Sewage treatment device capable of quantitatively collecting water quantity

A sewage treatment device, quantitative collection technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

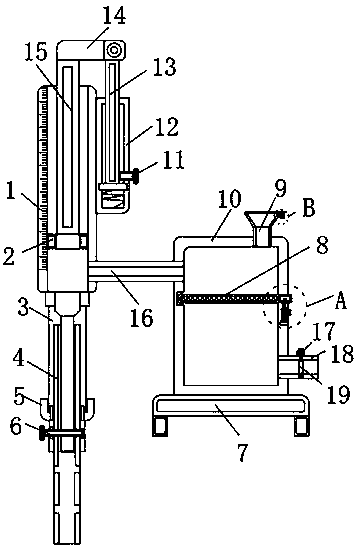

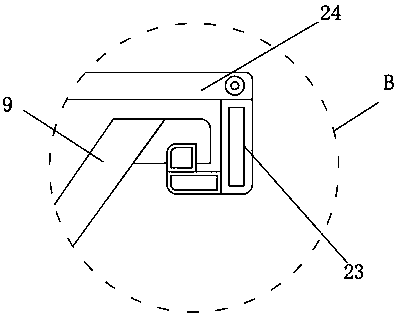

[0023] A sewage treatment device for quantitative collection of water, comprising a metering barrel 1, a second sliding rod 15 is inserted inside the metering barrel 1, and a connecting rod 14 is fixedly connected to the top of the second sliding rod 15, and the right side of the connecting rod 14 The first slide bar 13 is hinged, and the bottom end of the first slide bar 13 is inserted in the inside of the fixed block 12, the right side of the fixed block 12 is fixedly connected with the first push button 11, and the bottom ends of the second slide bar 15 are two The side is fixedly connected with a sealing ring 2, and the bottom end of the metering barrel 1 is fixed with a telescopic tube 3, and the inside of the telescopic tube 3 is inserted with a first connecting tube 4, and the inside of the first connecting tube 4 is inserted with a clamping shaft 6. The surface of a connecting pipe 4 is inserted with a rotary knob 5, and the right side of the bottom end of the metering ...

Embodiment 2

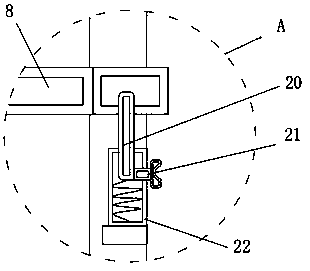

[0025] The inner wall of the metering barrel 1 is in conflict with the surface of the sealing ring 2, the sealing ring 2 and the metering barrel 1 form a telescopic structure, the sealing ring 2 is made of rubber, the surface of the sealing ring 2 is in conflict with the inner wall of the metering barrel 1, and the second slide bar 15 and the gap on the inner wall of the metering barrel 1 is sealed to prevent air leakage from causing insufficient suction when the second slide bar 15 is pulled. The block 12 forms a telescopic structure, and the bottom end of the first slide bar 13 is welded with a spring, and the bottom end of the spring is welded on the inner wall of the fixed block 12, and the first slide bar 13 is pushed upward to slide on the inner wall of the fixed block 12, and the fixed The spring at the bottom of the block 12 is stretched and deformed, and the movement of the second slide bar 15 generates suction to suck the sewage into the metering barrel 1. The surface...

Embodiment 3

[0027] The inside of the first connecting pipe 4 is in conflict with the surface of the clamping shaft 6, and the clamping shaft 6 and the first connecting tube 4 form an engaging structure, and the inside of the first connecting pipe 4 is in conflict with the surface of the clamping shaft 6, and the clamping shaft 6 and the The first connecting pipe 4 forms a snap-fit structure, and the clamping shaft 6 is pulled out, so that the internal through hole of the first connecting pipe 4 can pass through normally. The telescopic tube 3 forms a rotating structure, the surface of the first connecting pipe 4 is fixed with an external thread, and the inner wall of the twist 5 is fixed with an internal thread, and the internal thread of the rotary 5 is used in conjunction with the external thread of the first connecting pipe 4. The rotation of the twist 5 moves the first connecting pipe 4, thereby adjusting the length of the first connecting pipe 4, thereby controlling the absorption o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com