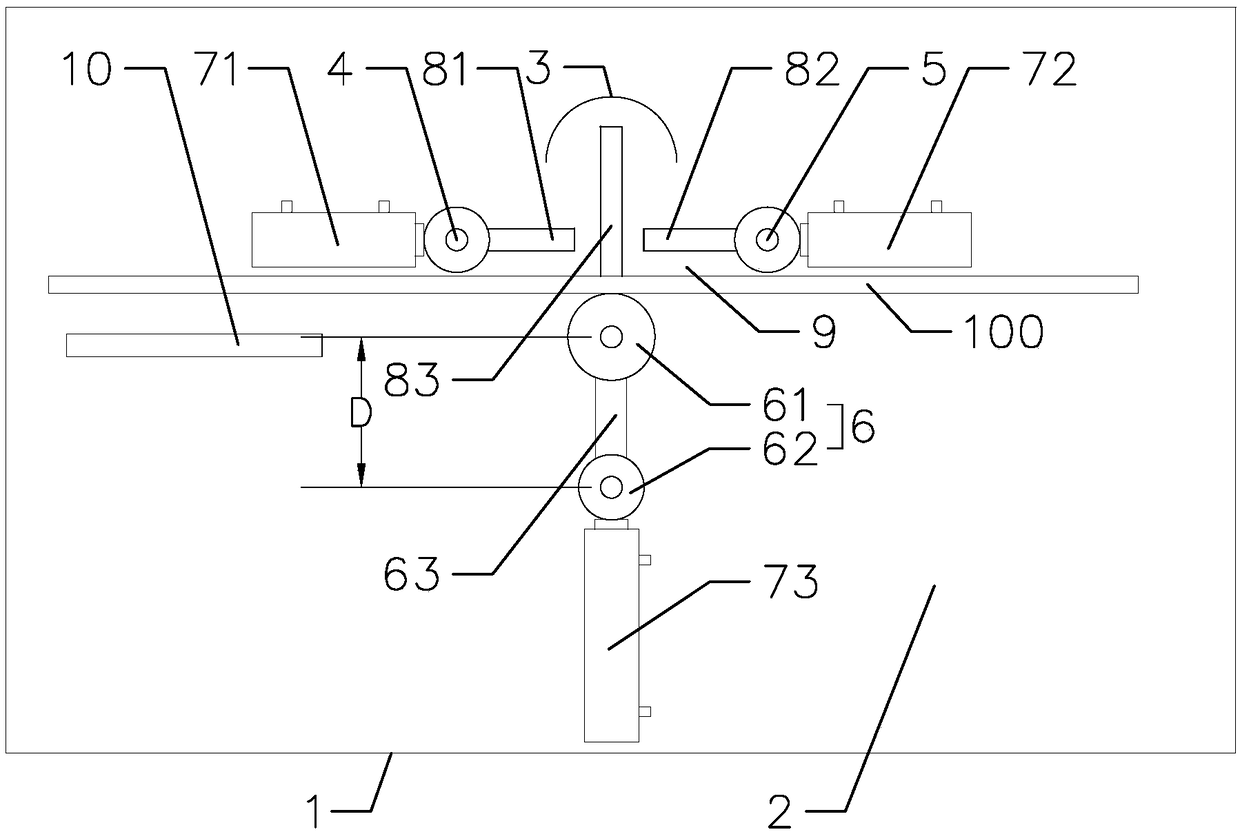

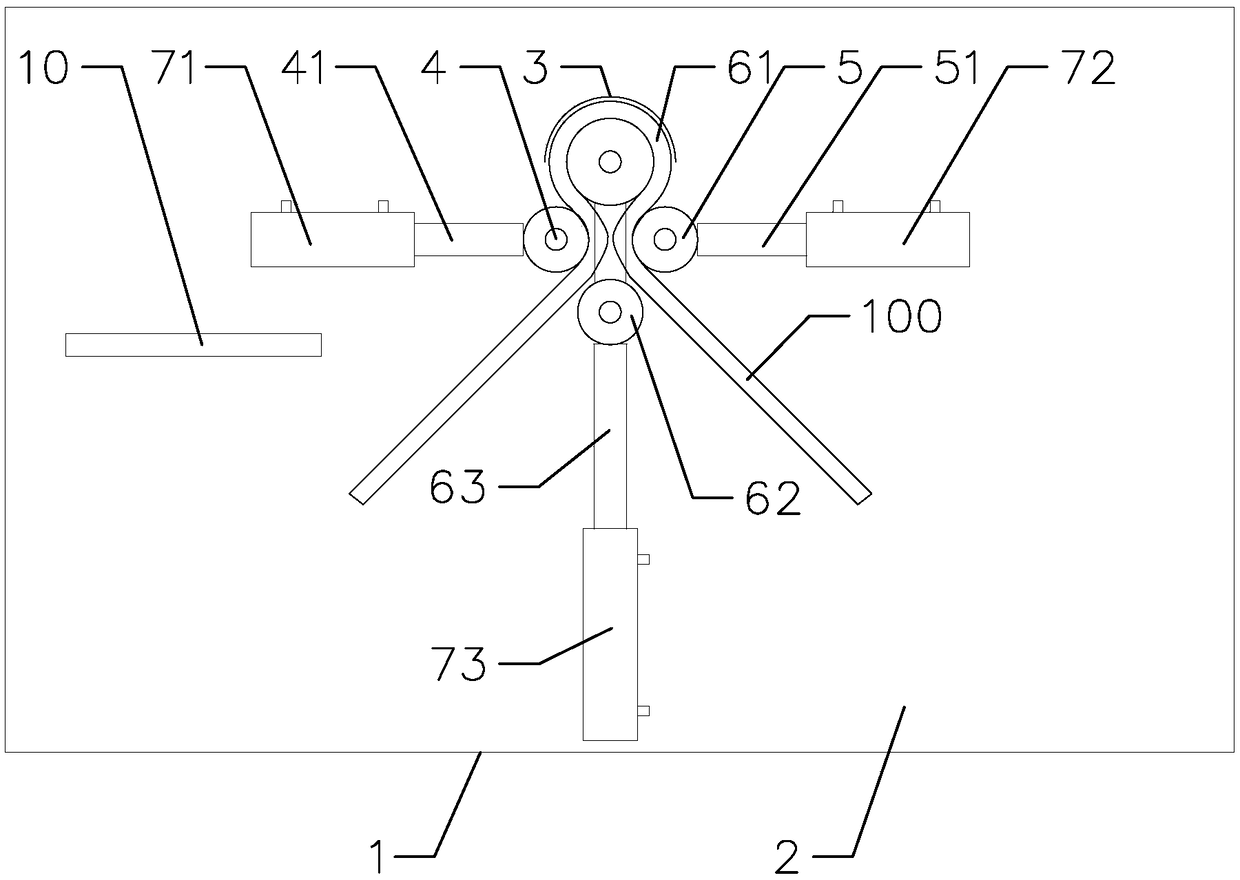

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as Figures 1 to 4As shown, the present invention provides a cable bending machine with high working efficiency, which includes a cabinet 1, an operating table 2 arranged above the cabinet 1, a wire bending die 3 arranged on the operating table 2, and a first auxiliary wheel 4 , the second auxiliary wheel 5 and the driving wheel 6, the first auxiliary wheel 4 is driven by the first hydraulic cylinder 71, the second auxiliary wheel 5 is driven by the second hydraulic cylinder 72, the driving wheel 6 is driven by the third hydraulic cylinder 73, the first The hydraulic cylinder 71, the second hydraulic cylinder 72 and the third hydraulic cylinder 73 are all arranged in the cabinet 1, and the console 2 is provided with the first auxiliary wheel 4, the second auxiliary wheel 5 and the driving wheel 6 to reciprocate respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com