Screw locking mechanism

A locking mechanism and screw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, high labor cost, difficulty in ensuring quality consistency, etc., and improve processing accuracy and efficiency. The effect of saving working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make those skilled in the art more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

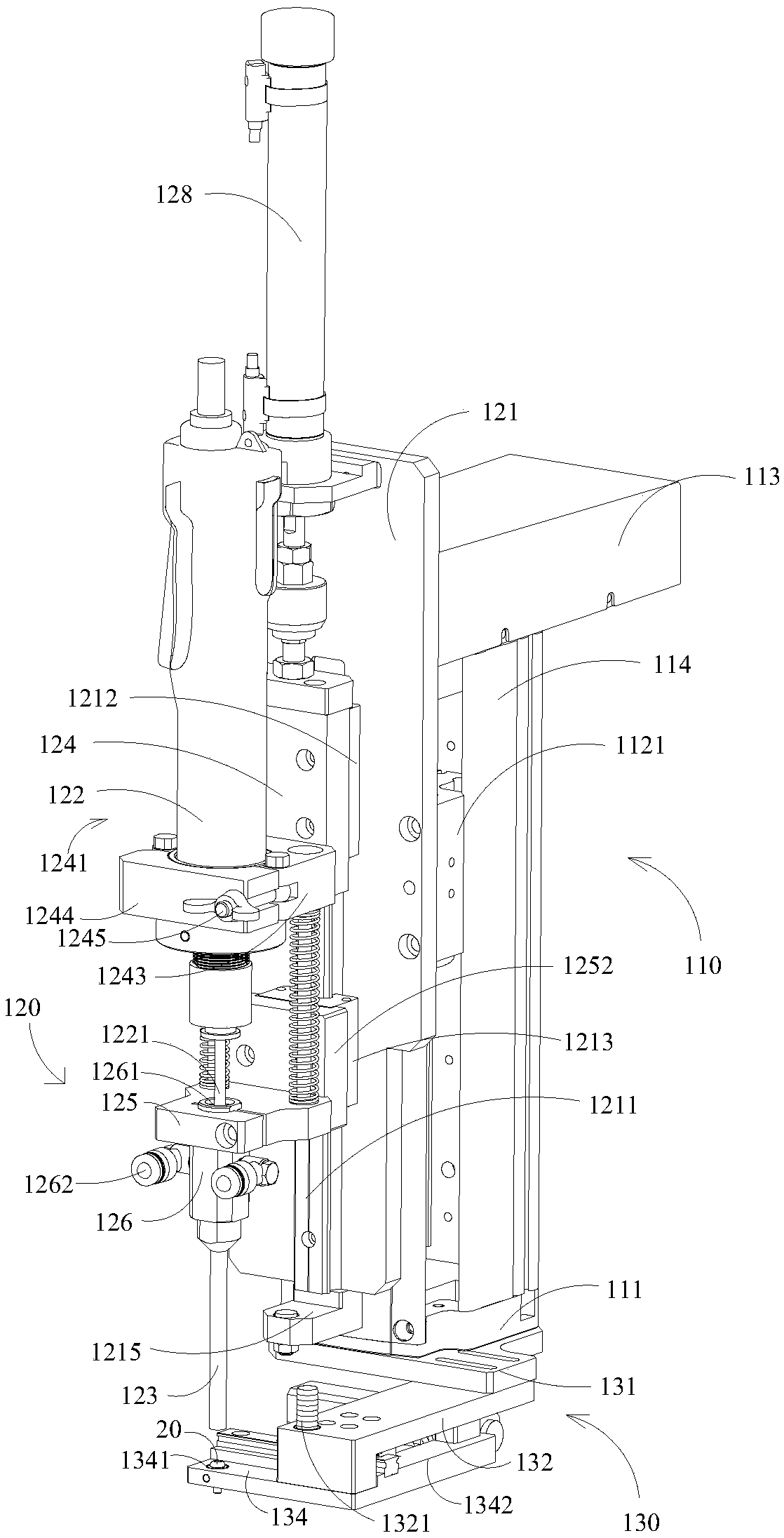

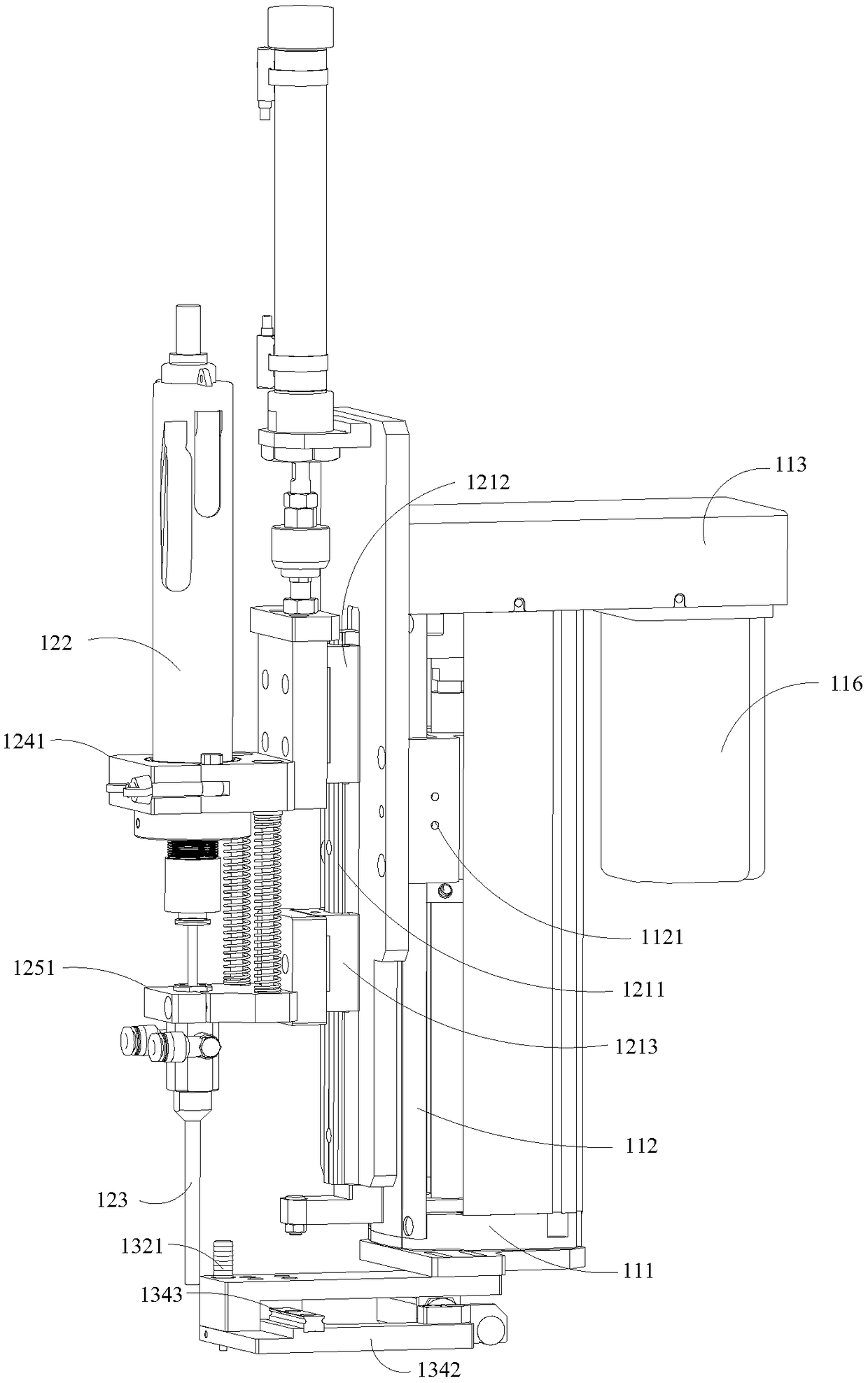

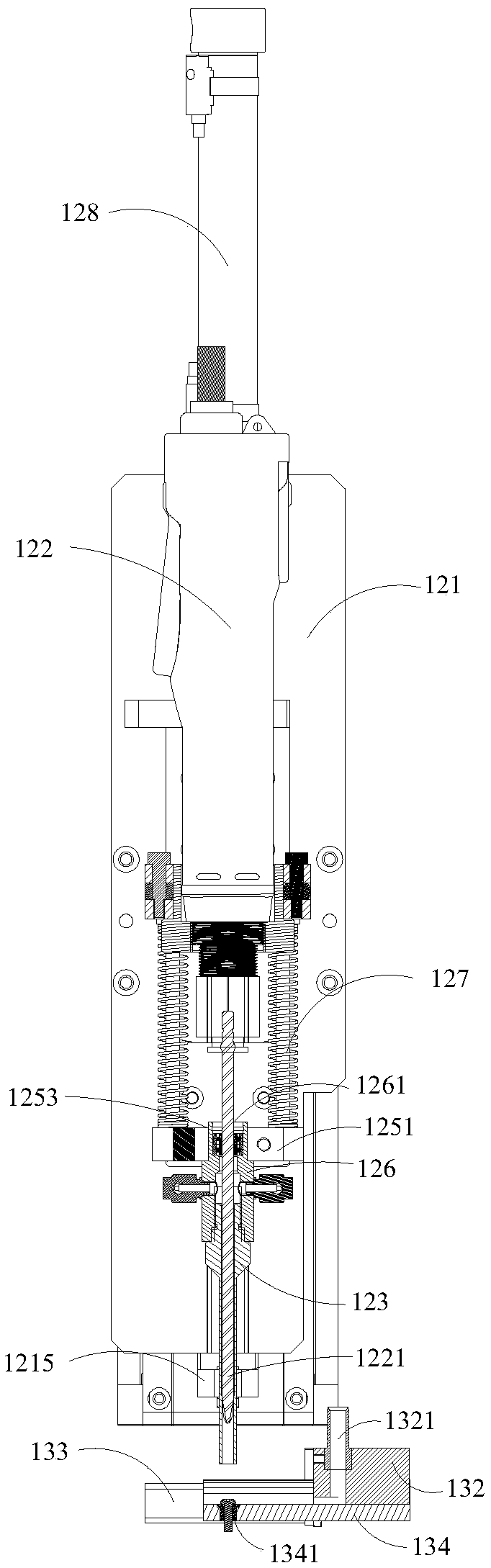

[0025] refer to Figure 1 to Figure 7 , in this embodiment, the screw locking mechanism includes a support module 110 , a locking module 120 and a screw feeding module 130 . Wherein, the support module 110 includes a support base 111 and a cover plate 112 , and the cover plate 112 is vertically arranged at one end of the support base 111 . The locking module 120 is arranged on one side of the supporting module 110, and includes a bottom plate 121, an electric batch 122 and a suction nozzle 123, and the bottom plate 121 is vertically arranged on one side of the supporting module 110 , the bottom plate 121 is installed on the cover plate 112, the electric batch mounting frame 124 and the suction nozzle mounting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com