Spherical bulb production line

A production line and light bulb technology, which is applied to machines with sequentially arranged working positions, etc., can solve the problems of poor product quality stability and consistency, increase production costs and management difficulties, and low production efficiency, and save assembly operation time and work. High efficiency and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

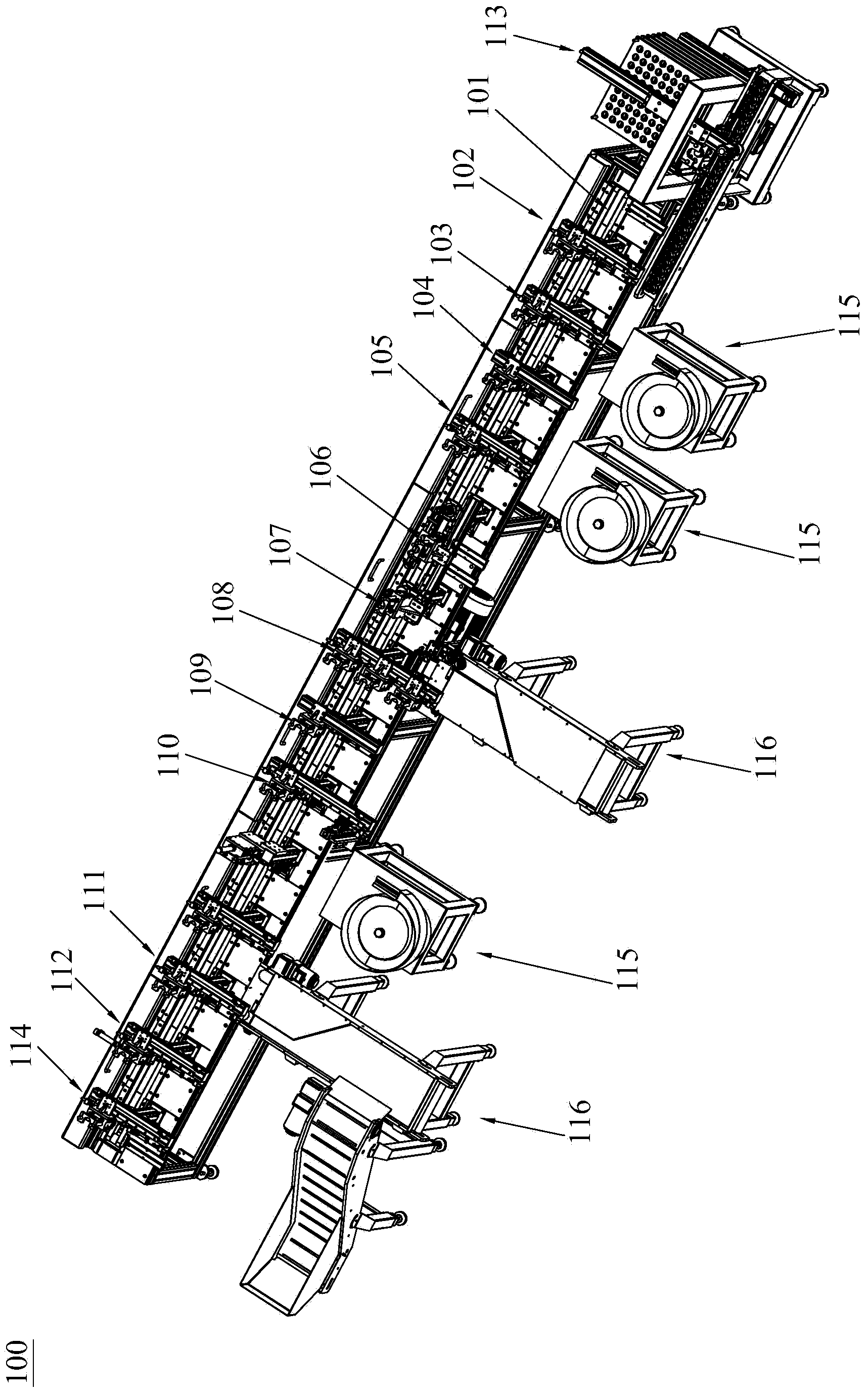

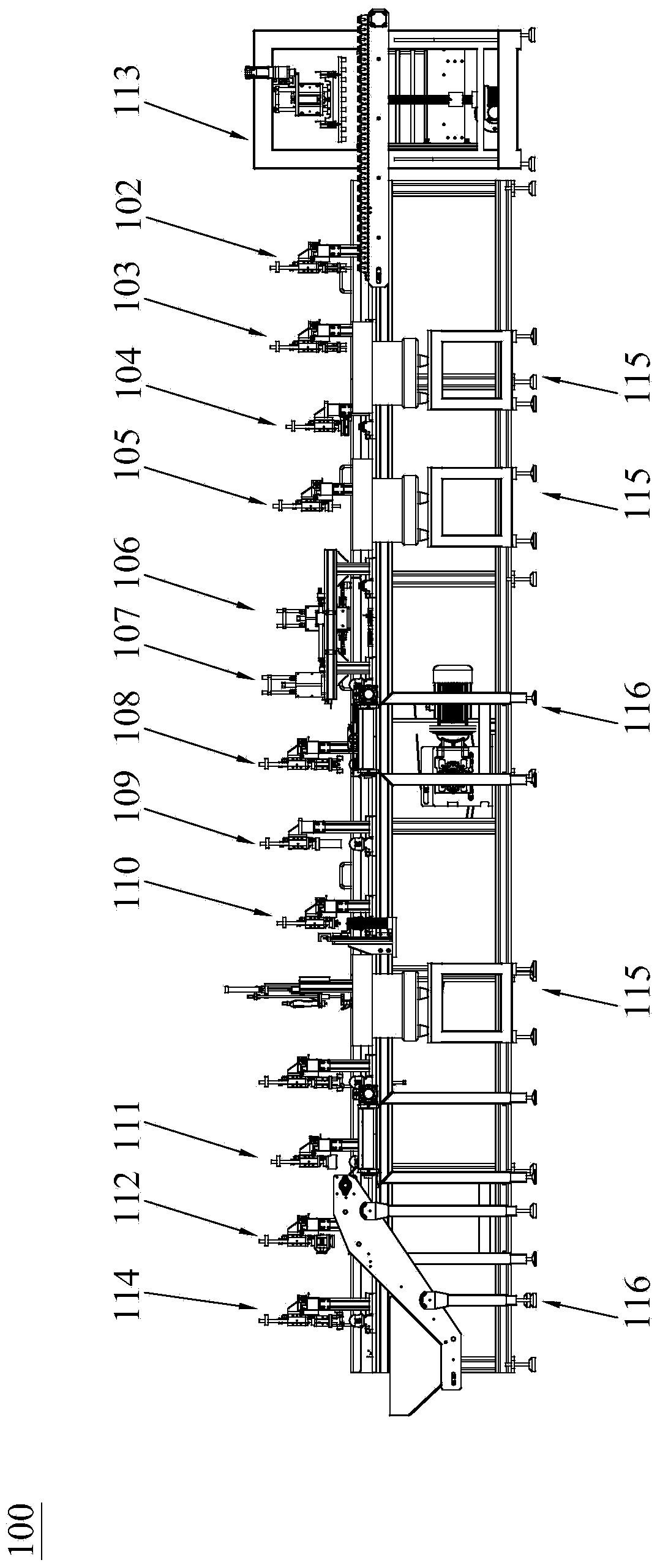

[0028] like figure 1 , figure 2 As shown, the spherical light bulb production line 100 of the present invention includes a conveyor belt 101, on which a lamp cup orientation device 102, a lamp cap adding device 103, a riveting lamp cap device 104, a lamp cap screw device 105, a lamp cup inversion device 106, and a lamp cup Positioning device 107, lamp holder unilateral positioning device 108, gluing device 109, power supply board device 110, lampshade adding device 111 and pressing and tightening device 112, the front end of conveyor belt 101 is also provided with automatic feeding device 113.

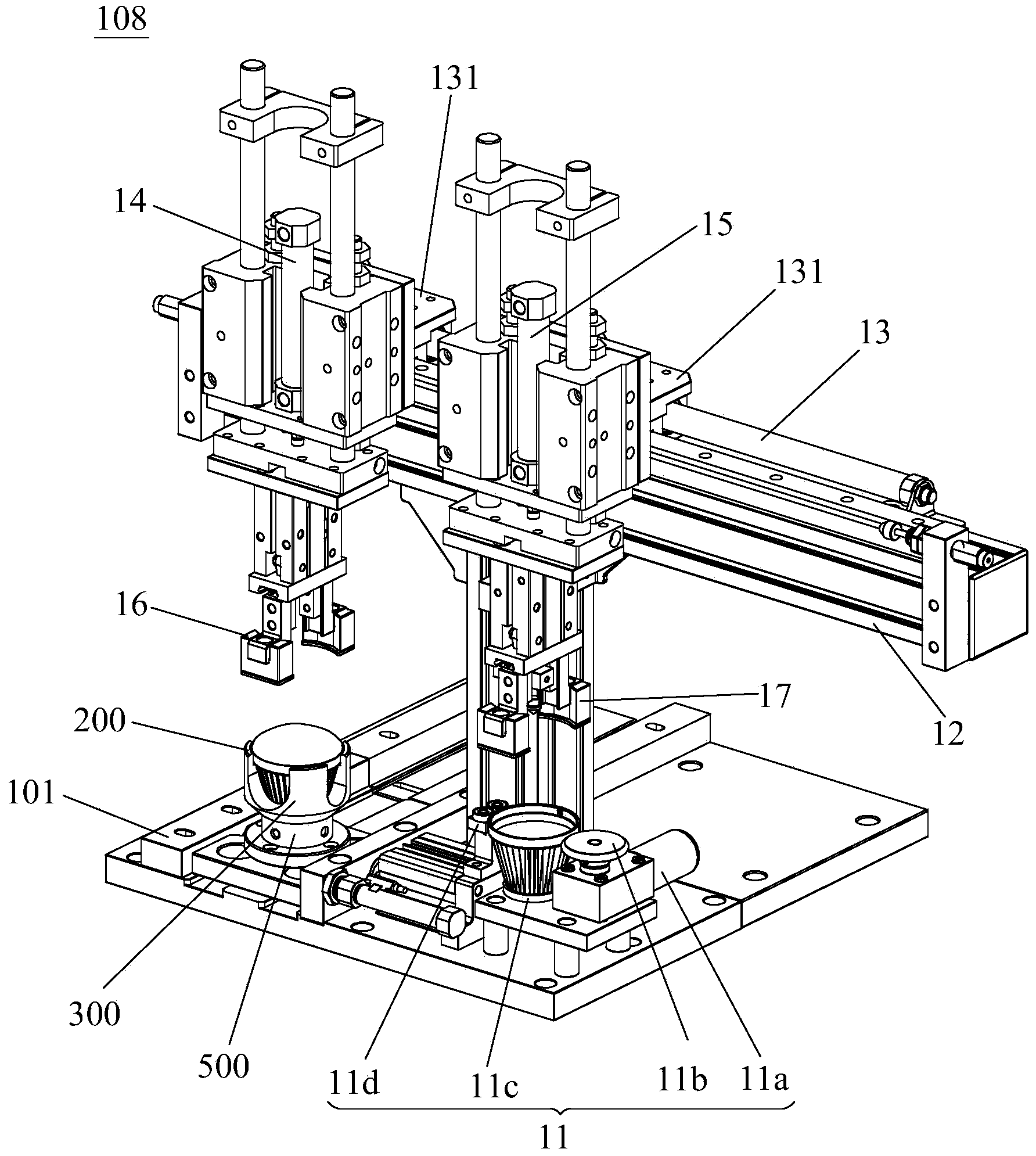

[0029] like Figure 3 to Figure 5 As shown, the lamp holder unilateral positioning device 108 includes a lamp holder positioning mechanism 11, a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com