Ceramic infiltrating irrigation integral pipeline

A technology of seepage irrigation and pipelines, which is applied in the field of ceramic seepage irrigation integrated pipelines, can solve the problems that cannot meet the needs of diversified agricultural production, the strength is difficult to guarantee, and the water passing volume is small, so as to increase the overall bonding strength and flexural strength. , The effect of strengthening the ability of external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

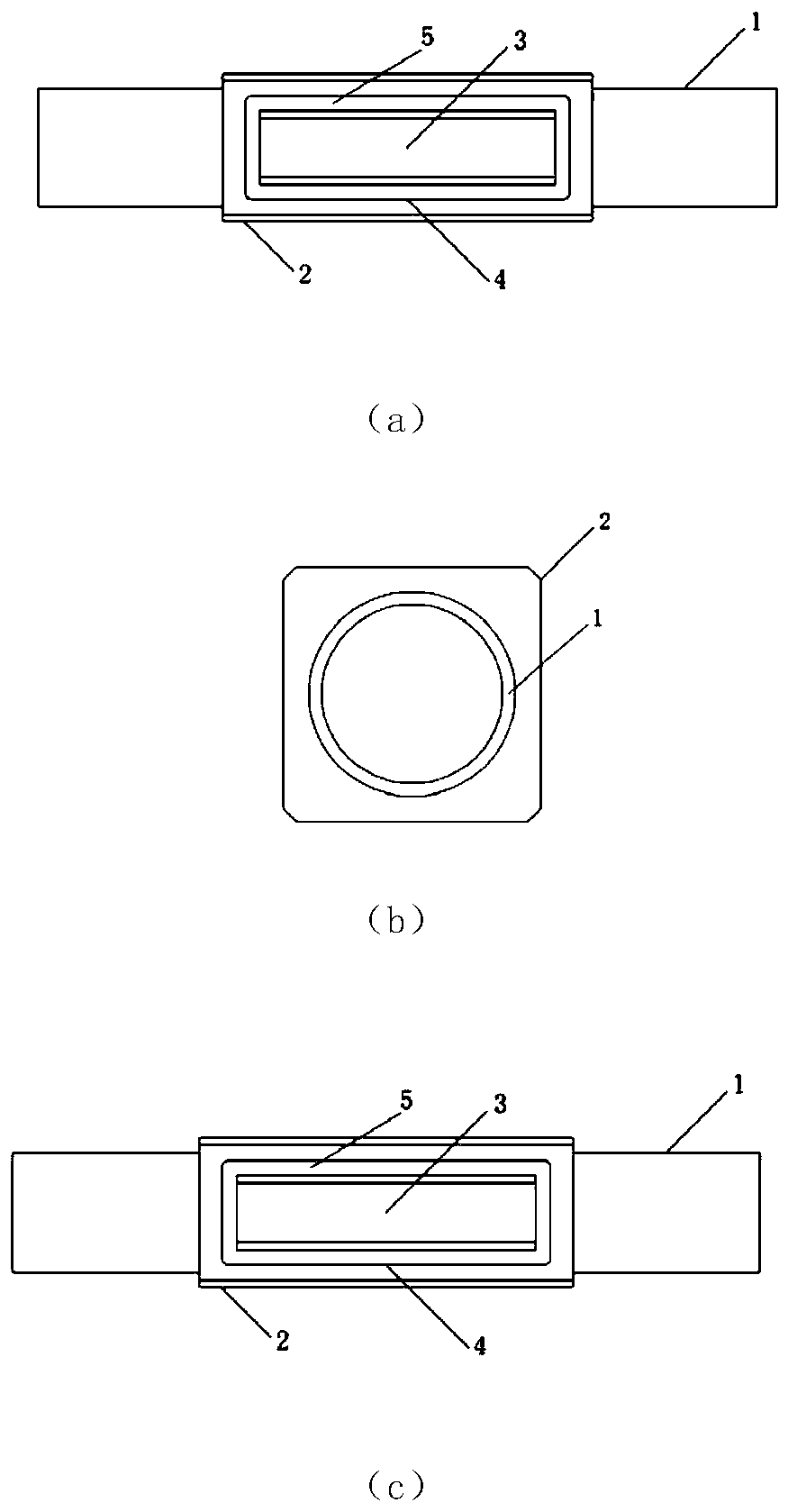

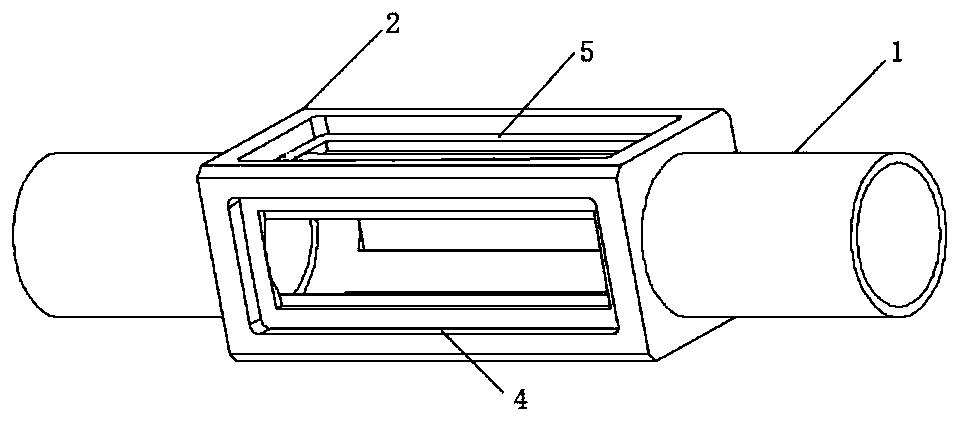

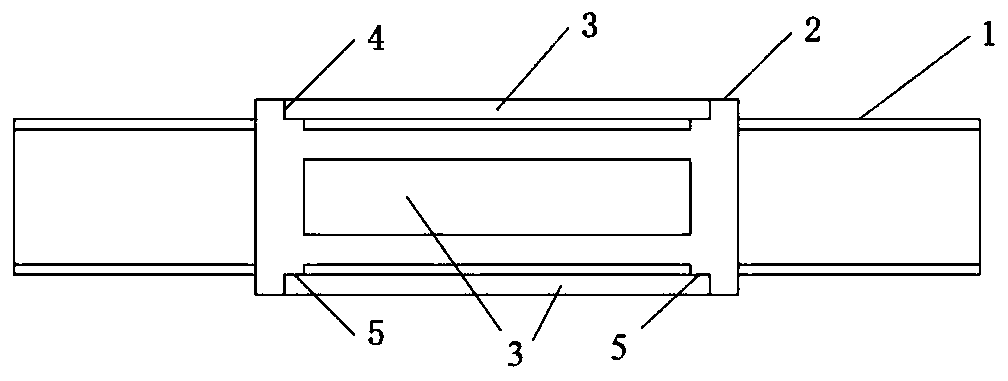

[0025] Comply with the above technical solutions, such as Figure 1 to Figure 7 As shown, this embodiment provides a ceramic seepage and irrigation integrated pipeline, the pipeline is an integrated structure, and its main components include a water conduit 1 , a three-dimensional frame 2 , and a ceramic water seepage patch 3 . The frame 2 is located outside the pipe 1 , and the ceramic seepage patch 3 is located inside the frame 2 .

[0026] Both ends of the frame 2 are connected to the pipe 1 , the water flows through the pipe 1 and flows through the frame 2 , then flows around the frame 2 and spreads outward through the ceramic water seepage patch 3 .

[0027] Each surface of the frame 2 is opened as a rectangular cavity 4 , the length, width and height of the rectangular cavity 4 are the same as those of the ceramic water seepage patch 3 .

[0028] The annular bracket 5 is located inside the frame, at the bottom of the rectangular slot 4 .

[0029] The ceramic water seep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com