Elevator cab and method for manufacturing same

A technology of elevator car and car, which is applied in the direction of elevators, transportation and packaging in buildings, and can solve the problems of difficult recyclability and high cost of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

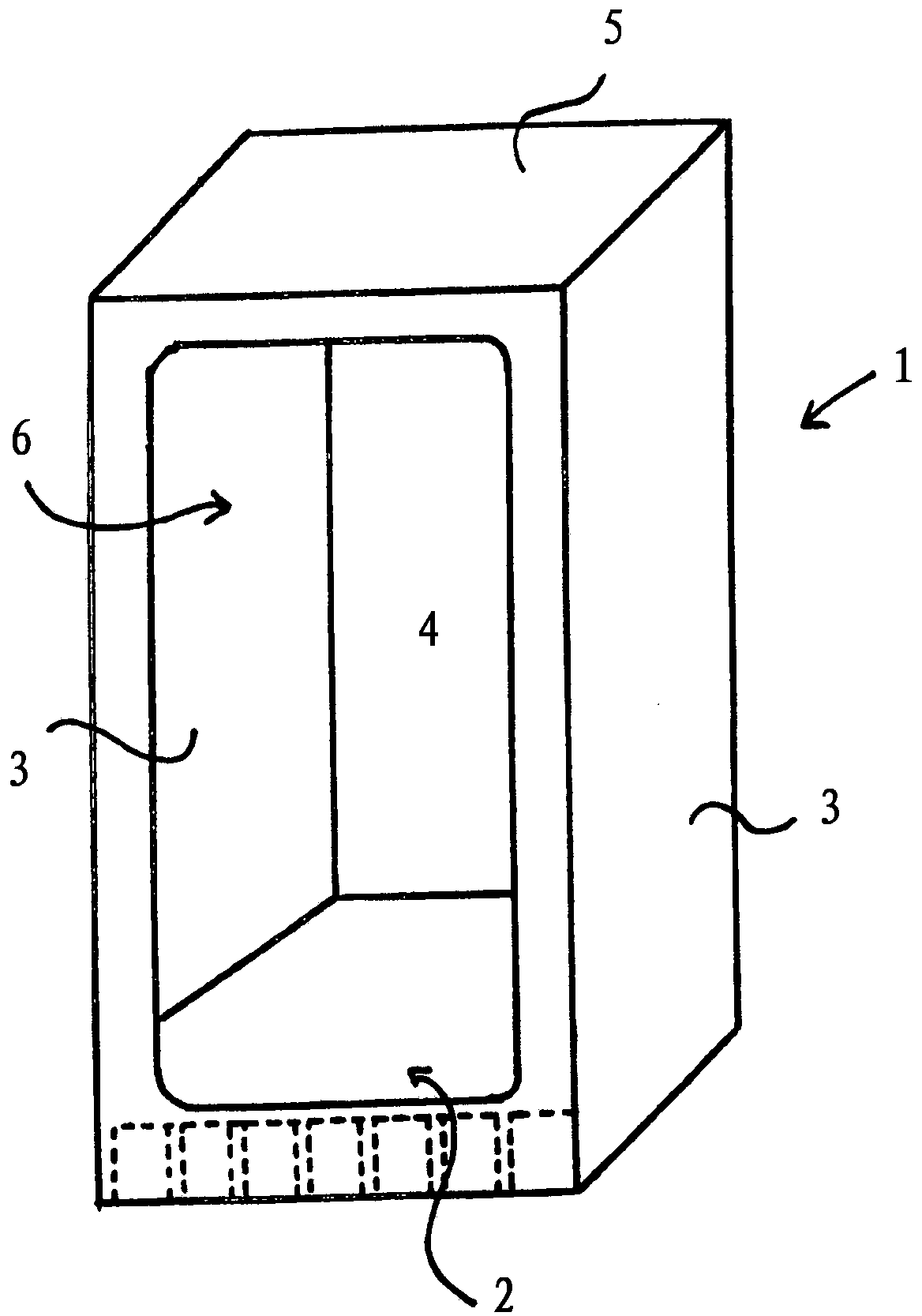

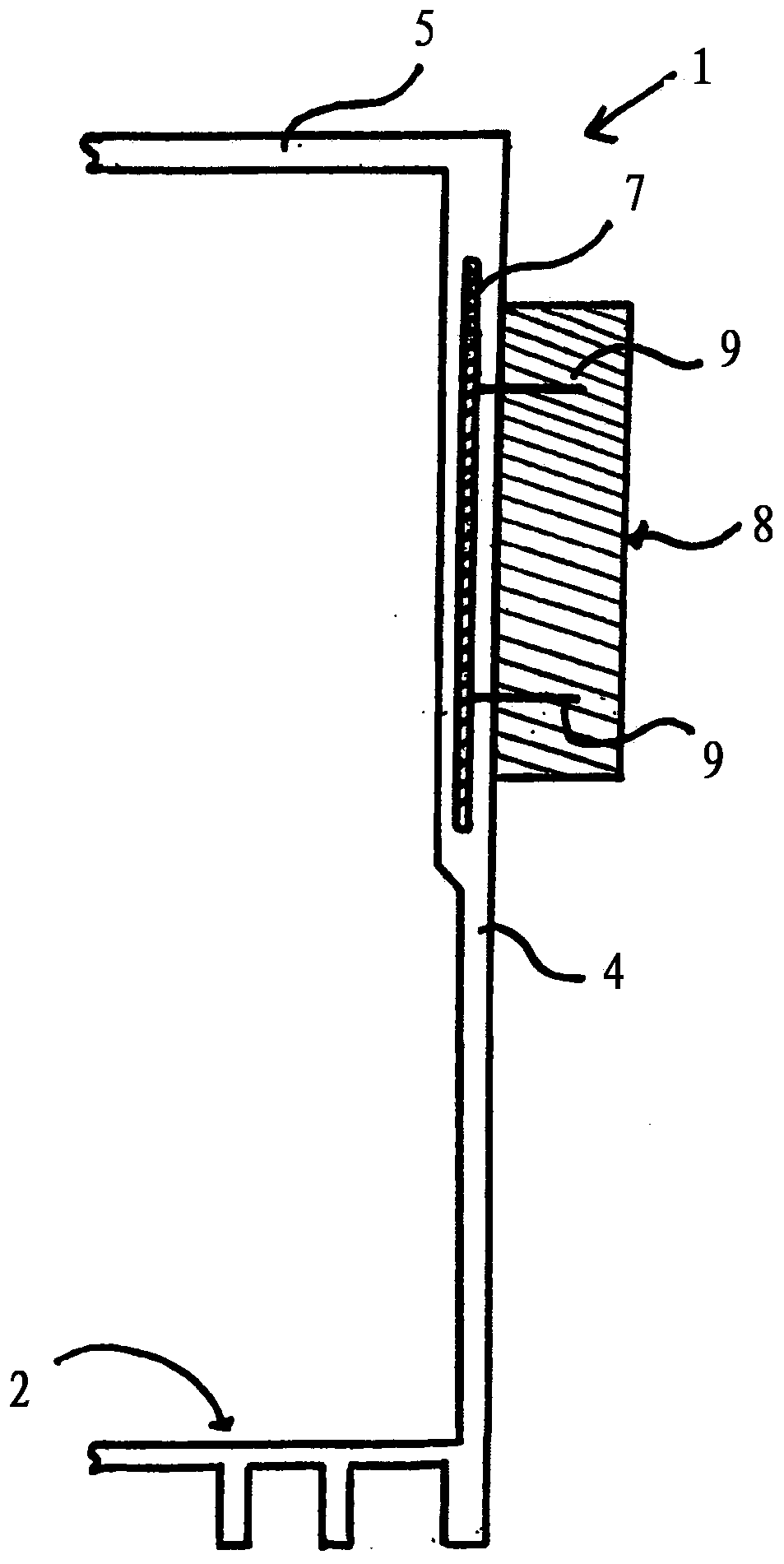

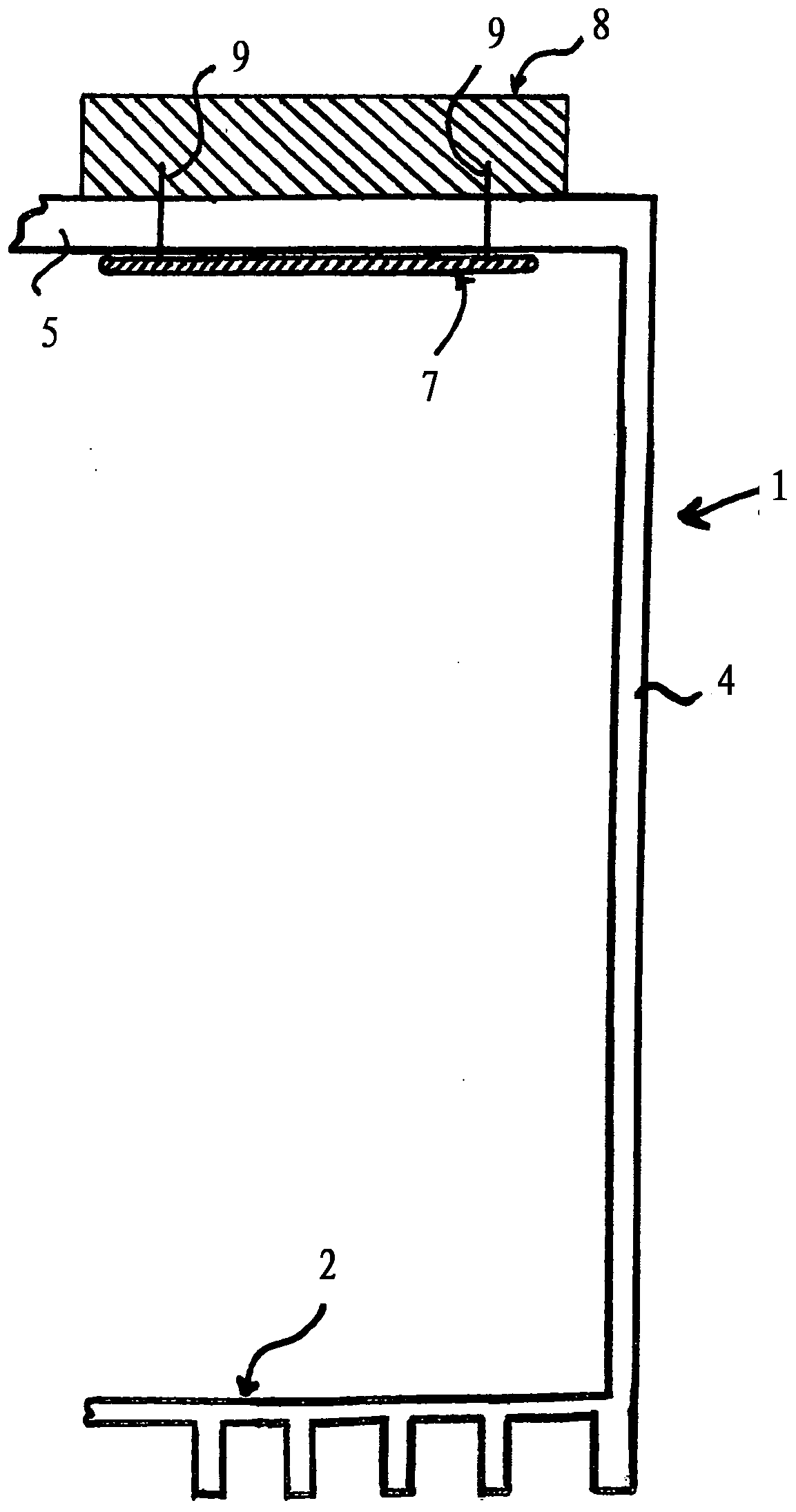

[0037] The drawing shows an elevator car 1 according to the invention for transporting people and goods, wherein in this exemplary embodiment the elevator car can be the elevator car 1 of a construction site elevator. The elevator car 1 according to the invention can be used, in particular, as an elevator for a wind power installation or a wind turbine, more precisely mainly during the construction of a wind power installation or a wind turbine. Preferably and in this embodiment, the elevator car 1 has a car floor 2 , three side walls 3 , 4 , a car ceiling 5 and a door opening 6 . Access to the elevator car 1 or loading of the elevator car can be achieved through the door opening 6 . Expediently, the door opening 6 is closed, preferably with a roller blind, not shown in this exemplary embodiment, in particular a venetian blind.

[0038] In this exemplary embodiment, the car ceiling 5 , the three side walls 3 , 4 and the supporting elements 11 of the car floor 2 are made or su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com