Fully automatic sand molding machine

A fully automatic, molding machine technology, applied in the direction of molding machines, casting molding equipment, cores, etc., can solve the problem of low processing efficiency and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

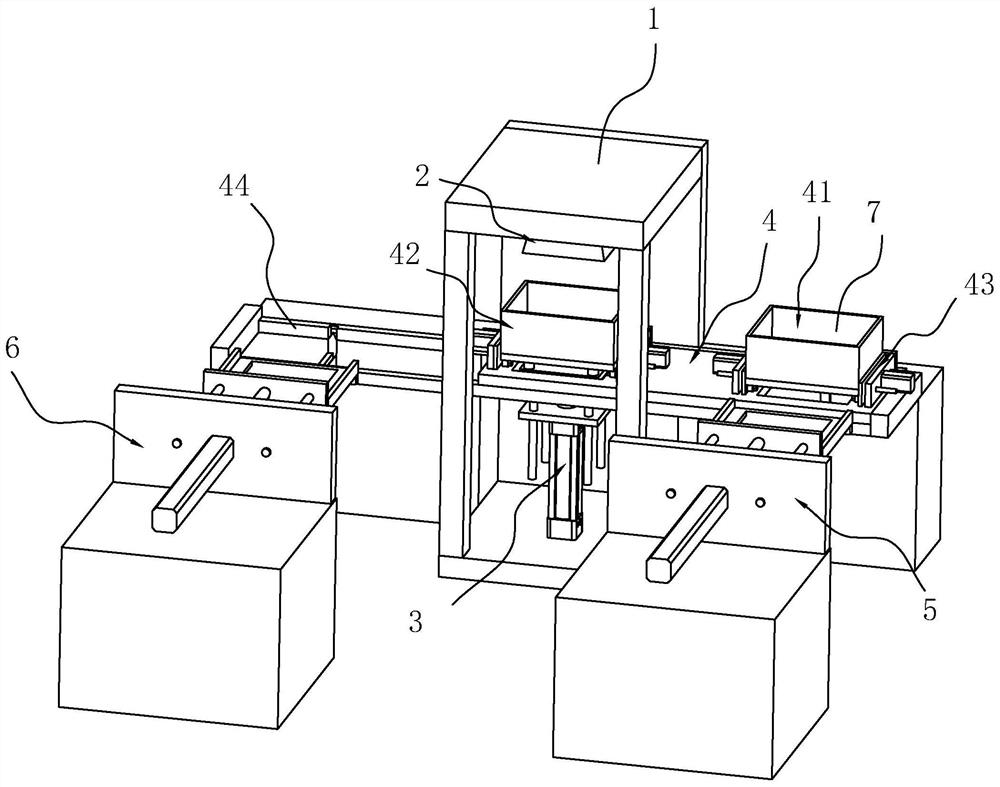

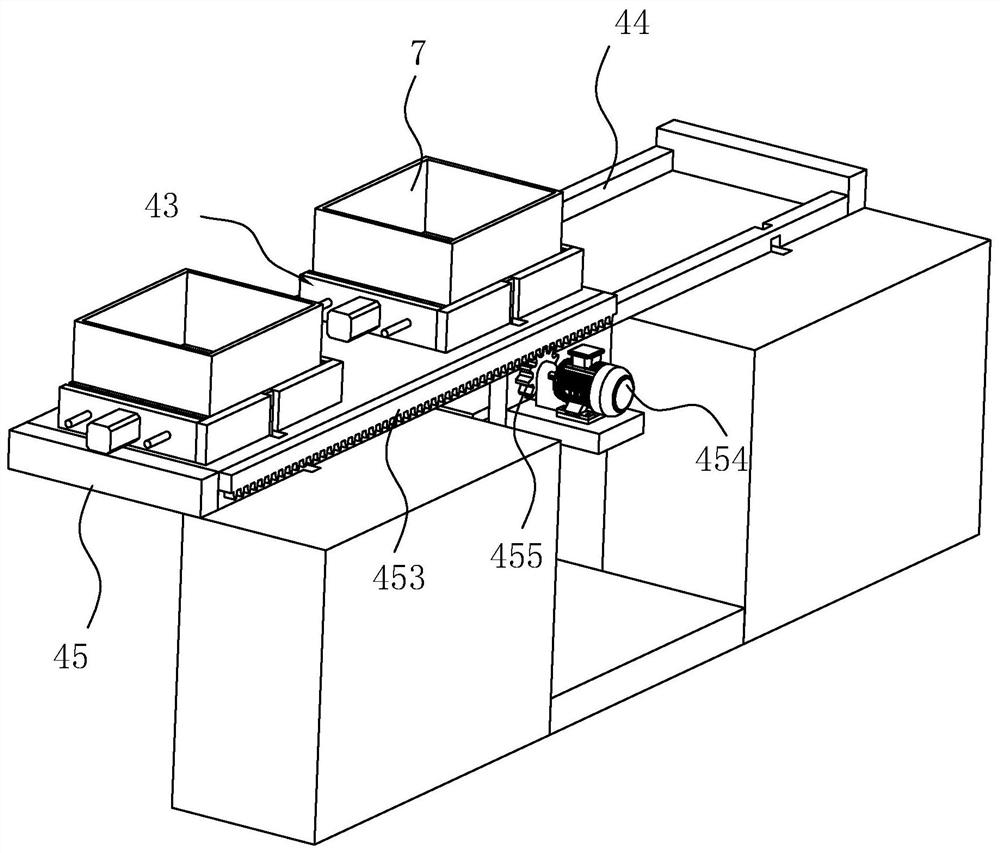

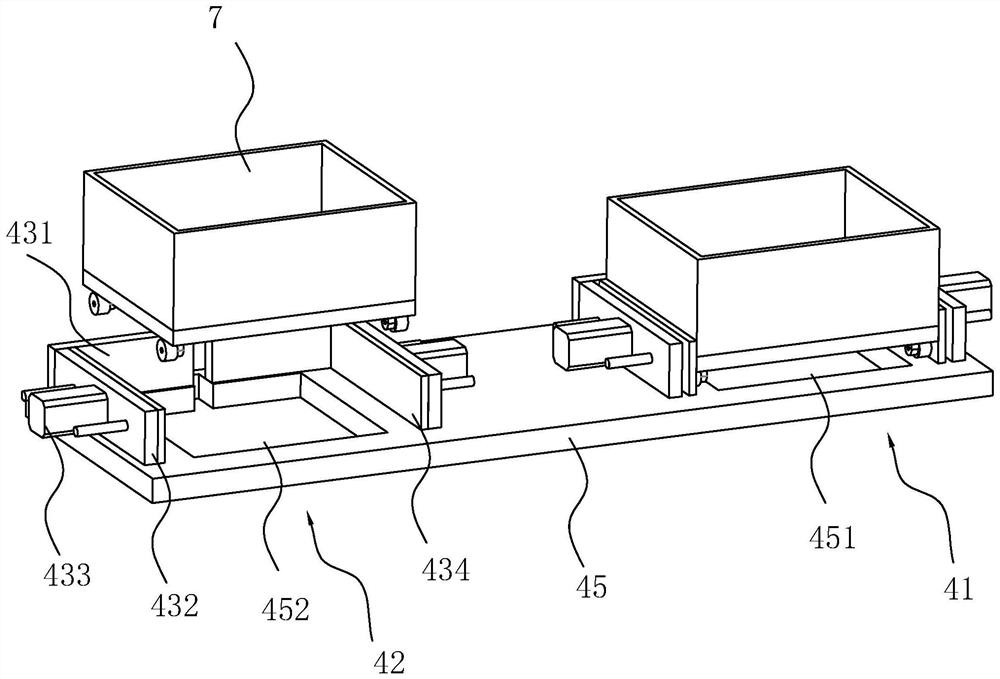

[0033] A fully automatic sand-covered molding machine, see figure 1 , including a frame 1, the top of the frame 1 is provided with a sand-coated blasting device 2, the bottom of the frame 1 is located at the bottom of the sand-coated blasting device 2, and a mold clamping and lifting device 3 is provided, and the middle part of the frame 1 is located at the sand-coated blasting device 2. There is a conveying device 4 arranged horizontally between the sand device and the clamping and ejecting device 3. The conveying device 4 is provided with two first station 41 and a second station 42 for placing the iron mold 7, and the conveying device 4 corresponds to the first station 42. The positions of the first station 41 and the second station 42 are provided with a positioning mechanism 43 for fixing the iron mold 7, and the two ends of the frame 1 are located at the conveying device 4 and are provided with the first discharge device 5 and the conveying device 4 perpendicular to the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap