Warehousing system based on two-dimensional code identification technology

An identification technology and storage system technology, applied in the field of waste disposal equipment, can solve the problems of inability to store statistical records of items, increase the time for picking, and the device is too simple, so as to improve storage efficiency, save manpower, and use safely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

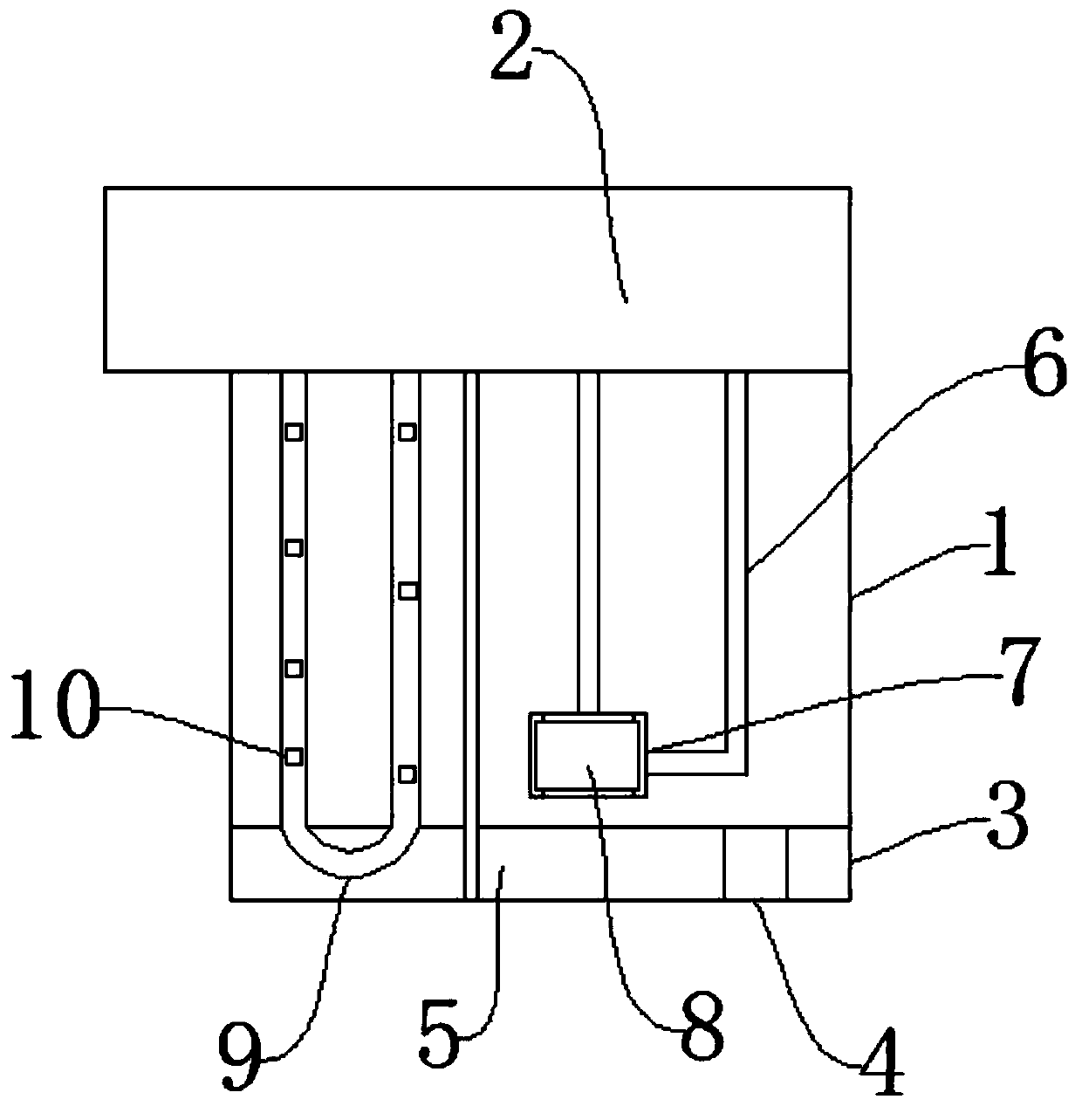

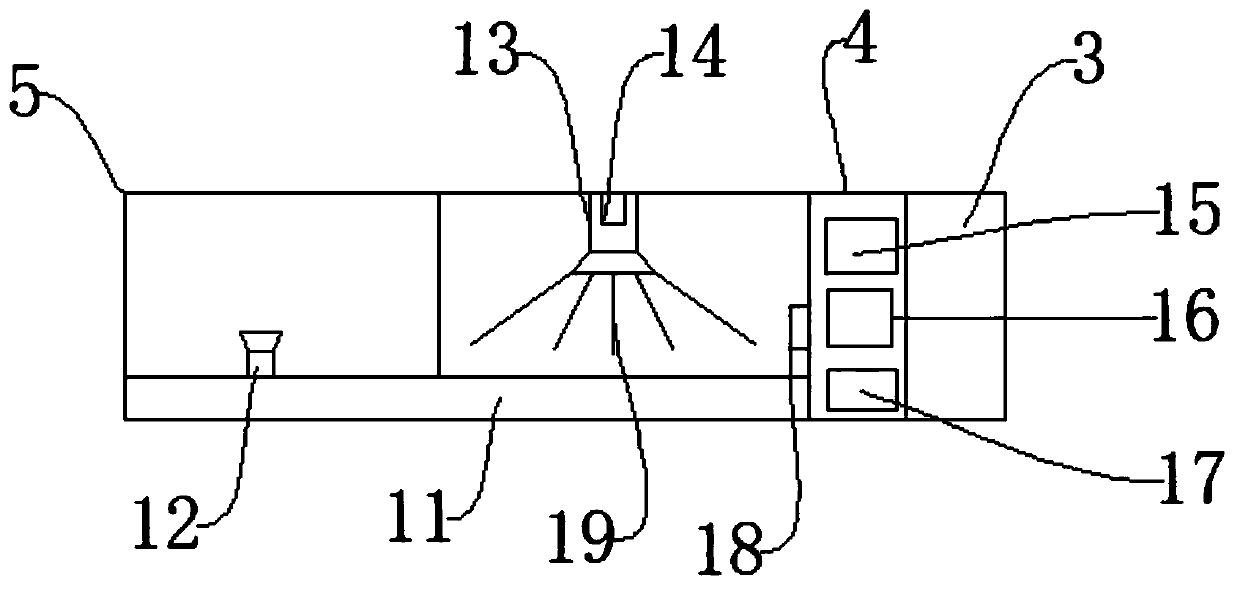

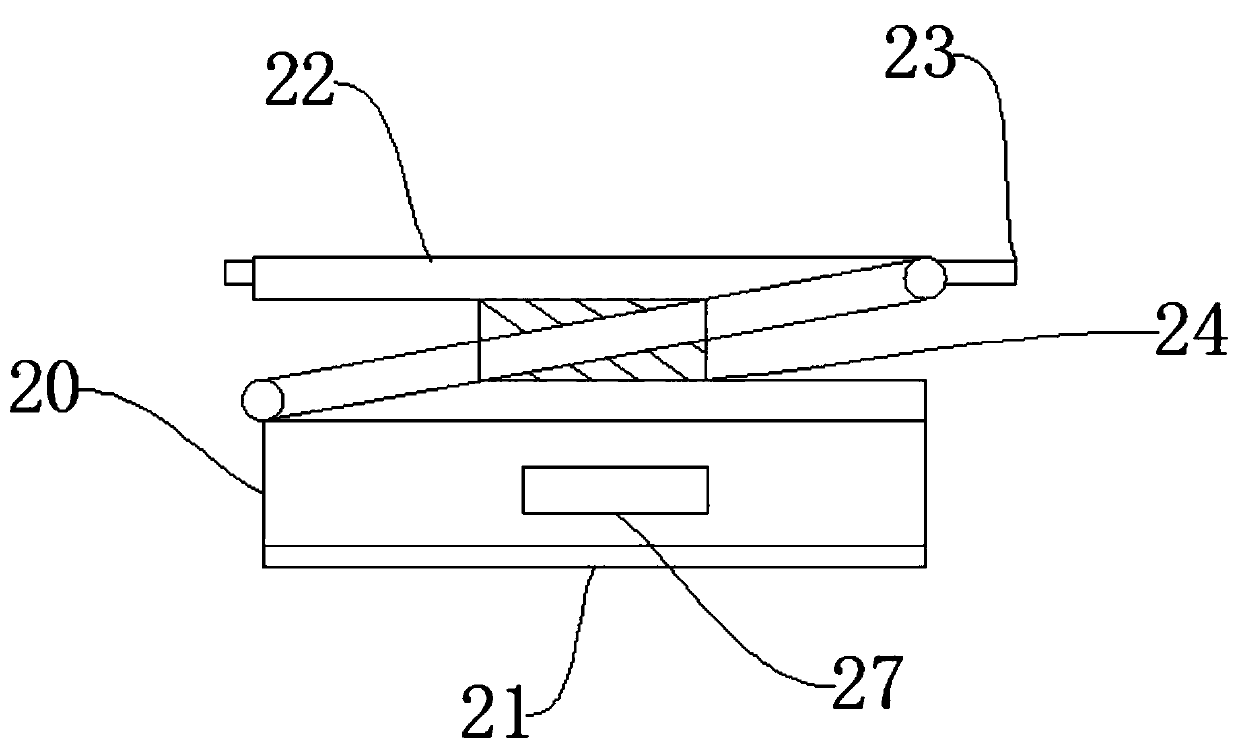

[0030] Such as Figure 1-Figure 5 As shown, a storage system based on two-dimensional code identification technology includes a conveying area 1, a storage area 2 is provided on one side of the conveying area 1, a guiding magnetic strip 6 is provided on the side of the conveying area 1, and the guiding magnetic strip 6 is provided on the side of the conveying area 1. A truck 7 is arranged above the bar 6, a car body 20 is arranged on the truck 7, a sensor 21 is arranged on the lower side of the car body 20, a walking controller 27 is arranged in the car body 20, and a vehicle body 20 is arranged on the car body 20. A support frame 22 is provided on the upper side of the body 20, a hydraulic mechanism 24 is arranged in the support frame 22, a support plate 23 is provided on the upper side of the support frame 22, a large storage box 8 is arranged on the support plate 23, and the Both sides of the large storage box 8 are provided with hanging arms 26, the outer wall surface of t...

Embodiment 2

[0032] The difference between this implementation and Embodiment 1 is:

[0033] In this embodiment, the suspended scanner 13 is fixed on the inner upper surface of the working area 5 by bolts, the catcher 14 is embedded in the suspended scanner 13, and the scanning capture area 19 corresponds to the two-dimensional Yard 25 area.

[0034] Specifically, such a setting makes it possible to scan the two-dimensional code 25 more accurately and quickly, shorten working time, and improve work efficiency.

[0035]Working principle: the control box 4 controls the storage system to start. When storing small items, the conveying mechanism 9 starts, and the small storage box 10 is transported to the small scanner 12, and the small scanner 12 to scan the article, after scanning, the identifier 15 in the control box 4 recognizes, and after the recognition, the processor 16 processes and analyzes the data, and then compares the information of the small article with the information on the sm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap