Part paint baking device and method for machining

A technology for mechanical processing and parts, applied in the field of paint baking devices for mechanical processing parts, can solve the problems of polluting parts, affecting the painting effect of parts, and the inability to separate the internal and external environments of the paint baking device, so as to avoid pollution and improve baking paint. effect, the effect of shortening the time required for baking paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

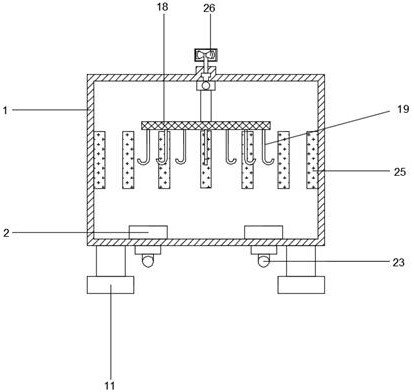

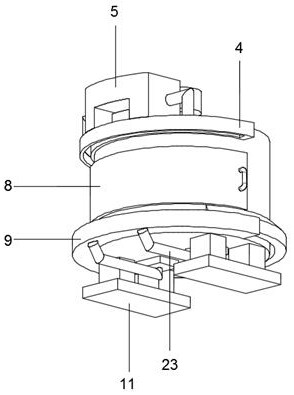

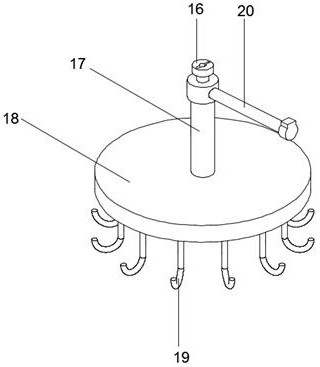

[0035] refer to Figure 1-6 , a kind of parts and components baking paint device and method for mechanical processing, comprise housing 1, base 11, exhaust valve 27, air receiving groove 9 and air inlet groove 4, the top outer wall of housing 1 is fixed with air curtain machine 5 by bolt, wind One side of the outer wall of the curtain machine 5 is fixed with an air inlet pipe 6 by screws, and the outer walls of both sides of the air curtain machine 5 are fixed with an air jet pipe 7 by screws, and one end of the air jet pipe 7 is connected to the top outer wall of the air inlet groove 4 through a socket , the air receiving groove 9 and the air inlet groove 4 are fixed on the outer wall of the housing 1 by bolts, the inner wall of the air receiving groove 9 is inserted with a slope slide bar 3, and the outer wall of the bottom of the air receiving groove 9 is sleeved with a downwind pipe 23, and the downwind One end of the pipe 23 is sleeved with an air outlet pipe 2, and the a...

Embodiment 2

[0045] refer to Figure 7 , a device and method for baking parts for mechanical processing. Compared with Embodiment 1, this embodiment also includes a spherical baking lamp 24 fixed on the inner wall of the bottom of the shell 1 by screws.

[0046] When in use, the spherical baking lamp 24 increases the baking angle of the parts and improves the baking effect of the parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com