Medium-speed coal mill static separator with real-time adjustment function

A static separation and separator technology, used in the separation of solids from solids by air flow, solid separation, mechanical equipment, etc., can solve the problems of difficult maintenance, large adjustment workload, poor site environment, etc., to avoid Static separator and dynamic separator, the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

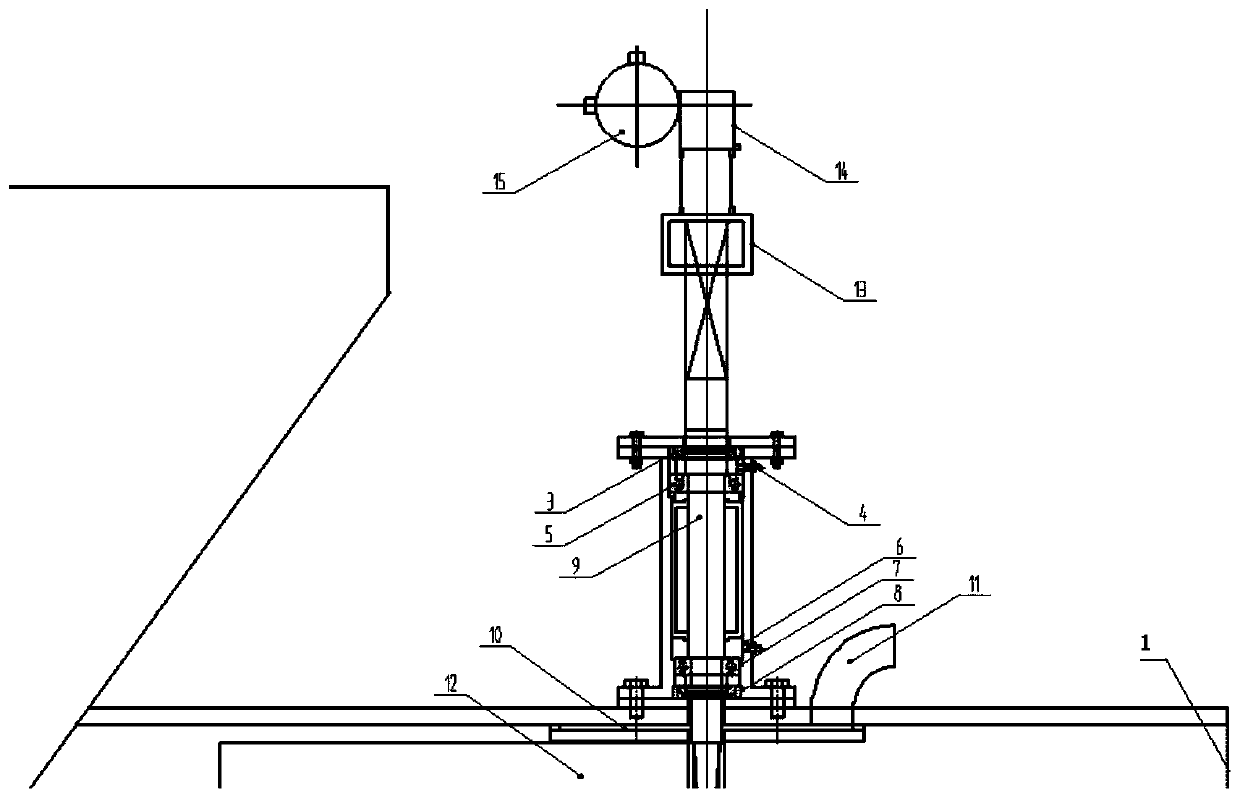

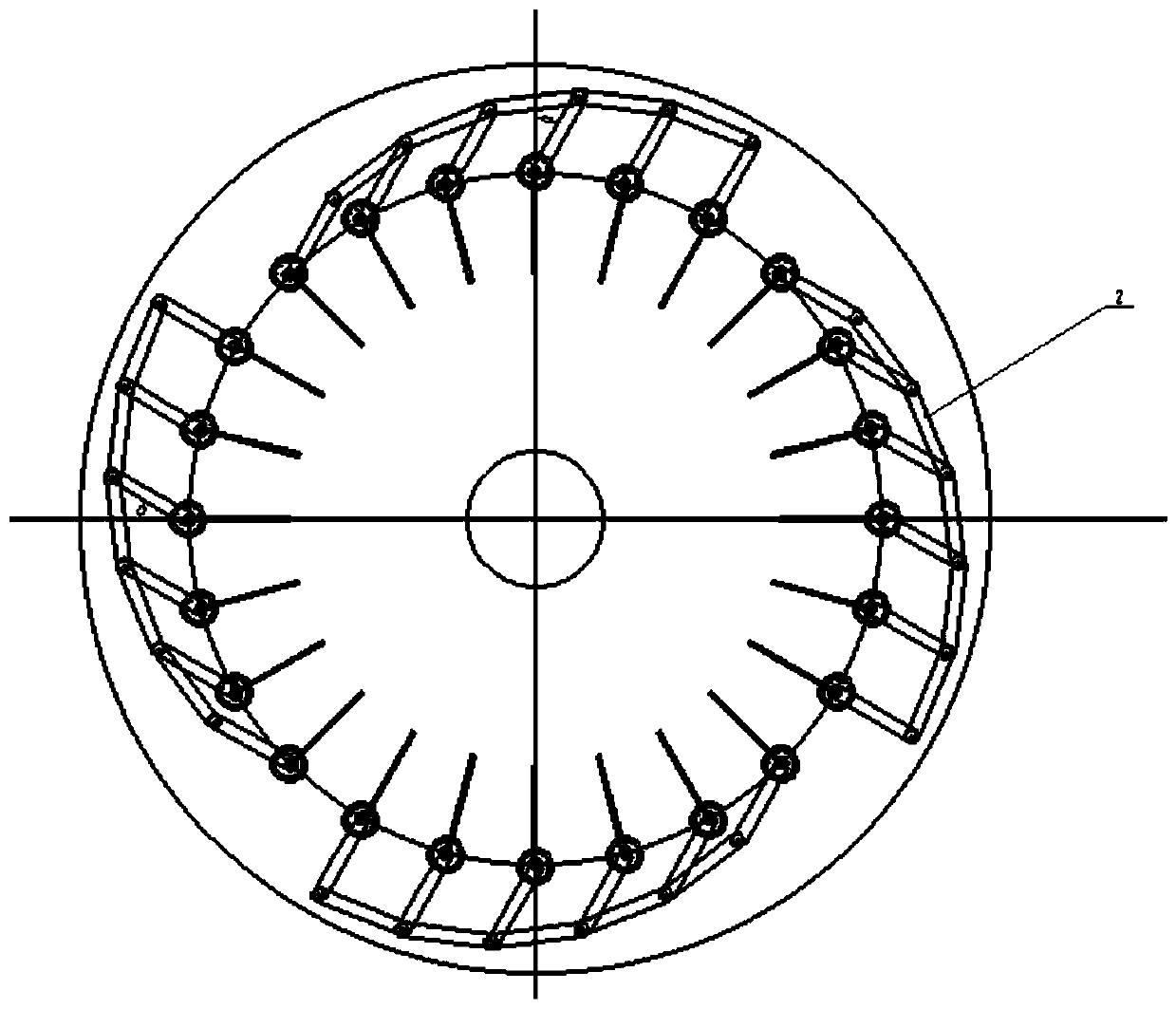

[0019] refer to figure 1 and figure 2 , the real-time adjustable medium-speed coal mill static separator of the present invention includes a coal mill separator shell 1, several baffle adjustment mechanisms, several electric control systems, and several coal mill separator shells 1 Separator baffle 12; all separator baffles 12 are divided into several groups, wherein, one group of separator baffles 12 corresponds to an electric control system, one separator baffle 12 corresponds to a baffle adjustment mechanism, and each baffle adjustment mechanism Both include a central shaft 9, and each electric control system includes a controller 14, a signal source 15 and a rotary actuator 13, and the output end of the external DCS control system is connected to the input end of the controller 14 through the signal source 15, and the controller 14 The output end of the rotary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com