Thin adjusting gasket convenient to fix

A technology for adjusting gaskets and thin profiles, applied in the direction of washers, threaded fasteners, locking fasteners, etc., which can solve the problems of easy loosening of nuts, inability of gaskets to provide sufficient cushioning, and high hardness of gasket bodies. Avoid the effect of vibration loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

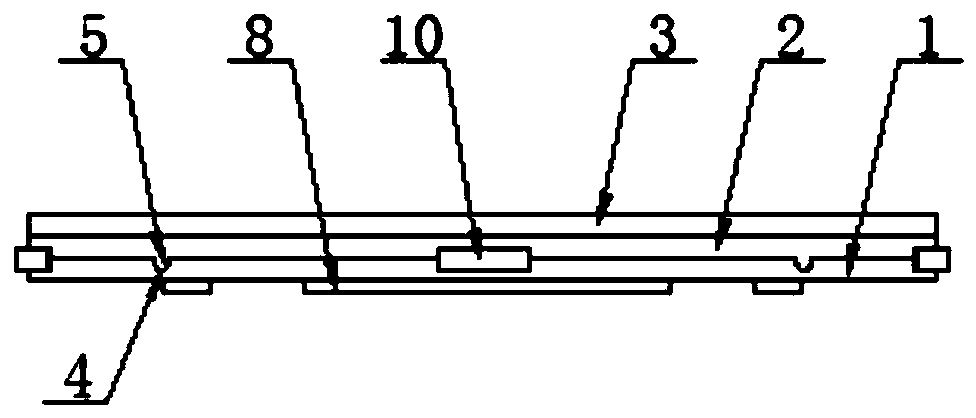

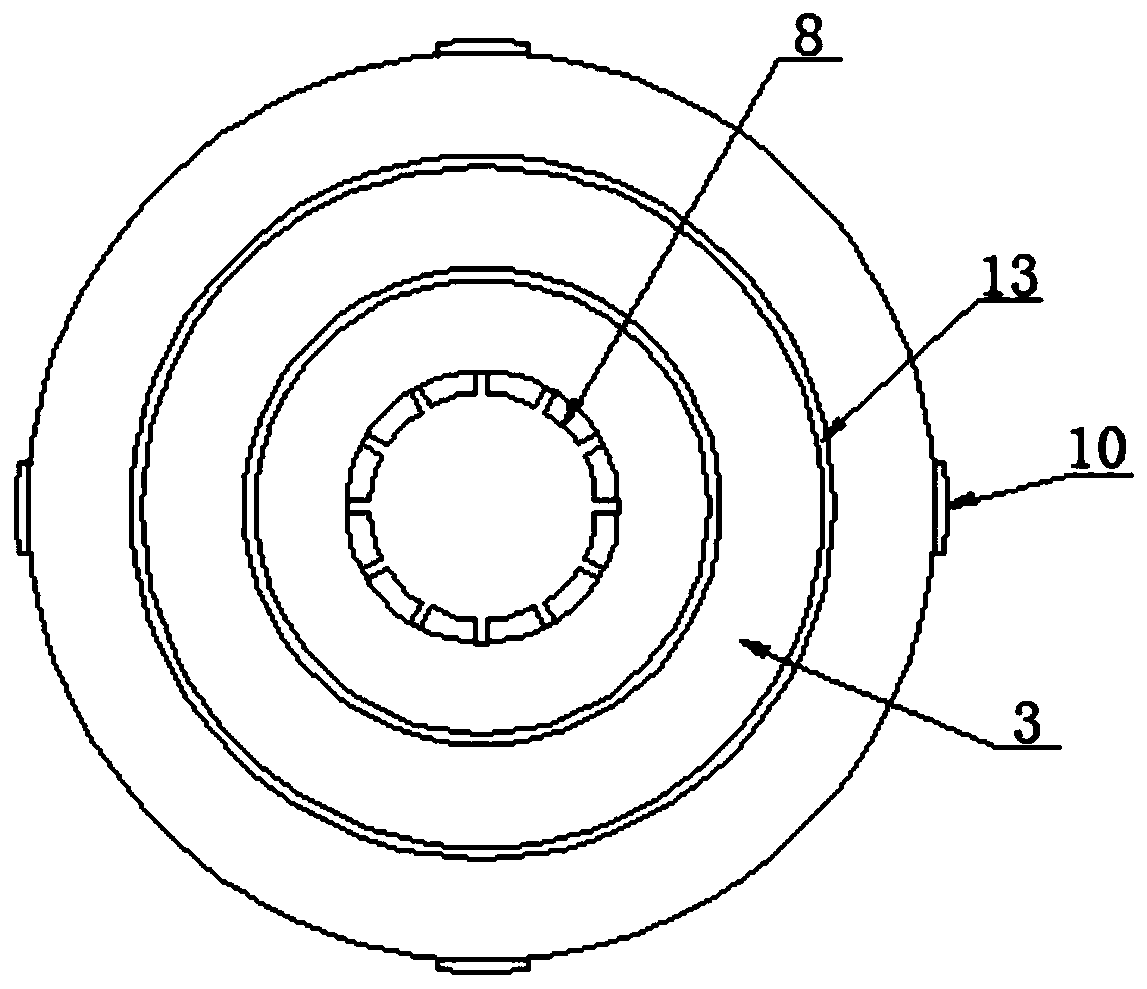

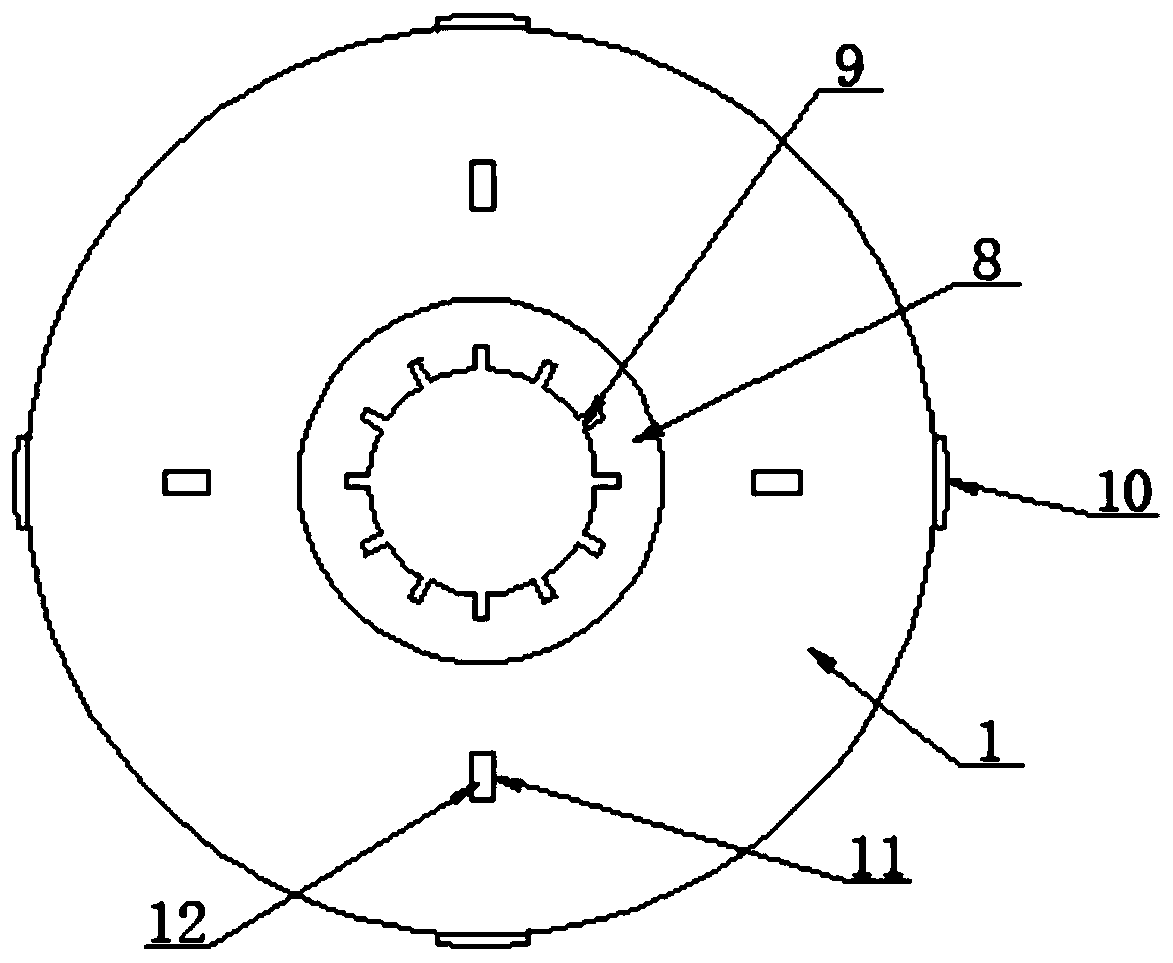

[0037] see as Figure 1-Figure 11 As shown, this specific embodiment includes No. 1 metal pad 1, No. 1 rubber pad 2, and No. 2 metal pad 3, wherein No. 1 metal pad 1, No. 1 rubber pad 2, and No. 2 metal pad 3 are stacked sequentially from bottom to top Setting; the upper surface of No. 1 metal pad 1 is provided with a limit groove 4, the inner end of the limit groove 4 is inserted on the inner side wall of the No. On the outer wall of the pad 1, the lower side wall of the No. 1 rubber pad 2 is integrally formed with a limit block 5, and the limit block 5 is movably fixed in the limit groove 4. The upper side of the outer wall of the No. 1 metal pad 1 The upper welding is provided with a limit plate 10, and the limit plate 10 is movably arranged on the outer wall of the No. 1 rubber pad 2. When the No. 1 metal pad 1 and No. 2 metal pad 3 squeeze the No. 1 rubber pad 2, the No. 1 rubber pad 2 Pad 2 deforms and overflows outward. At this time, the limit plate 10 is against the N...

specific Embodiment approach 2

[0045] see as Figure 12 to Figure 17 As shown, the difference between this specific embodiment and the specific embodiment one is: the rough pad 6 is replaced by a fixed ring 14, and a ring groove 18 is opened on the outer side of the lower side wall of the No. 2 metal pad 3 for fixing The ring 14 is movably arranged in the ring groove 18, the lower side wall of the No. 2 metal pad 3 is provided with a No. 1 card slot 16, and the outer end of the No. 1 card slot 16 is connected with the ring groove 18, and the No. 1 rubber pad 2 The upper side wall is provided with a No. 2 draw-in groove 17, and the inner side wall of the fixed ring 14 is welded with a clamp block 15. The upper side of the clamp block 15 is movable in the No. 1 draw-in slot 16. Limit movable card is located in No. two draw-in slot 17, after No. 1 rubber pad 2 is enclosed within on the bolt, at first put on fixed ring 14, then put on No. two metal pad 3, at this moment, No. 1 draw-in slot 16, The second slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com