Combustion unit with thermal insulation pad

A technology of a combustion device and a thermal insulation pad, which is applied to burners, burners utilizing capillary action, combustion types, etc., can solve the problems of accumulated high temperature, unfavorable heat dissipation, and danger, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

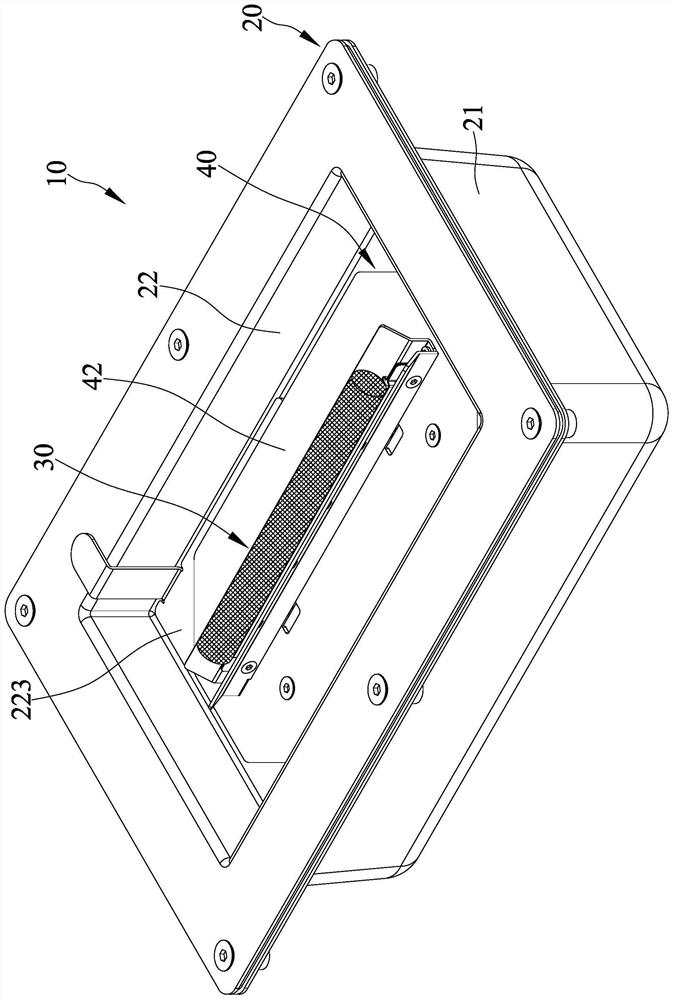

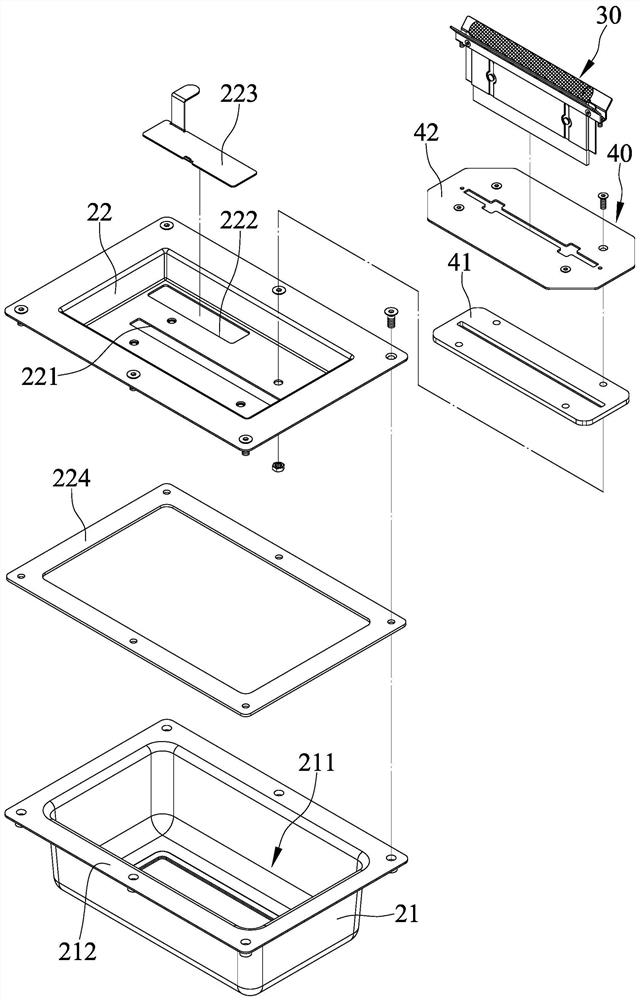

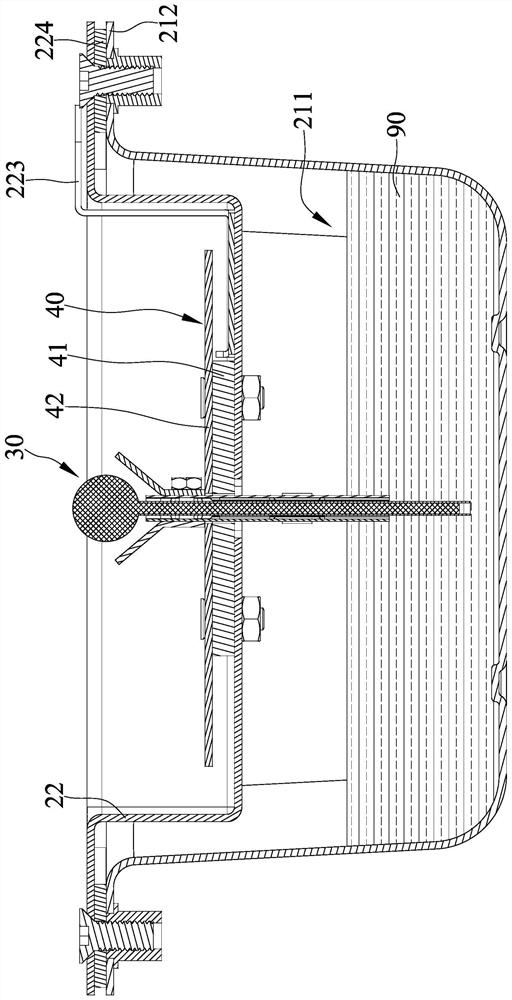

[0024] Please refer to Figure 1 to Figure 5 Shown is the three-dimensional appearance view, three-dimensional exploded view, cross-sectional structure view and use state view of the combustion device with heat-dissipating and heat-insulating pads of the present invention. The combustion device 10 of the present invention includes a fuel tank 20, a candle wick 30 and a heat dissipation pad 40; wherein:

[0025] The fuel tank 20 includes a tank body 21 and a fuel tray 22, the tank body 21 is recessed from top to bottom along the vertical direction with a receiving groove 211, and the tank body 21 opens above the receiving groove 211 An abutment rim 212 is provided around. The fuel tray 22 is arranged above the accommodating groove 211 along the vertical direction, and the fuel tray 22 is pierced with an insertion hole 221 and a filling port 222. The fuel tray 22 is connected with a cover 223, and the cover 223 Slidingly disposed on a side of the fuel tray 22 different from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com