Concrete layered pouring type arch ring construction method

A technology of layered pouring and construction method, applied in arch bridges, buildings, bridge forms, etc., can solve the problems of steel arches being unable to carry loads, twisting deformation, collapse, etc. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

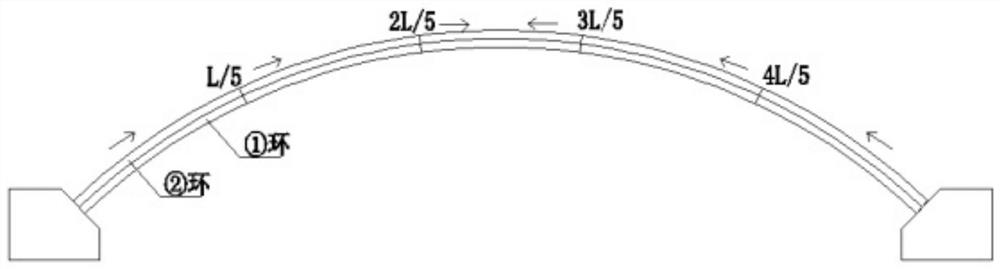

[0024] The concrete layered pouring arch ring construction method provided by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] see figure 1 , a kind of concrete layered pouring type arch ring construction method provided by the invention, comprises the following steps:

[0026] construction of abutments;

[0027] Install steel arches;

[0028] Install steel bars and embedded parts;

[0029] Install the template;

[0030] The arch ring concrete is poured in layers and sections;

[0031] After curing, the formwork and steel arches are removed.

[0032] Further, the concrete pouring of the arch ring adopts symmetrical segmented ring construction, and the arch ring is divided into 5 sections in the longitudinal direction, and the vertical ring is divided into 2 rings. First, the first ring is poured and formed into a ring to achieve the design The pouring of the second ring is carried out a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com