Material processing stress on-line removal and straightening and cutting technology

A material processing and straightening technology, applied in the field of material processing stress on-line removal and straightening and cutting, can solve the problems of high processing efficiency, low air-cooling cooling efficiency, high degree of cold work hardening, etc., to achieve high processing efficiency and save work. The effect of time-saving and processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

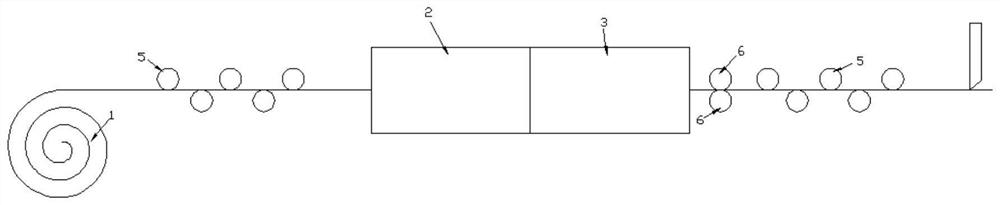

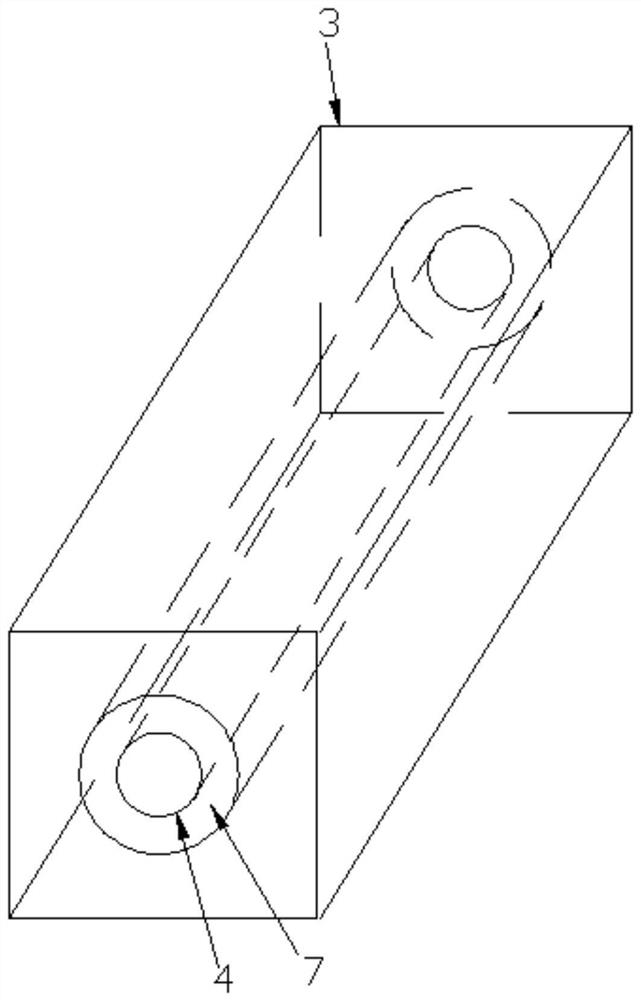

[0014] Such as figure 1 , figure 2 As shown, the present invention is a process for online removal of material processing stress and straightening and cutting, including the following steps: unwinding of stainless steel wire rod 1, straightening, heat treatment, cooling, secondary straightening and shearing; The heat treatment adopts the tube furnace 2 for tempering treatment. The length of the tube furnace 2 is 8 meters, the heat treatment temperature is 900° C., and the wire speed of the stainless steel wire rod 1 is 4-5 m / min. The tube furnace 2 has a power of 65KW; the cooling process adopts tube cooling: the heat-treated wire rod passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com