Aluminum plate color code electronic automatic positioning system

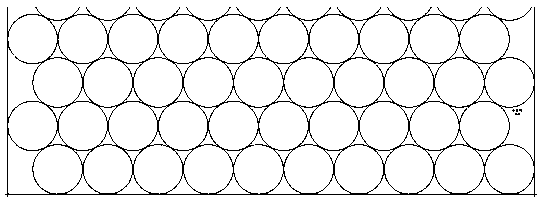

An automatic positioning and color-coding technology, applied in the field of machinery, can solve the problems of inability to achieve accurate positioning, increased scrap rate, deviation of aluminum plate pattern and plate edge displacement, etc., to reduce pattern deviation, improve stamping accuracy, and improve the effect of pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

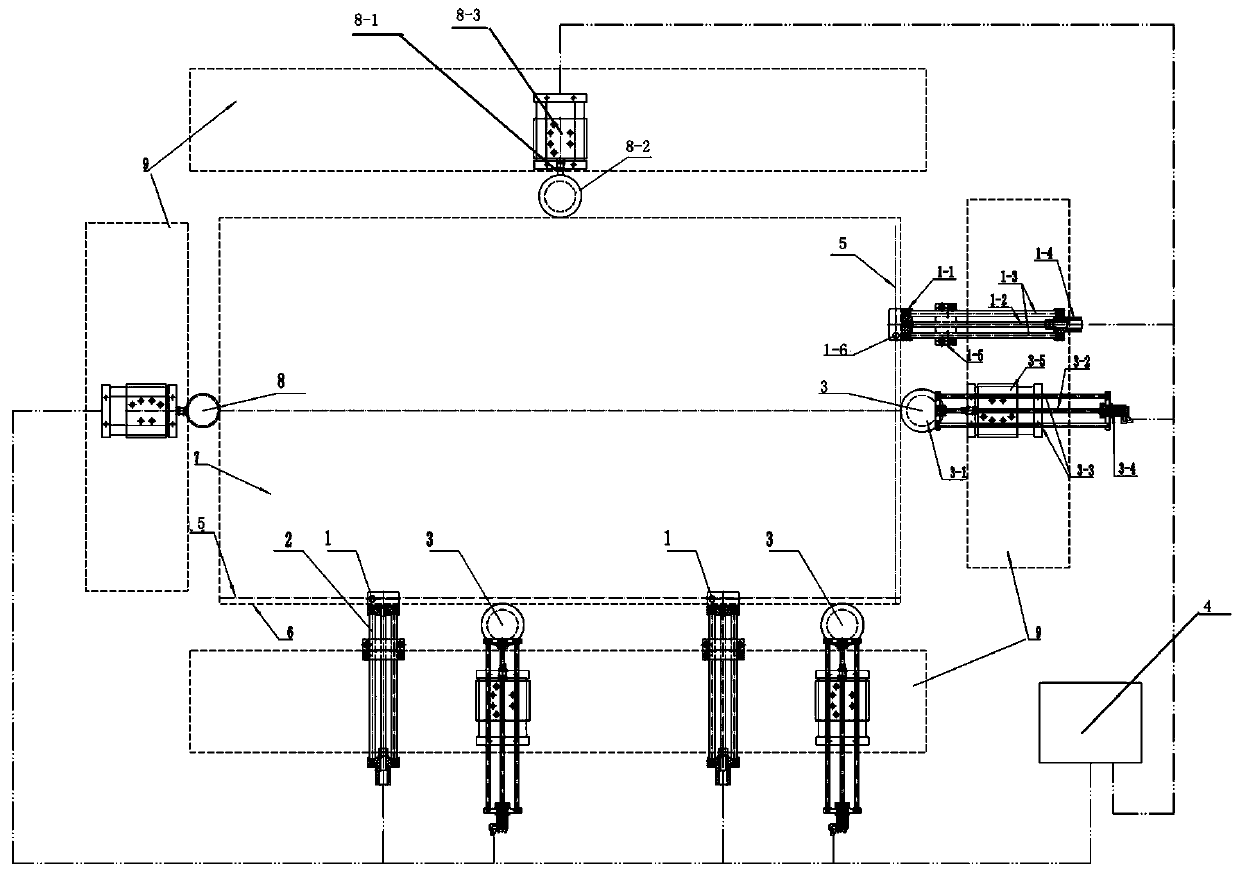

[0012] In order to better understand and implement, the following is combined with the attached figure 2 Further description of the present invention: the aluminum plate color code electronic automatic positioning system includes a controller 4 and four support bases 9, the four support bases 9 are respectively located around the aluminum plate 7, and two support bases 9-1 are provided on the front side A color mark sensing device 1 and two execution devices 3 are arranged at intervals, and a color mark sensing device 1 and an execution device 3 are arranged on the right support base 9-2 , a guide push wheel device 8 is respectively arranged on the rear support base 9-3 and the left support base 9-4, and the color code sensing device 1 and the execution device 3 are all connected to each other with the PLC automatic controller 4 through lines; The push wheel device 8 is connected to the PLC automatic controller 4 through a pneumatic circuit, and the front of the PLC automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com